Contents

1. System introduction..............................................................................................................................4

1.1. About this manual ....................................................................................................................4

2. System Operations.............................................................................................................................4

2.1. Installation................................................................................................................................4

2.2. Steps of power on/off...............................................................................................................4

2.3. Introduction for the applications................................................................................................4

2.4. Quick Start...............................................................................................................................5

3. Application Instruction.........................................................................................................................6

3.1. SP7500 introduction.................................................................................................................6

3.2. New Specifications of SB0X.....................................................................................................6

3.2.1. Automatically nozzle heights compensation...................................................................6

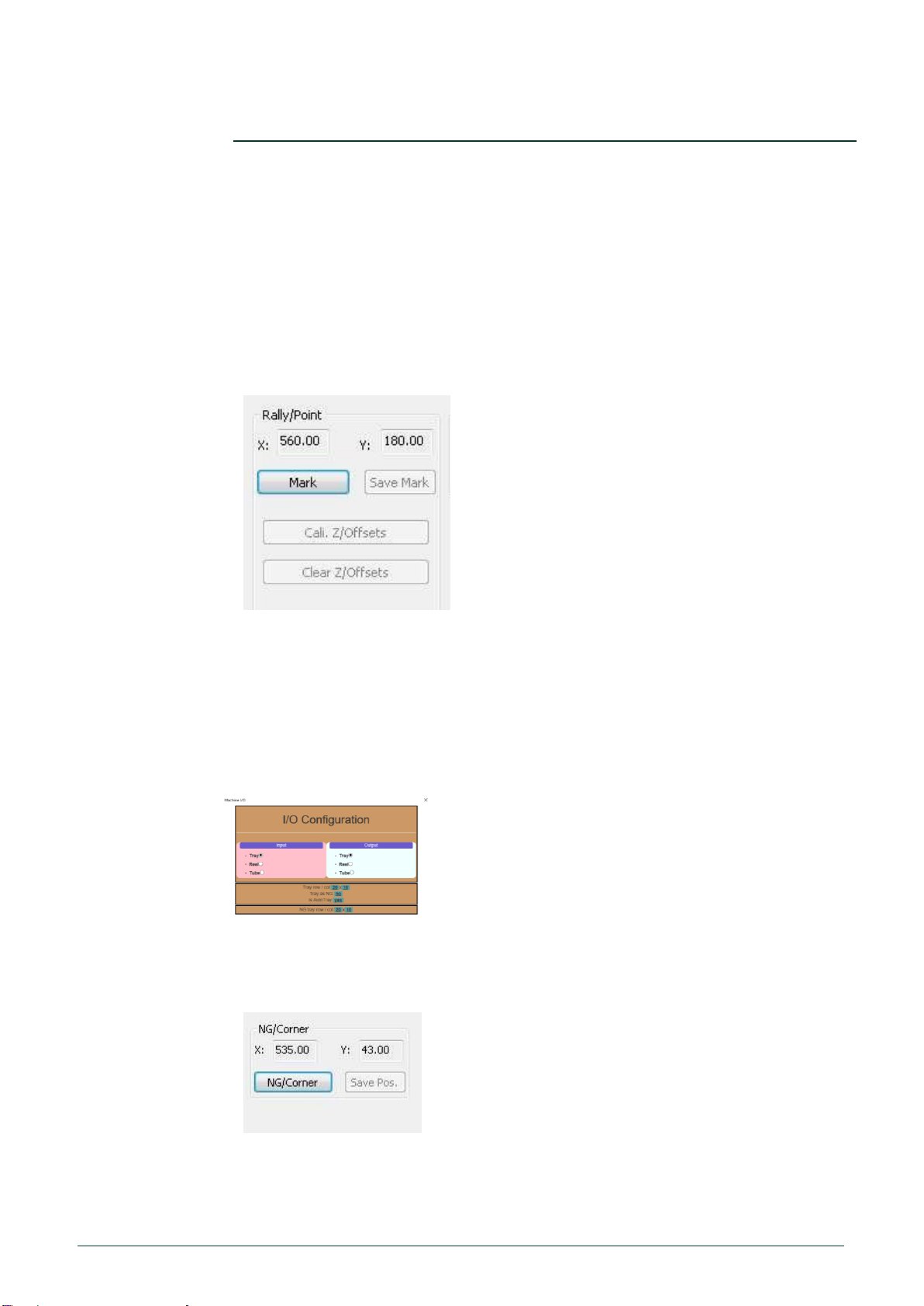

3.2.2. Added NG tray function .................................................................................................6

3.2.3. Added the position setting of the NG corner ..................................................................6

3.2.4. Added instant pause, status retention, and recovery features........................................7

3.2.5. New information display interface, real-time display of UPH and work order status.......7

3.3. SB0X Specifications.................................................................................................................7

3.3.1. Tool Bars.......................................................................................................................7

3.3.2. I/O settings....................................................................................................................7

3.3.3. Configuration settings....................................................................................................8

