Contents

1. Safety precautions........................................................................................................................... 1

Explanation of pictograms.................................................................................................................. 1

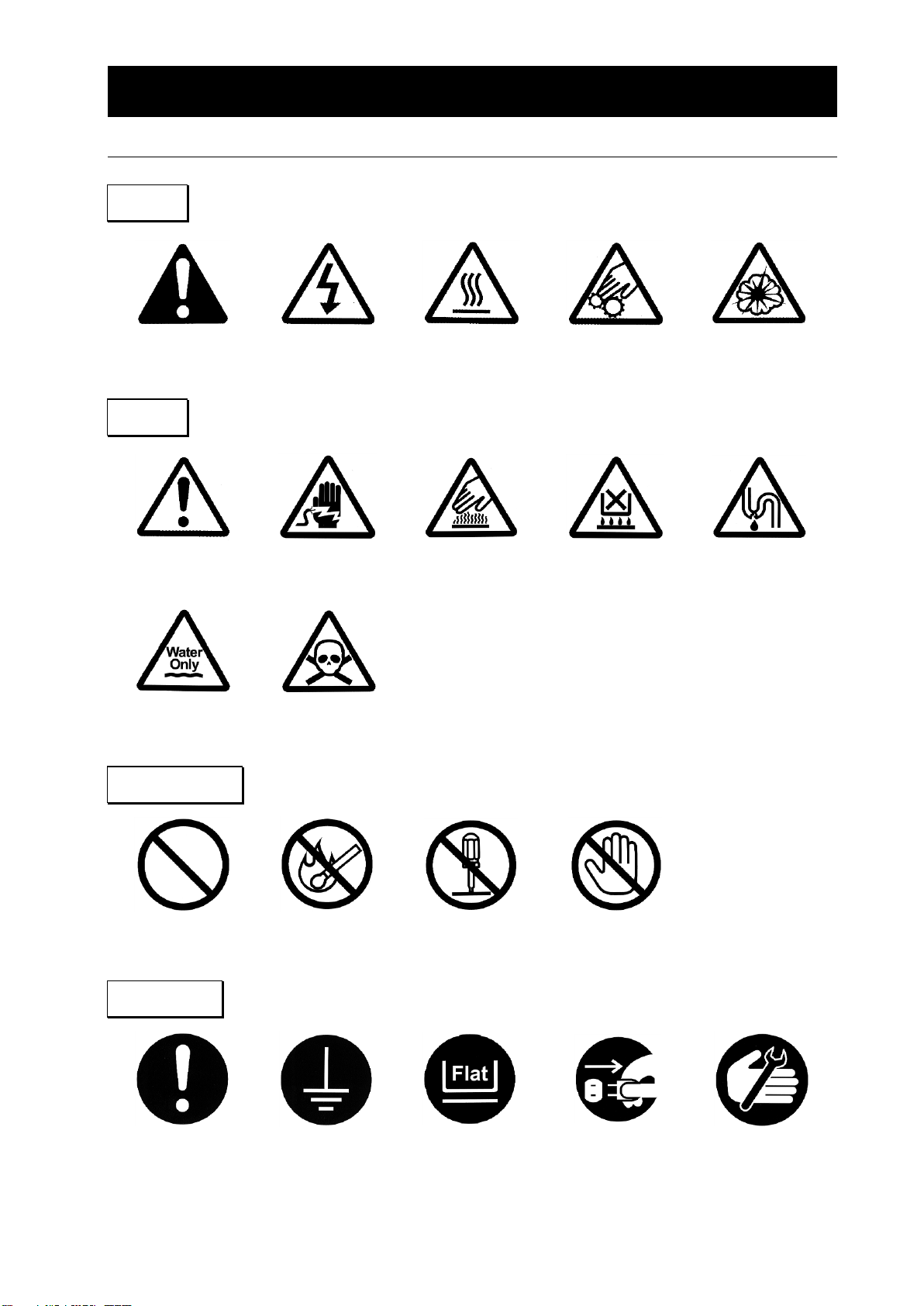

List of symbols ................................................................................................................................... 2

