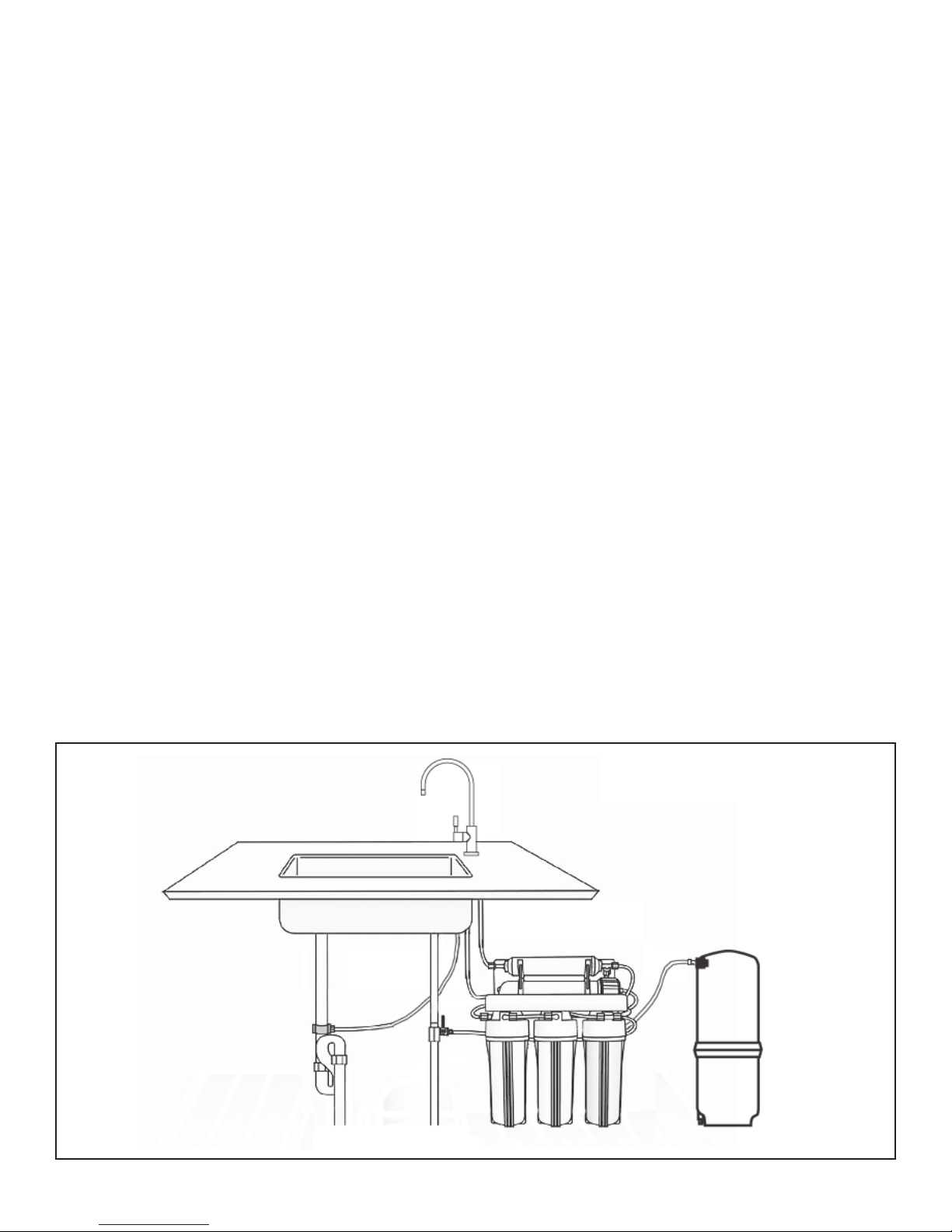

3

SAFETY GUIDELINES

•ReadallstepsandguidescarefullybeforeinstallingandusingyourWaterSTATION.Followallstepsexactlytocorrectly

install.

