Flat rooF application

Framed and frameless PV - Modules

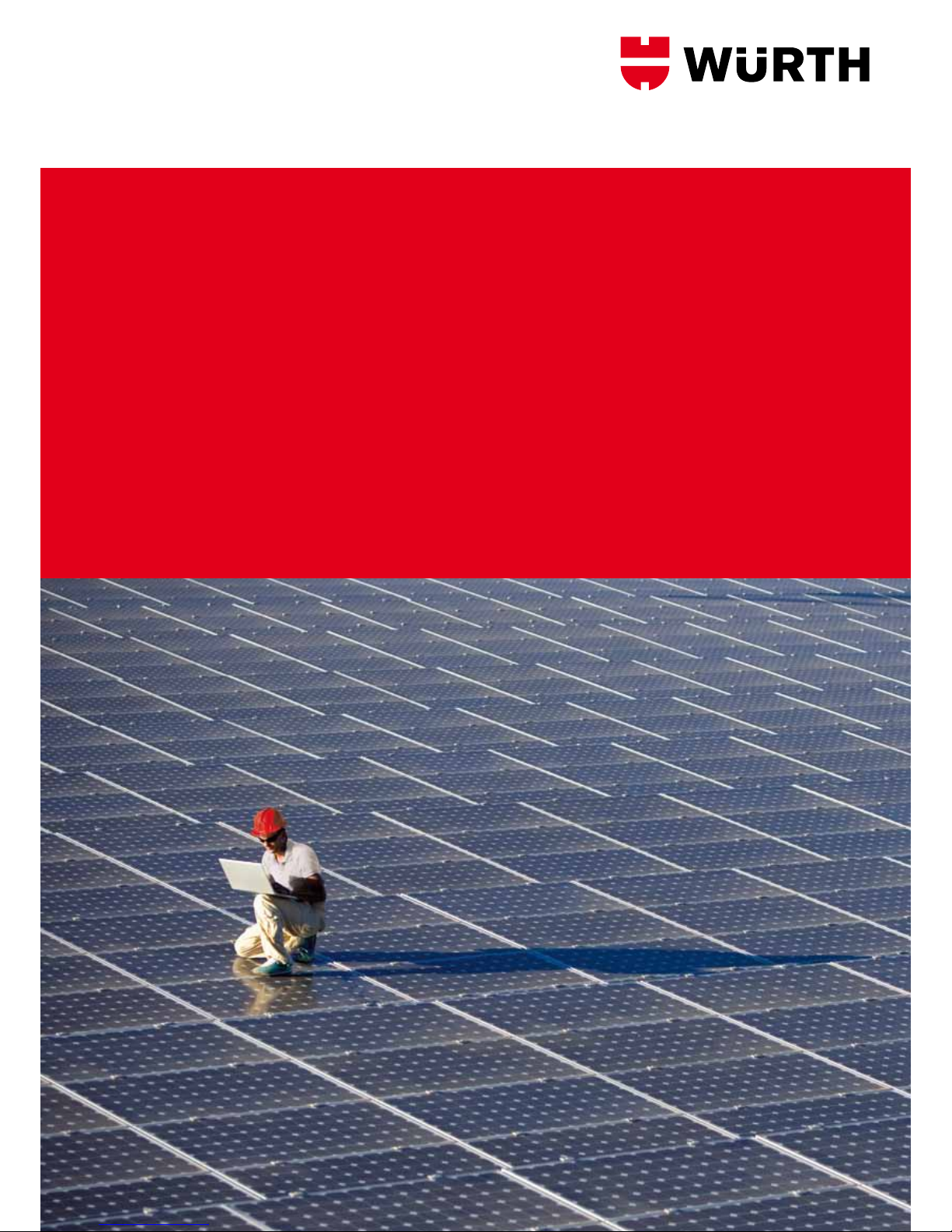

Installing Triangles:

Trianglescannowbemountedto

baserails.Todothisproperlyspace

trianglesonthebaserail,perthe

structuralsitespecicdrawings,and

attachwithcrossadapters.

