5

Warning & Safety Information..................................................................................................... 2

Safety Messages ........................................................................................................................... 3

Oven Description.......................................................................................................................... 6

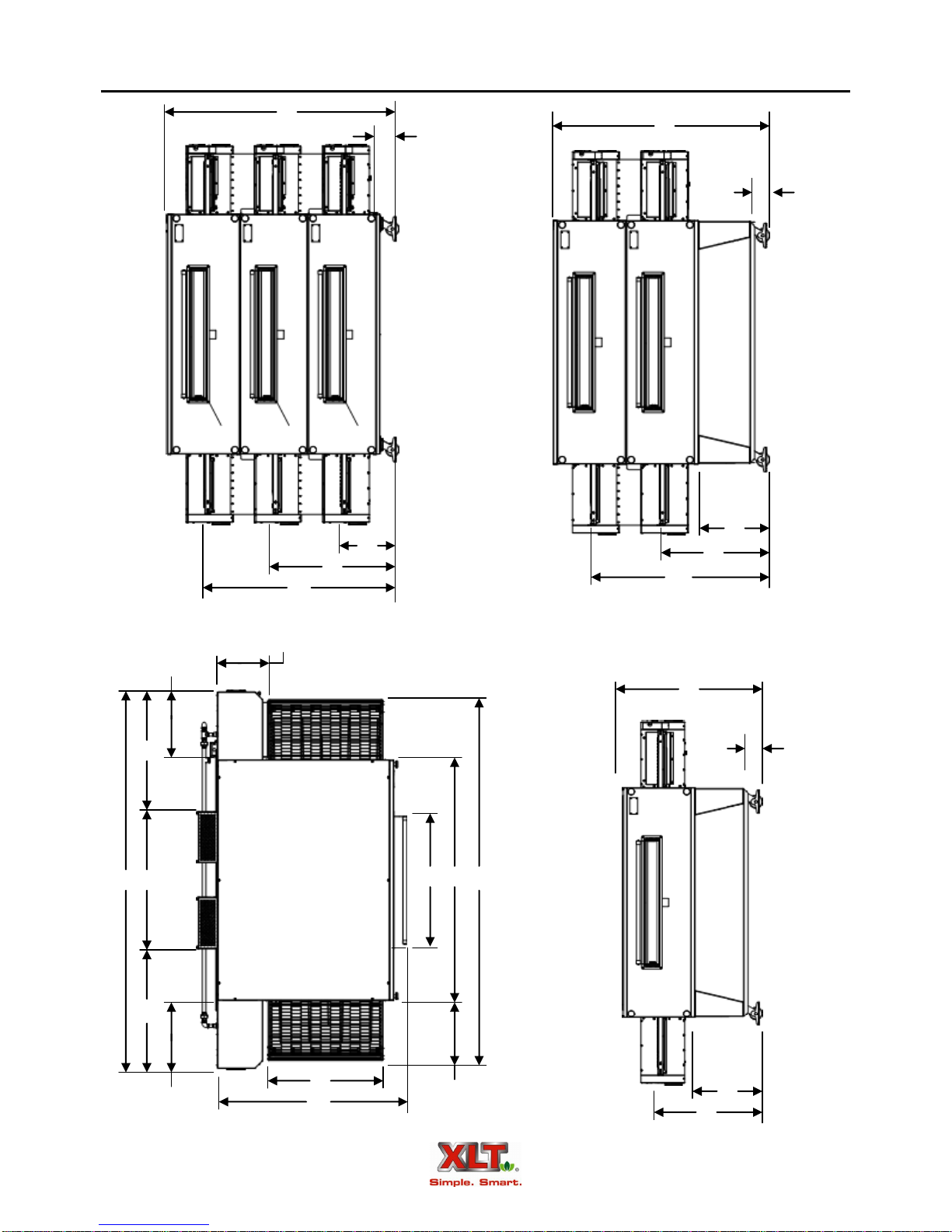

Oven Dimensions......................................................................................................................... 8

Gas & Electrical Connection Dimensions.................................................................................. 10

Oven Electrical Requirements.................................................................................................... 12

Oven Gas Requirements............................................................................................................. 13

Oven Only Rough-In Specifications ..........................................................................................15

Oven Assembly ..........................................................................................................................17

Oven Installation ........................................................................................................................ 23

Oven Ventilation Requirements & Guidelines........................................................................... 27

Oven Initial Start-Up.................................................................................................................. 29

Oven Operator Controls .............................................................................................................33

Oven Operation ..........................................................................................................................35

Oven Cleaning............................................................................................................................36

Oven Maintenance......................................................................................................................40

Oven Troubleshooting................................................................................................................ 41

Hood Description ....................................................................................................................... 44

Hood Dimensions.......................................................................................................................45

Hood Electrical Requirements................................................................................................... 47

Hood Ventilation Requirements................................................................................................. 64

Hood Rough-In Specifications...................................................................................................65

Hood Installation........................................................................................................................ 66

Variable Frequency Drive Adjustments..................................................................................... 85

Hood Operator Controls.............................................................................................................86

Hood Initial Start-Up.................................................................................................................. 87

Hood Valance Kit....................................................................................................................... 89

Hood Cleaning............................................................................................................................92

Hood Troubleshooting................................................................................................................94

International Distributors ...........................................................................................................94

Electrical Schematics .................................................................................................................95

Revision History Table

Revision Comments Date

01 Initial Release 1/19/2011

02 Updated Hood Installation Dimensions page 45 3/8/2011

03 Revised MJ/hr 04/07/2011

TABLE OF CONTENTS