Page 9

SECTION V - INSPECTION AND PREVENTIVE

MAINTENANCE

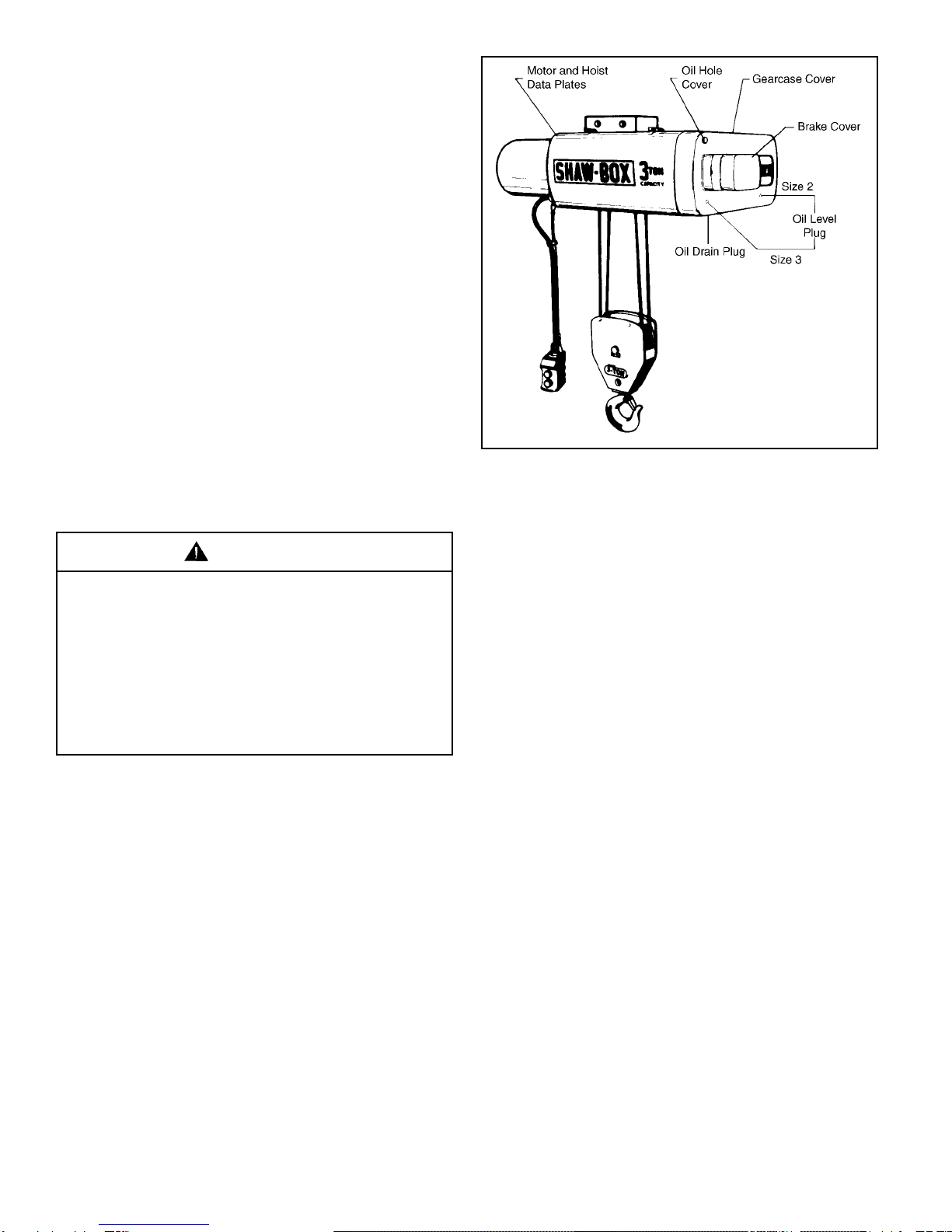

5-1. GENERAL. All SHAW-BOX, Series “700,” hoists are

inspected and tested at the factory. Regular in service inspection

and preventive maintenance programs not only help reduce

overall maintenance costs but may also prevent service

shutdowns by forewarning of problems that could cause these

shutdowns. Regular inspections, periodic minor adjustments,

regular cleaning and lubrication and replacement of worn parts

can help preserve good performance and operation of your

hoist.

