K-ro2()

' Usespacer

to adjust the h8sd heighl Fig. HFig.I

Capslsn Moto.

Fig.J

I ELECTRI

CAL ADJUSTMENTS

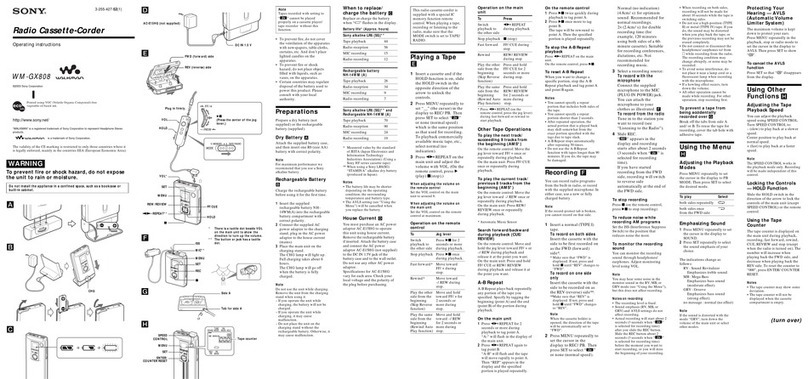

O PLAYBACK

ADJUSTMENTS

* Makesureto use

a new tape of I

ECstandards

for atest

taDe.

Alignmenttape

Normal TDK AC223 or YAMAHA NR 60

CrO2 TDK AC512 or YAMAHA CR 60

METAL TDK ACl12 or YAMAHA MR 60

o Proceed

with the playback

adjustmentsafter having

finished

the mechanical

adjustments.

