Contents

1. Cautions in using with safety ........................................................................................................ 1

Explanation .......................................................................... 1

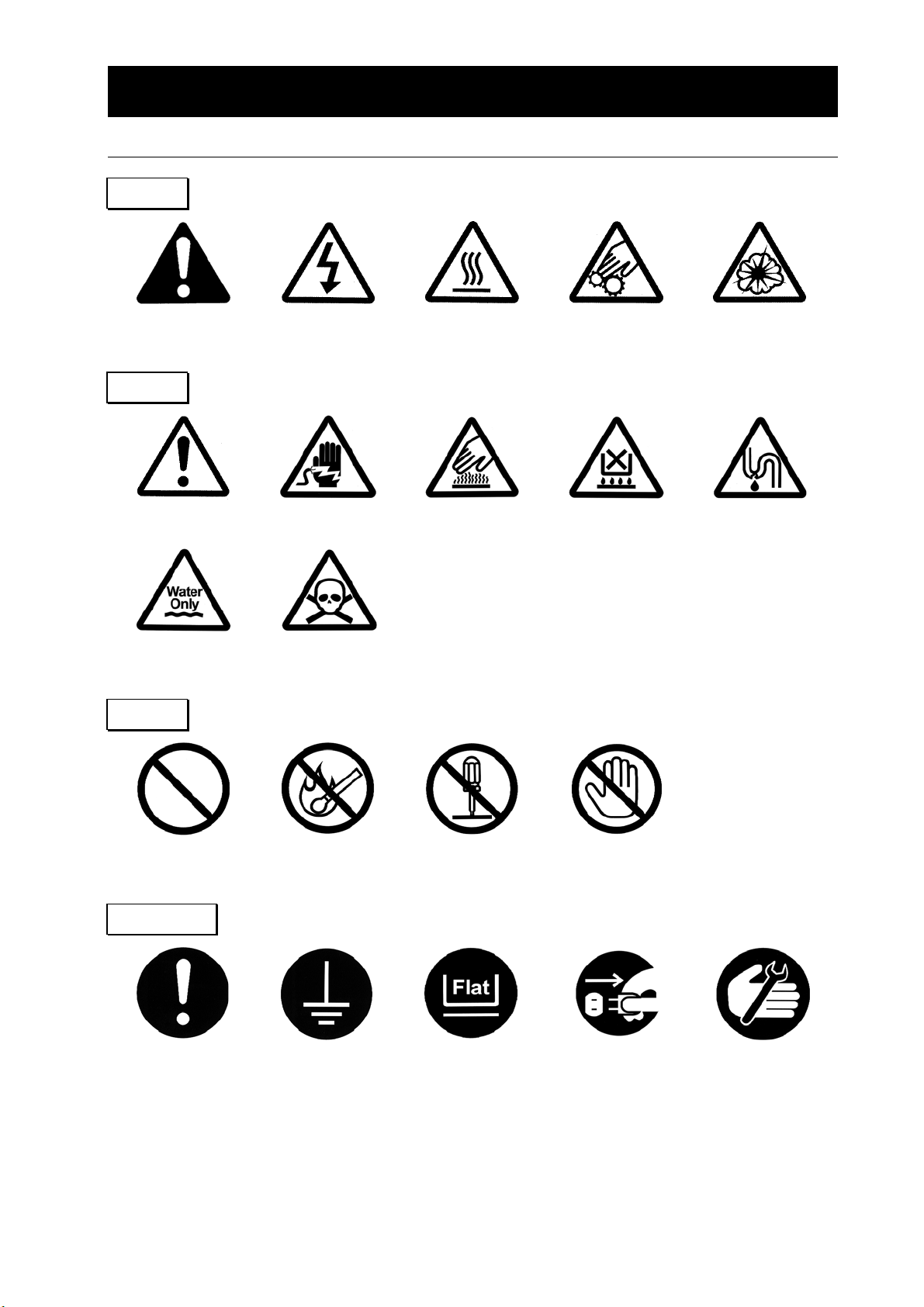

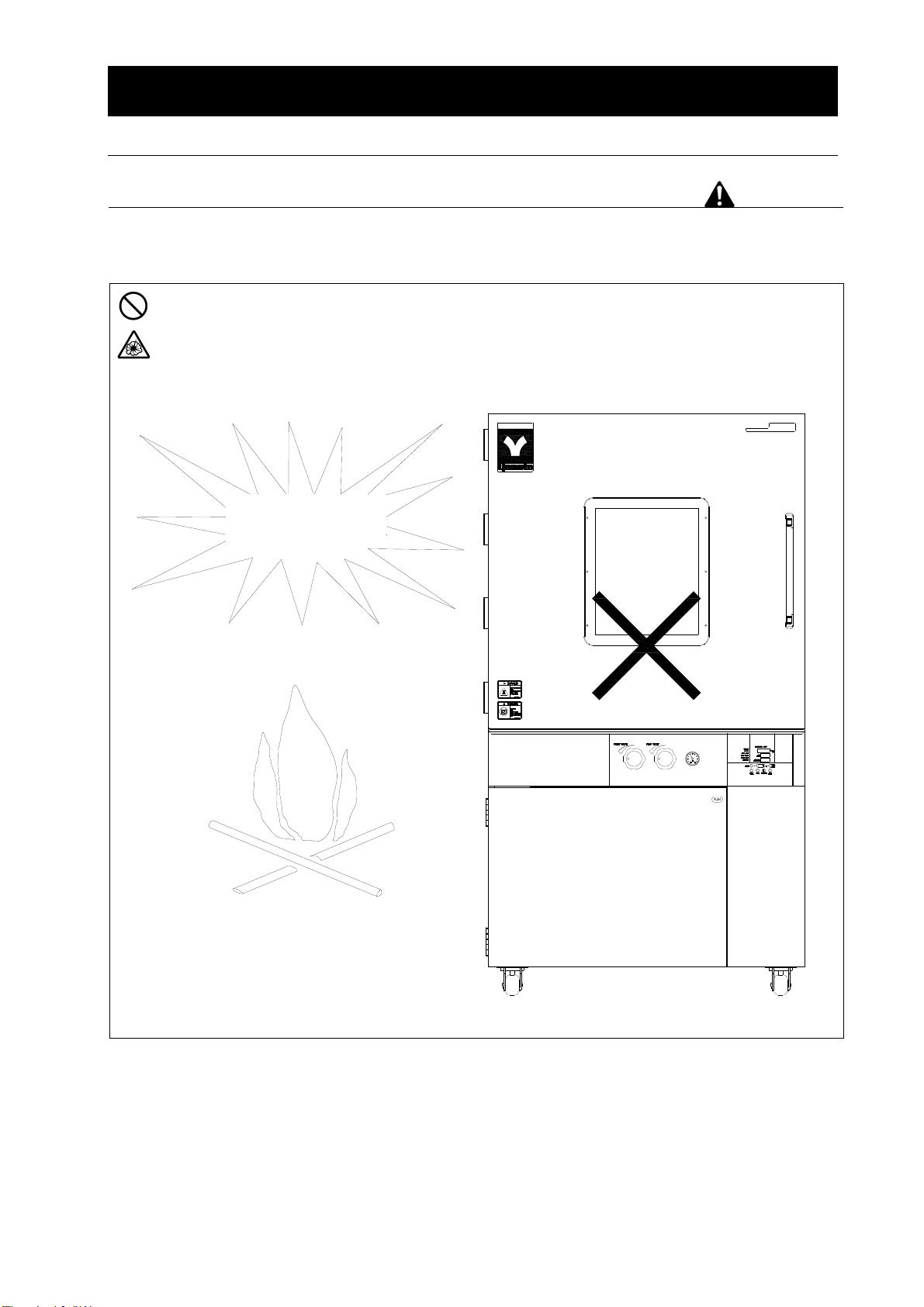

Table of Illustrated Symbols ............................................................ 2

Fundamental Matters of "WARNING!" and "CAUTION!" .................................... 3

2. Before using this unit .................................................................................................................... 4

Requirements for Installation ........................................................... 4

3. Description and Function of Each Part ........................................................................................ 9

Main Unit ............................................................................ 9

Operation Panel ..................................................................... 11

Characters of the Controller ........................................................... 12

4. Operation Method ........................................................................................................................ 14

Operation Mode and Function List ..................................................... 14

Operation Mode, Function Setting Key, and Characters ................................... 16

Setting of Overheating Prevention Device ............................................... 17

Fixed Temperature Operation .......................................................... 18

Quick Auto Stop Operation ............................................................ 19

Auto Stop Operation ................................................................. 21

Auto Start Operation ................................................................. 23

Program Operation .................................................................. 25

Program Repeat Function ............................................................. 30

Programming Preparation Form ....................................................... 31

Other Functions (Calibration) .......................................................... 33

Other Functions (Lock) ............................................................... 34

Vacuumizing and air inflow ............................................................ 35

5. Handling Precautions .................................................................................................................. 36

6. Maintenance Method ................................................................................................................... 38

Daily Inspection and Maintenance ...................................................... 38

7. Long storage and disposal ......................................................................................................... 39

When not using this unit for long term / When disposing ................................... 39

Disposal Notice ..................................................................... 39

8. In the Event of Failure .................................................................................................................. 40

Safety Device and Error Code ......................................................... 40

Trouble Shooting .................................................................... 41

9. After Service and Warranty ......................................................................................................... 42

When requesting a repair ............................................................. 42

10. Specification ............................................................................................................................... 43

11. Wiring Diagram ........................................................................................................................... 45

12. Replacement Parts Table ........................................................................................................... 47

13. List of Dangerous Substances .................................................................................................. 48

14. Installation Manual ..................................................................................................................... 49