1

Table of Contents

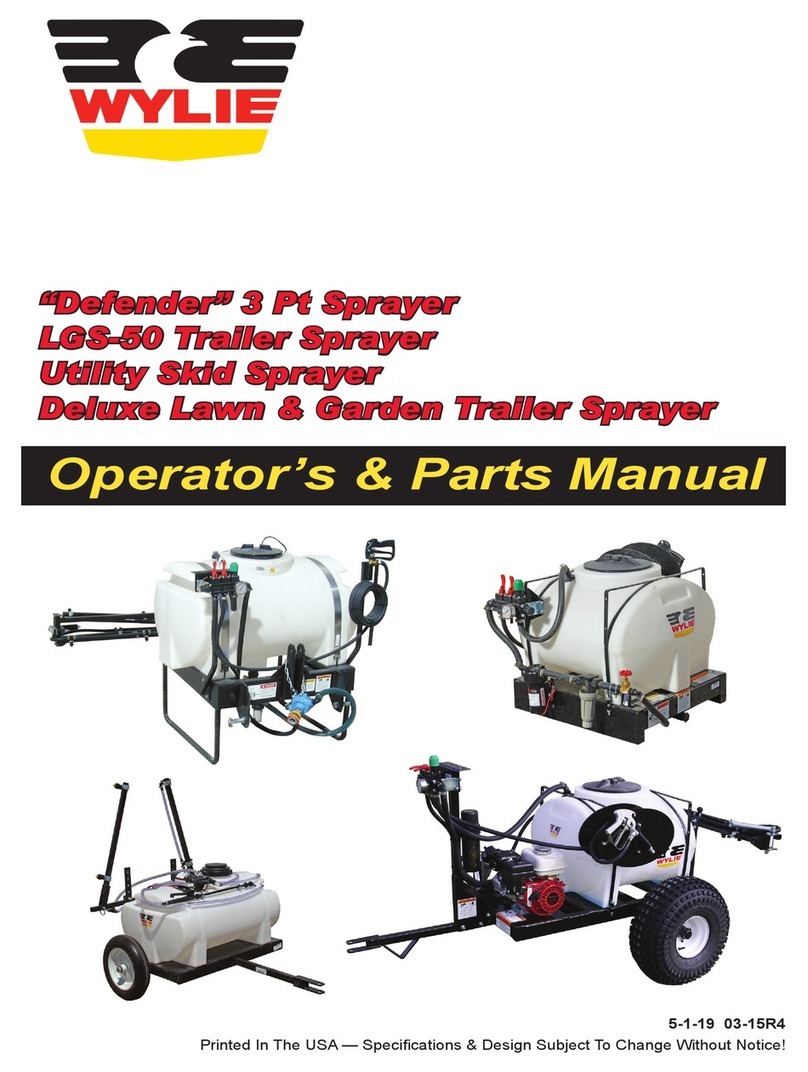

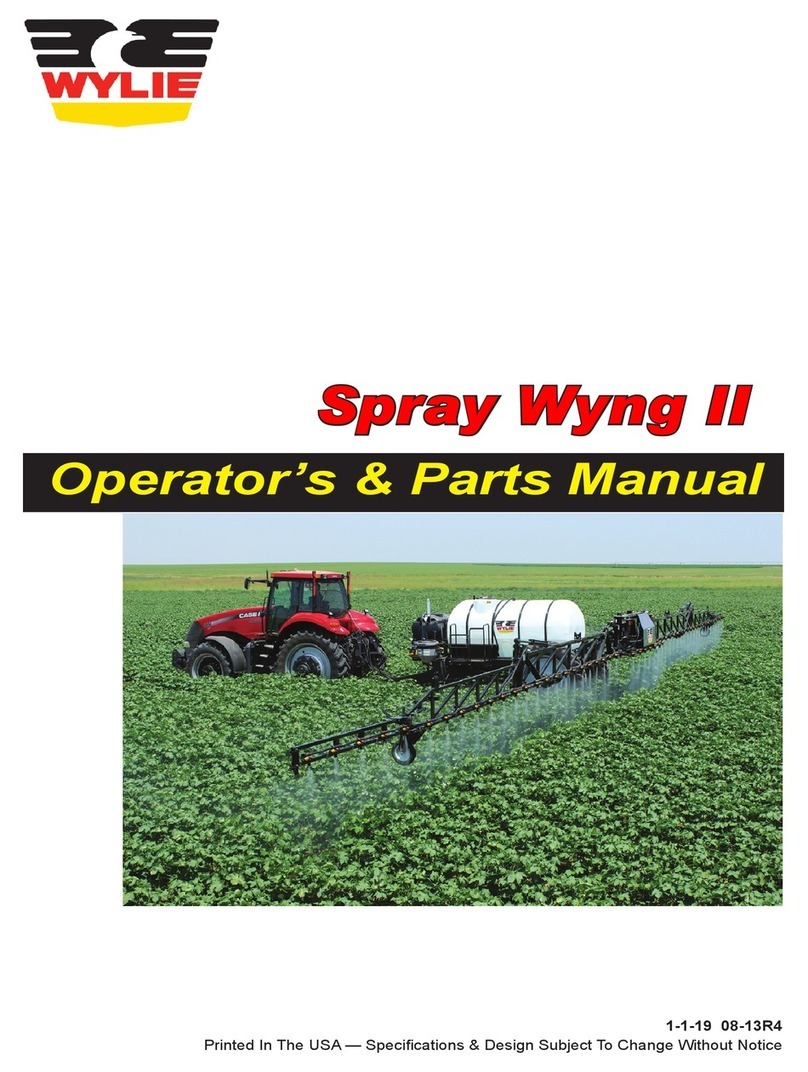

Table Of Contents

Safety Issues .............................................................................................................................................................2-3