] (dbx

circuit I I

{dbx

circuit i

I 1 board) 1-____1 I board) I

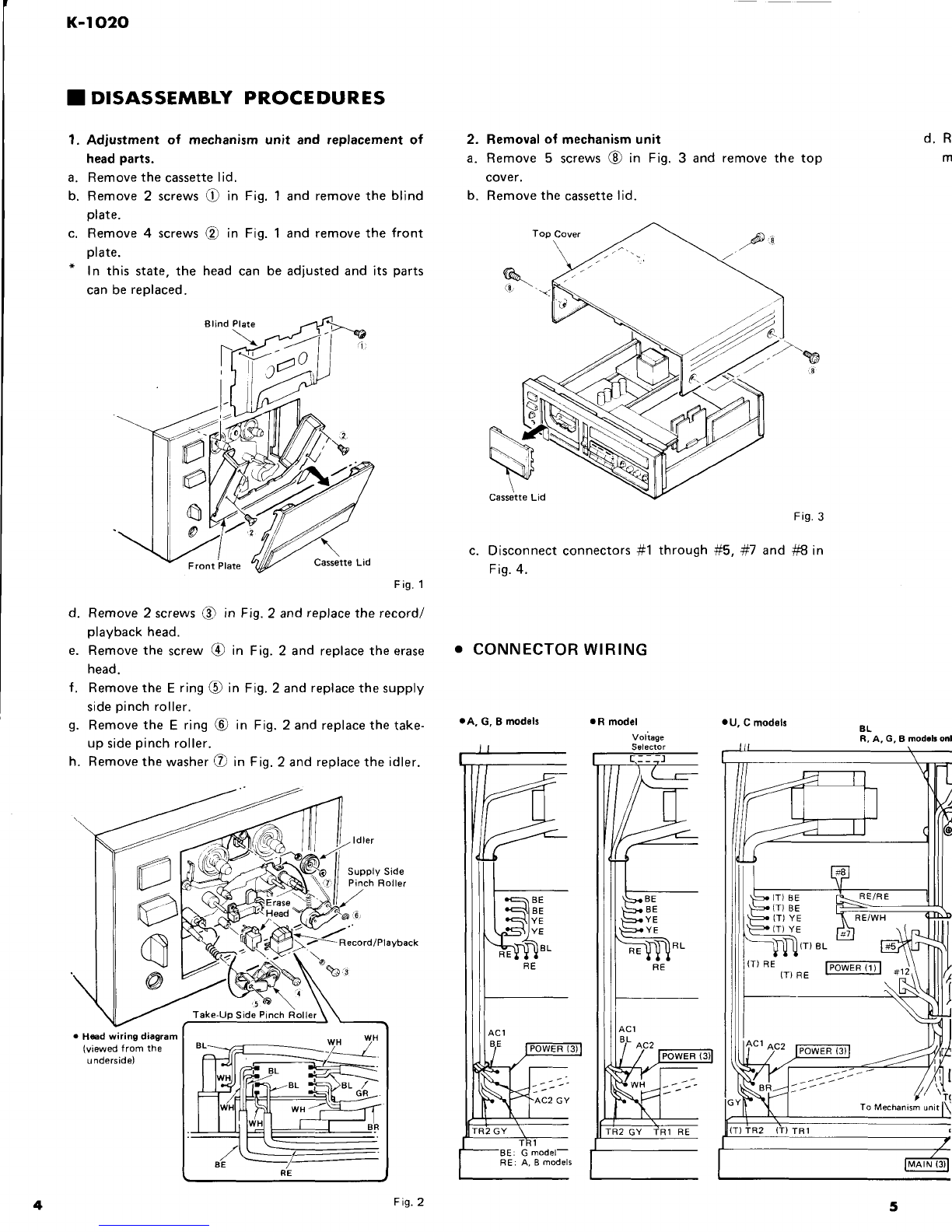

. RECORDINGADJUSTMENT

. Proceedwith the recording

adiustments

after havingfinished

the playback

adjustments.

{

t

uHe8d

Hei0hr

Orivcr

/

/

(]-\

\\\ \\ \

F;f *r;,-.";;-l-;""- -j-,*l1;l*-[ Tffr# JW";;11

E.o^-" r J;';iat-r-I D.cr/M

frtorl *roir'il- o.rfoc --

i iDc.offset lrP2{B)-E i I I vR102(R) i

i-t-lFr"yb".ki'^

r - i{tztzc l Lrrveou-f-eivnr---trl uRlon-L)

-i 36otls--v

--

I I | 1stsa, \ i (Acvort/da I I vR1o4(R) I t-g.o+tdBv)

i I I \toonwo/m/ I I rvteter)

I l

F_+ _+ _ __ f__t _ I

I s ietayuacr

rrequency Mrr.3s6u I r-rr.re

oui I ; 6nt i t-f---T;"*;,"*;'"

J i r".oonre

confirmation I {3t80

+70ps1 i 1 1 lshoutd

bewrthin

specifi-

response

conTtrmatton (J tUU

+ /Ups, 1 i lshould

bewtthin speciti-

I ],.I,.r';',,tuo|,,I I i ] lcationinFie'K

a ldbx rc 1 Tpl -rp2 D.C.V.M. 1

Srop 1 vRTOt i 15

t 2mVD.C.

I I (dbx

circuit ] {dbx

circuit

t-Aai-'tf"ntT , " -"t^Tt T..rj:l:jt- ,. . ' M"".u,"-"nt Jnai"tln"',tl *;- *.*,--

["n".n=."";r lL^;F;;* faoa*".AppryarkHz

sine*;-]u"*.tLr-r l*aaE

r"n-*,-i -'-l

Meter OUT signal

from LINE lN so iVR5O4

{R) I

(red}

should I

r 1(+4.5dBl I rLiNE l-Au;it that LINE OUT voltasers I ltisf't. I

r ltno

uott j li-,i"

]fll$,"."", $'J*,i,'-iyJrlirtase

is

I lrisht i

fF;k L"*f oscillator f,ppty" rri. rinu

*u* fvnsor tr-r I

ooe,"g-"n, -iwrt"n

nllnsrEn

-----l

Meter signal

from LINE lN so 1VR502

(R) i(redl should FADER isdecreasedL l

l(OdB) 1 that LINE OUT voltage i tliStrt. and R segments

i 'is 360mV (-gdBV). L aroundOdBshould

I 1 fade

out almostsimul-

* Use360mV

(-9dBV) for 0dBas

the

standardlevelof

this

unit.

. \')A

9

8ek Teosion (5 iteps)

at Playback mode @

@@

l(OdB) 1 that LINE OUT voltage I llight. and R segments

is

360mV {-gdBV}. ] around

OdBshould

' , I L fade

out almostsimur- i

_l _ taneousty. I