OP

Installation, Maintenance, Service & Part List Manual

1Safety

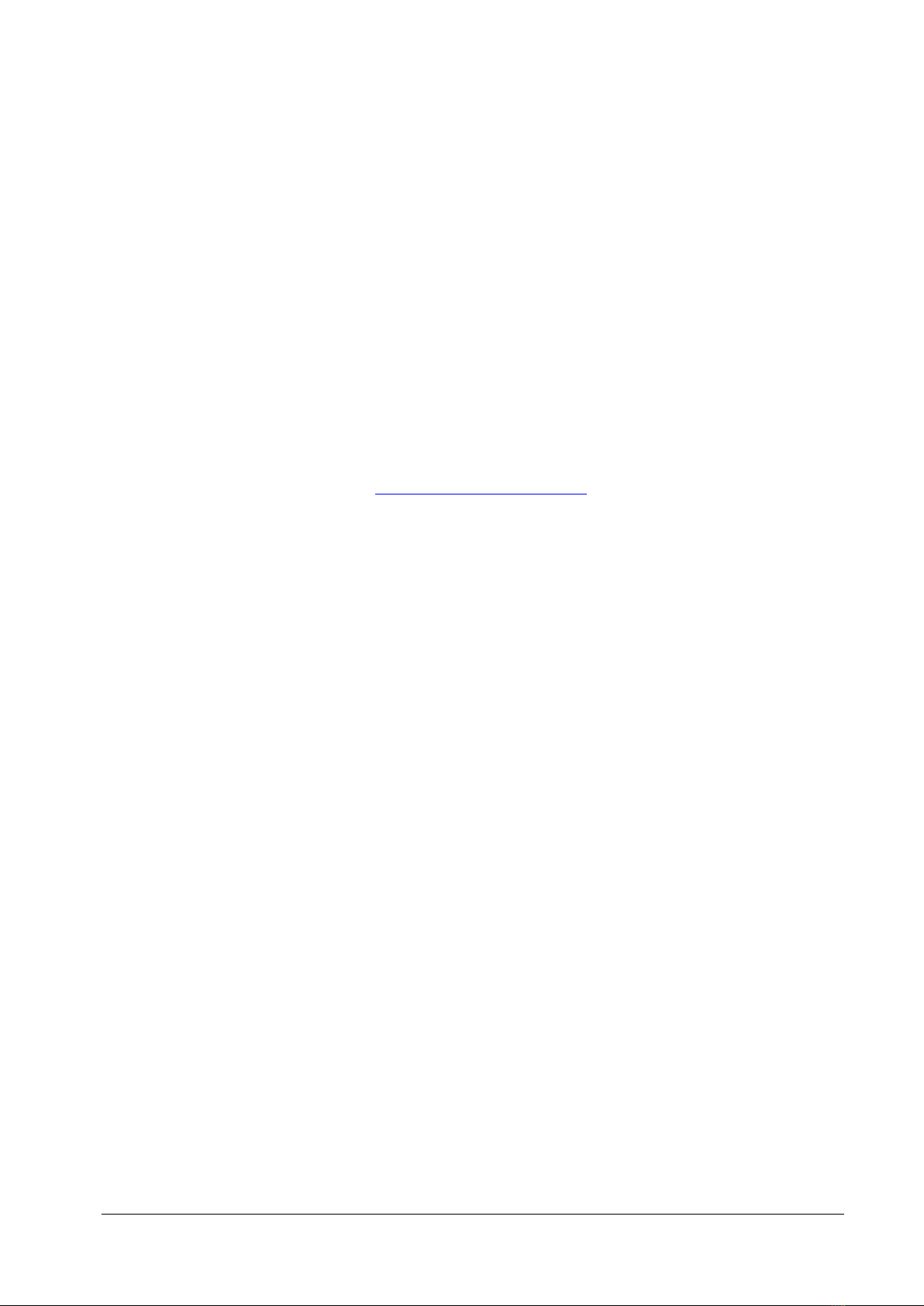

The safe operation of the 2 OP Mill depends on its proper use and the precautions taken by each operator.

1.1 Safe Operating Information

It is the responsibility of the employer, machine owner or machine controller to ensure that this machine is

installed, operated and maintained in accordance with the Provision and Use of Work Equipment

Regulations 1998 (PUWER) or equivalent local regulations.

In particular, the responsible person must:

•Undertake a Risk Assessment on the use of this machine, paying particular attention to the specific

characteristics of this machine; including:

oTransportation by trolley jack,

oUnrestricted operating mode selection.

•Generate and apply Safe Operating Procedures for the use of the Prototrak machine

•Provide any additional training, safeguarding or PPE identified by the risk assessment.