Atotalof4crossadapterswillbe

usedtoattacheachtriangletothe

twobaserails.

Clickcrossadaptersonto

railwiththecurvedlipof

thecrossadaptersfacing

theC-Channelonthe

sidesofthetrianglebase

rails.Tightenthescrews

clockwise.See Figures

4.1 & 4.2

(Torque:6to8ft.lbs.)

Crossadapterswillbe

attachedonbothsidesof

eachtriangleforeachbase

rail.See Figure 4.3

Nowthatonetriangleisattachedtothebaserails,continuetheprocesswith

therestofthetrianglesmakingsurethatthetrianglesareproperlyspaced

accordingtostructuralsitespecicdrawings.

Cross Rail Installation:

Next,modulemountingcrossrailswillbemountedtotheangledfaceofthe

triangles.See Figure 5.1

Thespacebetweenthecrossbar

clampsisabout½ofthemodule

heightinthecaseofframedmodules

thataremountedonend.Thespace

betweenthelowercrossbarclamps

andthebaserailisequaltoabout¼

ofthemoduleheight.See Figure 5.2

Pleasefollowtheinstructionsofthemodulemanufacturer.

Now,positionthemountingrailonthecross

adapterclampsandhookthecrossbar

clampsinthemodulerackslots.Useacord

forprecisealignmentofmodulerackswith

oneanother.Useasplicetoattachmore

moduleracks.Afterallmoduleracksare

positionedcorrectly,fastenthescrewsofthe

crossadapterclampsbyturninghardware

clockwise.See Figure 5.3

(Torque:6to8ft.lbs.)

Tolineupseveralmodulemountingrailswithoneanother,slidethesplice

halfwayontotheassembledmodulemountingrailuntiltherivetonthesplice

stopstheinsertionofthesplice.