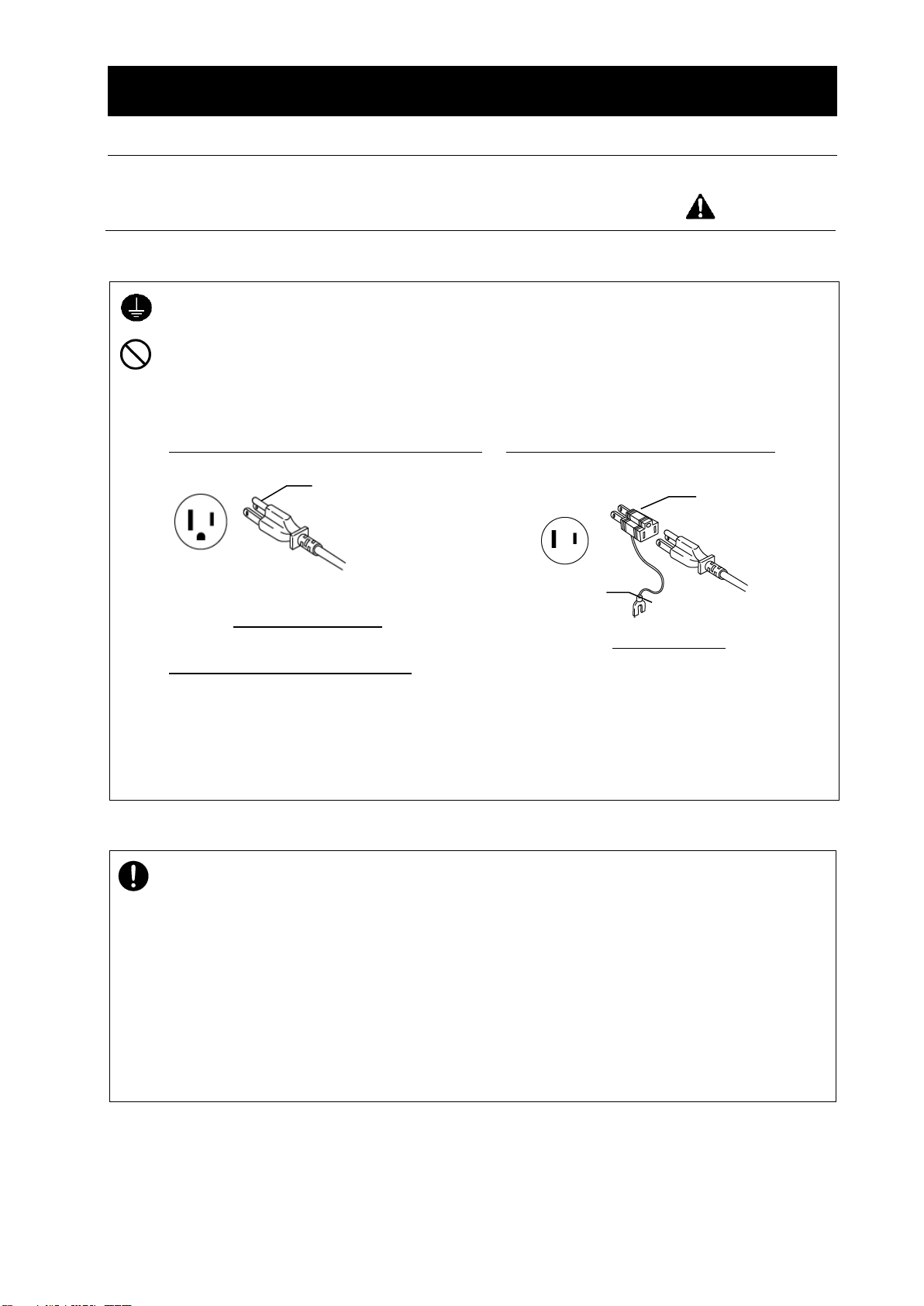

Warnings & Cautions.......................................................................................................................... 3

2. Before operating the unit................................................................................................................ 5

Cautions for installation...................................................................................................................... 5

Installation procedures/precautions ................................................................................................... 9

3. Name and Functions of each Part................................................................................................ 10

Main body......................................................................................................................................... 10

Details of each part ...........................................................................................................................11

4. Operation Method.......................................................................................................................... 12

Operation method ............................................................................................................................ 12

Operation method ............................................................................................................................ 13

Cooling Curve(Reference data)................................................................................................... 14

5. Cautions for Handling................................................................................................................... 15

6. Maintenance................................................................................................................................... 17

Daily inspection/maintenance .......................................................................................................... 17

7. When the unit is not to be used for a long time or when disposing......................................... 18

When the unit is not to be used for a long time or when disposing.................................................. 18

Requests in case of disposal ........................................................................................................... 18

8.Troubleshooting Guide .................................................................................................................. 19

Check list.......................................................................................................................................... 19

9. After sales service and warranty.................................................................................................. 20

When requesting a repair................................................................................................................. 20

10.Specifications ............................................................................................................................... 21

11.Connection Diagram..................................................................................................................... 22

Connection diagram......................................................................................................................... 22

12. Replacement Parts List............................................................................................................... 23

13. List of dangerous materials........................................................................................................ 24

14. Standard installation manual...................................................................................................... 25