60L3D1X

General information

How to use this manual....................................................................................1

Manual format...............................................................................................1

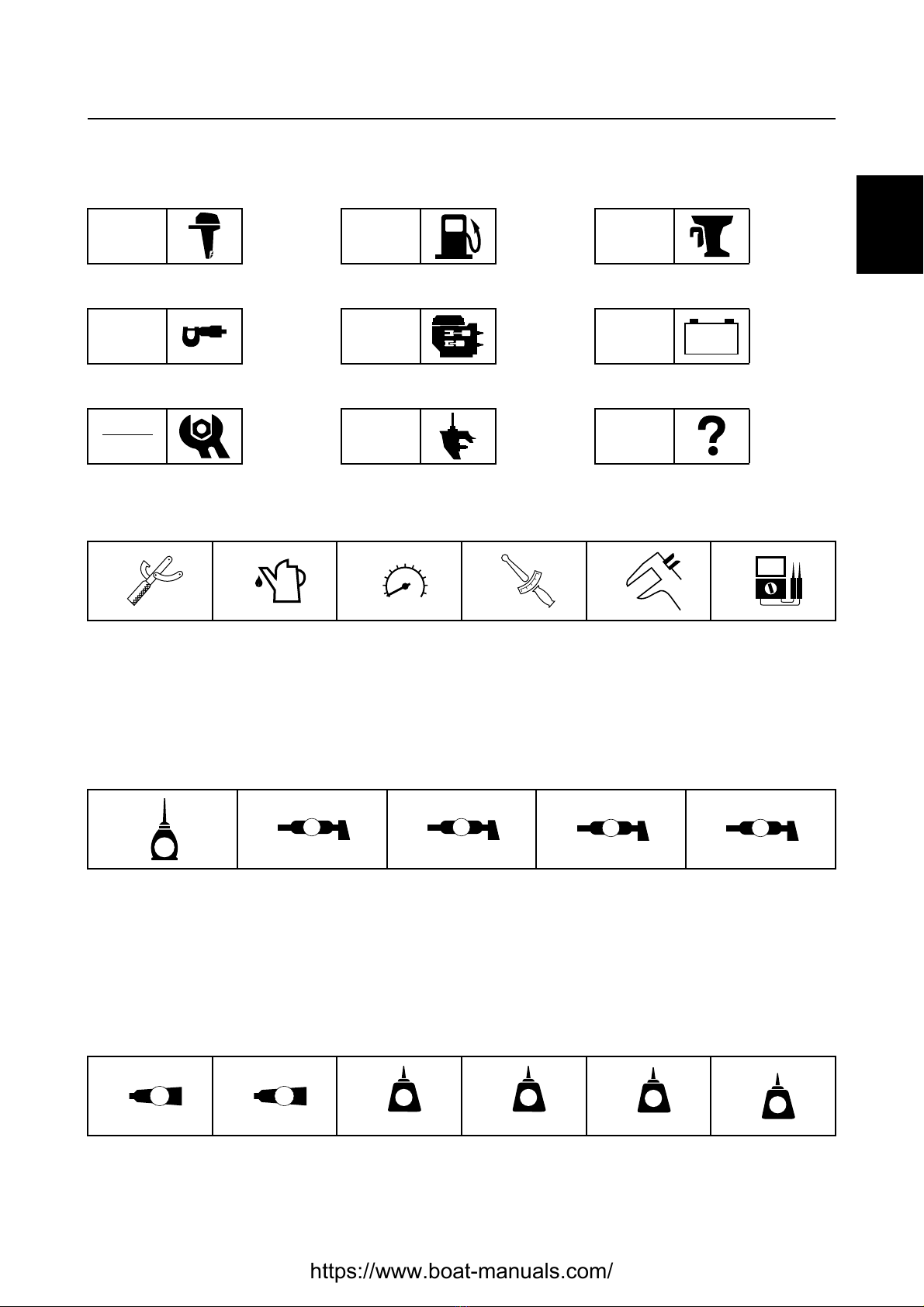

Symbols........................................................................................................2

Identification......................................................................................................3

Applicable models ........................................................................................3

Serial number...............................................................................................3

Features and benefits.......................................................................................4

Electronic control system..............................................................................4