Thenplacetheopposingrailovertheexposedendofthespliceandpush

railstogetheragainsttherivet.½”gaporseparationbetweenrailsis

requiredforthermalexpansion.See Figure 5.4

SubjecttotechnicalchangesCopyright©2009HatiConSolar,LLC Page5of11

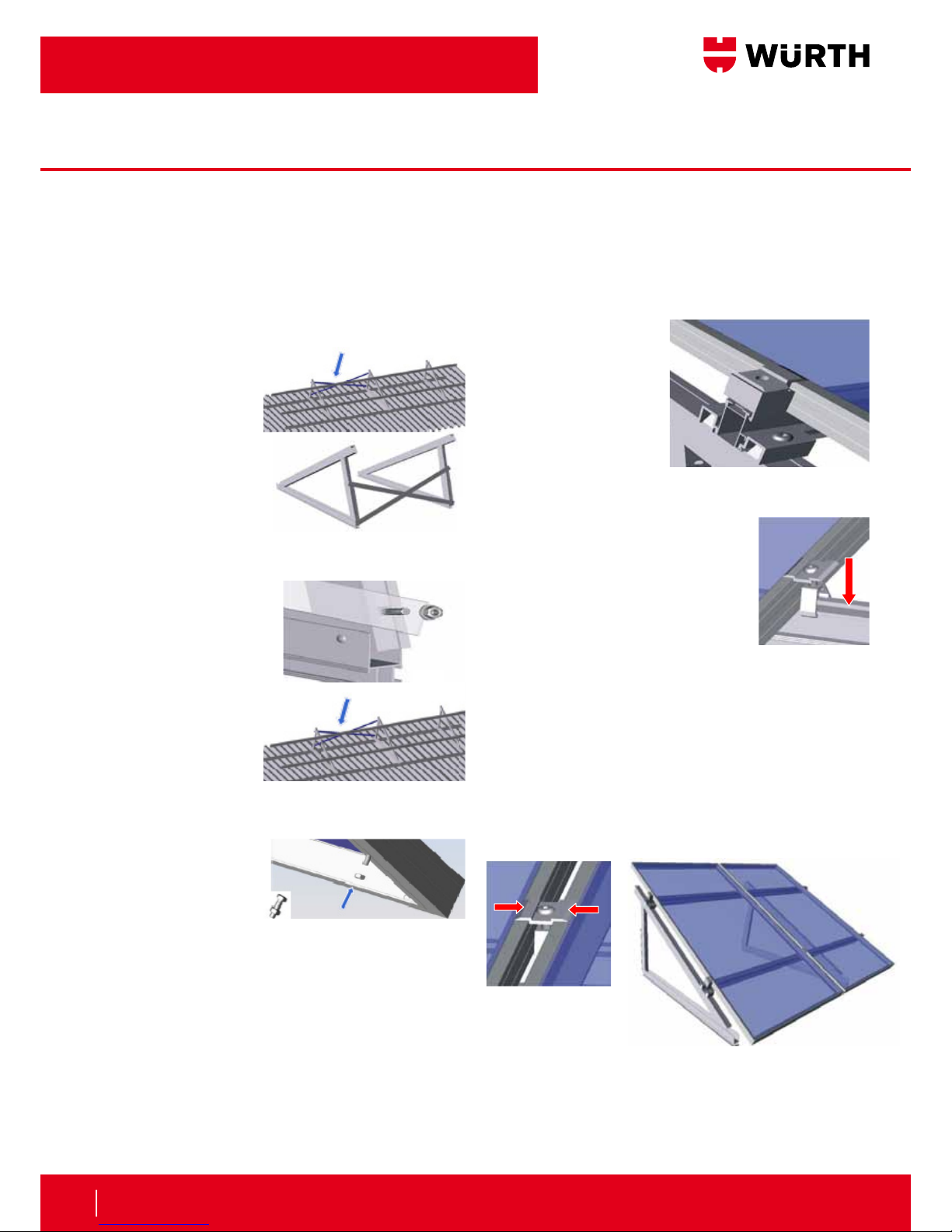

InstallingTriangles:

Trianglescannowbemountedtobaserails.Todothis

properlyspacetrianglesonthebaserail,perthe

structuralsitespecificdrawings,andattachwithcross

adapters.

Atotalof4crossadapterswillbeusedtoattacheach

triangletothetwobaserails.

Clickcrossadaptersontorailwiththecurvedlipofthe

crossadaptersfacingtheC‐Channelonthesidesofthe

trianglebaserails.Tightenthescrewsclockwise.

SeeFigures4.1&4.2

(Torque:6to8ft.lbs.)

Crossadapterswillbeattachedonbothsidesofeach

triangleforeachbaserail.

SeeFigure4.3

Nowthatonetriangleisattachedtothebaserails,

continuetheprocesswiththerestofthetriangles

makingsurethatthetrianglesareproperlyspaced

accordingtostructuralsitespecificdrawings.

SubjecttotechnicalchangesCopyright©2009HatiConSolar,LLC Page5of11

InstallingTriangles:

Trianglescannowbemountedtobaserails.Todothis

properlyspacetrianglesonthebaserail,perthe

structuralsitespecificdrawings,andattachwithcross

adapters.

Atotalof4crossadapterswillbeusedtoattacheach

triangletothetwobaserails.

Clickcrossadaptersontorailwiththecurvedlipofthe

crossadaptersfacingtheC‐Channelonthesidesofthe

trianglebaserails.Tightenthescrewsclockwise.

SeeFigures4.1&4.2

(Torque:6to8ft.lbs.)

Crossadapterswillbeattachedonbothsidesofeach

triangleforeachbaserail.

SeeFigure4.3

Nowthatonetriangleisattachedtothebaserails,

continuetheprocesswiththerestofthetriangles

makingsurethatthetrianglesareproperlyspaced

accordingtostructuralsitespecificdrawings.

Click

4.1

4.2

4.3

4.4

SubjecttotechnicalchangesCopyright©2009HatiConSolar,LLC Page5of11

InstallingTriangles:

Trianglescannowbemountedtobaserails.Todothis

properlyspacetrianglesonthebaserail,perthe

structuralsitespecificdrawings,andattachwithcross

adapters.

