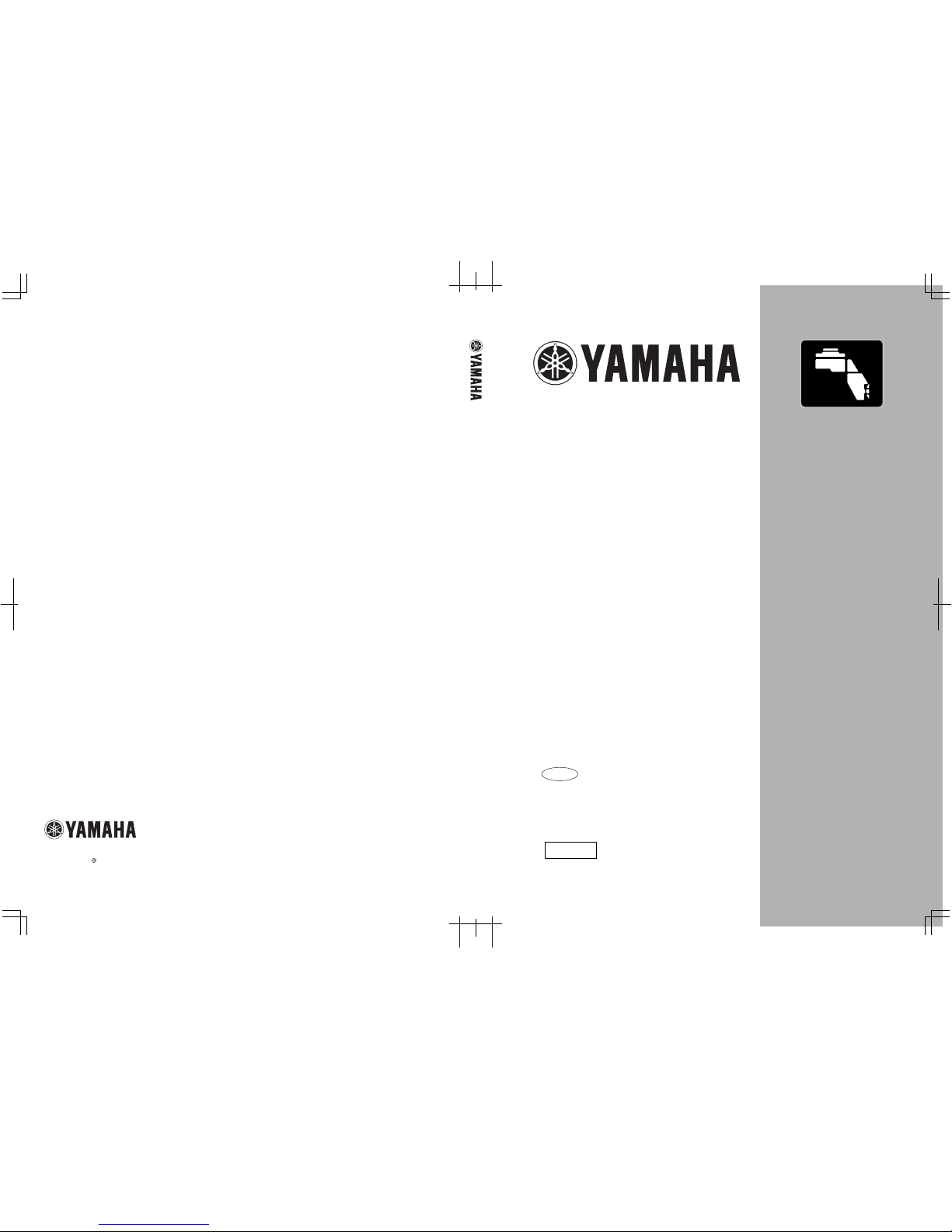

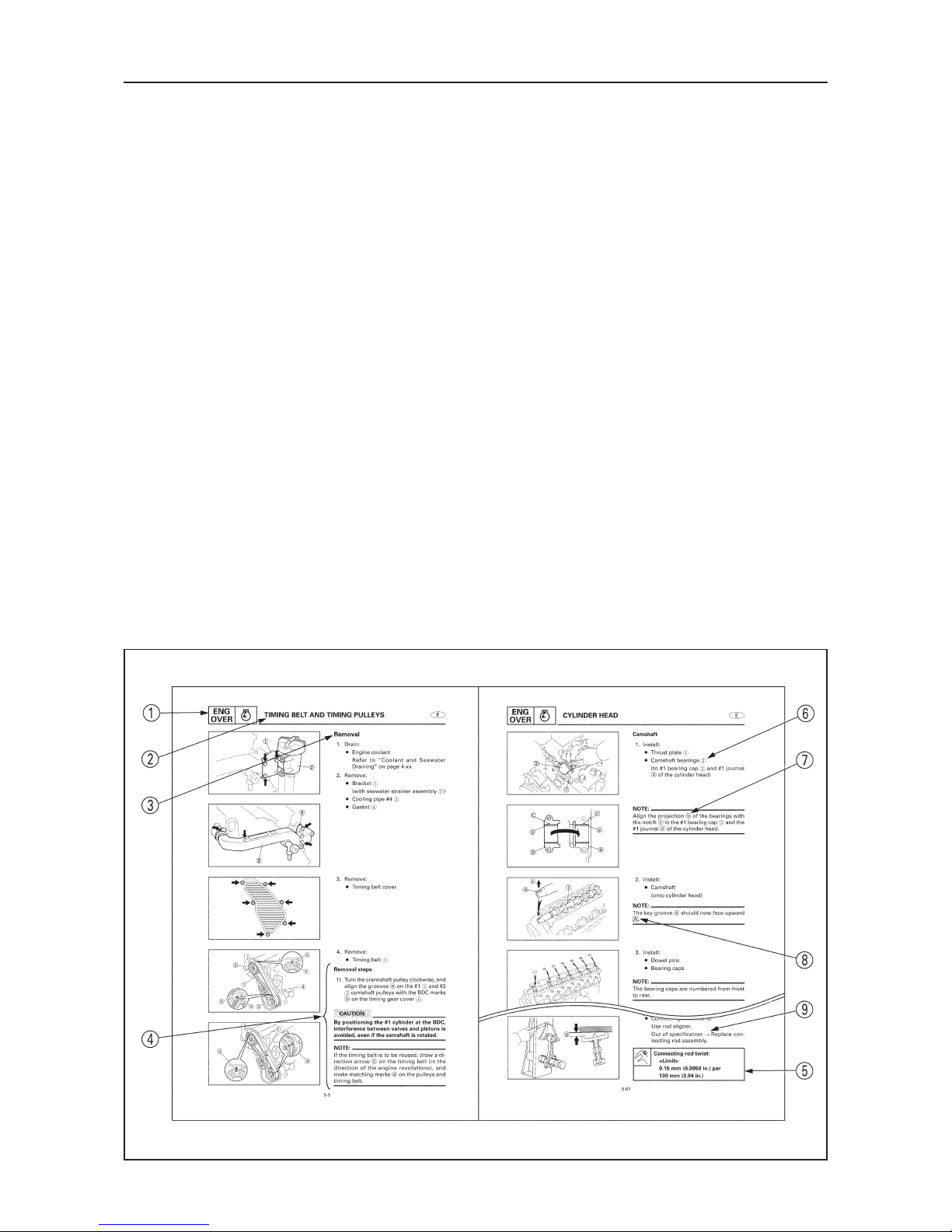

SYMBOLS

Symbols 1to Aare designed as thumb-tabs

and indicate the content of a chapter.