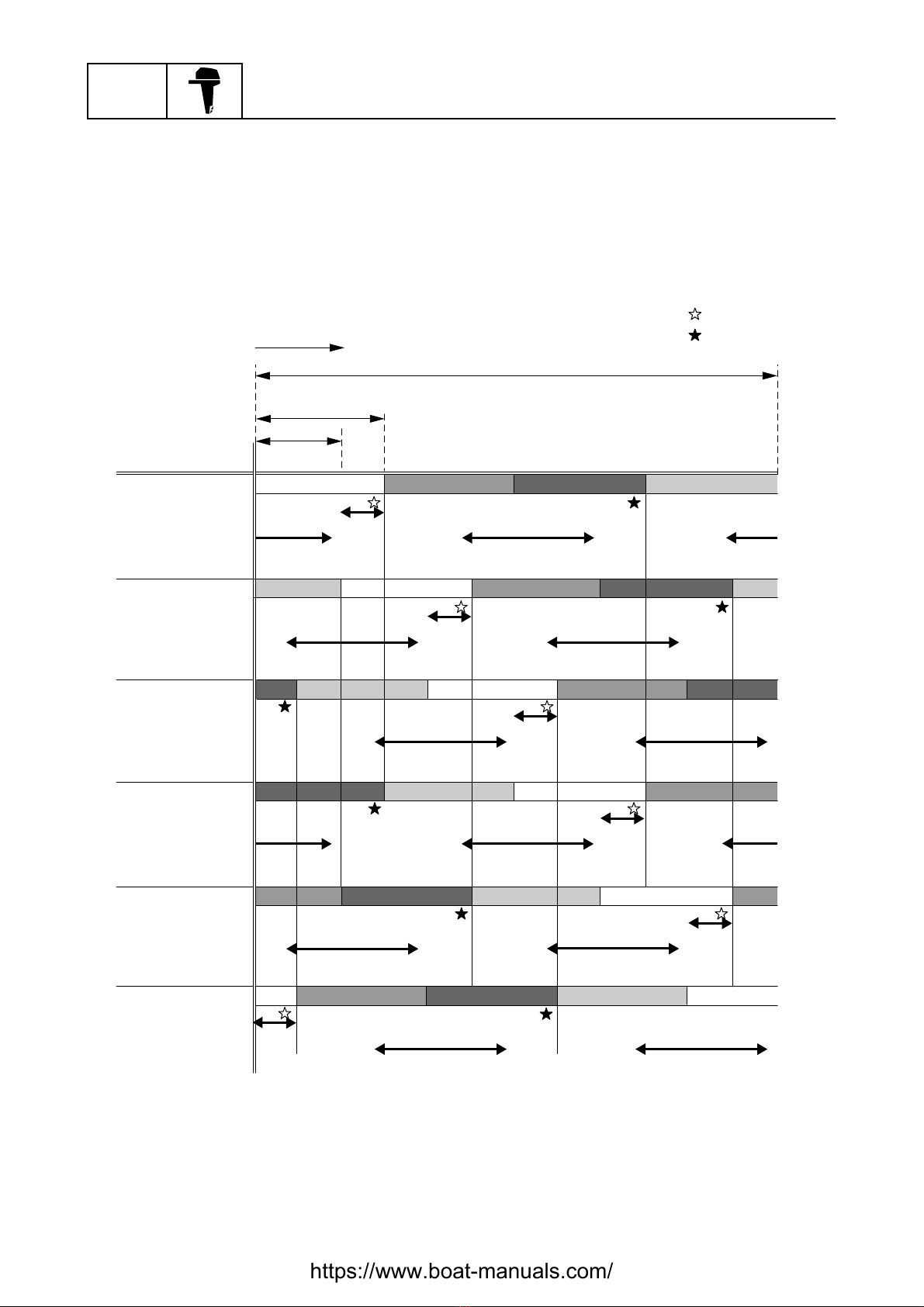

Ignition and fuel injection timing ...................................................................5

Technical tips....................................................................................................6

Fuel injection control.....................................................................................6

Propeller selection............................................................................................7

Propeller size................................................................................................7

Selection.......................................................................................................7

Predelivery checks ...........................................................................................8

Checking the fuel system .............................................................................8

Checking the gear oil....................................................................................8

Checking the engine oil................................................................................8

Checking the battery.....................................................................................8

Checking the outboard motor mounting height.............................................9

Checking the remote control cables.............................................................9

Checking the steering wheel ......................................................................10

Checking the gearshift and throttle operation.............................................10

Checking the tilt system..............................................................................10

Checking the engine start switch and engine stop switch/

engine shut-off switch...............................................................................10

Checking the cooling water pilot hole.........................................................11

Test run ......................................................................................................11

Break-in......................................................................................................11

After test run...............................................................................................11

https://www.boat-manuals.com/