•Thissystemmustbeinstalledinaccordancewithapplicablecity,provincial,stateandlocalplumbingcodes.

•To ensure this system continues to operate at its optimum level, it is necessary to have a routine maintenance and

replacement schedule. Please check the filter replacement frequency in the system specification section and maintenance

section of this manual. Frequency at which filters must be changed will depend on quality of feed water supply and level

of system usage. The replacement of the water treatment components of this unit is critical to maintain the performance

of the system.

•Thissystem shouldnot beused wherethe wateris microbiologically unsafe or with water of unknown quality without

adequate disinfection before and/or after the filter. Please refer to the conditions use section in this manual.

•Topreventpersonalinjury,completelyrelievethesystempressurebeforereplacingorinstallingfiltersandmembrane.

•Donotplacethissystemwhereitwillbeexposedtothefreezingand/ordirectsunlight.Pleaserefertoconditionsforuse

section in this manual

NOTE: The Reverse Osmosis system contains a replaceable treatment component, critical for the effective reduction of

total dissolved solids, and that product water shall be tested periodically to verify that the system is performing properly.

SYSTEM SPECIFICATIONS

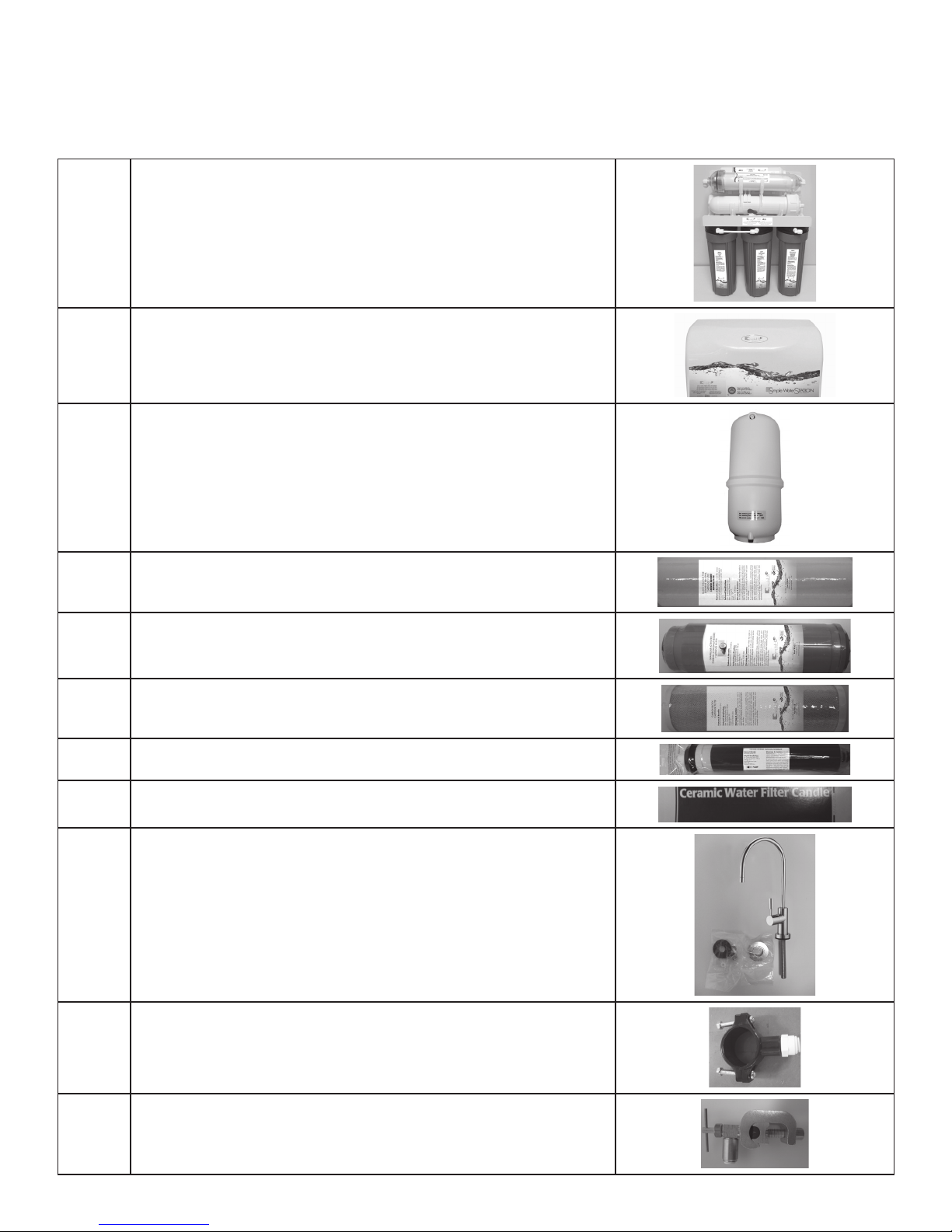

WaterSTATION Item #: 940270

Model #: PuR100-7

Item # Stage Filter / Type Capacity

92621 First Stage

(Pre Filter) Sediment Filter 5 Micron Sediment Filter,

10" Length

Reduces suspended particles in water such as dirt or

sediment. Reduces the particles 8 times smaller than

what the naked eye can see.**

4,440 L

92622

(Pre Filter)

Granular Activated

Carbon Filter 10 Micron GAC Filter, 10" Length Reduces chlorine from the water to protect TFC

membrane.** 9,250 L

92623

(Pre Filter) Carbon Block Filter 10 Micron Carbon Block Filter,

10" Length Reduces taste & odor from water.** 9,250 L

