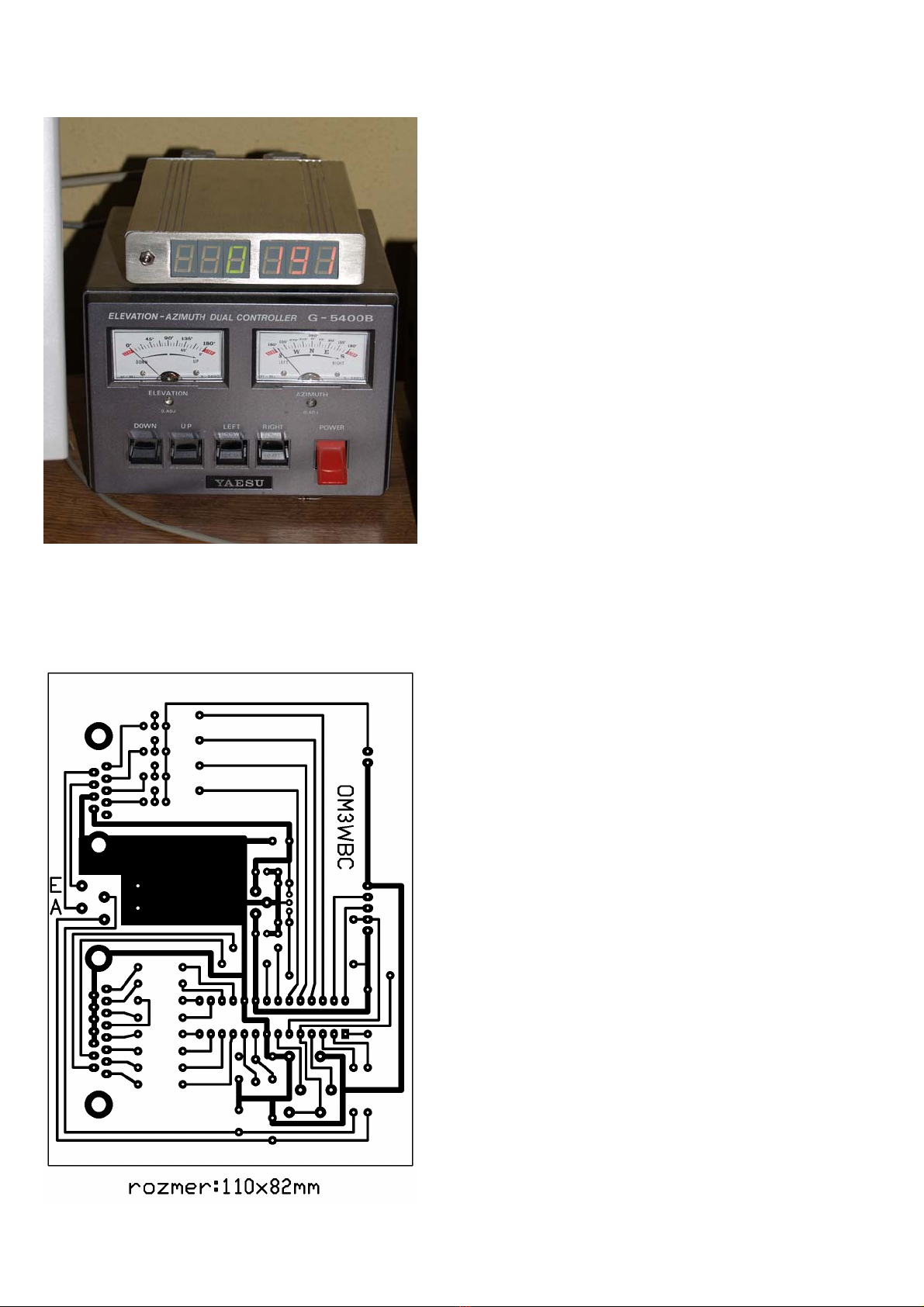

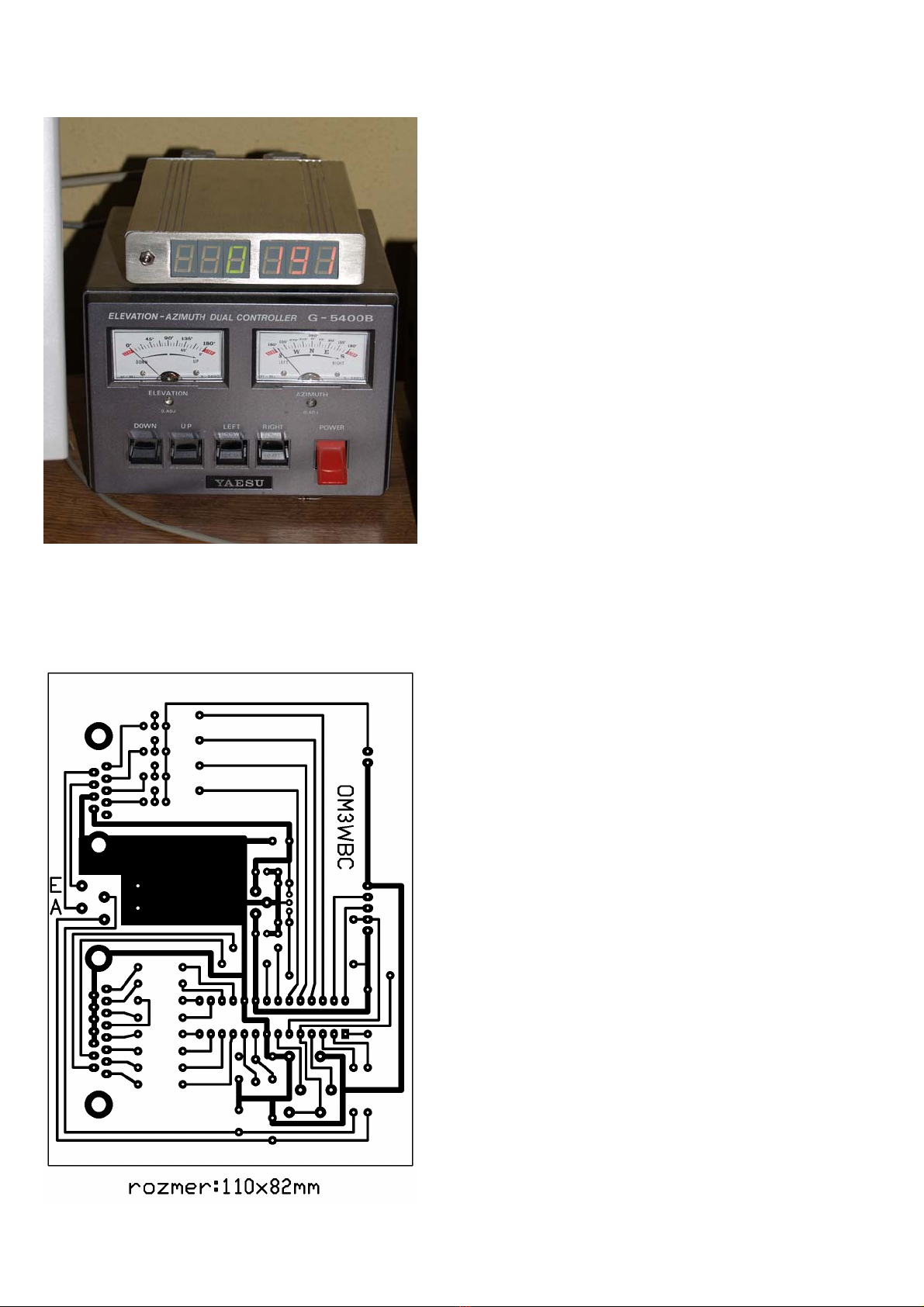

Interface for Yaesu G-5400 and G-5600 Antenna-rotators

I started to deal with Earth-Moon-Earth communications in

the middle of 2005. I had to realize, that my two-bay

DJ9BV (2.1 wavelength boom length each) antenna array is

not enough for this mode of communications. It seemed to

be an obvious solution to improve the boom length of the

existing antennas which are otherwise consisting of mod-

ules. Unfortunately, after modifying the antennas it became

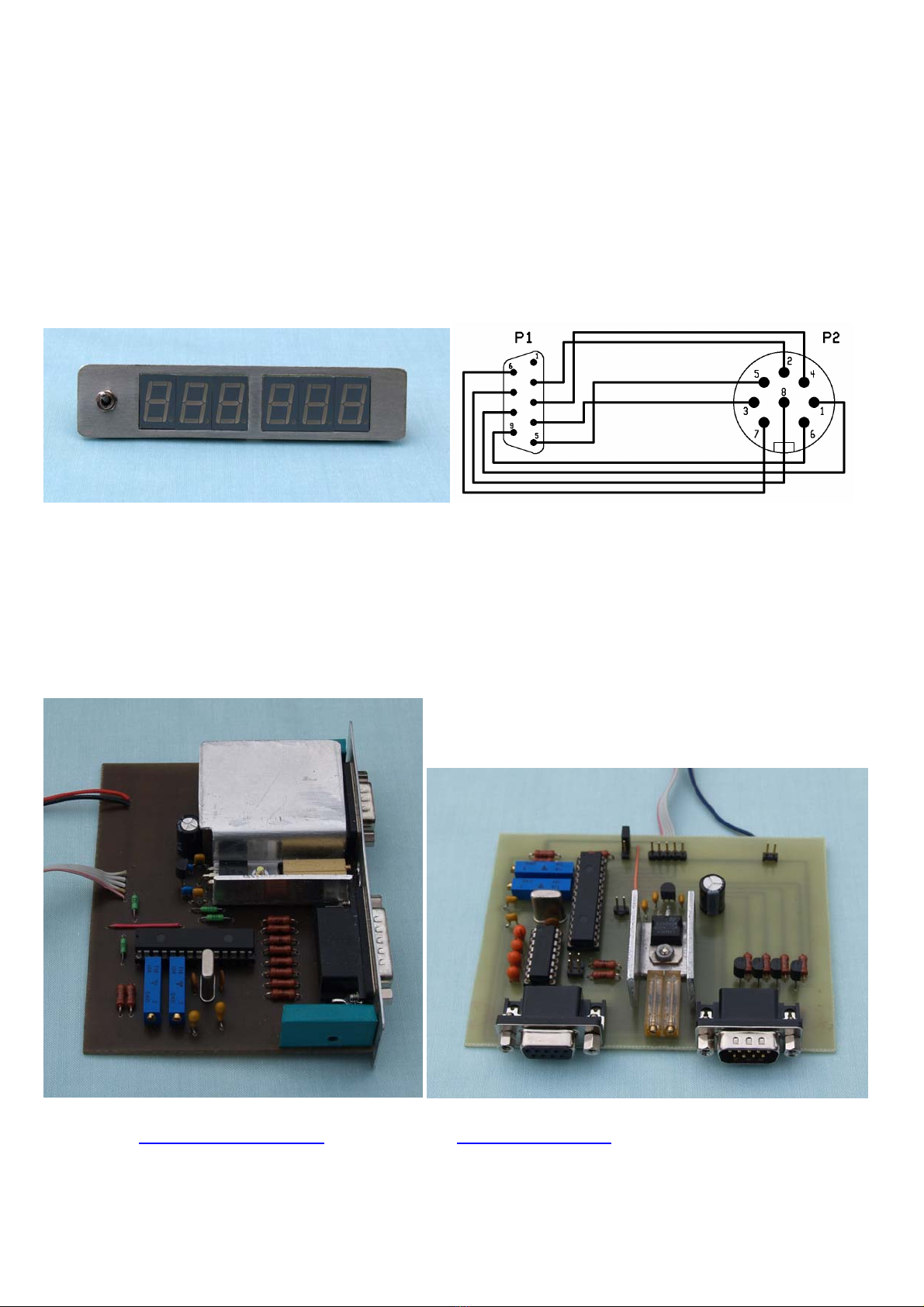

evident, the original display solution using Deprez meters

