YASKAWA PS M07 User manual

PS | M07-2BA00 | Manual

HB400 | PS | M07-2BA00 | en | 20-02

VIPA System MICRO

Power supply - PS M07

M07-2BA00_000_PS M07,1,EN - © 2020

YASKAWA Europe GmbH

Ohmstraße 4

91074 Herzogenaurach

Tel.: +49 9132 744 0

Fax: +49 9132 744 186

Email: [email protected]

Internet: www.yaskawa.eu.com

Table of contents

1 General.................................................................................................................... 4

1.1 Copyright © YASKAWA Europe GmbH............................................................ 4

1.2 About this manual............................................................................................. 6

1.3 Safety instructions............................................................................................ 7

2 Basics and mounting............................................................................................. 8

2.1 Safety information for users.............................................................................. 8

2.2 System conception........................................................................................... 9

2.3 Dimensions..................................................................................................... 10

2.4 Mounting......................................................................................................... 12

2.4.1 Mounting without mounting rail.................................................................... 13

2.4.2 Mounting with mounting rail......................................................................... 13

2.5 Wiring............................................................................................................. 15

2.5.1 Wiring power supply.................................................................................... 15

2.6 Demounting.................................................................................................... 16

2.7 Installation guidelines..................................................................................... 19

2.8 General data................................................................................................... 21

3 Power supply........................................................................................................ 23

3.1 Safety instructions.......................................................................................... 23

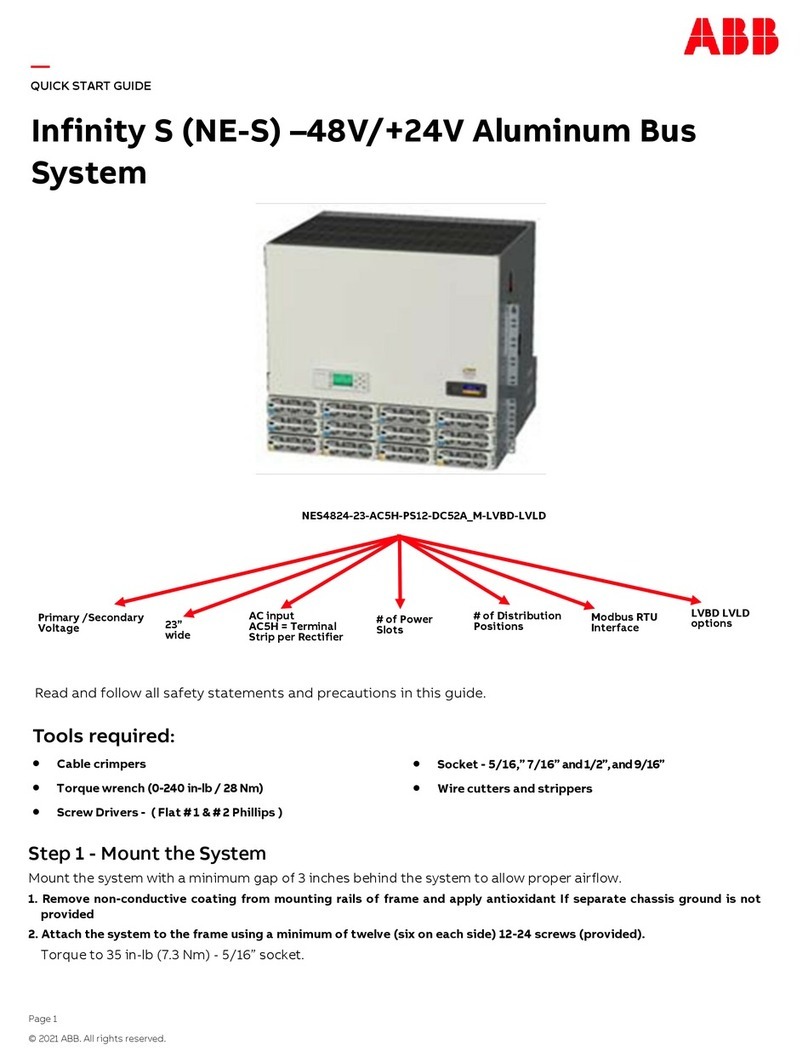

3.2 PS M07 DC24V, 1.5A_AC120V-240V............................................................ 24

3.3 Technical data................................................................................................. 27

Appendix............................................................................................................... 29

A History of changes............................................................................................ 31

VIPA System MICRO Table of contents

HB400 | PS | M07-2BA00 | en | 20-02 3

1 General

1.1 Copyright © YASKAWA Europe GmbH

This document contains proprietary information of YASKAWA and is not to be disclosed

or used except in accordance with applicable agreements.

This material is protected by copyright laws. It may not be reproduced, distributed, or

altered in any fashion by any entity (either internal or external to YASKAWA) except in

accordance with applicable agreements, contracts or licensing, without the express

written consent of YASKAWA and the business management owner of the material.

For permission to reproduce or distribute, please contact: YASKAWA Europe GmbH,

European Headquarters, Hauptstraße 185, 65760 Eschborn, Germany

Tel.: +49 6196 569 300

Fax.: +49 6196 569 398

Email: [email protected]

Internet: www.yaskawa.eu.com

Every effort has been made to ensure that the information contained in

this document was complete and accurate at the time of publishing. Nev-

ertheless, the authors retain the right to modify the information.

This customer document describes all the hardware units and functions

known at the present time. Descriptions may be included for units which

are not present at the customer site. The exact scope of delivery is

described in the respective purchase contract.

