UltraLo‐1800AlphaParticleCounterXIALLCPage5

2. Gasrequirements

TheUltraLo‐1800requiresasourceofpure,dryArgongas–ideally,thegasprovidedisboilofffrom

atankofliquidArgon.Allmetaltubing(i.e.copperorstainless)shouldbeusedwhenrunningthegas

fromthesourcetanktotheUltraLo‐1800,andtheplumbingsystemshouldbefreefromleaks.Thegas

pressureattheinputtotheUltraLo‐1800isrequiredtobe21psi(150kPa)±5%.

ThegasinputfittingontheUltraLo‐1800isaSwagelok‐typeconnector:P/NSS‐400‐61,andrequires

¼”ODmetaltubing.AllnecessaryfittinghardwareissuppliedwiththeUltraLo‐1800system.The

installationprocessforthegastubeandfittingisstraightforward.IfanXIALLCrepresentativeispresent

duringsysteminstallation,theywillperformthisinstallationstep.

Figure2:GasInputInterface(Imagefromswagelok.com)

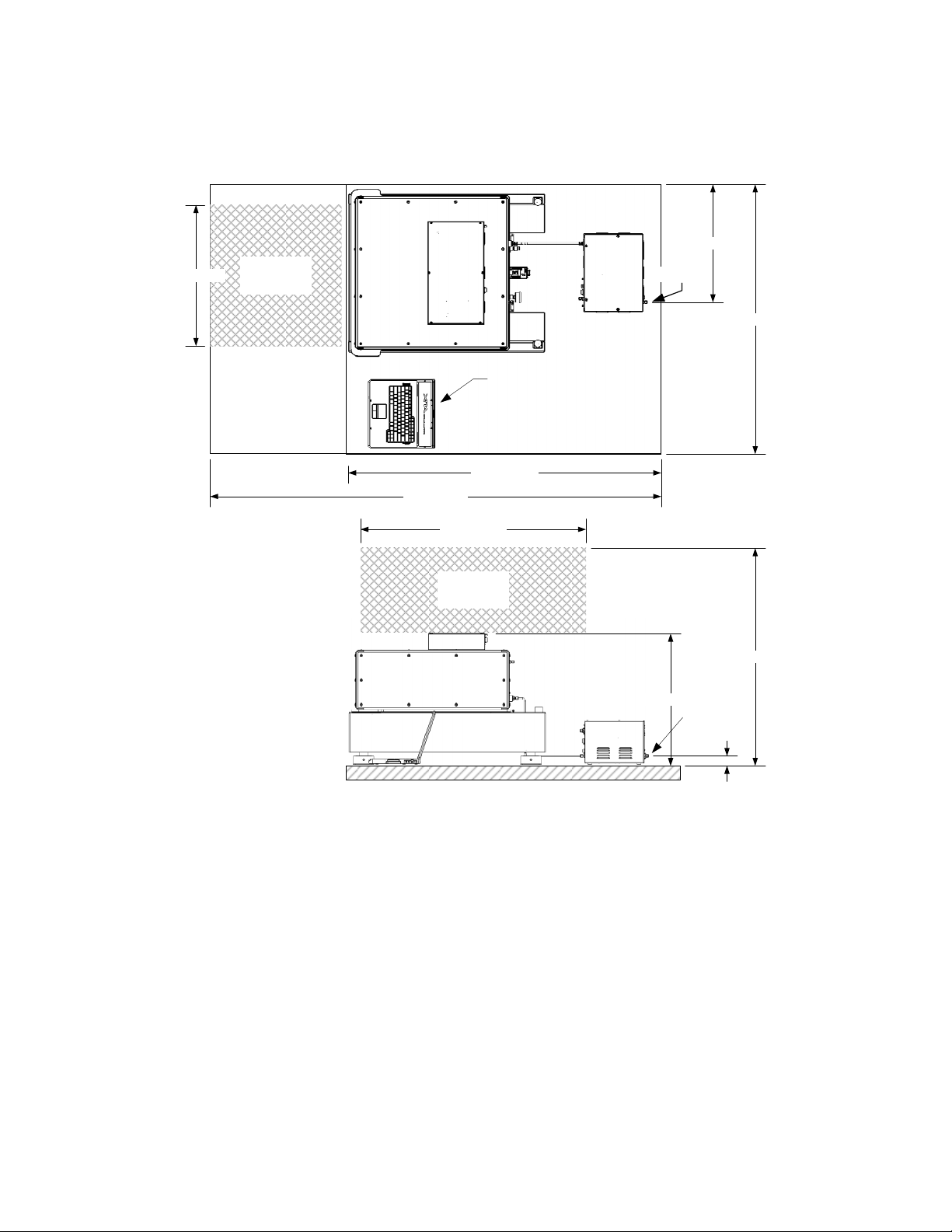

a) GasInletLocation

ThelocationofthegasinputfittingiscalledoutinFigure1.Priortothescheduleddateof

installation,thegastubingmustberunfromthegassourcetothesiteofinstallation,andterminateat

thespecifiedgasinletlocation.Theterminationofthe¼”metaltube(atthegasinletlocation)shallbe

runinsuchamannerastoprovideapproximately10”ofplay(inalldirections)forfinalalignmentduring

systeminstallation.

b) Summary:

Requirement(atinputtoUltraLo)Specification

GasArgon

Pressure21psi(150kPa)±5%

Tubing1/4"ODmetaltube

LocationAscalledoutinFigure1,±10”alldirections

c) Gassupplyandconsumption:

OurrecommendationistouseadewarofliquidArgon,andplumbtheboiloffgastothecounter.In

regardstogasconsumption,theUltraLo‐1800hastwodefinedflowrates;‘normal’(3.5LPM)and

‘purge’(15LPM).Whenyouinsertanewsample,thesystemrunsatthepurgerateforabout45

minutes,afterwhichtheflowisautomaticallythrottleddowntothenormalrateforthemeasurement.

Yourgasconsumptionwilldependonhowmanytimesyouinsertnewsamples.Forreference,the

countersatXIArunoffof230literliquiddewars.Onecounterrunningdailymeasurements(averagingat

least1purge/day)willconsumethedewarinabitovertwoweeks.