1General information

2Specifications

3Periodic check and adjustment

4Engine removal and installation

5Engine

6Fuel system

7Exhaust system

8Cooling system

9Lubrication system

0Turbocharger

APower steering system

BElectrical system

CTroubleshooting

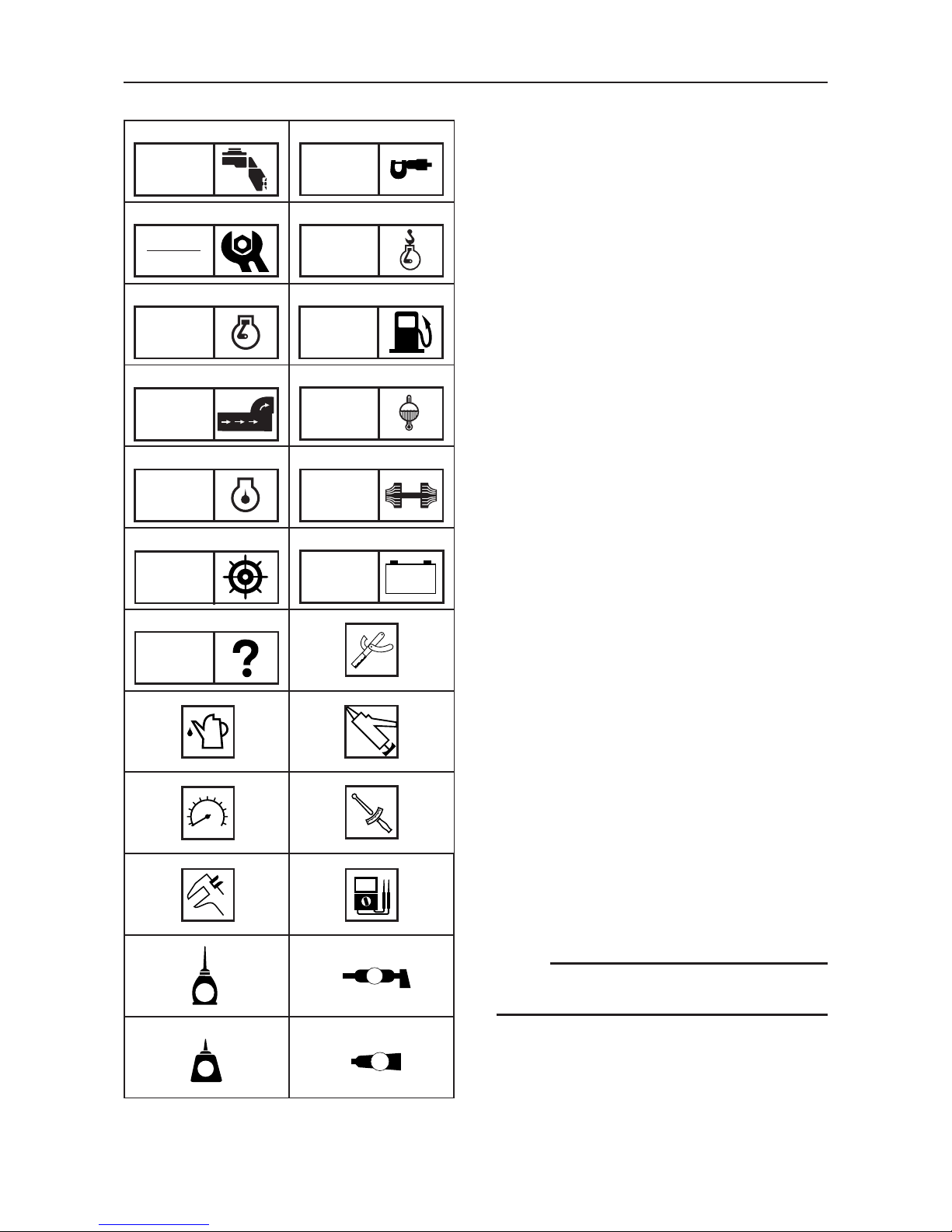

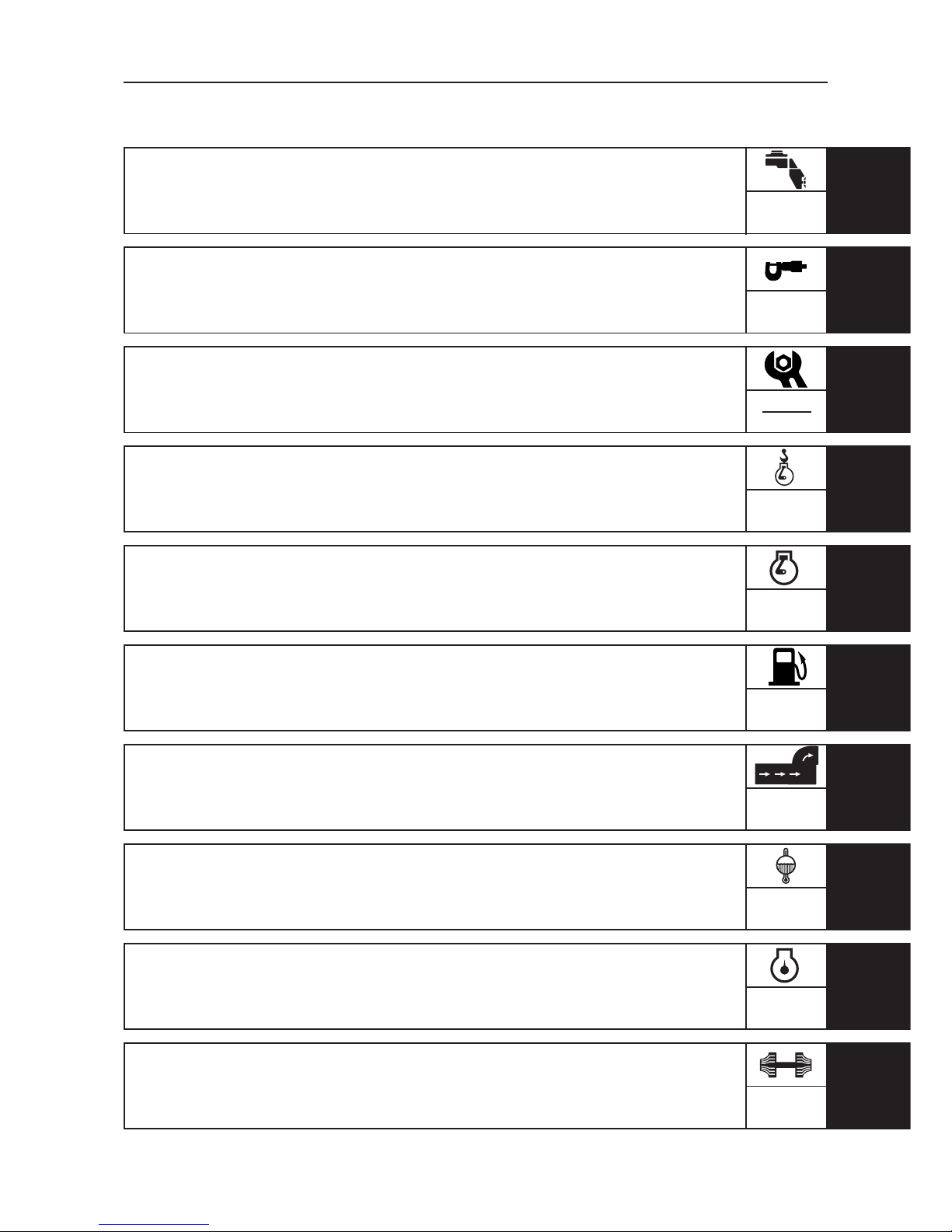

Symbols Dto Jindicate specific data:

DSpecial tool

ERecommended fuel

FLubricant

GEngine speed

HTightening torque

ISpecified value, service, limit

JResistance (Ω), Voltage (V), Electric cur-

rent (A)

Symbols Kand Lin an exploded diagram

indicate grade of lubricant and location of

lubrication point:

KApply Yamaha gear-case lubricant

LApply water resistant grease (Yamaha

marine grease A, Yamaha marine grease)

Symbols Mand Nin an exploded diagram

indicate grade of sealing or locking agent,

and location of application point:

MApply LOCTITE®No. 243, 271, 572

NApply Three Bond®TB-1207B, 1322, 1324

NOTE:

Some of the above symbols may not appear

in this manual.

12

34

56

78

90

AB

CD

EF

GH

IJ

K

N

L

M

T.R

A

LT

LT

G

TB

GEN

INFO SPEC

CHK

ADJ

REM

INST

ENG

OVER FUEL

EXHT COOL

LUB TURB

STEER

ELEC –

+

TRBL