Hereby, YASKAWA Europe GmbH declares that the products and systems are in compli-

ance with the essential requirements and other relevant provisions. Conformity is indi-

cated by the CE marking affixed to the product.

For more information regarding CE marking and Declaration of Conformity (DoC), please

contact your local representative of YASKAWA Europe GmbH.

VIPA, SLIO, System 100V, System 200V, System 300V, System 300S, System 400V,

System 500S and Commander Compact are registered trademarks of YASKAWA Europe

GmbH.

SPEED7 is a registered trademark of YASKAWA Europe GmbH.

SIMATIC, STEP, SINEC, TIA Portal, S7-300, S7-400 and S7-1500 are registered trade-

marks of Siemens AG.

Microsoft and Windows are registered trademarks of Microsoft Inc., USA.

Portable Document Format (PDF) and Postscript are registered trademarks of Adobe

Systems, Inc.

All other trademarks, logos and service or product marks specified herein are owned by

their respective companies.

All Rights Reserved

EC conformity declaration

Conformity Information

Trademarks

VIPA System MICRO

General

Copyright © YASKAWA Europe GmbH

HB400 | PS | M07-2BA00 | en | 20-02 4

Contact your local representative of YASKAWA Europe GmbH if you have errors or ques-

tions regarding the content of this document. If such a location is not available, you can

reach YASKAWA Europe GmbH via the following contact:

YASKAWA Europe GmbH, Ohmstraße 4, 91074 Herzogenaurach, Germany

Fax: +49 9132 744 29 1204

Email: [email protected]

Contact your local representative of YASKAWA Europe GmbH if you encounter problems

or have questions regarding the product. If such a location is not available, you can reach

the YASKAWA customer service via the following contact:

YASKAWA Europe GmbH,

European Headquarters, Hauptstraße 185, 65760 Eschborn, Germany

Tel.: +49 6196 569 500 (hotline)

Email: [email protected]

Document support

Technical support

VIPA System MICRO General

Copyright © YASKAWA Europe GmbH

HB400 | PS | M07-2BA00 | en | 20-02 5

1.2 About this manual

The manual describes the power supply (PS) that can be used in the VIPA System

MICRO. Described are construction, application and technical data.

Product Order no. as of HW state:

PS M07 DC24V, 1.5A_AC120V-240V M07-2BA00 01

The manual is targeted at users who have a background in automation technology.

The manual consists of chapters. Every chapter provides a self-contained description of a

specific topic.

The following guides are available in the manual:

nAn overall table of contents at the beginning of the manual

nReferences with page numbers

The manual is available in:

nprinted form, on paper

nin electronic form as PDF-file (Adobe Acrobat Reader)

Important passages in the text are highlighted by following icons and headings:

DANGER!

Immediate or likely danger. Personal injury is possible.

CAUTION!

Damages to property is likely if these warnings are not heeded.

Supplementary information and useful tips.

Objective and contents

Target audience

Structure of the manual

Guide to the document

Availability

Icons Headings

VIPA System MICRO

General

About this manual

HB400 | PS | M07-2BA00 | en | 20-02 6

1.3 Safety instructions

DANGER!

There is a warning symbol on the housing of the power supply. This indi-

cates that all safety instructions listed in this manual must be observed

before commissioning!

DANGER!

Failure to comply with the specification may affect the protective functions

of the system!

The power supply is constructed and produced for:

nthe DC 24V supply of components.

noperation within the environmental conditions specified in the technical data

nthe installation on a 35mm mounting rail in a control cabinet, which provides protec-

tion against fire, environmental influences and mechanical impact

nindustrial applications

DANGER!

This device is not certified for applications in

– in explosive environments (EX-zone)

The manual must be available to all personnel in the

nproject design department

ninstallation department

ncommissioning

noperation

CAUTION!

The following conditions must be met before using or commis-

sioning the components described in this manual:

– Hardware modifications should only be carried out when the system

has been disconnected from power!

– Installation and hardware modifications only by properly trained per-

sonnel.

– The national rules and regulations of the respective country must be

satisfied (installation, safety, EMC ...)

National rules and regulations apply to the disposal of the unit!

Warning symbol on the

housing

Intended use

Documentation

Disposal

VIPA System MICRO General

Safety instructions

HB400 | PS | M07-2BA00 | en | 20-02 7

2 Basics and mounting

2.1 Safety information for users

VIPA modules make use of highly integrated components in MOS-Technology. These

components are extremely sensitive to over-voltages that can occur during electrostatic

discharges. The following symbol is attached to modules that can be destroyed by elec-

trostatic discharges.

The Symbol is located on the module, the module rack or on packing material and it indi-

cates the presence of electrostatic sensitive equipment. It is possible that electrostatic

sensitive equipment is destroyed by energies and voltages that are far less than the

human threshold of perception. These voltages can occur where persons do not dis-

charge themselves before handling electrostatic sensitive modules and they can damage

components thereby, causing the module to become inoperable or unusable. Modules

that have been damaged by electrostatic discharges can fail after a temperature change,

mechanical shock or changes in the electrical load. Only the consequent implementation

of protection devices and meticulous attention to the applicable rules and regulations for

handling the respective equipment can prevent failures of electrostatic sensitive modules.

Modules must be shipped in the original packing material.

When you are conducting measurements on electrostatic sensitive modules you should

take the following precautions:

nFloating instruments must be discharged before use.

nInstruments must be grounded.

Modifying electrostatic sensitive modules you should only use soldering irons with

grounded tips.

CAUTION!

Personnel and instruments should be grounded when working on electro-

static sensitive modules.