Atotalof4crossadapterswillbeusedtoattacheach

triangletothetwobaserails.

Clickcrossadaptersontorailwiththecurvedlipofthe

crossadaptersfacingtheC‐Channelonthesidesofthe

trianglebaserails.Tightenthescrewsclockwise.

SeeFigures4.1&4.2

(Torque:6to8ft.lbs.)

Crossadapterswillbeattachedonbothsidesofeach

triangleforeachbaserail.

SeeFigure4.3

Nowthatonetriangleisattachedtothebaserails,

continuetheprocesswiththerestofthetriangles

makingsurethatthetrianglesareproperlyspaced

accordingtostructuralsitespecificdrawings.

Click

4.1

4.2

4.3

4.4

SubjecttotechnicalchangesCopyright©2009HatiConSolar,LLC Page5of11

InstallingTriangles:

Trianglescannowbemountedtobaserails.Todothis

properlyspacetrianglesonthebaserail,perthe

structuralsitespecificdrawings,andattachwithcross

adapters.

Atotalof4crossadapterswillbeusedtoattacheach

triangletothetwobaserails.

Clickcrossadaptersontorailwiththecurvedlipofthe

crossadaptersfacingtheC‐Channelonthesidesofthe

trianglebaserails.Tightenthescrewsclockwise.

SeeFigures4.1&4.2

(Torque:6to8ft.lbs.)

Crossadapterswillbeattachedonbothsidesofeach

triangleforeachbaserail.

SeeFigure4.3

Nowthatonetriangleisattachedtothebaserails,

continuetheprocesswiththerestofthetriangles

makingsurethatthetrianglesareproperlyspaced

accordingtostructuralsitespecificdrawings.

