28-13-336-Rev1 4/8

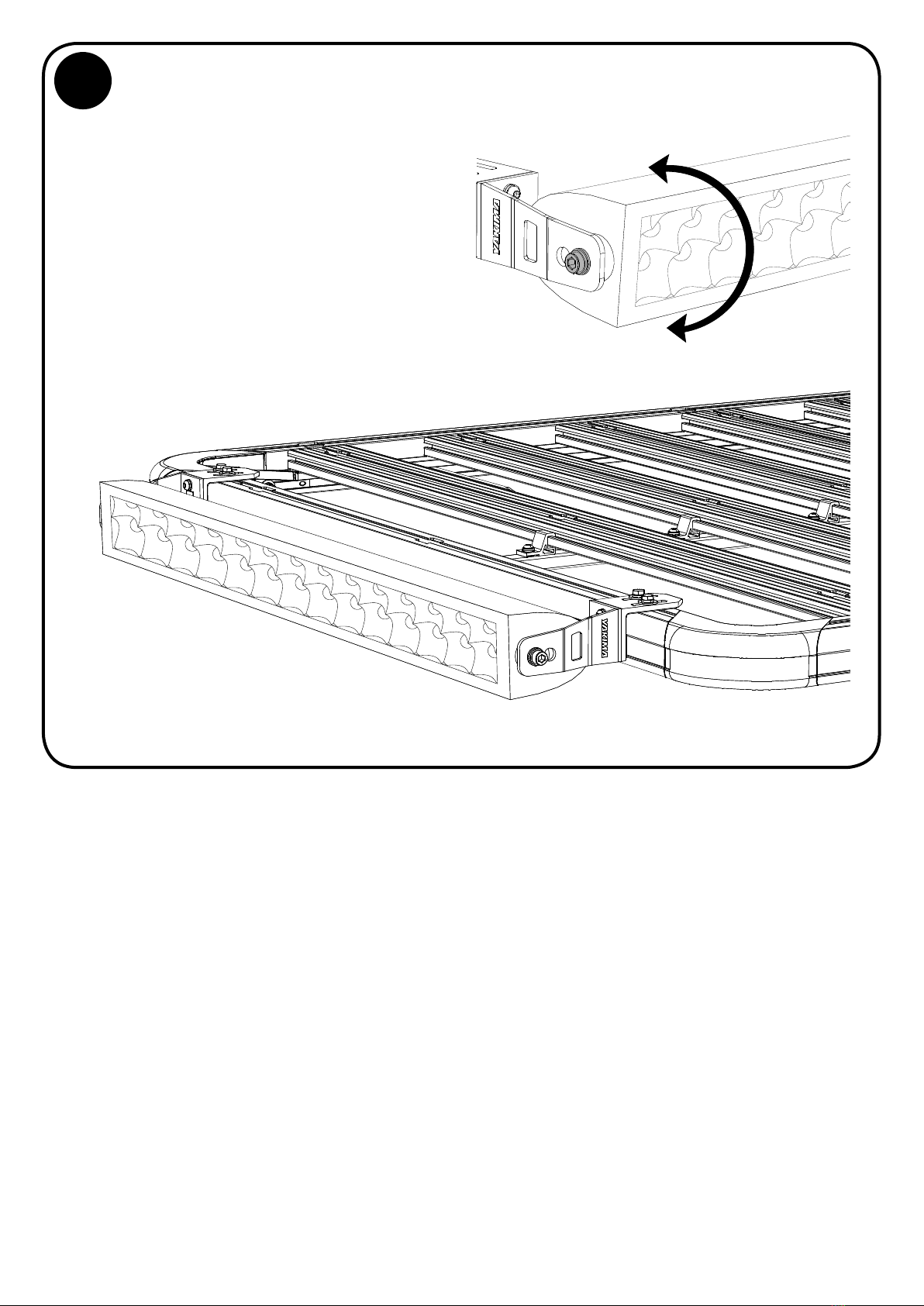

ATTACH BRACKET ASSEMBLIES TO

LIGHT BAR

Attach the 2 Bracket assemblies

to your light bar using the screws

supplied within your light bar kit

and the appropriate sized washers

supplied in the LOCKN’LOAD Light

Bracket Kit.

Finger tighten screws to allow the

light bar to be adjusted once mounted.

6

NOTE - M8 Light Bar hardware is shown in this example.