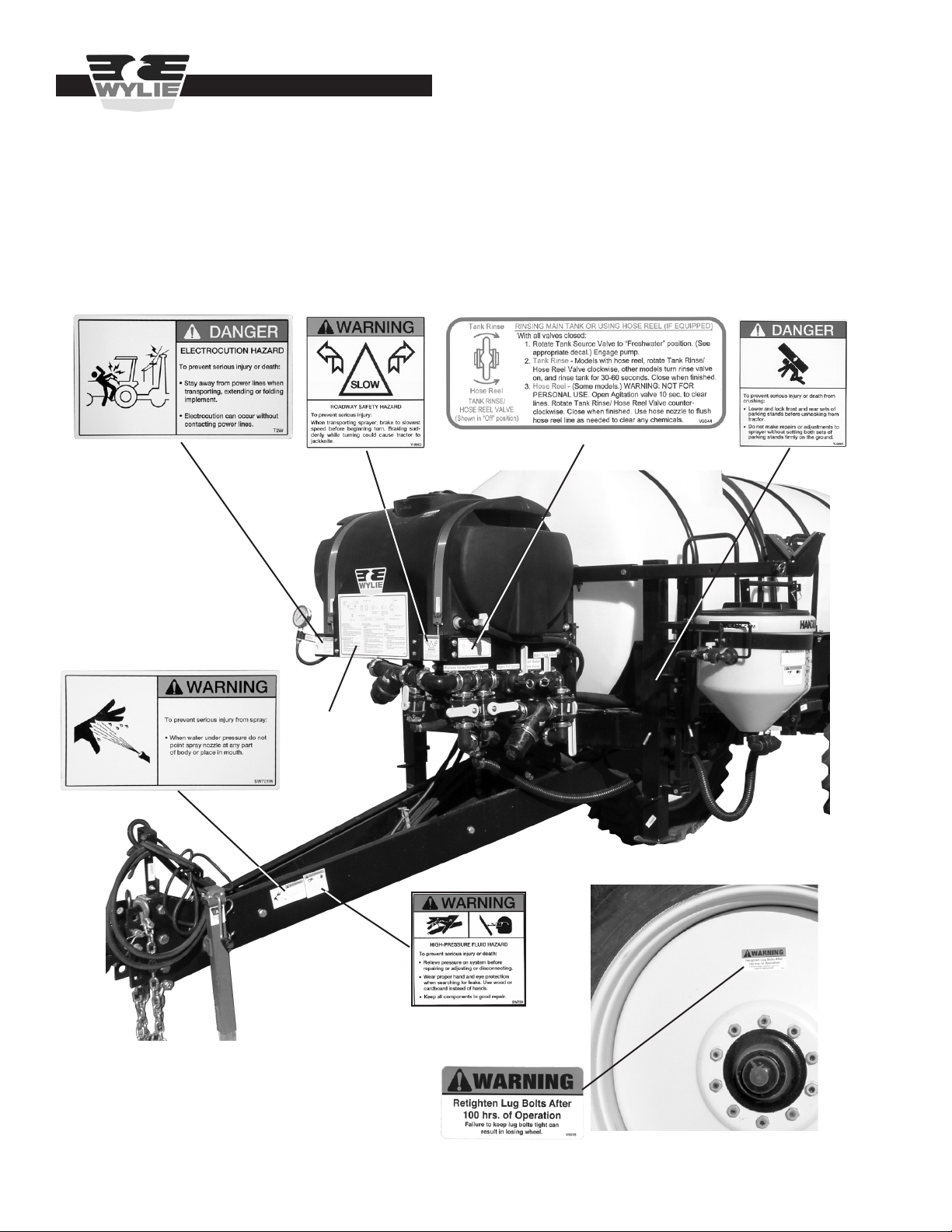

Safety Decals & Placement .......................................................................................................................................4-8

Introduction ................................................................................................................................................................... 9

Inspection & Setup ................................................................................................................................................10-12

Boom Operation ....................................................................................................................................................13-14