Click

4.1

4.2

4.3

4.4

Fig. 4.1

Fig. 5.1

Fig. 5.2

Fig. 5.4

Fig. 5.3

Fig. 4.2

Fig. 4.3

Fig. 4.4

SubjecttotechnicalchangesCopyright©2009HatiConSolar,LLC Page6of11

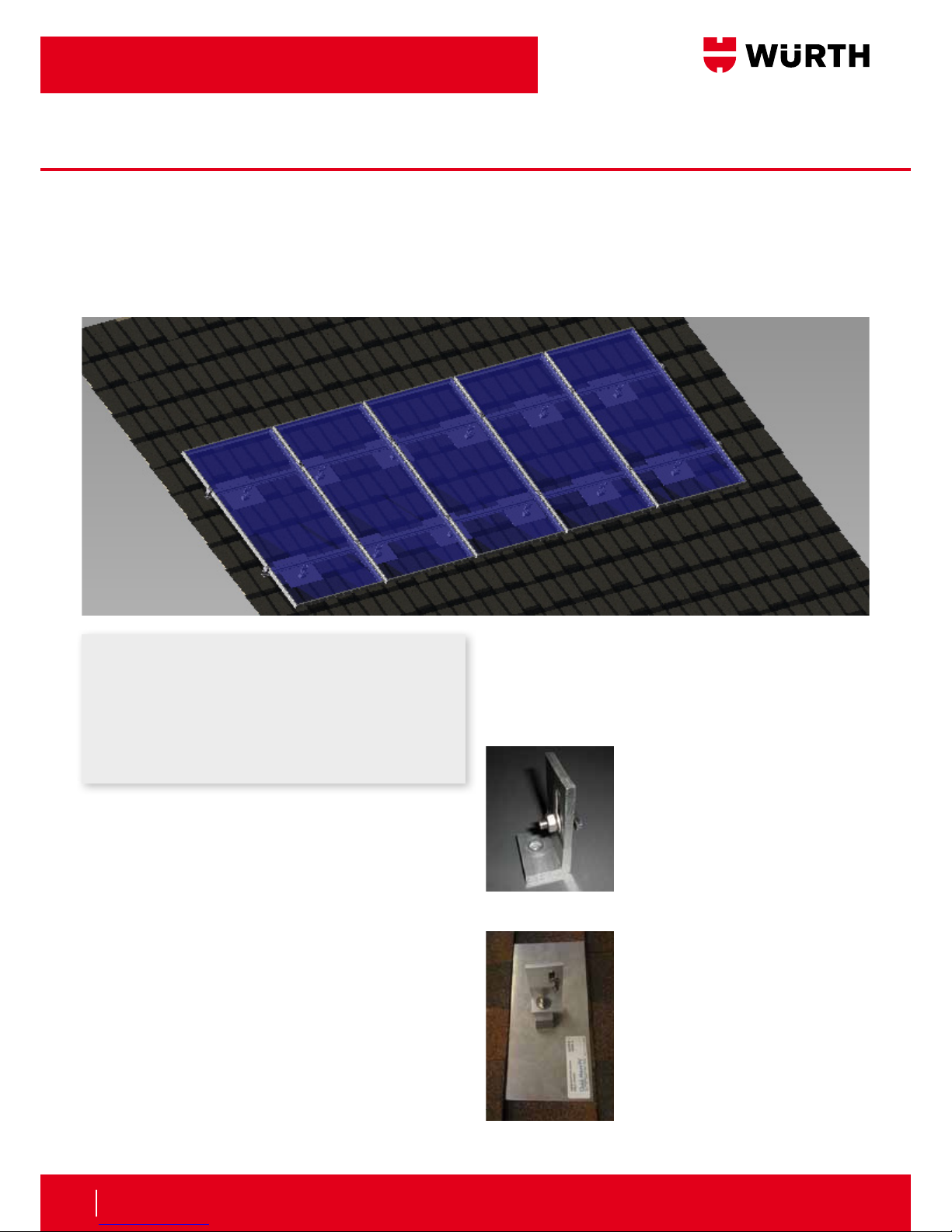

CrossRailInstallation:

Next,modulemountingcrossrailswillbemountedto

theangledfaceofthetriangles.

SeeFigure5.1

Thespacebetweenthecrossbarclampsisabout½of

themoduleheightinthecaseofframedmodulesthat

aremountedonend.Thespacebetweenthelower

crossbarclampsandthebaserailisequaltoabout¼of

themoduleheight.

SeeFigure5.2

Pleasefollowtheinstructionsofthemodule

manufacturer.

Now,positionthemountingrailonthecrossadapter

clampsandhookthecrossbarclampsinthemodule

rackslots.Useacordforprecisealignmentofmodule

rackswithoneanother.Useasplicetoattachmore

moduleracks.Afterallmoduleracksarepositioned

correctly,fastenthescrewsofthecrossadapterclamps

byturninghardwareclockwise.

SeeFigure5.3

(Torque:6to8ft.lbs.)

Tolineupseveralmodulemountingrailswithone

another,slidethesplicehalfwayontothe

assembledmodulemountingrailuntiltheriveton

thesplicestopstheinsertionofthesplice.

Thenplacetheopposingrailovertheexposedendof

thespliceandpushrailstogetheragainsttherivet.½”

gaporseparationbetweenrailsisrequiredforthermal

expansion.

SeeFigure5.4

Note:Donotattempttothroughboltanysplices.The

splicewasdesignedtoallowthealuminumrailsto

expandandcontractunderthermalconditions.

5.1

5.2

5.3

5.4

SubjecttotechnicalchangesCopyright©2009HatiConSolar,LLC Page6of11

CrossRailInstallation:

Next,modulemountingcrossrailswillbemountedto

theangledfaceofthetriangles.

SeeFigure5.1

Thespacebetweenthecrossbarclampsisabout½of

themoduleheightinthecaseofframedmodulesthat

aremountedonend.Thespacebetweenthelower

crossbarclampsandthebaserailisequaltoabout¼of

themoduleheight.

SeeFigure5.2

Pleasefollowtheinstructionsofthemodule

manufacturer.

Now,positionthemountingrailonthecrossadapter

clampsandhookthecrossbarclampsinthemodule

rackslots.Useacordforprecisealignmentofmodule

rackswithoneanother.Useasplicetoattachmore

moduleracks.Afterallmoduleracksarepositioned

correctly,fastenthescrewsofthecrossadapterclamps

byturninghardwareclockwise.

