Scan here to learn more

about outboard flushing.*

Scan here to see a video about

the three flushing methods.*

What’s so important about flushing my outboard?

I boat exclusively in freshwater, do I still need to?

Your Yamaha outboard is raw-water cooled, meaning it uses the water it’s operating on as cooling

water. All water, fresh or salt, contains contaminants that will eventually build up in the cooling

passages over time. Additionally, saltwater is naturally corrosive and any remaining in those cooling

water passages after use is left there to do its worst, unabated. Saltwater can also experience

crystallization when exposed to heat above 170 degrees, which causes deposits to form and

potentially restrict cooling water passages. For these

reasons, it’s a must that you flush your engine

thoroughly with fresh, clean water after every use.

How do I go about flushing my outboard?

Use one of these three basic methods to flush after each trip.

•Use the built-in flush attachment. This is a great procedure to follow, especially if

you can’t remove your boat from the water, or if your outboard has dual water inlets

and you don’t have the special adapter. Simply connect a garden hose to the inlet

side of your non-running outboard’s built-in flush attachment, turn the spigot on full

blast, and let the hose’s water pressure do the work. Let the water run for 15 minutes

to ensure it fully circulates through the entire cooling system several times. If your

boat’s out of the water, like on a trailer or a lift, the fresh water will also trickle down

and adequately clean the water pump and the lower unit’s cooling water passages.

•The flush muff method. This is the most common and often-used fresh water

flushing method. Simply connect a garden hose to clean fresh water on one end

and a “flush muff” attachment, which slides around the lower unit to provide water

to both sides of the raw water inlet, to the other end. Turn on the water until you

see water squirting out the sides of the flush muff, then start your outboard in

neutral. Set the outboard to no more than a fast idle (900-RPM max) and allow to

run for 15 minutes in neutral. Increase hose water pressure enough to maintain a

bit of squirting out from under the flush muffs at all times while the outboard is

running. This helps ensure it gets fed enough cooling water.

Note: Outboards utilizing two cooling water inlets require a special adapter to use this method. Check with your

outboard’s manufacturer.

Note: Increasing engine speed may cause water demand to exceed supply. If you notice the hose becoming flat while

the outboard is running using this procedure, increase the water flow and/or decrease the engine RPM.

Warning: For safety, we suggest you remove the propeller before you begin. Accidental engagement of the outboard

into gear with the outboard running will cause an exposed propeller to spin rapidly, possibly resulting in serious

injury or death.

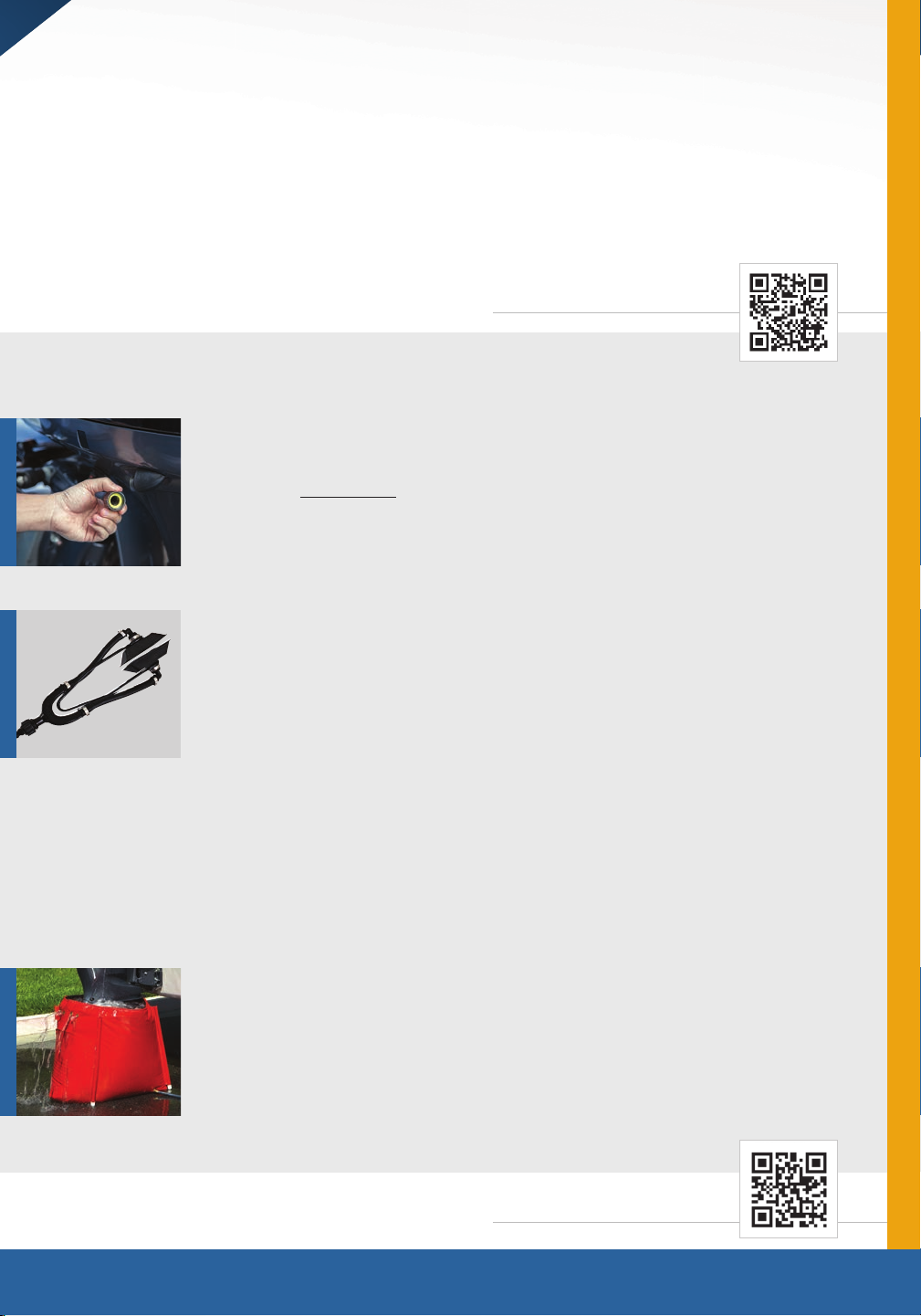

•The flush bag method. This method can be used for a boat on a trailer or when

moored. A flush bag, when filled with water, simulates the outboard idling in its

normal state but immerses the lower unit in fresh, clean tap water. Simply place

the bag around the outboard, attach the hose, and fill the bag. Ensure the water

level reaches the height of the outboard’s water pump (about 1” above the lower

unit separation seam). Start the engine, and run for 15 minutes in neutral. Leave

the hose running during this entire procedure. When complete, stop the outboard,

then the hose, and then drain the bag.

Note: Thoroughly dry the bag before storage.

7