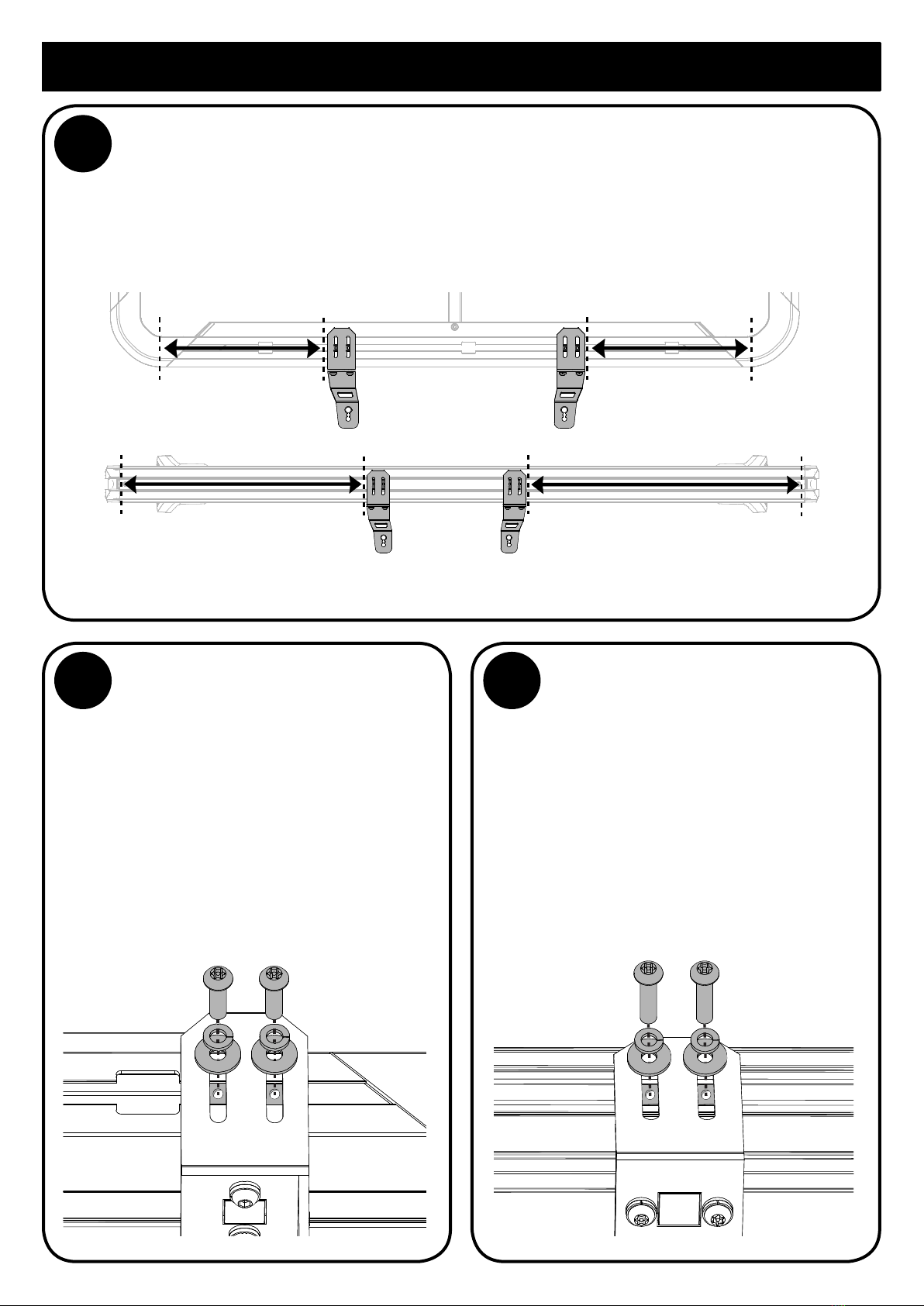

CENTRE LIGHT BAR AND ADJUST SLOT/SPRING NUTS

Position and centre light bar and Bracket assembly on Platform or Crossbar by ensuring there

is an equal distance from the Platform corners or Crossbar ends as shown. Adjust Slot/Spring

nuts in the channel so that they align with the openings in Bracket Bases. The Torx Key can be

used to assist Nut movement within the channel.

NOTE - Ensure that position of light bar, or multiple light bars, complies with relevant state legislation.

