EN

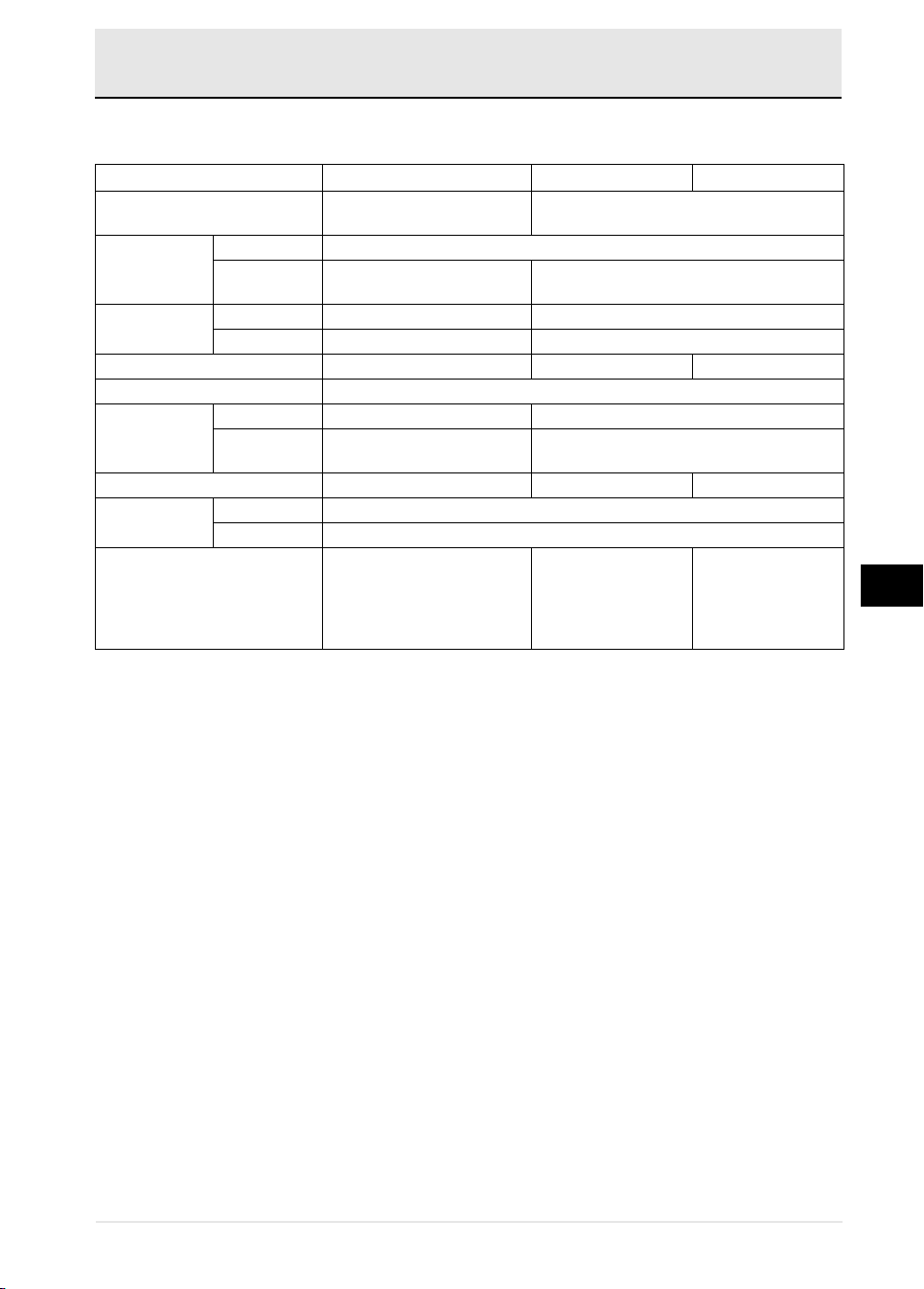

Introduction ................................................... 3

1. For Your Safety ........................................ 4

1.1 Safety Precautions For Inspection .... 4

2. Specifications ........................................... 7

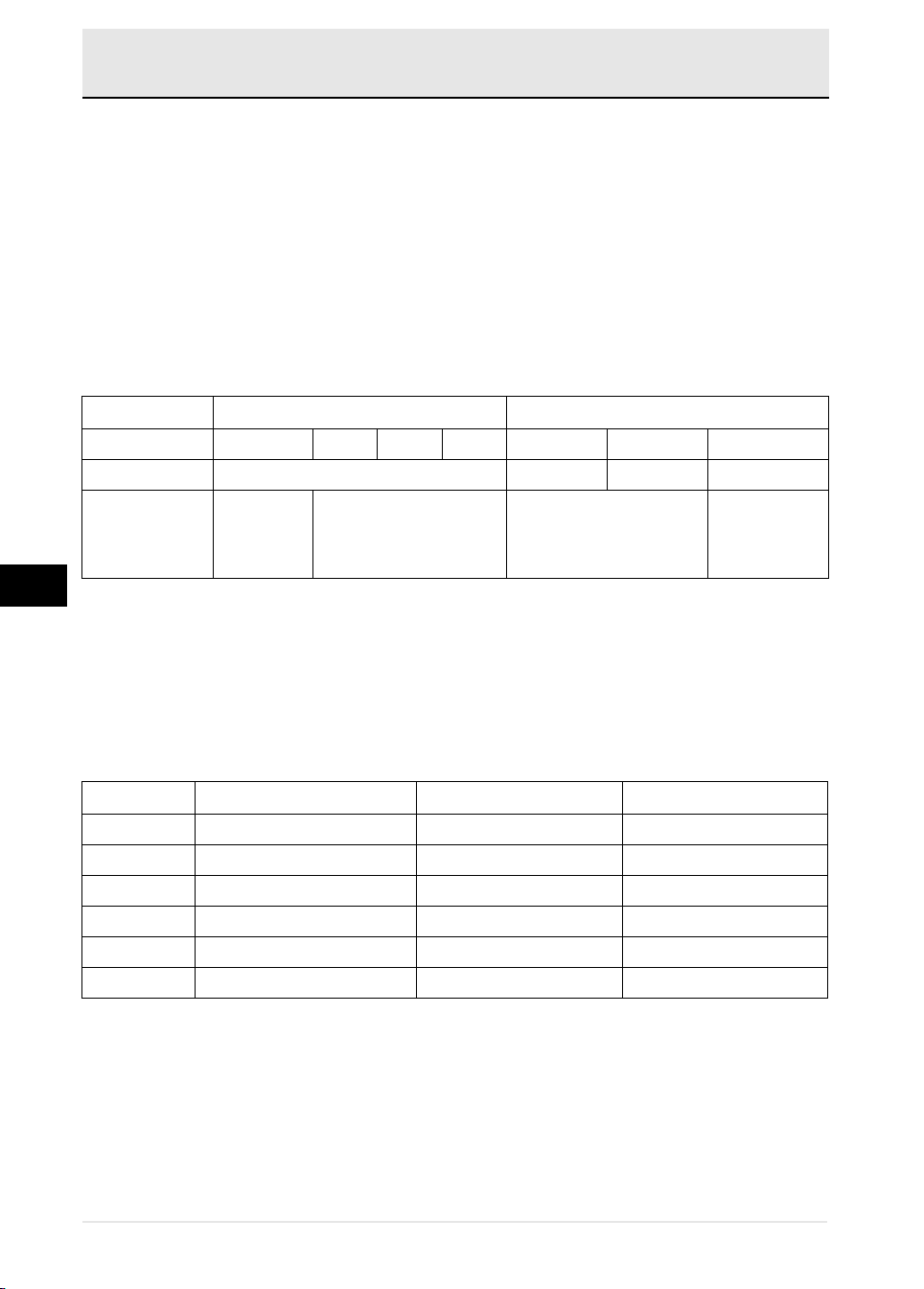

3. Selecting Lubricating Oil ........................... 8

3.1 Choice of lube oil .............................. 8

3.2 Kind of lube oil .................................. 8

3.3 Lube oil viscosity ............................... 9

4. Starting the New Sail-Drive for the First

Time .................................................. 10

4.1 Filling with lubricating oil ................. 10

4.1.1 SD20 and SD50/-4T .............. 10

4.2 Check of instrument panel alarm sys-

tem: 11

4.3 Remote-Control Device Check ........ 12

4.4 Fitting for Fixed Propeller (2-blade) . 14

4.5 Recommended Propeller Size (Max.) .

14

5. Method of Operation .............................. 16

5.1 Engine Cooling Water ..................... 16

5.1.1 SD20 ..................................... 16

5.1.2 SD50/SD50-4T ...................... 17

6. Periodic Inspections and Maintenance ... 18

6.1 Lubricating oil system ...................... 19

6.1.1 SD20 ..................................... 19

6.1.2 SD50/-4T ............................... 20

6.2 Procedure for filling and removing oil in

the Sail-Drive; SD50/-4T 21

6.2.1 When the boat is in the water 22

6.2.2 When the boat is out of the water

26

6.3 Anticorrosive zinc ............................ 29

6.3.1 SD20 and SD50/ SD50-4T .... 29

6.4 Rubber diaphragms (A) and (B) (SD20

and SD50/-4T) 29

6.5 When the boat hull is raised onto a

block, inspect the following: 30

7. Electrical Wiring Diagrams ......................31