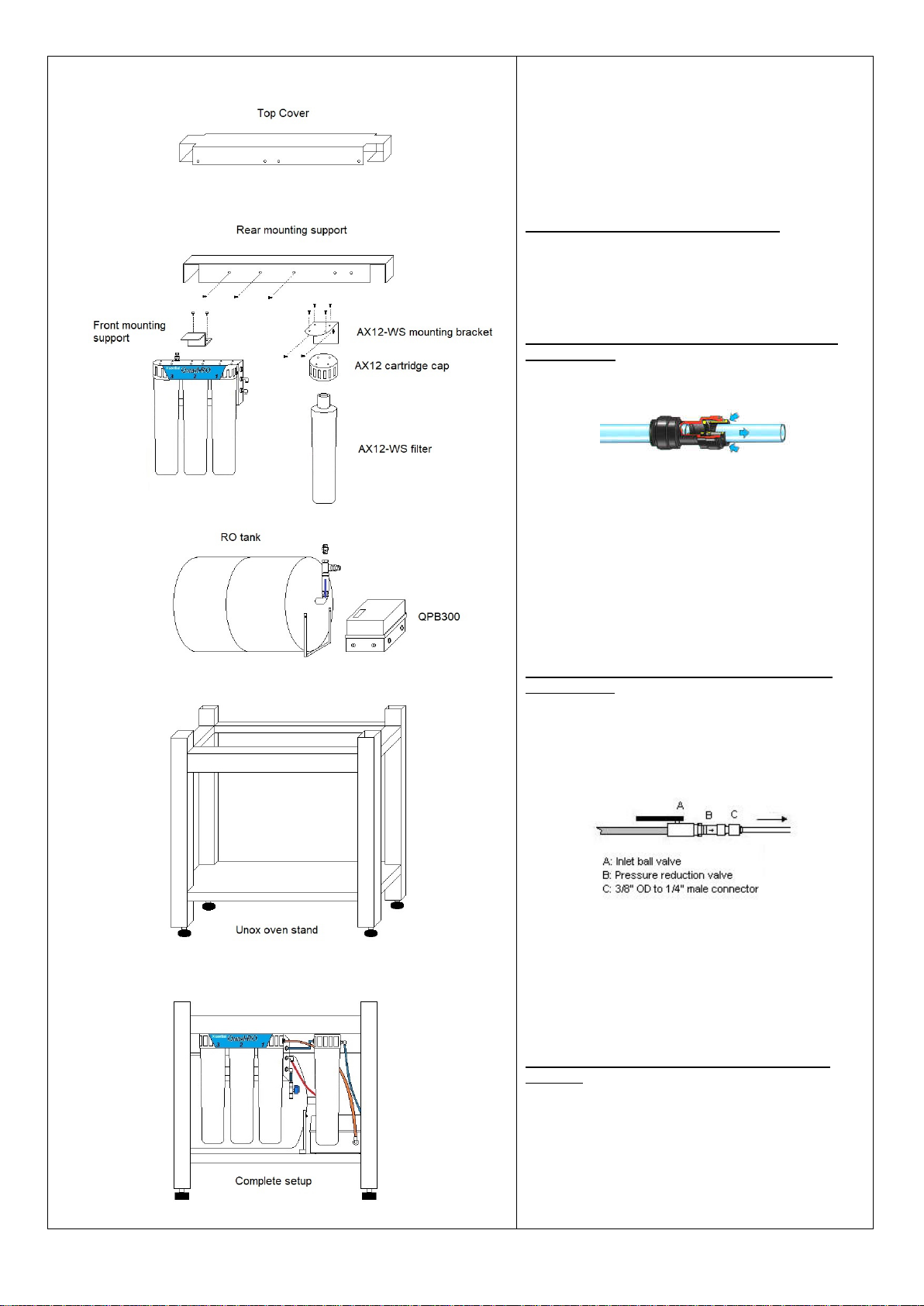

screws. Look for the “IN” marking on the cap and screw cap on the bracket with IN inlet facing the left handside of the

bracket.

3. Remove the two front screws from the cartridge 2 (yellow colour sticker). Screw the QuadRO front mounting support on

the two screw holes.

4. Place the rear mounting support on the Unox oven stand

5. Hang the QuadRO R.O. system onto three screws with 3mm gap. You can move the mounting support forward. Make

sure the front support is seated on to the front oven horizontal frame evenly.