92624

TFC Membrane 100 TFC* GPD Membrane,

10" Length Reduces TDS from water.** 37,000 L

92625 Fifth Stage

Inline Carbon Filter 10 Micron Carbon Filter,

10" Length Reduces taste and odor from the water.** 5,550 L

92626 Sixth Stage

Inline Calcite Filter Calcite Filter, 10" Length Increase pH of water‡. Add minerals to improve the

5,550 L

92627

Ceramic Filter 0.5 Micron Ceramic Filter,

10" Length

an added particulate reduction to 0.5 micron.**

7,400 L

92657 Plastic 3.8 Gallon / 14.4 L Storage Capacity Storage for Product Water -

Chemical Parameters Max mg/L

Community / Private Chlorinated / Non-Chlorinated Hardness (CaCO3) < 350 (20 gpg)

PH Range 3.0 - 11.0 Iron (Fe) < 0.1

Maximum TDS Level < 2000 ppm Manganese (Mn) < 0.05

Turbidity < 1.0 NTU 2S) 0.00

Maximum SDI < 4.0 Residual Chlorine (Cl2) < 2.0

Pressure 50 - 100 psi †† NTU - Nephelometric Turbidity Unit

SDI - Silt Density Index

Temperature 4 - 38ºC

CONDITIONS FOR USE

†† Booster Pump is required if the inlet pressure of the water is below 50 psi.

100GPD. Nominal product water ratings are based on the following

conditions: Supply TDS of 250 ppm conditioned tap water, 50 psi, 77ºF, pH 8 and 15% recovery with

outlet to atmosphere

99%. Rejection percentages are dependent on the supply conditions and the

substance being measured

This system is not intended to be used for the treatment of water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or after the system.

The performance of a reverse osmosis membrane is highly dependent upon pressure,

temperature and TDS. The actual volume of product water and rejection percentage will vary with

differences and the test conditions that membrane ratings are based upon.

‡ The processed water from TFC membrane has low pH and is aggressive and tends to dissolve

substances with which it is in contact.

* TFC refers to reverse osmosis membrane constructed from a THIN FILM COMPOSITE