can not meet the new requirements. To solve this problem

this interface was born, which beside the exact display

makes it possible to rotate the antenna by computer control,

so it is a great help in providing satellite communications as

well. Those who use shorter antenna for satellite tracking

only, can build the interface without digital display. The

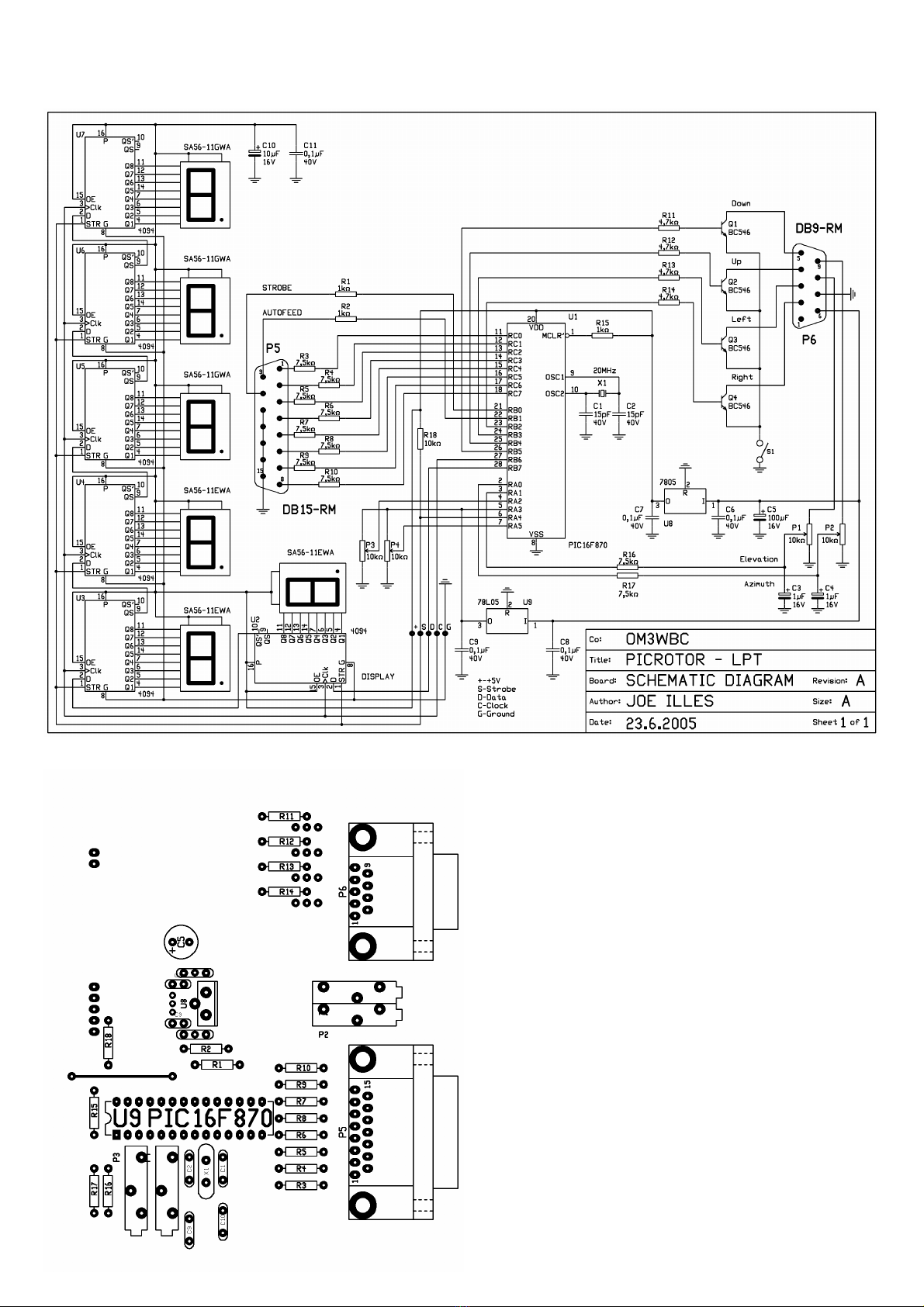

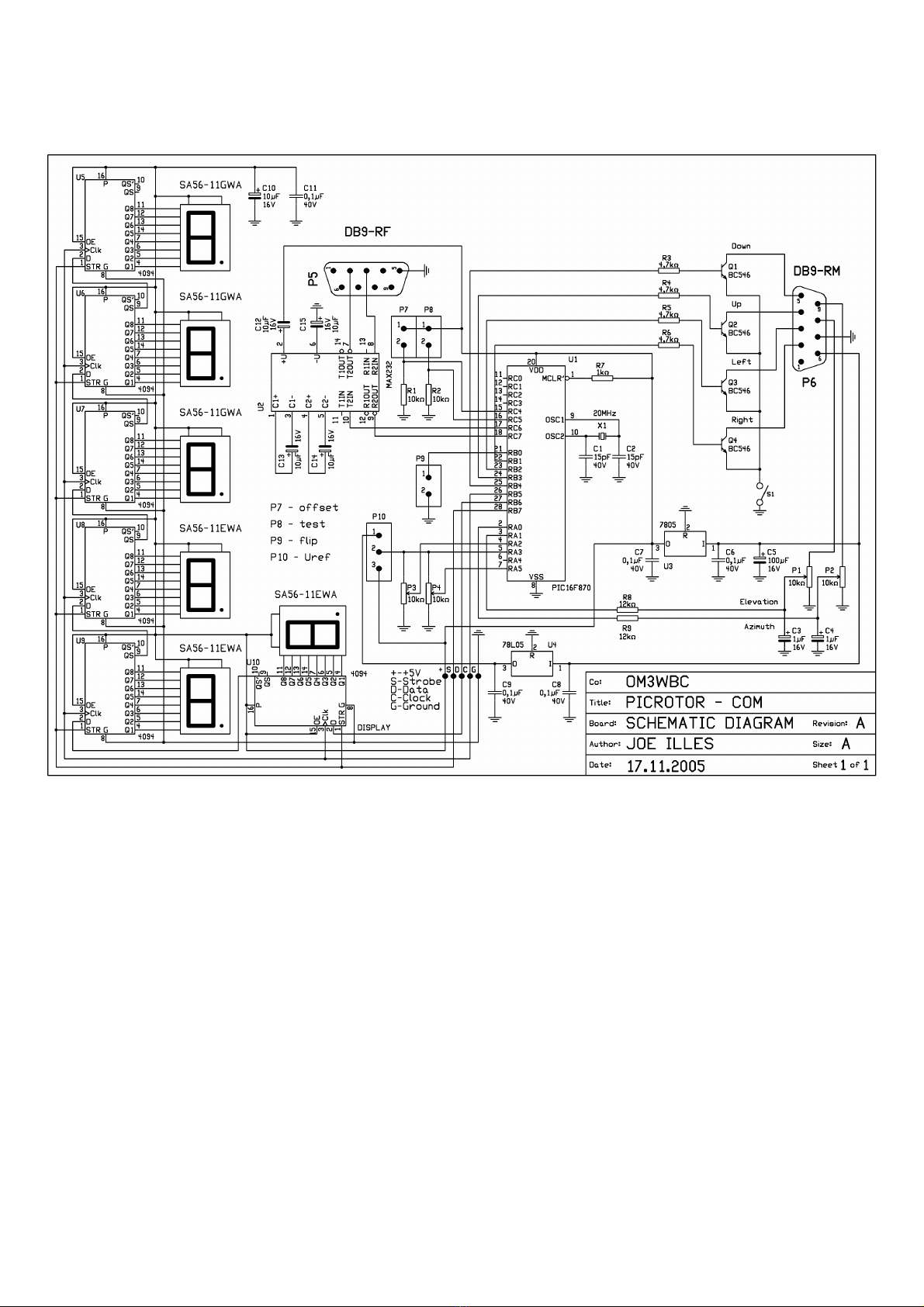

interface was made in two versions. One of them makes use

of a parallel port the other uses a serial port for communica-

tions with the rotator. Both solutions have advantages and