Handling of electrostatic

sensitive modules

Shipping of modules

Measurements and altera-

tions on electrostatic sen-

sitive modules

VIPA System MICRO

Basics and mounting

Safety information for users

HB400 | PS | M07-2BA00 | en | 20-02 8

2.2 System conception

The System MICRO is a modular automation system for assembly on a 35mm mounting

rail. By means of periphery modules this system may be adapted matching to your auto-

mation tasks. In addition, it is possible to expand your CPU by appropriate interfaces. The

wiring complexity is low, because the DC 24V electronic section supply is integrated to

the backplane bus and this allows replacement with standing wire.

nCPU

nExtension module

nPeriphery module

With the CPU electronic, input/output components and power supply are integrated to

one casing. In addition, up to 8 periphery modules of the System MICRO can be con-

nected to the backplane bus. As head module via the integrated power module for power

supply CPU electronic and the I/O components are supplied as well as the electronic of

the periphery modules, which are connected via backplane bus. To connect the power

supply of the I/O components and for DC 24V electronic power supply of the periphery

modules, which are connected via backplane bus, the CPU has removable connectors.

By installing of up to 8 periphery modules at the backplane bus of the CPU, these are

electrically connected, this means these are assigned to the backplane bus and con-

nected to the DC 24V electronic power supply.

By using extension modules you can extend the interfaces of the CPU. The attachment to

the CPU is made by plugging on the left side of the CPU. You can only connect one

extension module to the CPU at a time.

Overview

Components

CPU

Extension module

VIPA System MICRO Basics and mounting

System conception

HB400 | PS | M07-2BA00 | en | 20-02 9

The power supply is mounted on the left side from the DIN rail with the System MICRO

modules. It serves for electronics and power supply.

By means of up to 8 periphery modules, you can extend the internal I/O areas. The

attachment to the CPU is made by plugging them on the right side of the CPU.

