WREN 75 - High Performance Gas Turbine Engine Page 8

To confirm all is connected correctly, check the operation of the starter and gas system. This should be

done outside in the open air away from flammables as we are generating a flame here. Turn off the

receiver, wait a few seconds and then turn back on again (this is how you reset the ECU). Always start with

the HDT display plugged into the ecu.

With the throttle stick down, raise your trim to full-up and confirm the display shows “Ready”.

The propane system you have, decides which starting procedure is used – see the following:

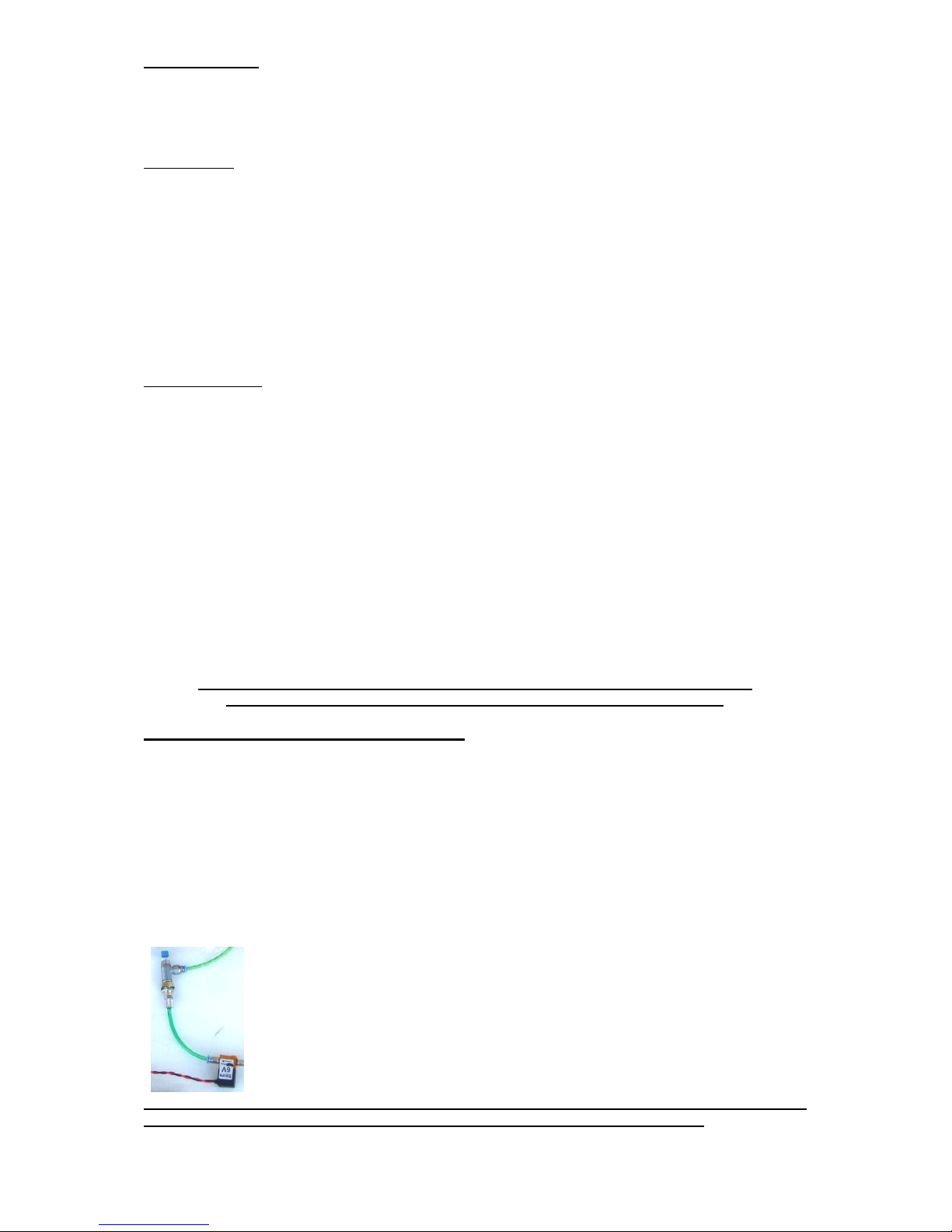

For off-board gas using a gas solenoid and flow control valve.