7

==

==

NOTE - Screws supplied

within your light bar kit

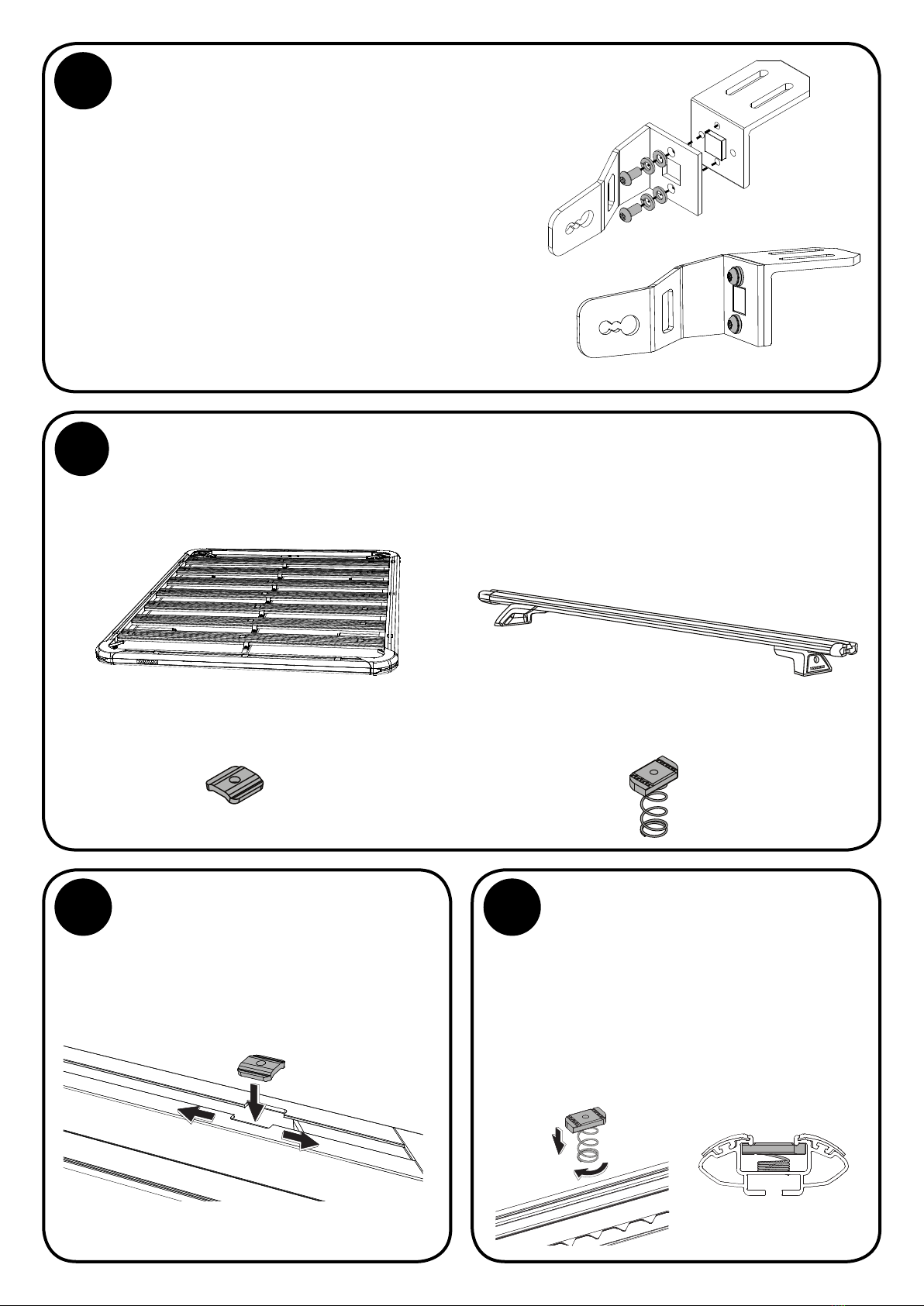

LIGHT BAR HARDWARE

Determine whether your light bar

uses M6, M8, M10 or M12 screws.

The overlapping holes as shown

from left to right are for M10/12,

M6 and M8.

Washers and Spring Washers

are provided in the LOCKN’LOAD

Light Bracket Kit to prevent

damage to your Brackets.

5

M10/12

M6

M8