Contents

1. Safety Precautions................................................................ 1

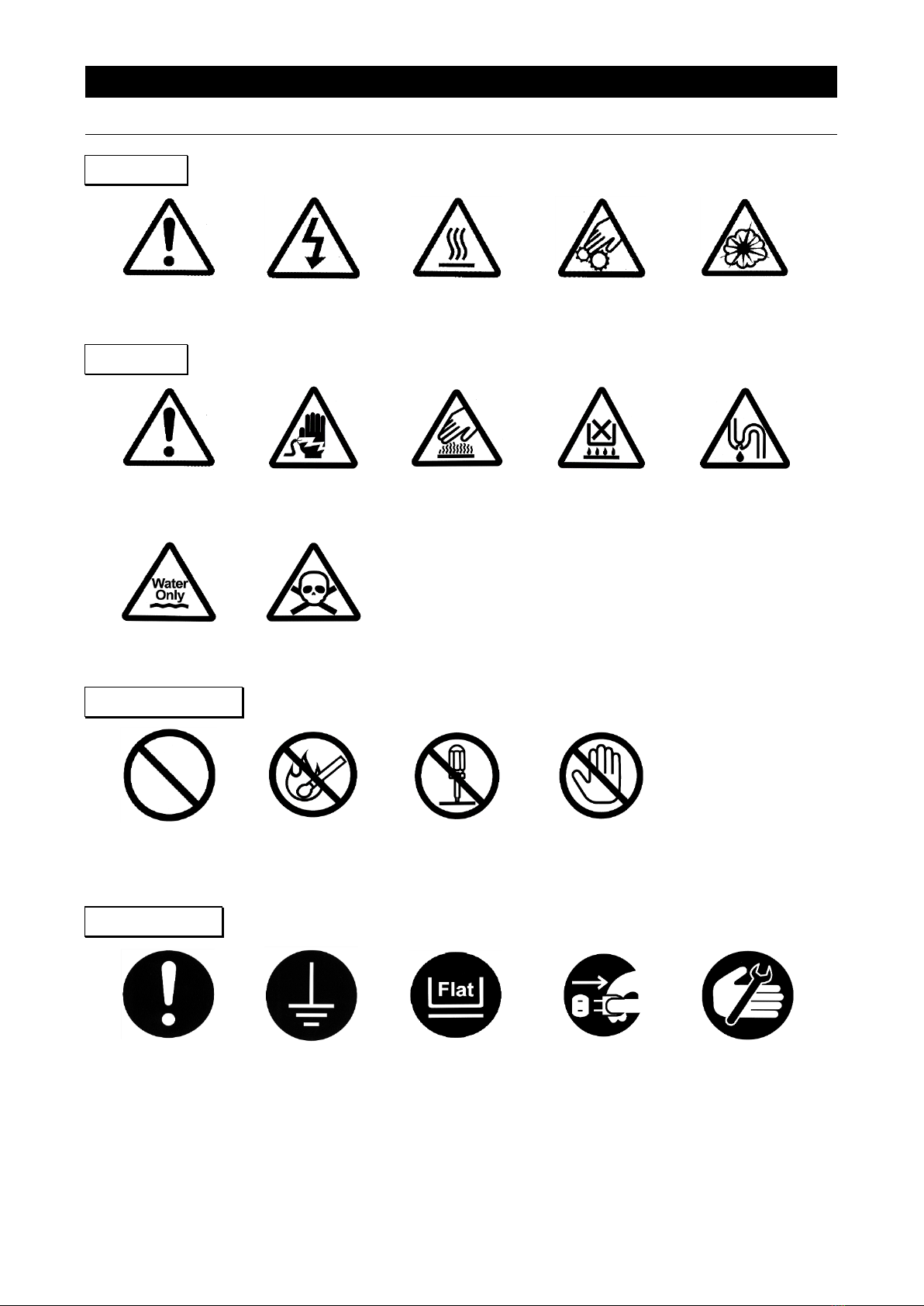

Explanation of symbols .................................................................1

List of symbols.........................................................................2

Residual risk map ......................................................................3

Warnings・Cautions.....................................................................4

Warnings・Cautions.....................................................................5

List of residual risks ....................................................................6

2. Before operating the Equipment.................................................... 7

Precautions when installing the Equipment ................................................7

2. Before operating the Equipment.................................................... 8

Precautions when installing the Equipment ................................................8

