物理 WU LI ─WH-2075 (2021V) 4

Operation Instructions

A. Operating Instructions

1. Check every fastener to make sure that the pump and engine/motor are installed

firmly onto the frame.

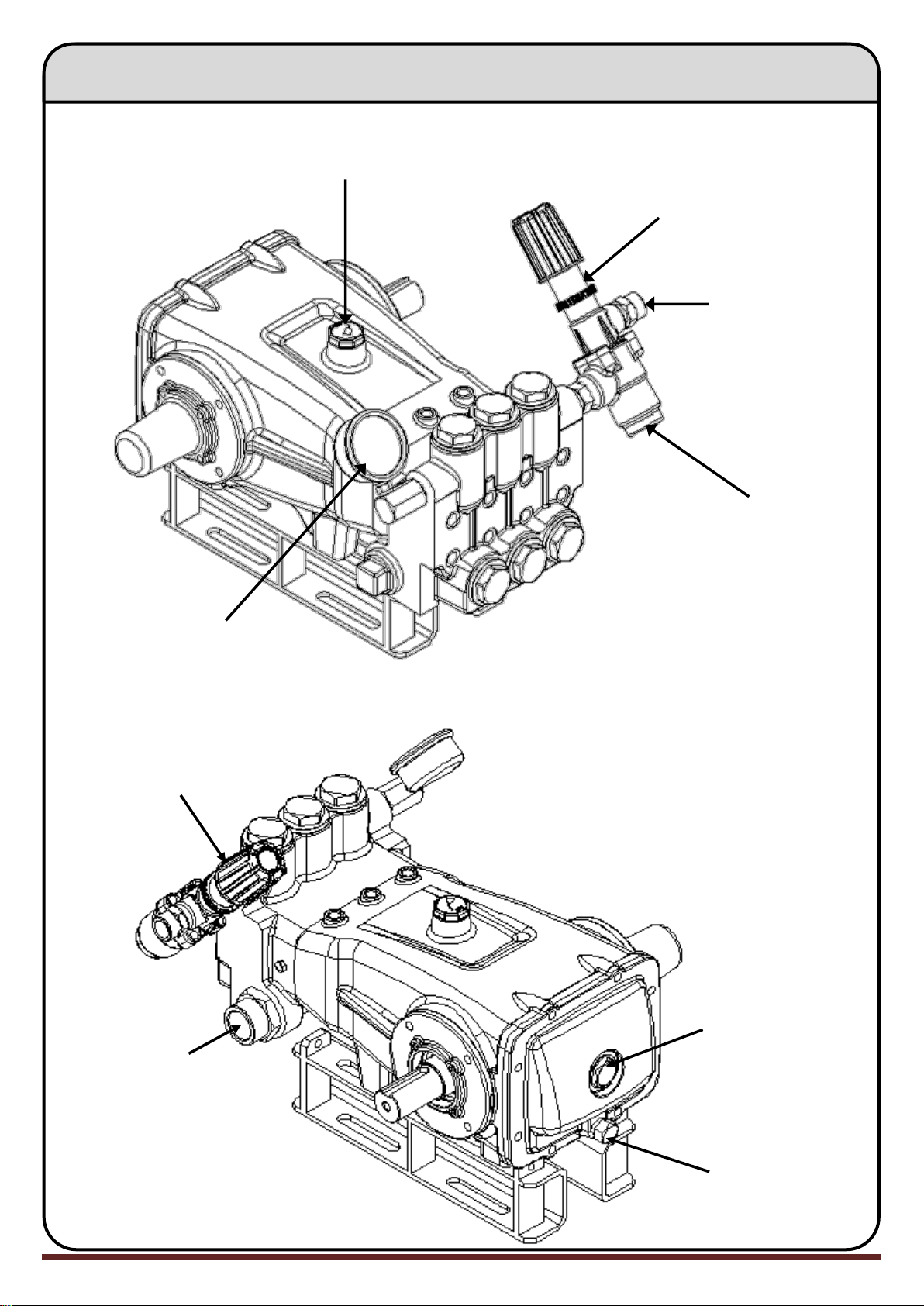

2. Connect the suction hose to the Water Inlet of the pump and secure the hose;

connect the high pressure hose to the Water Outlet.

3. Put the suction hose (with filter) into the water tank and make sure that water

flows smoothly. Please suspend the suction filter around 20cm above the bottom

of the water tank to avoid suctioning residue which might reduce the product’s

life.

4. Check if the motor is connected to the right voltage; check if the engine fuel is

suitable and sufficient.

5. Always release air from the pump when first starting it.

6. Pressure adjustment:

◇Check the pressure displayed on Pressure Gauge for reference when adjusting it.

◇The maximum pressure should not exceed the pump’s working pressure.

◇Hold the spray gun trigger when adjusting the pressure.

◇Turn the knob clockwise to increase pressure; counterclockwise decrease.

7. When finished using the pump, turn off the power of motor or engine and

squeeze the spray gun trigger again to release the pressure stored in the high

pressure hose.

B. Oil Change

1. Replace the oil in the pump after the first 100 hours of use. After this, the oil

should be changed after every 300 hours of use.

2. Unscrew the Oil Drainage Screw and drain the oil from the pump.

3. Tighten the Oil Drainage Screw before refilling with clean motor oil SAE

#30~#40 up to the level of 2/3 of the Oil Window.

※Attention: When replacing the oil, please turn off the product and

make sure that the oil temperature has cooled before replacing.