7

Table of ontents

Table of ontentsTable of ontents

Table of ontents

·

··

·De laration of Conformity

De laration of ConformityDe laration of Conformity

De laration of Conformity

····························································2

·

··

·Introdu tion

Introdu tionIntrodu tion

Introdu tion

················································································3

·

··

·For safe operation

For safe operationFor safe operation

For safe operation

·······································································3

·

··

·Warnings and aution

Warnings and autionWarnings and aution

Warnings and autions

ss

s

································································4

·

··

·Operating aution

Operating autionOperating aution

Operating aution

·······································································6

·

··

·Table of ontents

Table of ontentsTable of ontents

Table of ontents

·········································································7

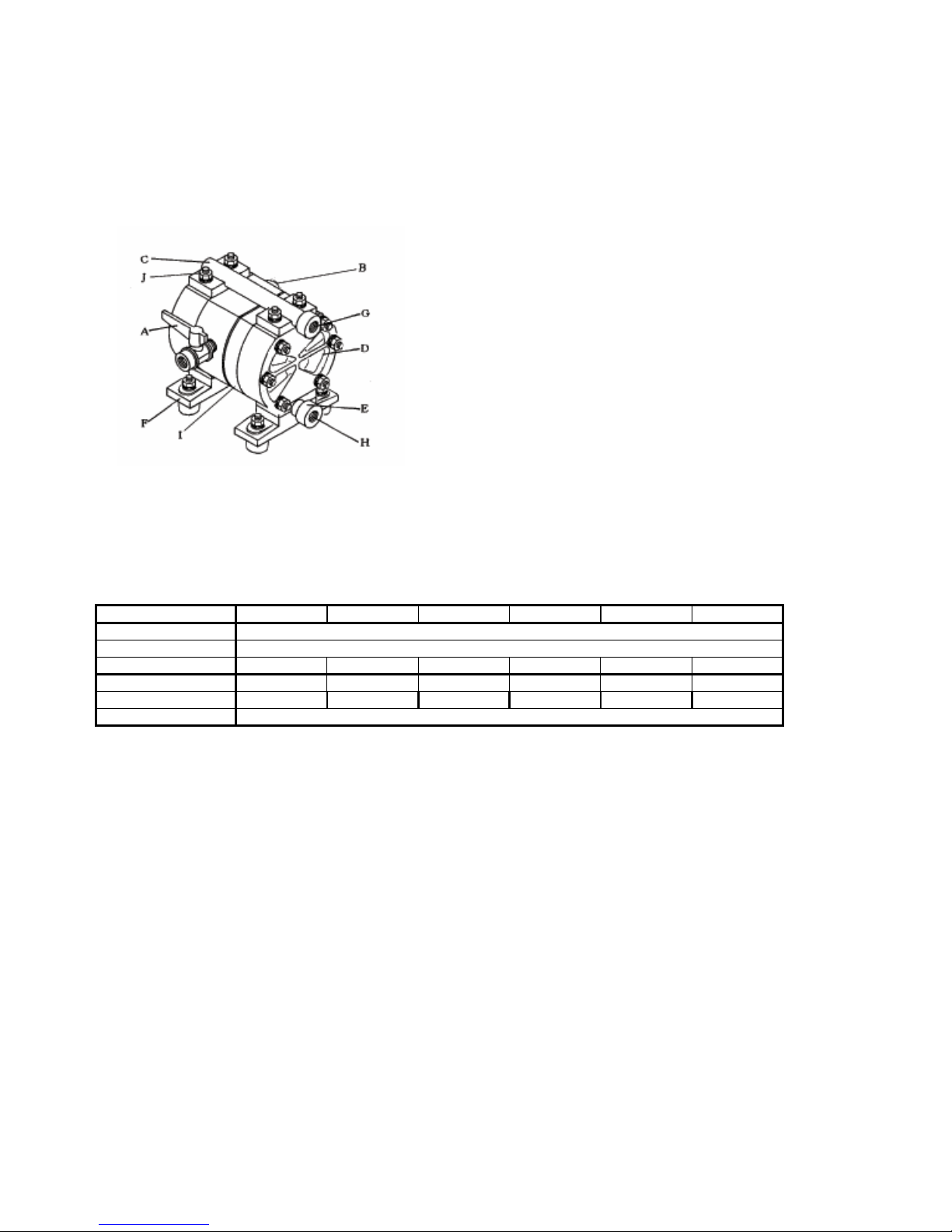

1. Names of parts and materials

1. Names of parts and materials1. Names of parts and materials

1. Names of parts and materials

1.1 NDP-5 series··········································································8

1.2 DP-10/12 series ······································································9

1.3 NDP-10/12 series ·································································· 10

1.4 NDP-15 series ······································································ 11

1.5 NDP-20, 25 series ································································· 12

1.6 NDP-40 series ······································································ 14

1.7 NDP-50 series ······································································ 15

1.8 NDP-80 series ······································································ 16

1.9 DP-F series·········································································· 17

2. Assembly

2. Assembly2. Assembly

2. Assembly

2.1 Installation of a essories ········································· ············· 18

3. Installation

3. Installation3. Installation

3. Installation

3.1 Method of transport················································· ············· 19

3.2 Installing the pump················································· ············· 19

3.3 Conne ting the ground wire ······································ ············· 21

3.3.1. Use in potentially explosive atmospheres·················· ············· 21

4. Conne tion

4. Conne tion4. Conne tion

4. Conne tion

4.1 Conne ting fluid piping ············································ ············· 23

4.2 Conne ting air piping ·············································· ············· 24

5. Operation

5. Operation5. Operation

5. Operation

5.1 Method of operation················································· ············· 25

5.2 Flow adjustment····················································· ············· 25

5.3 Shutdown······························································ ············· 26

5.4 Releasing the pressure············································· ············· 26

6. Method of leaning

6. Method of leaning6. Method of leaning

6. Method of leaning

···································· ·········

27

7. Daily he k

7. Daily he k7. Daily he k

7. Daily he k

············································ ·········

28

8. Troubleshooting

8. Troubleshooting8. Troubleshooting

8. Troubleshooting

8.1 Pump does not run ·················································· ············· 28

8.2 Pump runs, but fluid does not ome out······················· ············· 28

8.3 Flow (dis harge quantity) de reased ··························· ············· 28

8.4 Liquid leakage from exhaust port (silen er)·················· ············· 29

8.5 High air onsumption during in operation···················· ············· 29

8.6 Irregular noise ······················································· ············· 29

8.7 Irregular vibration ·················································· ············· 29

9. Returning the produ

9. Returning the produ9. Returning the produ

9. Returning the produ t for servi ing

t for servi ingt for servi ing

t for servi ing

9.1 How to use the FAX sheet········································· ············· 29

9.2 Before returning the produ t····································· ············· 29

10. Main body spe ifi ations

10. Main body spe ifi ations10. Main body spe ifi ations

10. Main body spe ifi ations

10.1 Main spe ifi ations ················································ ············· 30

10.2 Appearan e and dimensions ···································· ············· 36

10.3 Performan e urve················································· ············· 52

11. Trouble

11. Trouble11. Trouble

11. Trouble-

--

-Reporting FAX Sheet

Reporting FAX SheetReporting FAX Sheet

Reporting FAX Sheet

························ ·········

58

12. Warning s

12. Warning s12. Warning s

12. Warning symbols

ymbolsymbols

ymbols

····································· ·········

59

13.

13.13.

13. Limited warranty

Limited warrantyLimited warranty

Limited warranty

···································· ·········

60