For more information, see the HSE Guidance document INDG291 “Providing and using work equipment

safely” available from the HSE website (http://www.hse.gov.uk/pubns/)

This machine, as supplied, is intended to be used for material removal by conventional milling processes on

common engineering materials, in manual or CNC controlled modes.

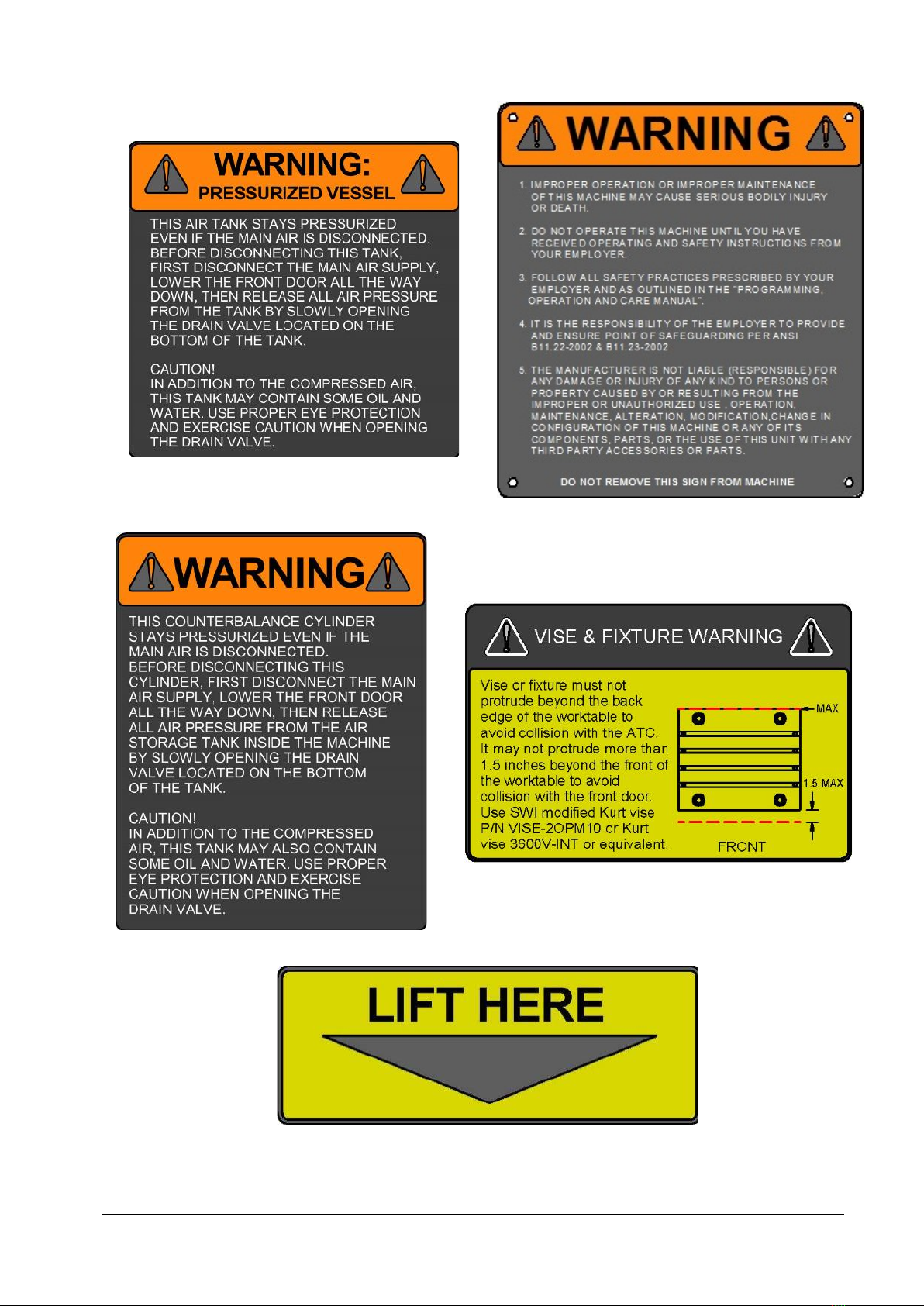

A risk assessment must always be undertaken to identify any special hazards due to specific processes or

materials and additional safety measures applied as appropriate. Special cases to consider include, but are

not limited to:

•Potentially flammable materials (e.g. magnesium, aluminium, titanium), or

•Materials which generate hazardous dusts when machined (e.g. Tufnol, beryllium).

This machine is designed to be used in a standard workshop environment only. It must not be used in

potentially explosive atmospheres.

All operators must read and study this manual and the 2 OP Programming, Operating, and Care Manual.

The machine must not be operated until operators understands the operation and safety requirements of

this machine.

This machine must only be operated by trained and experienced operators. Any other users should first be

subjected to a risk assessment by a responsible, trained person.