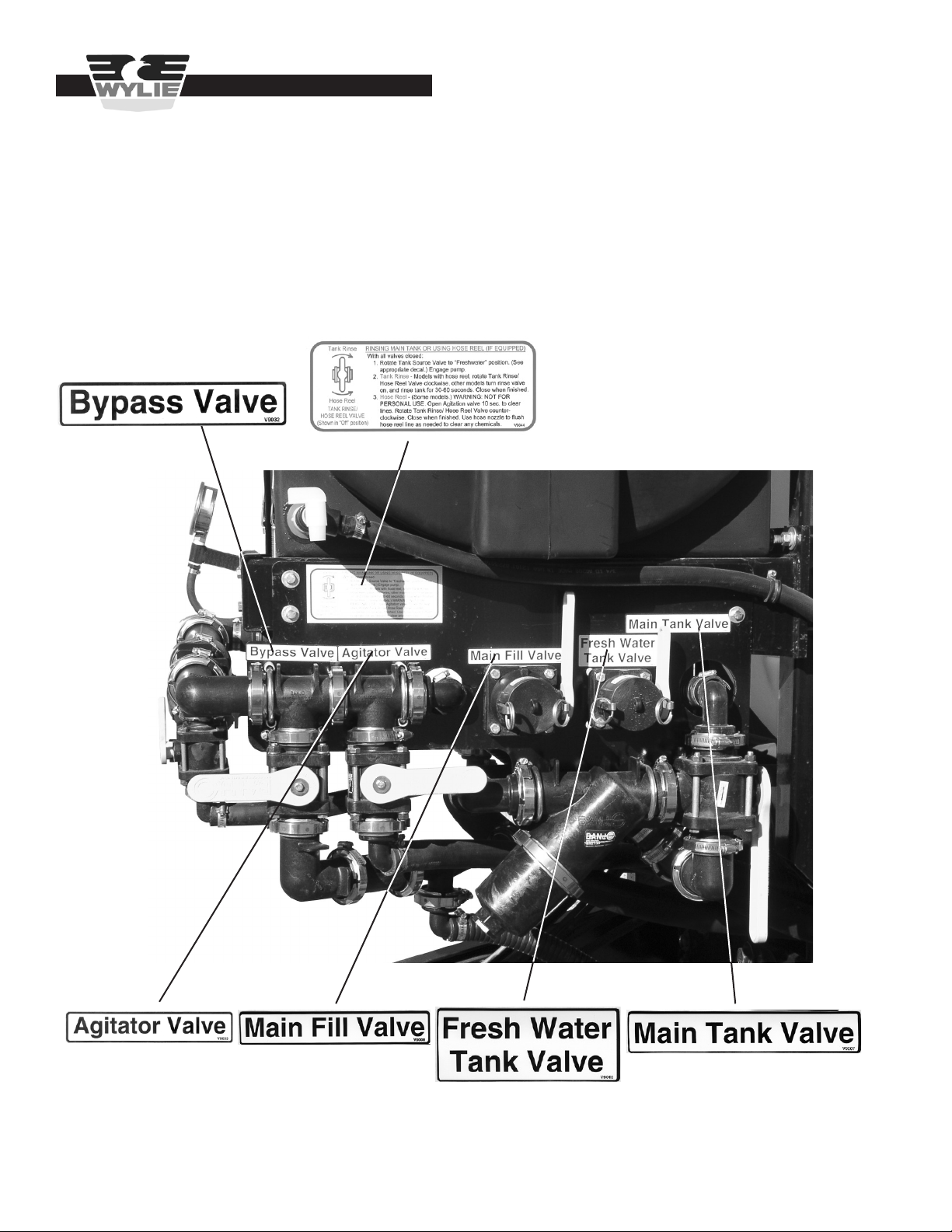

Sprayer Operation .................................................................................................................................................15-23

Maintenance ............................................................................................................................................................... 24

Boom Adjustment ..................................................................................................................................................25-26

Trailer Adjustment ..................................................................................................................................................27-28

Lubrication .............................................................................................................................................................28-29

Troubleshooting Guidelines ...................................................................................................................................30-32

Repair Parts...........................................................................................................................................................33-59

Row Wyng Carrier Frame Section .................................................................................... 34

Row Wyng Center Section ............................................................................................... 34

Row Wyng Primary/Secondary Section ........................................................................... 35

Row Wyng Boom Plumbing Kit ........................................................................................ 36

3 Point Fill Kit ................................................................................................................... 36

Carrier Plumbing and Pump ............................................................................................. 37

VersaTrakr Trailer ............................................................................................................. 38

VersaTrail Trailer .............................................................................................................. 39

VersaTrakr/WyngTrakr Articulated Hydraulic System .......................................................40

VersaTrakr/VersaTrail Wheels and Axle ........................................................................... 41

1,600 Spray Trailer ........................................................................................................... 42

Wyng Trakr Trailer ............................................................................................................43

1,000 Gal. Single Axle Trailer ........................................................................................... 44

1,000 Gal. Tandem Axle Trailer ........................................................................................ 45

EP-1000 HCS Trailer ........................................................................................................ 46

Hi-Lift Linkage .................................................................................................................. 47

VersaTrakr, VersaTrail, 1,600 Spray Trailer Plumbing .................................................48-51

1,000 Gallon Trailer Plumbing .....................................................................................52-53

Wyng Trakr Plumbing .......................................................................................................54

Handler™ Mix Assembly .................................................................................................. 55

1,600 Agitator Assembly ................................................................................................... 55

Mix n’ Fill Assembly .......................................................................................................... 56

3 Point Row Wyng Mount ................................................................................................. 56

Hydraulic and Flow Control .............................................................................................. 57

Hydraulic System ............................................................................................................. 58

Raven Boom Valves ......................................................................................................... 59