Wren 44 TurboProp Users Manual. Copyright Wren Turbines Ltd February 2008 Page 7

What is the effect of airspeed on the engine?

Once the aircraft is in the air the propeller rpm will increase as its load reduces with forward

speed. An rpm increase of 10-15% can be expected in the air so always choose a propellor that

keeps the output speed below 9,000rpm. It is this increase in propeller rpm in the air which gives

the turbo-prop powered aircraft a high airspeed capability and shows a definite edge over it's I/C

engine counterpart. I/C engines have a more limited unloaded speed capability, as it can result in

the engine mixture strength "leaning out" which can cause engine damage. By contrast the turbo-

prop will enjoy running cooler as the propeller speed unloads leading to longer life and reduced

loading on critical components.

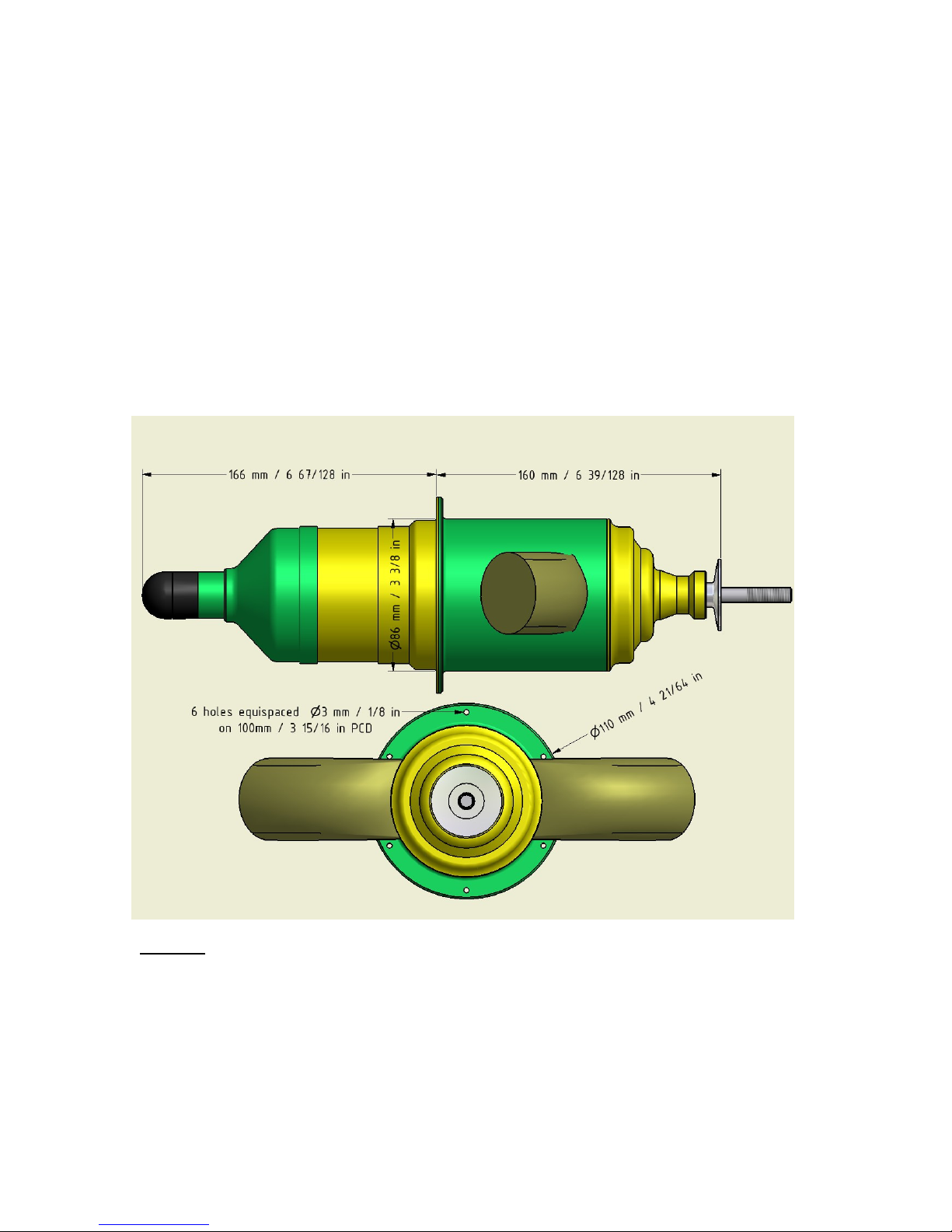

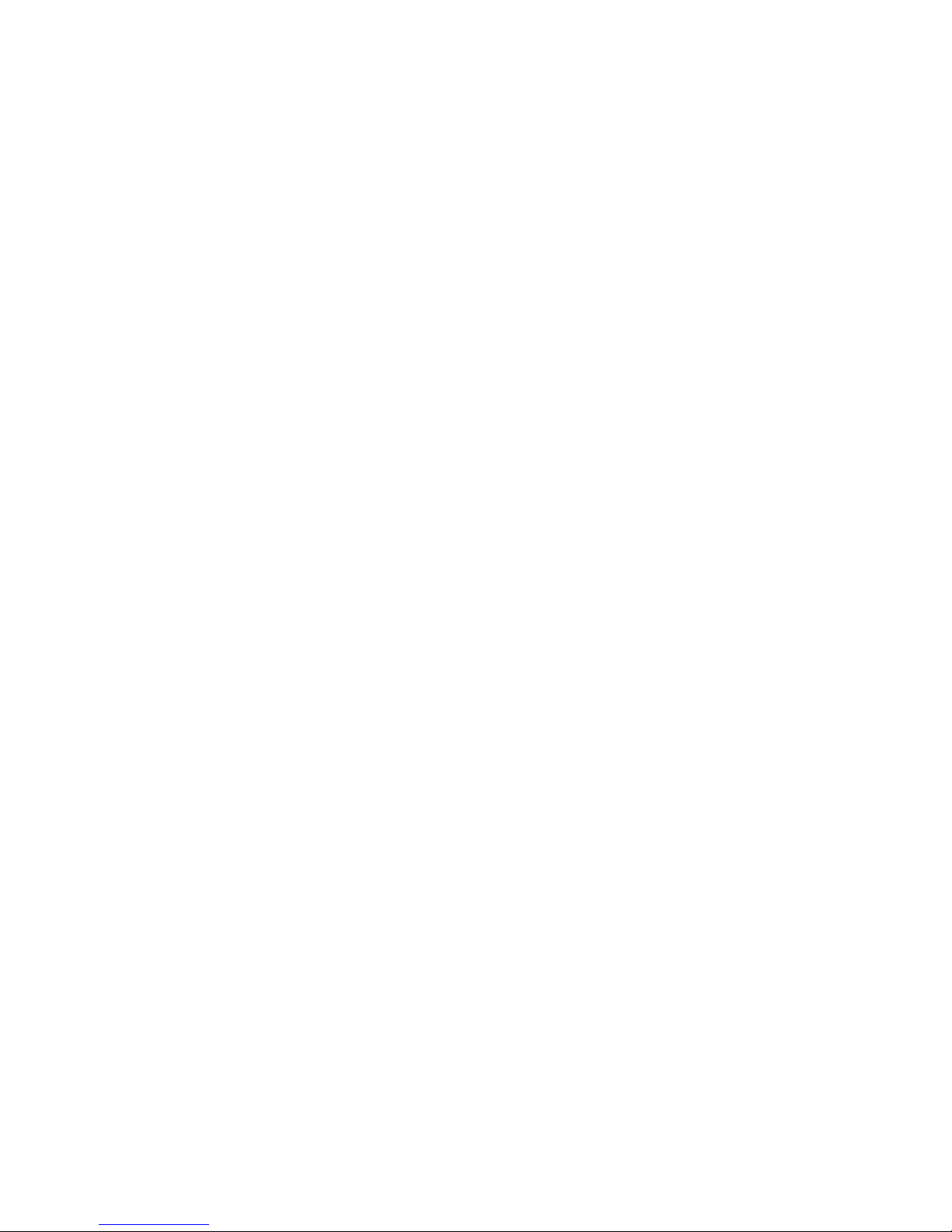

How is it mounted?

The unit is housed within a purpose made containment system which encloses the hot section

components in a three-section aluminium jacket enabling the installation to be limited to a simple

firewall mounting and six bolts and nuts. This firewall provides the essential air separation for gas

generator intake air and the warm air generated by the exhaust unit by placing a solid partition

between them. In normal running the casing will only reach about 100-130'C minimising the

chances of heat damage to the aircraft fuselage. No further stiffening is required or advised for

the unit, this approach enabling the conversion from I/C engine to turbo-prop power to be

accomplished with ease. The mounting supports the engine and gearbox at the approximate

centre of gravity and is built to withstand all normal loads such as might be subjected to the

equivalent I/C engine.

Aren't gas turbine more dangerous than I/C engines?

No. In the unfortunate event of a sudden arrival (or crash) the mounting helps to maintain

containment of all the hot section parts from heat sensitive parts of the airframe and accessories.

Turbine fuel has a high flashpoint which means at normal ambient temperatures it is extremely

difficult to ignite, unlike gasoline or glow fuel which is a low vapour temperature and ignites easily.

With no exposed high temperature components the risk of accidental combustion is greatly

reduced. As starting is undertaken with the operator and observers behind the propeller there is

no possiblility of a sudden power surge allowing the aircraft and propeller to run forward to the

operator such as can happen with I/C engines, with disastrous consequences for fingers and

limbs. The 2nd stage fully encloses the outlet of the gas turbine section affording a high degree of

protection against any component failure due to accidental damage or persistent operation

beyond the normal operational duty cycle.

What's it like to operate?