disadvantages. The version making use of a parallel port

has a great disadvantage because the port can handle eight

bits only; hence the best possible definition is 1.4 degree.

On the other hand, while the serial ports are generally in

use for different communication purposes, parallel ports are not utilized i.e. later printer models are made for

USB ports. The base of both versions is a PIC16F870 microprocessor which includes a ten-bit A/D converter

and a serial port driver too.

Interface for the parallel port

Operation

This interface uses the protocol of the FODTRACK pro-

gram. This driver can be freely downloaded from the Inter-

net. Latest software like WXTRACK is able to handle an

interface like this, by default. The co-ordinates of azimuth

and elevation are calculated in eight bit accuracy. AUTO-

FEED output decides which data is active at a given time.

The high level output of STROBE shows the validity of

data. The processor continuously checks STROBE signal

and in its active state it decides depending on the level of

AUTOFEED signal, whether data is to be applied as azi-

muth or as elevation. According this, it puts data into a

variable. In case the content of variables does not corre-

spond with the momentary position of the antenna then it

gives an instruction to turn the antenna until it reaches the

required position. In this version the maximum elevation of

the antenna can be 90 degrees. The FLIP function of satel-

lite-tracking software is disabled. To turn the antenna into a

position exactly without climbing the tower or mast, the

interface is equipped with two variable resistors to make it

possible to correct the difference between the displayed

values and the real position of the antenna. These adjust-

ments can be done by connecting STROBE and AUTO-

FEED inputs to low logic level before the interface is