SeeFigure5.3

(Torque:6to8ft.lbs.)

Tolineupseveralmodulemountingrailswithone

another,slidethesplicehalfwayontothe

assembledmodulemountingrailuntiltheriveton

thesplicestopstheinsertionofthesplice.

Thenplacetheopposingrailovertheexposedendof

thespliceandpushrailstogetheragainsttherivet.½”

gaporseparationbetweenrailsisrequiredforthermal

expansion.

SeeFigure5.4

Note:Donotattempttothroughboltanysplices.The

splicewasdesignedtoallowthealuminumrailsto

expandandcontractunderthermalconditions.

5.1

5.2

5.3

5.4

SubjecttotechnicalchangesCopyright©2009HatiConSolar,LLC Page6of11

CrossRailInstallation:

Next,modulemountingcrossrailswillbemountedto

theangledfaceofthetriangles.

SeeFigure5.1

Thespacebetweenthecrossbarclampsisabout½of

themoduleheightinthecaseofframedmodulesthat

aremountedonend.Thespacebetweenthelower

crossbarclampsandthebaserailisequaltoabout¼of

themoduleheight.

SeeFigure5.2

Pleasefollowtheinstructionsofthemodule

manufacturer.

Now,positionthemountingrailonthecrossadapter

clampsandhookthecrossbarclampsinthemodule

rackslots.Useacordforprecisealignmentofmodule

rackswithoneanother.Useasplicetoattachmore

moduleracks.Afterallmoduleracksarepositioned

correctly,fastenthescrewsofthecrossadapterclamps

byturninghardwareclockwise.

SeeFigure5.3

(Torque:6to8ft.lbs.)

Tolineupseveralmodulemountingrailswithone

another,slidethesplicehalfwayontothe

assembledmodulemountingrailuntiltheriveton

thesplicestopstheinsertionofthesplice.

Thenplacetheopposingrailovertheexposedendof

thespliceandpushrailstogetheragainsttherivet.½”

gaporseparationbetweenrailsisrequiredforthermal

expansion.

SeeFigure5.4

Note:Donotattempttothroughboltanysplices.The

splicewasdesignedtoallowthealuminumrailsto

expandandcontractunderthermalconditions.