At the start of each work shift:

•Inspect the guard window for signs of damage or degradation. Replace if necessary or if the

serviceable life has expired, as indicated by the label. Use only mild cleaning agents (such as water-

based detergents) to clean the window. Do not use aggressive solvents. The polycarbonate used for

the window is degraded over time by exposure to cutting fluids. For this reason the replacement

schedule must be adhered to.

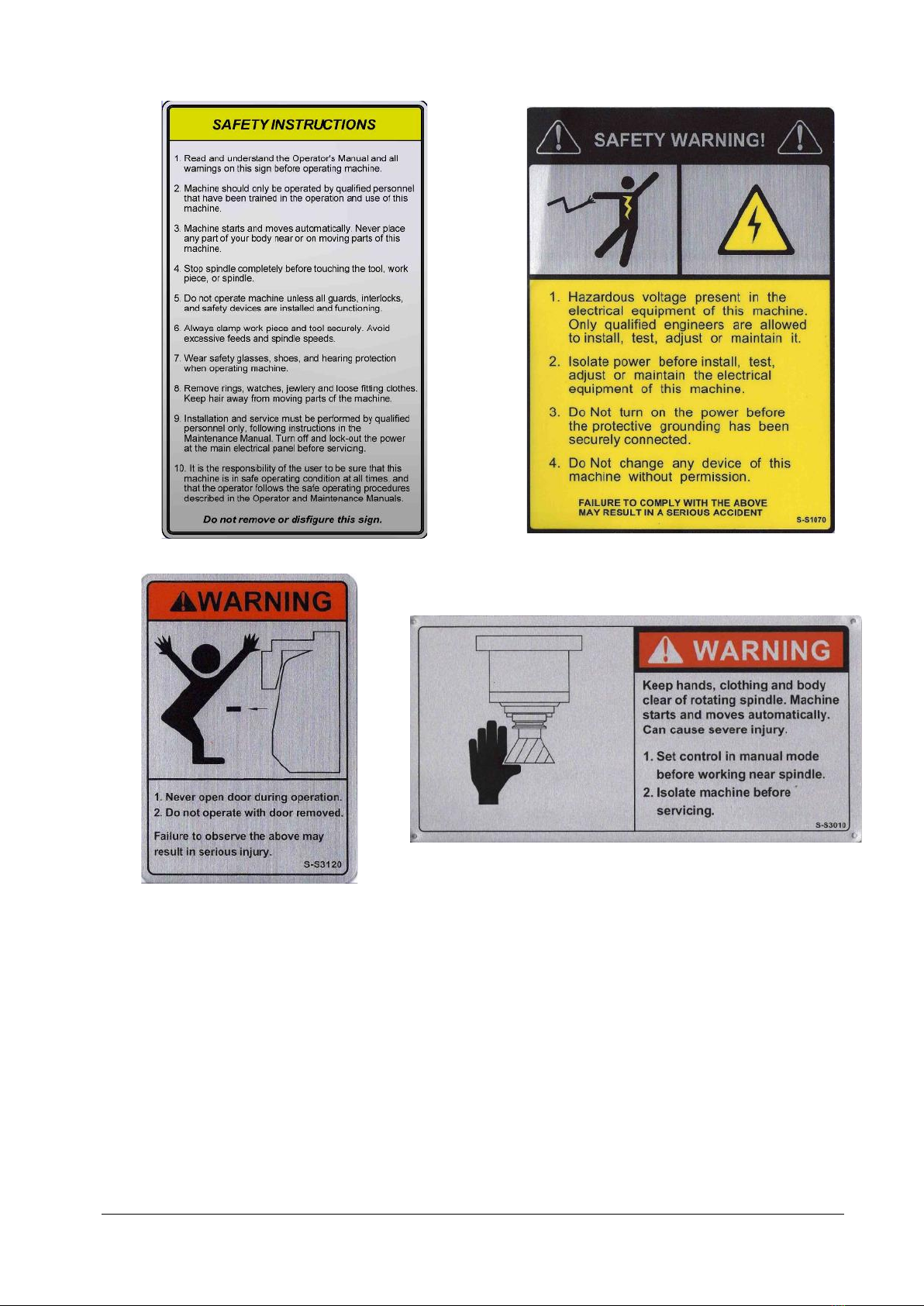

•Test the following safety functions. Do not use the machine if the function fails:

•E-stop (Must stop spindle, axes and de-pressurise the air system – note the reservoir for the

door air assist will NOT be de-pressurised – this must be done manually if undertaking

maintenance work on this system)

•Door guard (spindle must not run with door open).

•Door lock (door must be locked when the spindle is running or during programme RUN).

When operating this machine, always observe the following safety precautions:

•Do not operate this machine without knowing the function of every control key, button,

knob, or handle. Ask your supervisor or a qualified instructor for help when needed.