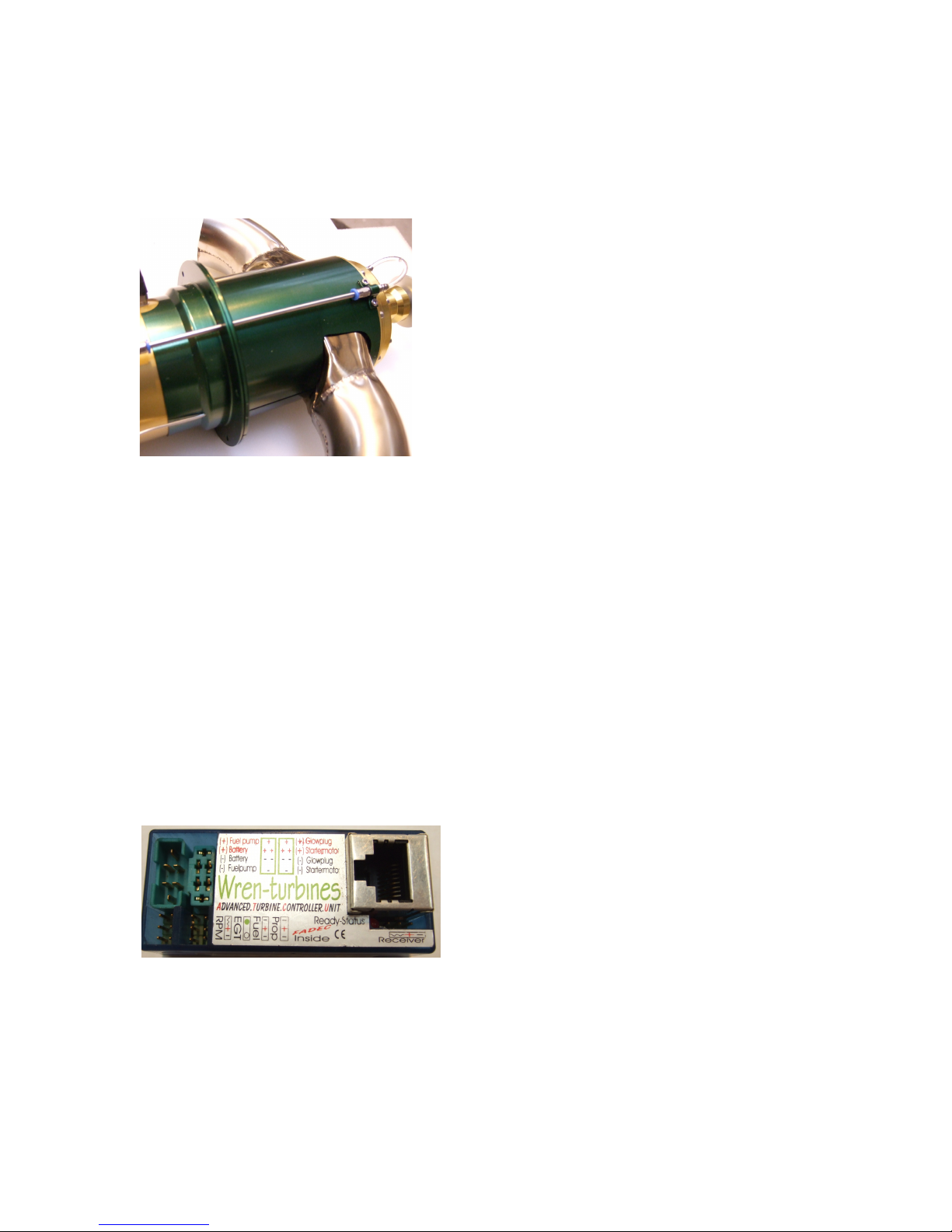

The power unit itself is operated as a normal miniature gas turbine and possesses all the

standard features of automatic push-button starting and cooling, totally vibration free operation,

very quiet running and exceptional power to weight ratio. The throttle response is of the best in its

class - the small gas generator rotor is small and light allowing very quick spooling to be achieved

safely. Being a very small gas turbine it's fuel consumption has been described as "stingy" - a

typical 10minute flight being easily achieved with a single 1ltr fuel tank, depending on the flying

style. Those fliers used to a 3ltr fuel tank for equivelent flights should find this aspect of operation

a welcome relief.

How does it compare to I/C power?

The exceptional power to weight ratio which is close in performance levels to an 80cc gasoline

engine but weighing in at only 1.71kg (3-3/4 lbs) allows the operator a level of dial-in performance

previously enjoyed by only those operating high performance specialist engines with tuned pipes

etc, with all the attendant noise, extreme vibration and operational issues associated with such

equipement. Scale fliers will really enjoy the smooth and quiet response and operation coupled

with high power reserve to get out of those difficult situations that scale aircraft with fully

articulated surfaces, flaps and fine surface detail, can find themselves in. The high torque ability

of the engine allows it to cope well with a wide range of prop sizes and shapes which will enable

those scale three and four blade props to be a practical reality and further add scale effect.

Almost all aircraft will enjoy an installed power to weight ratio exceeding 1:1 - in many cases