Connect the external gas to the quick connector and open the gas cannister valve two turns open. Confirm

the gas screwdown valve is set 1-1/2 turns open from fully off.

Raise the throttle stick to full and quickly back down again (within 1 second). This is the signal for the ECU

to start the engine. The starter will kick in and spin the engine gently and the gas should light with a gentle

plop. If the “plop” is too small then open the flow valve by half a turn. Do NOT open the flow valve on the

gas solenoid wide open in an attempt to make the engine light quicker or better – you will only make a big

“whoosh” when the gas does light and there will be far too much. Aim for the smallest amount required.

Reduce the flow if the “plop” is too aggressive.

When ignition of the gas happens the temperature on the ECU display should be seen to rise fairly quickly

and the starter will start to accelerate the engine. As soon as you see this lower the trim back to zero to

terminate the start sequence. The gas solenoid will then shut off the gas supply to engine. Practice further

starts and adjust the amount you open the flow valve so you get a quick temp rise but no external flame or

aggressive burning noises. You will quickly find a setting that works best and lock the small lock-ring on the

flow valve to hold the setting. If after a couple of attempts the engine stops with the temp reading above

100’C, lower trim to zero and you can use the throttle stick to pulse the starter in short bursts to cool the

engine. Don’t try starting the engine while the temp is over 100’C.

On-board gas using propane tank, gas solenoid and flow control valve.

Once the gas tank is filled, use the same procedure as for “off-board gas using gas solenoid and flow

control valve” above except there is no external gas cannister connected. Be sure to keep the flow control

open to only the minimum. Never attempt to use this system without a flow control valve fitted.

If the tank needs the gas emptying for any reason, connect the gas cannister to the tank using the quick

connector. Invert the tank so the outlet is downwards, open the cannister valve and the liquid propane

should flow to the cannister. When the flow ceases turn off the cannister valve. There will always be some

residual gas remaining in the pipework and gas tank so use the cannister valve without the cannister fitted

to gently release remaining gas – always do this in the open air away from sources of ignition.

For off-board gas, without gas solenoid or flow control valve:

Connect the external gas to the quick connector but do not turn on yet. Raise the throttle stick to full and

quickly back down again (within 1 second). This is the signal for the ECU to start the engine. The starter will

kick in and spin the engine gently. At this point crack open the gas valve on your cannister a small amount

until the gas ignites with a gentle “plop”. DO NOT open the valve several turns open in an attempt to make

the engine light quicker or better – you will only make a big “whoosh” when the gas does light and there will

be far too much flow – flame could even appear at the front of the engine. Aim for the smallest flow

required. Remember you are controlling the flow with the cannister valve, so go gently.

When ignition of the gas happens the temperature on the ECU display should be seen to rise fairly quickly

and the starter will start to accelerate the engine. As soon as you see this, turn off the gas and lower the

trim back to zero to terminate the start sequence. Practice further starts and adjust the amount you open

the gas cannister so you get a quick temp rise but no external flame or aggressive burning noises. You will

quickly find a setting that works best. Try to reproduce the setting each time you make your starts until it

becomes automatic. If the engine stops with the temp reading above 100’C you can use the throttle stick to

pulse the starter in short bursts to cool the engine. Don’t try starting the engine while the temp is over

100’C.

In all cases, less gas rather than more usually works best but you will need to experiment. Remember you

are not adding any lubricant to the engine by spinning it up on gas so don’t do this more that a few times or

the bearings will dry out.

Running the engine.

Once you have done a few practice gas light-ups you can connect up your fuel tank and prepare for a

proper engine run. Secure your test stand or aircraft firmly. Position it in a suitable place in a well ventilated