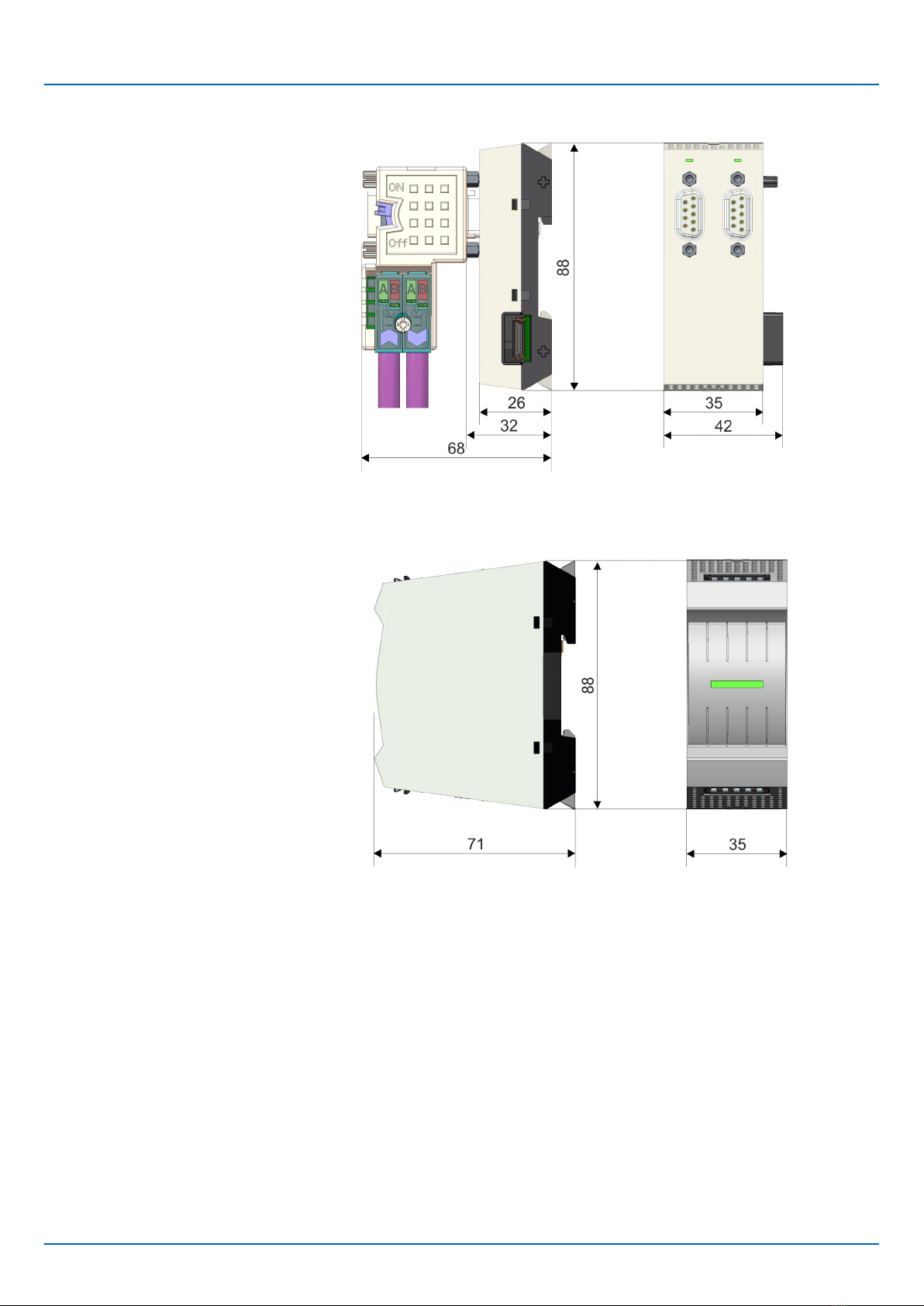

2.3 Dimensions

Dimensions in mm

Power supply

Periphery module

Dimensions CPU M13C

VIPA System MICRO

Basics and mounting

Dimensions

HB400 | PS | M07-2BA00 | en | 20-02 10

Dimensions in mm

Dimensions extension

module EM M09

Dimensions power supply

VIPA System MICRO Basics and mounting

Dimensions

HB400 | PS | M07-2BA00 | en | 20-02 11

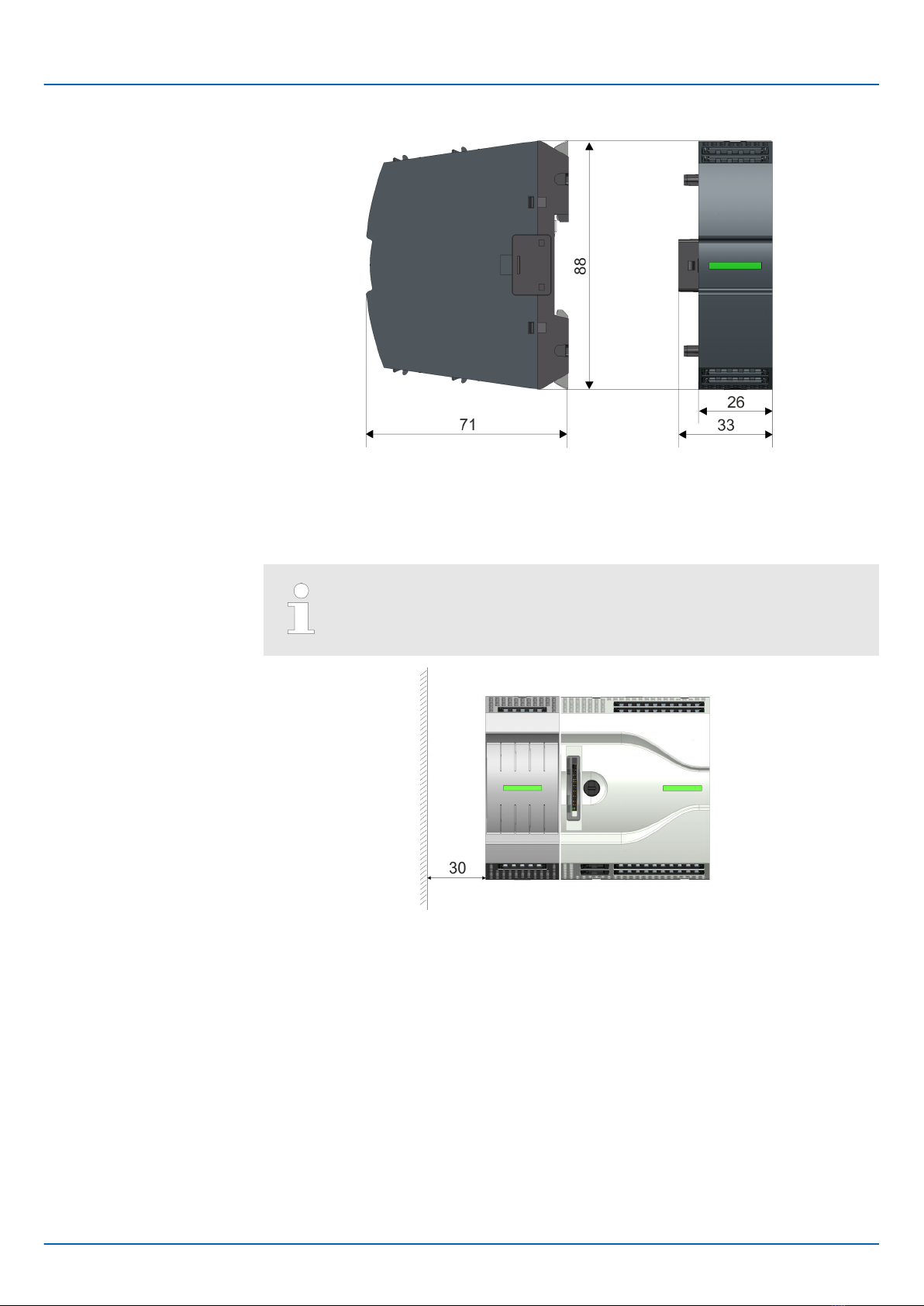

Dimensions in mm

2.4 Mounting

Observe minimum distance!

For operation within the specified nominal values, they must comply with

a minimum distance of 30 mm on one side of the module!

Dimensions in mm

Dimensions periphery

module

VIPA System MICRO

Basics and mounting

Mounting

HB400 | PS | M07-2BA00 | en | 20-02 12

2.4.1 Mounting without mounting rail

You can screw the power supply to the back wall by means of screws via the locking

levers. The happens with the following proceeding:

Dimensions in mm

1. The power supply has a locking lever on the upper and lower side. Pull these levers

outwards as shown in the figure, until these engage 2x audible.

ðBy this openings on the locking levers get visible.

2. Use this openings to fix your power supply to your back wall with appropriate

screws. Consider the installation clearances for the power supply.

ðThe power supply is now mounted and can be wired.