5.1

5.2

5.3

5.4

SubjecttotechnicalchangesCopyright©2009HatiConSolar,LLC Page6of11

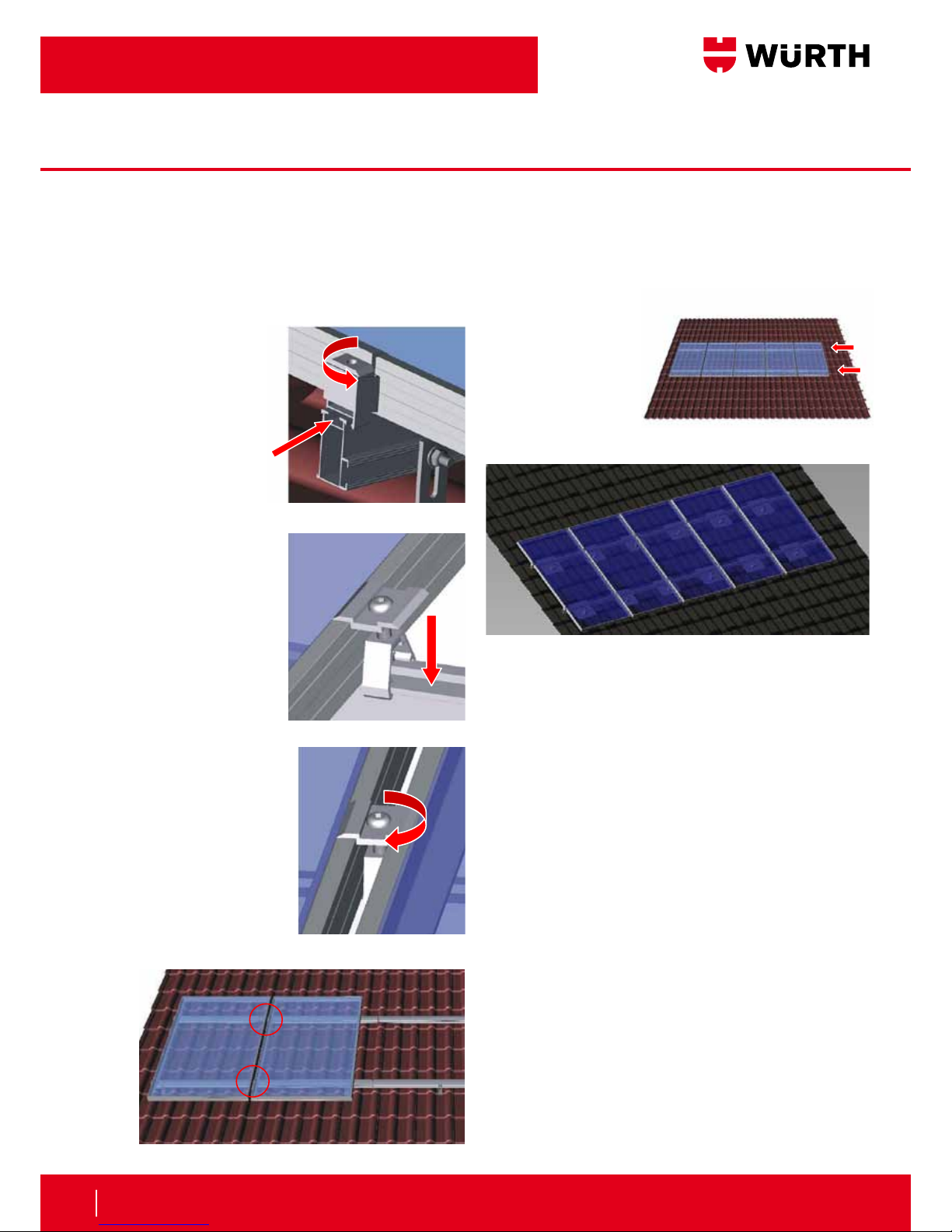

CrossRailInstallation:

Next,modulemountingcrossrailswillbemountedto

theangledfaceofthetriangles.

SeeFigure5.1

Thespacebetweenthecrossbarclampsisabout½of

themoduleheightinthecaseofframedmodulesthat

aremountedonend.Thespacebetweenthelower

crossbarclampsandthebaserailisequaltoabout¼of

themoduleheight.

SeeFigure5.2

Pleasefollowtheinstructionsofthemodule

manufacturer.

Now,positionthemountingrailonthecrossadapter

clampsandhookthecrossbarclampsinthemodule

rackslots.Useacordforprecisealignmentofmodule

rackswithoneanother.Useasplicetoattachmore

moduleracks.Afterallmoduleracksarepositioned

correctly,fastenthescrewsofthecrossadapterclamps

byturninghardwareclockwise.

SeeFigure5.3

(Torque:6to8ft.lbs.)

Tolineupseveralmodulemountingrailswithone

another,slidethesplicehalfwayontothe

assembledmodulemountingrailuntiltheriveton

thesplicestopstheinsertionofthesplice.

Thenplacetheopposingrailovertheexposedendof

thespliceandpushrailstogetheragainsttherivet.½”

gaporseparationbetweenrailsisrequiredforthermal

expansion.

SeeFigure5.4

Note:Donotattempttothroughboltanysplices.The

splicewasdesignedtoallowthealuminumrailsto

expandandcontractunderthermalconditions.

5.1

5.2

5.3

5.4

Note:

Note:Donotattempttothrough-boltanysplices.Thesplicewas

designedtoallowthealuminumrailstoexpandandcontractunder

thermalconditions.

¼Module

Height ½ModuleHeight

Assembly Instructions

5Solar Mounting Sytem