Table of Contents

SAFETY PRECAUTIONS .................................................................................................................1

Explanation of pictograms ..............................................................................................................1

Symbol mark table ..........................................................................................................................2

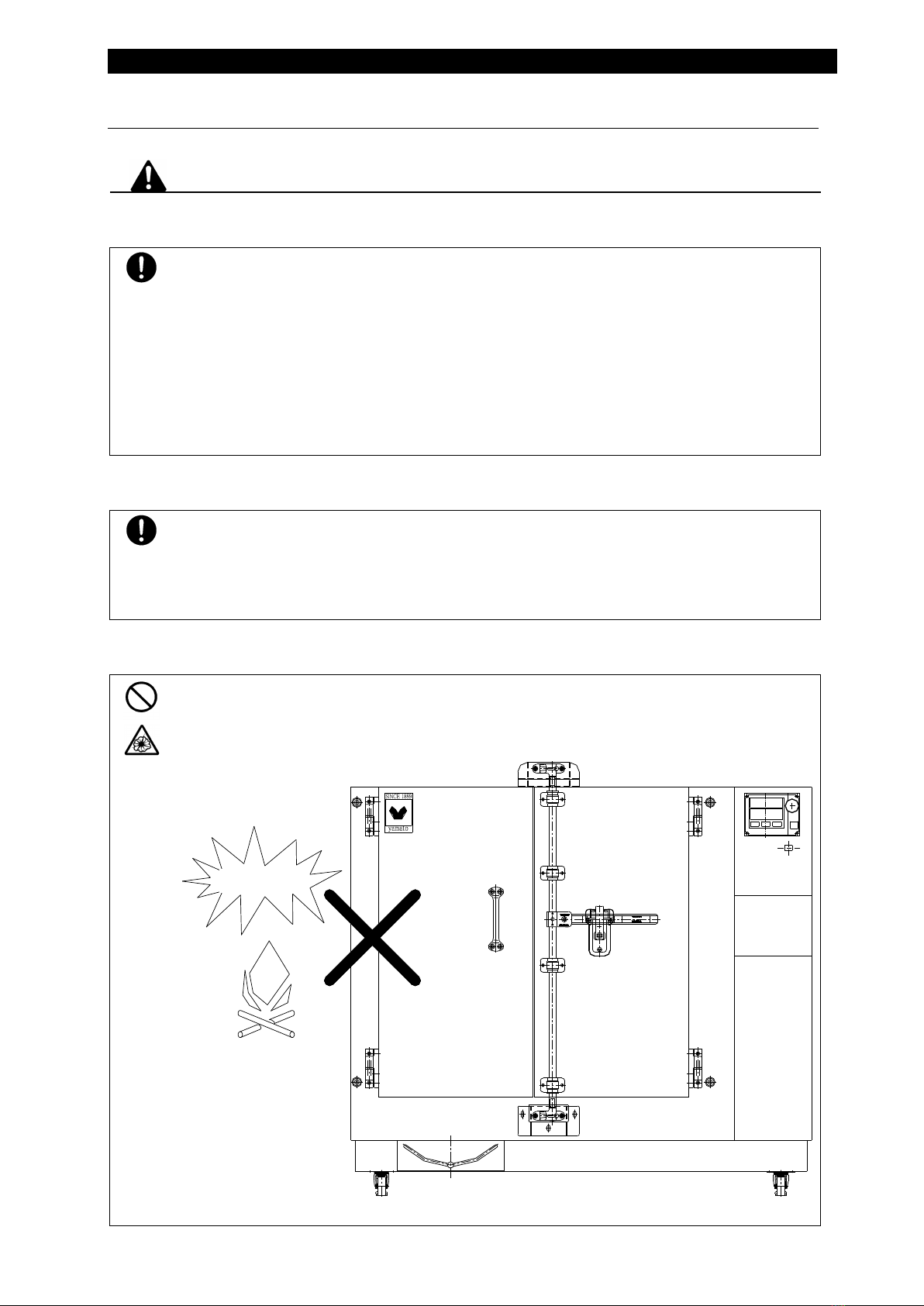

Warning・Cautions.........................................................................................................................3

BEFORE USING IT ..........................................................................................................................4

To install and preparation before using.........................................................................................4

PRECAUTIONS IN HANDLING......................................................................................................8

SAFETY DEVICES AND ERROR CODES .....................................................................................12

Purposes and Operations of Safety Device and Counter-measures...........................................12

DESCRIPTION AND FUNCTION OF EACH PART......................................................................13

Main unit .......................................................................................................................................13

Control Panel .................................................................................................................................14

PREPARATION AND CHECK BEFORE USING ..........................................................................15

POWER ON/OFF.............................................................................................................................16

METHOD OF OPERATION MENU ...............................................................................................17

Selection of operation mode ..........................................................................................................17

FIXED TEMPERATURE OPERATION INSTRUCTION ..........................................................19

AUTO START OPERATION INSTRUCTION ............................................................................21

AUTO STOP OPERATION METHOD ........................................................................................23

PROGRAMMED OPERATION METHOD......................................................................................26

To choose program menu function ...............................................................................................29

TO MAKE OUT NEW PROGRAM...............................................................................................31

TO EDIT PROGRAM ....................................................................................................................32

TO EDIT SEGMENT ....................................................................................................................33

TO ADD SEGMENT......................................................................................................................37

TO FINISH PROGRAM EDITING ..............................................................................................38

TO DELETE PROGRAM ..............................................................................................................39

HANDLING METHOD OF FUNCTION MENU ............................................................................40

To select function menu item........................................................................................................40

TO SET UP TIMER MODE.............................................................................................................43

TO SET UP KEYLOCK MODE.......................................................................................................44

TO SET UP BUZZER MODE ..........................................................................................................45

CALIBRATION OFFSET FUNCTION ...........................................................................................46

SETTING THE CALIBRATION OFFSET FUNCTION .................................................................47

TO CHECK ACCUMULATED OPERATION TIME.......................................................................48

TO ADJUST TIME..........................................................................................................................49

TO MODULATE FAN BLADE (OPTION) ......................................................................................51

TO MODULATE DAMPER (OPTION) ...........................................................................................52

SETTING THE COMMUNICATION LOCKOUT (OPTION) .........................................................54

INDEPENDENT OVERHEAT PREVENTION...............................................................................55

Activation/Setting Method ............................................................................................................55

Precautions ....................................................................................................................................55

MAINTENANCE AND INSPECTION............................................................................................56

Daily check/care.............................................................................................................................56

LONG STORAGE AND DISPOSAL................................................................................................56

AFTER SERVICE AND WARRANTY.............................................................................................57

TROUBLESHOOTING ...................................................................................................................57

MEASURE.......................................................................................................................................58

SCHEMATICS.................................................................................................................................59

REPLACEMENT PARTS TABLE...................................................................................................64