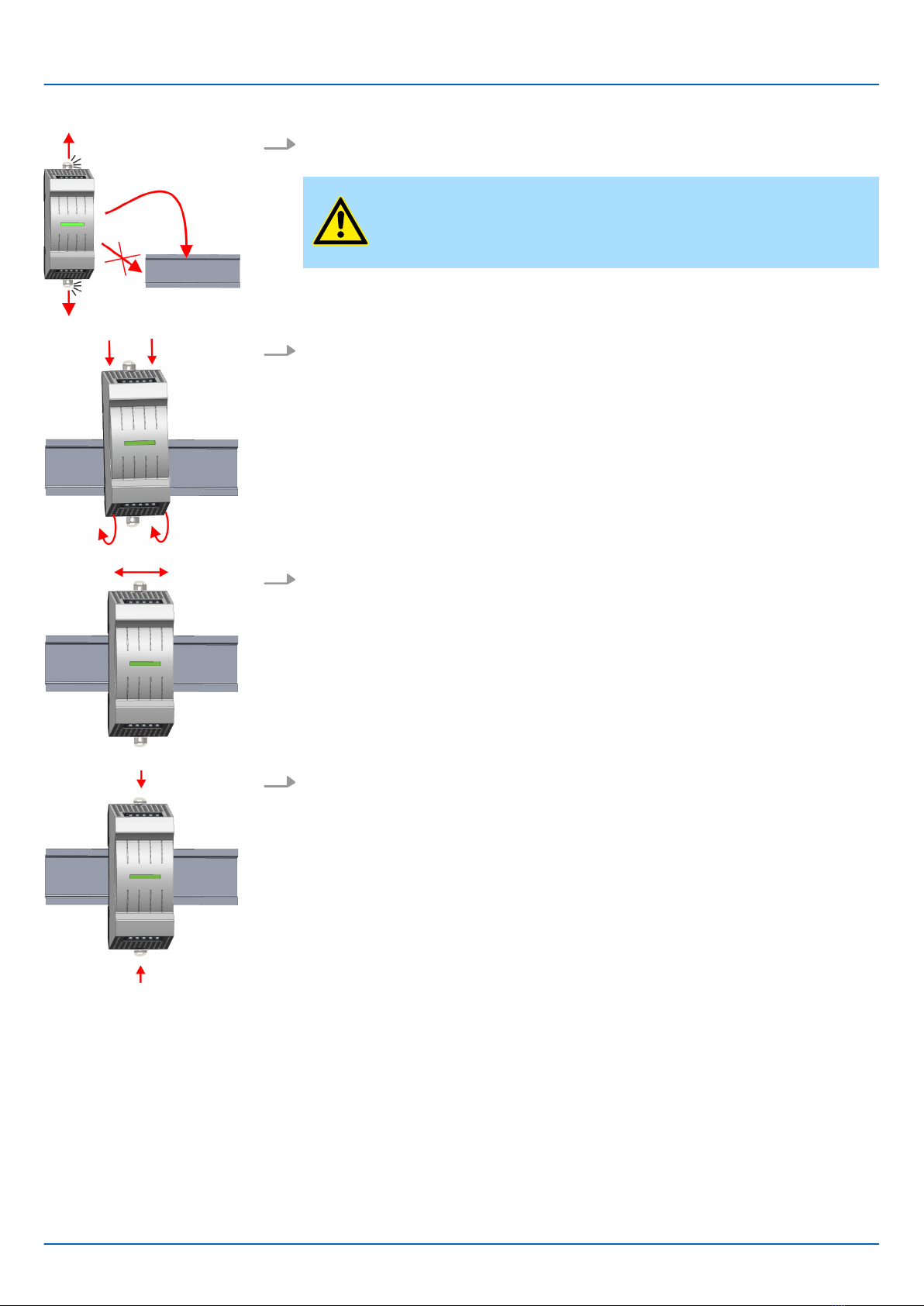

2.4.2 Mounting with mounting rail

Dimensions in mm

1. Mount the mounting rail. Please consider that a clearance from the middle of the

mounting rail of at least 44mm respectively 55mm above and below exists.

Proceeding

Proceeding

VIPA System MICRO Basics and mounting

Mounting > Mounting with mounting rail

HB400 | PS | M07-2BA00 | en | 20-02 13

2. The power supply has a locking lever on the upper and lower side. Pull these levers

outwards as shown in the figure, until these engage audible.

CAUTION!

It is not allowed to mount the module sideways on the mounting rail,

as otherwise the module may be damaged.

3. Plug the power supply from the top onto the mounting rail and turn the power supply

downward until it rests on the mounting rail.

4. Move the power supply on the mounting rail at its position.

5. To fix the power supply at the mounting rail, move the locking levers back to the ini-

tial position.

ðThe power supply is now mounted and can be wired.

VIPA System MICRO

Basics and mounting

Mounting > Mounting with mounting rail

HB400 | PS | M07-2BA00 | en | 20-02 14

2.5 Wiring

DANGER!

Consider strain relief of the supply lines!

Since the plug for the supply lines of the input voltage has no (double)

insulation, not permanently fixed supply lines must be relieved from push

and pull!

CAUTION!

Consider temperature for external cables!

Cables may experience temperature increase due to system heat dissi-

pation. Thus the cabling specification must be chosen 25°C above

ambient temperature!

CAUTION!

Separate insulation areas!

The system is specified for SELV/PELV environment. Devices, which are

attached to the system must meet theses specifications. Installation and

cable routing other than SELV/PELV specification must be separated

from the system’s equipment!