Many factors influence the inspection and preventive

maintenance program required for your hoist. Frequency and

severity of service and material handled, local environmental

conditions and various applicable codes are some of the factors

that the user must consider to adjust inspection and

maintenance program outlined in this section to meet his

specific conditions.

The inspection and maintenance services outlined in this

section are considered minimum. Recommended in the

schedule are minimum inspection and maintenance intervals

based on average daily use in a normal environment. Average

daily use is based on 1000 operational hours per year maximum

and intermittent operation of the hoist eight hours per day, five

days per week with a maximum 40 percent “on” time and the

average loading not exceeding 65 percent of rated load.

Environmental conditions in which the hoist operates are also

important considerations for the user when adjusting hoist

inspection and maintenance programs to local conditions.

Frequency of inspection and maintenance must be increased

if hoist is subjected to severe atmospheric environmental

conditions, such as corrosive vapors, extreme heat or cold,

cement or dust and other airborne contaminants. The user

should carefully consider all environmental conditions and adjust

frequency and degree of maintenance for his local conditions.

Consult Lift-Tech Field Service Department for advice for

unusual environmental conditions.

Various codes also regulate inspection and maintenance

programs. Attention must be given to applicable federal

standards, OSHA regulations, national standards, state and

local codes which may include mandatory rules relating to

hoist inspection and maintenance. The user should become

familiar with all applicable codes for his area and be guided

accordingly.

Listed on the Recommended Inspection and Maintenance

Schedule are inspection frequencies and requirements. Perform

these inspections regularly as scheduled and additional

inspections as may be required for activity, service and

environment of your hoist. The hoist operator must be

responsible for determining the operating conditions and severity

of service.

Inspection Schedule and Maintenance Report Form.

Shown on page 11 of this manual is a recommended Inspection

Schedule and Maintenance Report form which lists various

components of the hoist. The form also includes trolley

components, runway components, and miscellaneous items.

This form is suggested as a guide for written inspection reports.

Inspections are recommended each month and should be

performed thoroughly enough to inform the hoist user of

deficiencies for any item listed. This form does not supersede

the Inspection and Maintenance Schedule listed below but may

be used to record scheduled inspection and maintenance

services required.

The user should revise the inspection interval, add additional

units or provide a similar form to suit particular conditions

which may exist.However, written, dated and signed inspection

reports should be maintained particularly on critical items, such

as hoist hooks, hoisting ropes, sheaves, drums and brakes.

Periodic review of old inspection reports can point out service

life of hoist components, forecasting need for adjustment, repair

or replacement of these components.

As a matter of expedience, appointed maintenance personnel

inspecting hoist can also take care of minor adjustments, repairs

and cleaning, where required. Note column on Inspection

Schedule and Maintenance Report form headed Corrective

Action and Notes. When corrective action is made during

inspection, note condition of part or unit as inspected in

appropriate Condition column with a check mark ("). Note

“during inspection” corrective action taken and date in space

provided. In this manner, items requiring further attention will

be checked (") without showing corrective action. This will

advise the designated person responsible for hoist operation

and safety, who reviews the reports, that deficiencies exist.

The designated person will check all deficiencies as listed and

reexamine or otherwise determine whether they constitute a

safety hazard.

Deficiencies may be hazardous to personnel and

equipment. Do not operate a hoist having deficiencies

unless a designated qualified person has determined

that these deficiencies DO NOT constitute a safety

hazard.

WARNING

Do not operate a hoist having unusual vibrations,

sounds or with anything wrong or apparently wrong.

Danger may be present that the hoist operator cannot

see. Determine and correct cause of unusual

conditions and make certain hoist can be operated

safely.

WARNING

Written, dated and signed inspection reports for many items

are mandatory under OSHA regulations, and many state safety

codes.It is strongly recommended that the Inspection Schedule

and Maintenance Report, shown herein, be completed by a

qualified person designated with the responsibility for hoist

operation and safety or an inspector appointed by this person.

Inspection records can point out the service life of hoist

components and help forecast the need for adjustments, repairs

and ordering of replacement parts. File and review these reports

after each inspection.