8.0 INSTALLATION OF WASTE WATER DRAIN AND PRESSURE RELEASE VALVE

The wastewater from the QuadRO system must be removed by allowing the wastewater to be drained away. This flow of the

waste water will assist in keeping the membrane free from mineral deposits and fouling. Cut the ¼” red tube to the length that is

required to connect the flow restrictor and the drainage cup. Insert the tube into a ¼” OD x ¼” stem elbow connector and insert it

into the drain connector of the QuadRO (location I in diagram 1) and secure the tube to the drainage cup.

Cut 80mm of the 3/8” tube. Insert the 3/8” tube into a 3/8” OD x 3/8” stem elbow connector. Insert the other end of the tube to the

3/8” OD x 3/8” OD ball valve. Insert the stem elbow into the TANK inlet of the QuadRO (J in diagram 1).

9.0 INSTALLATION OF AX12-WS WATER STABALISER SYSTEM

1. Measure the distance between the APP outlet and the AX12-WS filter head and cut the 3/8” tube according to the

measurement.

2. Insert the tube into the APP of the QuadRO and “IN” inlet of the AX12-WS filter

10.0 INSTALLATION OF STORAGE TANK AND QPB300 PUMP

NOTE: PRESSURE ADJUSTMENT IS NOT REQUIRED as the storage tank is shipped with pressurised air. The tank comes with

the stainless steel horizontal bracket. Put the RO tank on the shelf right behind the QuadRO system and the QPB300 pump right

next to the outlet of the tank. Do not plug in the power plug of the QPB300 at this stage.

1. Measure the distance between the QPB300 “From Tank” outlet and “OUT” of the AX12-WS filter and cut the 3/8” tube

accordingly.

2. Insert one end of the 3/8” tube to a 3/8” OD x 3/8” stem elbow connector and insert the connector into the “OUT” outlet of

the AX12-WS filter. Insert the other end of the tube to “From Tank” of the QPB300 pump.

3. Measure the distance between the QPB300 and the tank inlet Q in diagram 1. Insert one end of the tube to “To Tank”

connection of the QPB300 pump and the other end of the 3/8” tube to MIP hole plastic nut (Q in diagram 1) and screw on

the fitting.

11.0 CONNECTING UP FEEDING WATER

1. Screw the pressure limiting valve with dual check to the isolation valve.

2. Tape and screw the 3/8” OD x ¼” NPT male connector to the pressure limiting valve.

3. Measure the distance between the water feed valve and the “Water In” of the QPB300 pump.

4. Cut a 3/8” poly tubing with the length measured. Insert the one of the tube to the connector B as shown in

diagram 1 and the other end to a 3/8” OD x 3/8” stem elbow connector. Insert the stem elbow connector to the

“Water In” of QPB300 pump.

5. Measure the distance between the QPB300 “OUT TO RO” and the red sticker water filter 1 of QuadRO. Cut the

tube and insert one end of the tube to the QPB300 pump (Out to RO) and the other end to the first filter (red

sticker) of the QuadRO system. You may need to use 3/8” OD x 3/8” stem connector to ensure that the tubes

are not under any stress.

12.0 CONNECTING UP THE APPLIANCE

Please note that the ¾” hose for connecting the RO tank to the oven is not supplied. The oven comes with the hose. Connect the

connection “P” of the tank to the oven hose.

13.0 START UP PROCEDURE

1. Double check the connection of installation. Make sure the pressure release ball valve (J in diagram 1) is in ON position and

RO tank is in OFF position (M in diagram 1).

2. Plug in the power for the QPB300 pump

3. Turn on water supply slowly.

4. Turn on the power for the QPB300. The pump should start pumping within 2 second.

5. Within a few minutes the water will start to flow from the water pressure release valve J.

6. Check for leaks. (If anything is leaking shut off water, repair, then start with step 1 again.

7. Let the water run for 15 minutes. This flushes out the preservative in the membrane.

8. Turn ON the RO tank valve (M in diagram 1) and Turn OFF the pressure release valve.

9. The installation is done.

14.0 TOTAL DISSOLVED SOLID (TDS) CHECK

To check if the QuadRO system is working or not. Simply press the red button of the TDS meter. The system will show the TDS

reading “Before” and “After”. You should see there is a significant reduction in the TDS reading on the after end of the meter.