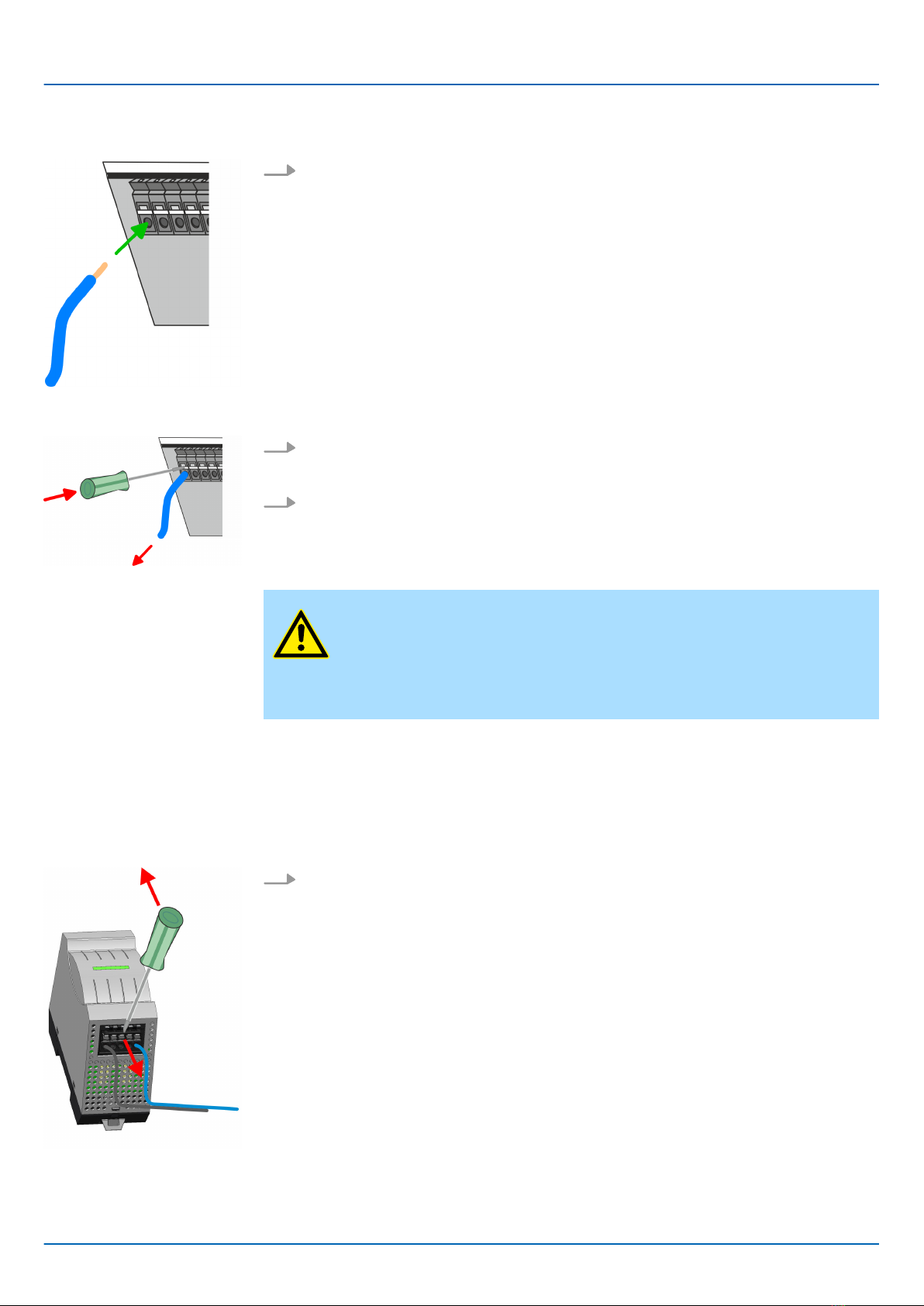

2.5.1 Wiring power supply

For wiring the power supply has removable connectors. With the wiring of the connectors

a "push-in" spring-clip technique is used. This allows a quick and easy connection of your

supply lines. The clamping off takes place by means of a screwdriver.

Umax 240V AC / 30V DC

Imax 2A

Cross section 0.2 ... 1.5mm2 (AWG 24 ... 16)

Stripping length 10mm

Use for wiring rigid wires respectively use wire sleeves. When using stranded wires you

have to press the release button with a screwdriver during the wiring.

1 Labeling on the casing

2 Release area

3 Connection hole for wire

4 Pin 1 of the connector is labelled by a white line.

Connectors

Data

Wiring procedure

VIPA System MICRO Basics and mounting

Wiring > Wiring power supply

HB400 | PS | M07-2BA00 | en | 20-02 15

The wiring happens without a tool.

Determine according to the casing labelling the connection position and insert

through the round connection hole of the according contact your prepared wire until

it stops, so that it is fixed.

ðBy pushing the contact spring opens, thus ensuring the necessary contact pres-

sure.

The wire is to be removed by means of a screwdriver with 2.5mm blade width.

1. Press with your screwdriver vertically at the release button.

ðThe contact spring releases the wire.

2. Pull the wire from the round hole.

CAUTION!