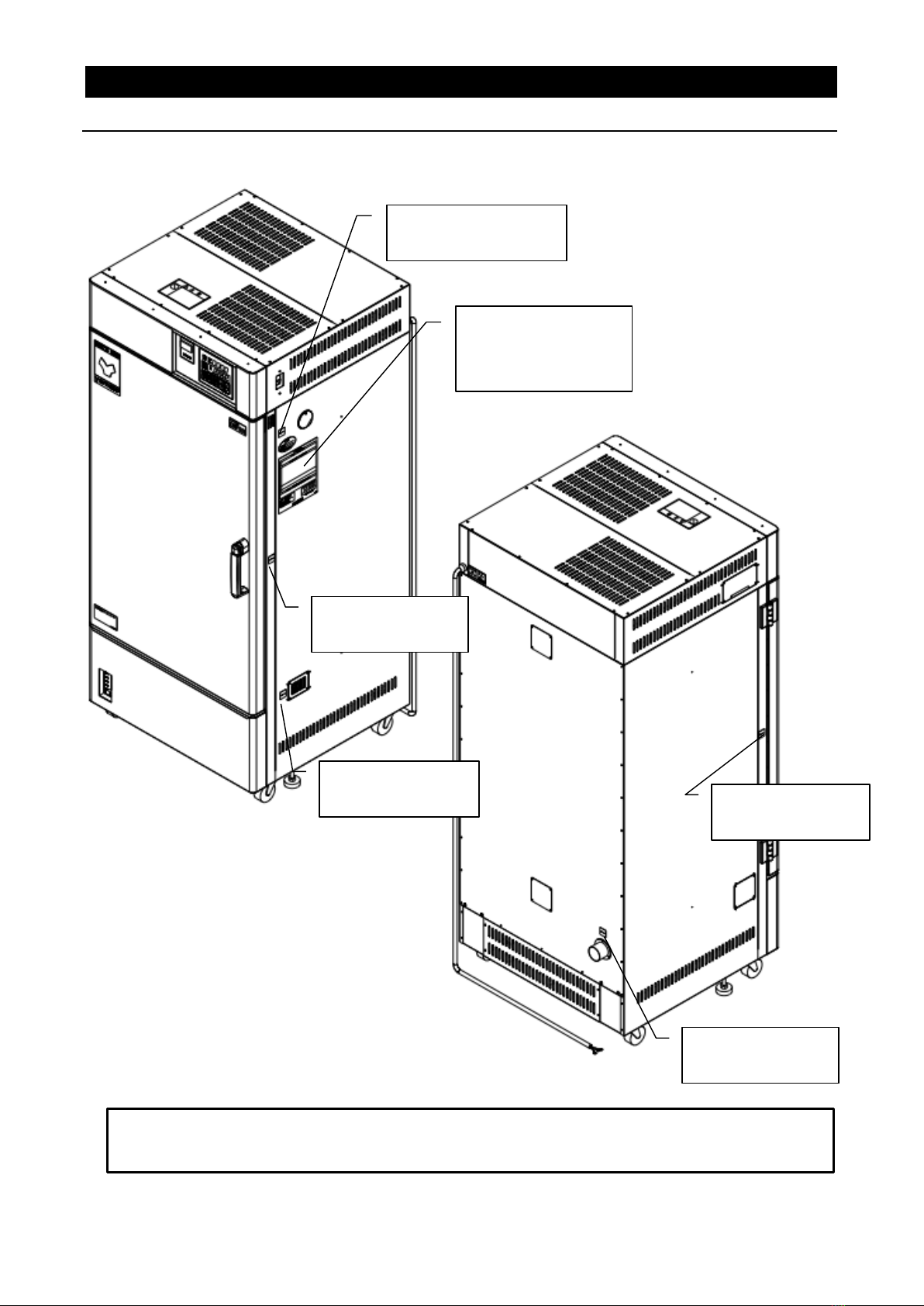

3. Names and functions of each part ................................................. 12

External view.........................................................................12

External view.........................................................................13

System ..............................................................................14

Structure diagram .....................................................................15

Control Panel.........................................................................16

4. Operating procedure ............................................................. 17

Prior confirmation .....................................................................17

Date & Time setting ...................................................................18

Buzzer function selection...............................................................20

Fixed temperature operation............................................................22

Auto stop operation....................................................................26

4. Operating procedure ................................................................29

Operation of the variable wind-speed function and the method of entry .......................32

Program operation ....................................................................34

Programming Method..................................................................37

How to copy or delete programs.........................................................44

About the wait function.................................................................46

Setting key lock mode .................................................................47

Calibration offset......................................................................48

Calibration offset......................................................................49

Setting the recovery mode..............................................................50

Resetting integrated CO2 volume and CO2 emission factor.................................51

Backup data saving / reading out / resetting...............................................53

Monitoring data .......................................................................54

Independent Overheat Prevention Device ................................................56

5. Handling precautions ............................................................ 57

Warnings and Cautions ................................................................57

Warnings and Cautions ................................................................58

6. Maintenance method............................................................. 63

Daily inspection/maintenance...........................................................63