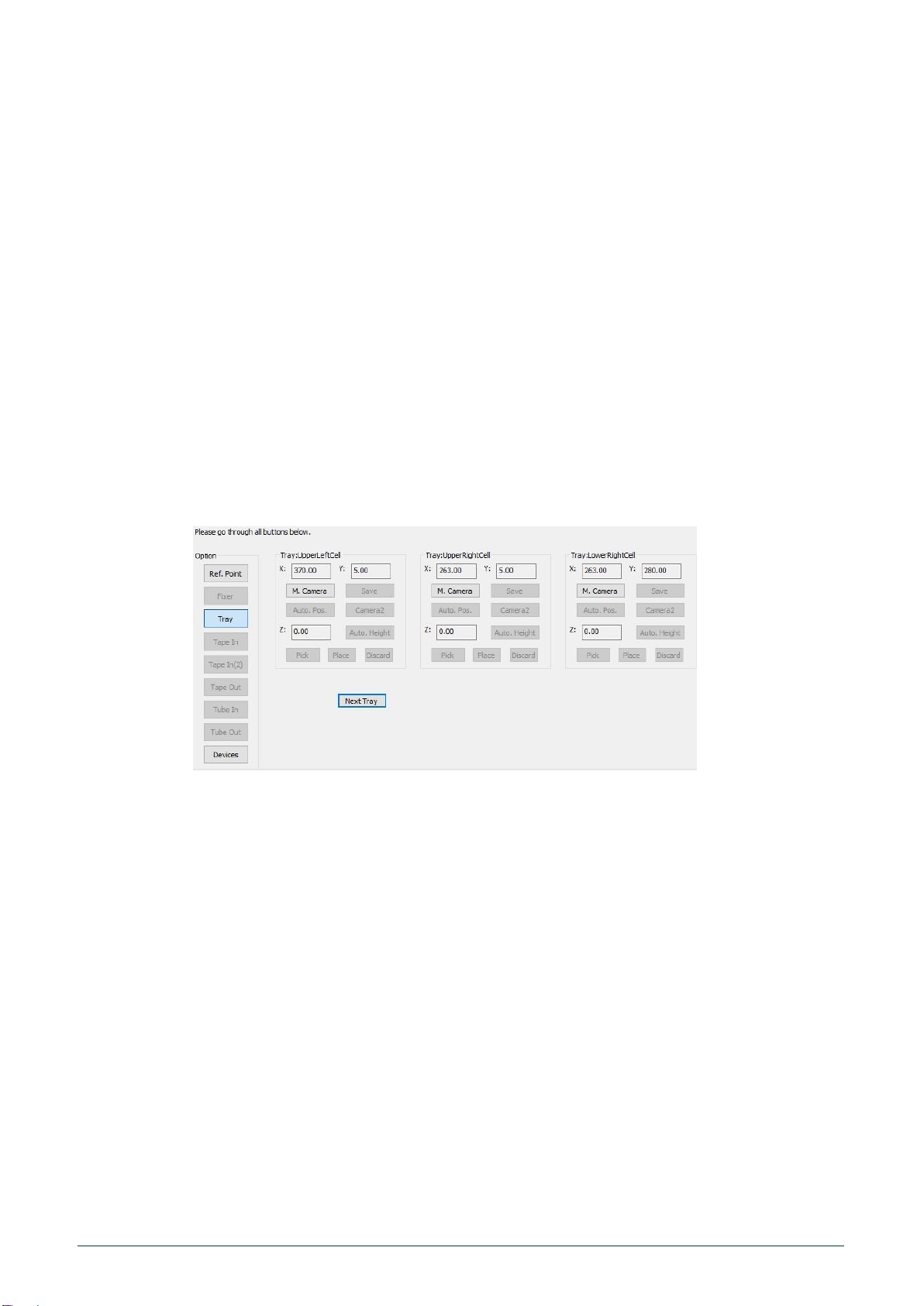

3.3.4. Positioning settings........................................................................................................8

3.3.5. Camera and Vision Check...........................................................................................11

3.3.6. Automatic programming...............................................................................................12

3.3.7. Reports........................................................................................................................12

3.3.8. Connect.......................................................................................................................12

4. Introduction of the mechanical system..............................................................................................13

4.1. System composition...............................................................................................................13

4.1.1. Total power supply and load switch.............................................................................13

4.1.2. Device switch button and emergency stop button........................................................13

4.1.3. Warning lights..............................................................................................................13

4.1.4. Security Door...............................................................................................................14

4.1.5. Control Circuit..............................................................................................................14

4.1.6. Programmers...............................................................................................................14

4.2. System Specification..............................................................................................................14

4.2.1. Motion parameters.......................................................................................................14

4.2.2. Visual parameters........................................................................................................15

4.2.3. Input and output components......................................................................................15

4.2.4. Power supply...............................................................................................................15

4.2.5. Air pressure.................................................................................................................15

5. Maintenance.....................................................................................................................................16

5.1. Daily Maintenance..................................................................................................................16

5.2. Regular Maintenance.............................................................................................................16

6. Trouble shooting...............................................................................................................................17

7. Appendix ..........................................................................................................................................18