To protect the power supply lines, you should use a circuit breaker with

the following characteristics:

– Rated current at AC 230V: 4A

– Tripping characteristic: C

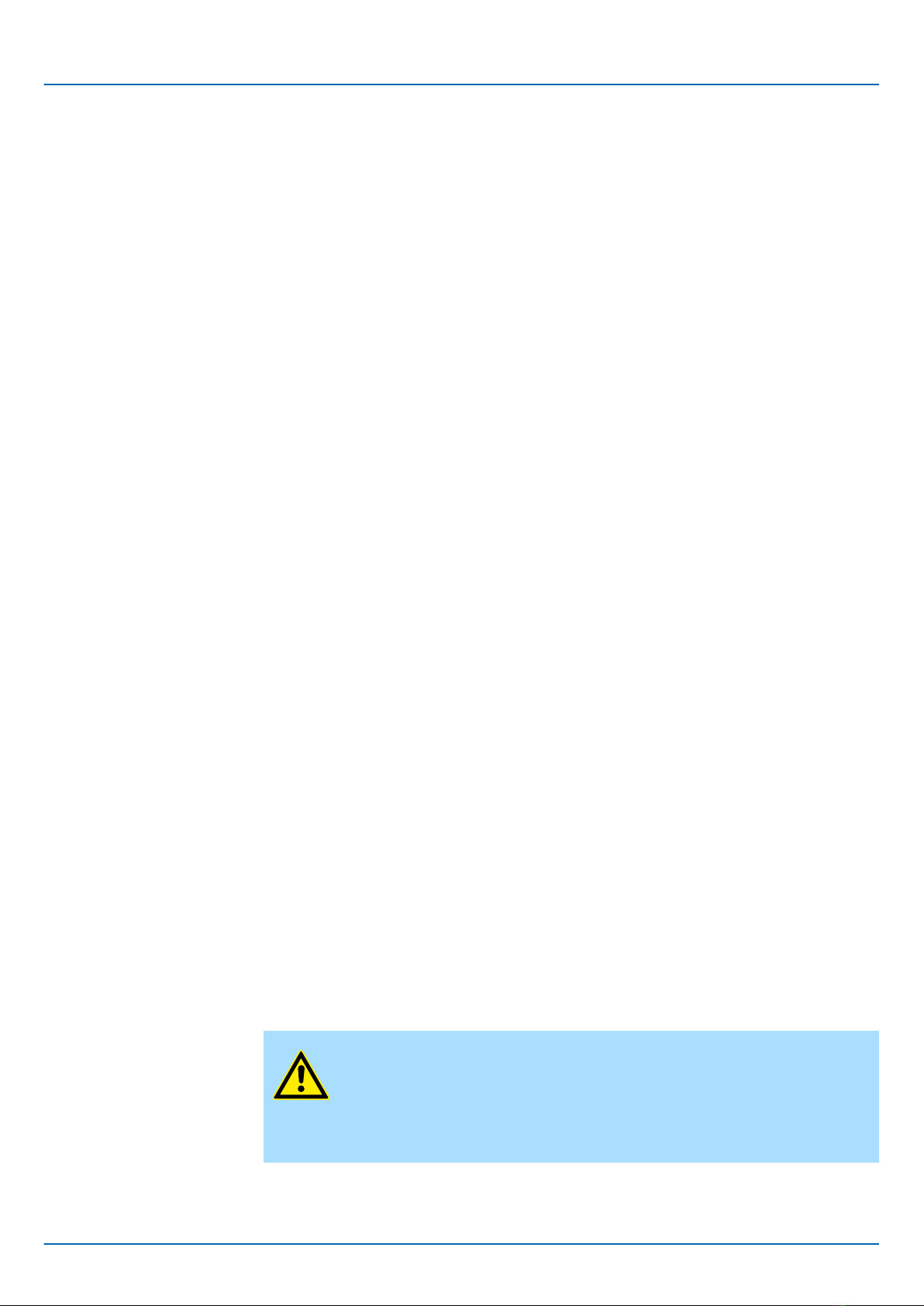

2.6 Demounting

By means of a screwdriver there is the possibility to remove the connectors e.g. for

module exchange with a fix wiring. For this each connector has indentations for unlocking

at the top. Unlocking takes place by the following proceeding:

1. Remove connector:

Insert your screwdriver from above into one of the indentations.

Insert wire

Remove wire

Fusing

Remove connector

VIPA System MICRO

Basics and mounting

Demounting

HB400 | PS | M07-2BA00 | en | 20-02 16

2. Push the screwdriver backwards:

ðThe connector is unlocked and can be removed.

CAUTION!

Via wrong operation such as pressing the screwdriver down-

ward, the release lever may be damaged.

3. In this way, remove all plugged connectors on the power supply.

The replacement of the power supply on the mounting rail happens with the following pro-

ceeding:

1. Use a screwdriver to pull the locking levers of the power supply outwards until these

engage audible.

2. Remove the power supply with a rotation upwards from the mounting rail.

3. Pull the locking levers of the new power supply outwards until these engage

audible. Plug the power supply from the top onto the mounting rail and turn the

power supply downward until it rests on the mounting rail.

CAUTION!

It is not allowed to mount the module sideways on the mounting rail,

as otherwise the module may be damaged!

Power supply replacement

Replacement on mounting

rail

VIPA System MICRO Basics and mounting

Demounting

HB400 | PS | M07-2BA00 | en | 20-02 17

4. Move the power supply on the mounting rail at its position.

5. To fix the power supply at the mounting rail, move the locking levers back to the ini-

tial position.

ðThe power supply is now mounted and can be wired.

1. Remove the connectors, which are not necessary at the power supply.

2. Plug again the wired connectors.

ðNow you can bring your system back into operation.

Plug connector

VIPA System MICRO

Basics and mounting

Demounting

HB400 | PS | M07-2BA00 | en | 20-02 18

2.7 Installation guidelines

The installation guidelines contain information about the interference free deployment of a

PLC system. There is the description of the ways, interference may occur in your PLC,

how you can make sure the electromagnetic compatibility (EMC), and how you manage

the isolation.

Electromagnetic compatibility (EMC) means the ability of an electrical device, to function

error free in an electromagnetic environment without being interfered respectively without

interfering the environment.

The VIPA components are developed for the deployment in industrial environments and

meets high demands on the EMC. Nevertheless you should project an EMC planning

before installing the components and take conceivable interference causes into account.

Electromagnetic interferences may interfere your control via different ways:

nElectromagnetic fields (RF coupling)

nMagnetic fields with power frequency

nBus system

nPower supply

nProtected earth conductor

Depending on the spreading medium (lead bound or lead free) and the distance to the

interference cause, interferences to your control occur by means of different coupling

mechanisms.

There are:

ngalvanic coupling

ncapacitive coupling

ninductive coupling

nradiant coupling

In the most times it is enough to take care of some elementary rules to guarantee the

EMC. Please regard the following basic rules when installing your PLC.

nTake care of a correct area-wide grounding of the inactive metal parts when installing

your components.

– Install a central connection between the ground and the protected earth conductor

system.

– Connect all inactive metal extensive and impedance-low.

– Please try not to use aluminium parts. Aluminium is easily oxidizing and is there-

fore less suitable for grounding.

nWhen cabling, take care of the correct line routing.

– Organize your cabling in line groups (high voltage, current supply, signal and data

lines).

– Always lay your high voltage lines and signal respectively data lines in separate

channels or bundles.

– Route the signal and data lines as near as possible beside ground areas (e.g.

suspension bars, metal rails, tin cabinet).

General

What does EMC mean?

Possible interference

causes

Basic rules for EMC

VIPA System MICRO Basics and mounting

Installation guidelines

HB400 | PS | M07-2BA00 | en | 20-02 19

nProof the correct fixing of the lead isolation.

– Data lines must be laid isolated.

– Analog lines must be laid isolated. When transmitting signals with small ampli-

tudes the one sided laying of the isolation may be favourable.

– Lay the line isolation extensively on an isolation/protected earth conductor rail

directly after the cabinet entry and fix the isolation with cable clamps.

– Make sure that the isolation/protected earth conductor rail is connected impe-

dance-low with the cabinet.

– Use metallic or metallised plug cases for isolated data lines.

nIn special use cases you should appoint special EMC actions.

– Consider to wire all inductivities with erase links.

– Please consider luminescent lamps can influence signal lines.

nCreate a homogeneous reference potential and ground all electrical operating sup-

plies when possible.

– Please take care for the targeted employment of the grounding actions. The

grounding of the PLC serves for protection and functionality activity.

– Connect installation parts and cabinets with your PLC in star topology with the

isolation/protected earth conductor system. So you avoid ground loops.

– If there are potential differences between installation parts and cabinets, lay suffi-

ciently dimensioned potential compensation lines.

Electrical, magnetically and electromagnetic interference fields are weakened by means

of an isolation, one talks of absorption. Via the isolation rail, that is connected conductive

with the rack, interference currents are shunt via cable isolation to the ground. Here you

have to make sure, that the connection to the protected earth conductor is impedance-

low, because otherwise the interference currents may appear as interference cause.

When isolating cables you have to regard the following:

nIf possible, use only cables with isolation tangle.

nThe hiding power of the isolation should be higher than 80%.

nNormally you should always lay the isolation of cables on both sides. Only by means

of the both-sided connection of the isolation you achieve high quality interference

suppression in the higher frequency area. Only as exception you may also lay the iso-

lation one-sided. Then you only achieve the absorption of the lower frequencies. A

one-sided isolation connection may be convenient, if:

– the conduction of a potential compensating line is not possible.

– analog signals (some mV respectively µA) are transferred.

– foil isolations (static isolations) are used.

nWith data lines always use metallic or metallised plugs for serial couplings. Fix the

isolation of the data line at the plug rack. Do not lay the isolation on the PIN 1 of the

plug bar!

nAt stationary operation it is convenient to strip the insulated cable interruption free

and lay it on the isolation/protected earth conductor line.

nTo fix the isolation tangles use cable clamps out of metal. The clamps must clasp the

isolation extensively and have well contact.

nLay the isolation on an isolation rail directly after the entry of the cable in the cabinet.

Lead the isolation further on to your PLC and don't lay it on there again!

CAUTION!

Please regard at installation!

At potential differences between the grounding points, there may be a

compensation current via the isolation connected at both sides.

Remedy: Potential compensation line

Isolation of conductors

VIPA System MICRO

Basics and mounting

Installation guidelines

HB400 | PS | M07-2BA00 | en | 20-02 20

This manual suits for next models

1

Table of contents

Other YASKAWA Power Supply manuals

YASKAWA

YASKAWA PS-A10HB User manual

YASKAWA

YASKAWA JEPMC-PSD3012-E User manual

YASKAWA

YASKAWA VIPA System 300S User manual

YASKAWA

YASKAWA U1000 Series User manual

YASKAWA

YASKAWA PS 307-1BA00 User manual

YASKAWA

YASKAWA SGMJ Series User manual

YASKAWA

YASKAWA PS-A10L User manual

YASKAWA

YASKAWA PS-A10LB User manual

Popular Power Supply manuals by other brands

HP

HP Lab Series OPERATING & SERVICE MANUAL

Electro-Automatik

Electro-Automatik PS 3000 C Series operating manual

Larson Electronics

Larson Electronics IND-MD-DF-ESF-R1 instruction manual

Gallagher

Gallagher S10 instructions

Vessel

Vessel HPB Series instruction manual

Tecnoware

Tecnoware EVO DSP PLUS TT 10 KVA user manual