Electro-Automatik PS 3000 C Series User manual

Elektro-Automatik

PS 3000 C

DC Power Supply

Operating Manual

Attention! This document is only

valid for devices with rmwares

“KE: 2.03”, “HMI: 2.02” and “DR:

2.0.1” or higher.

Doc ID: PS3EN

Revision: 02

Date: 04/2021

Page 3

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

TABLE OF CONTENTS

1GENERAL

1.1 About this document......................................4

1.1.1 Retention and use..........................................4

1.1.2 Copyright........................................................4

1.1.3 Validity ............................................................4

1.1.4 Symbols and warnings ..................................4

1.2 Warranty.........................................................4

1.3 Limit of liability ................................................4

1.4 Disposal of equipment ...................................5

1.5 Product key ....................................................5

1.6 Intended usage ..............................................5

1.7 Safety .............................................................6

1.7.1 Safety notices.................................................6

1.7.2 Responsibility of the user...............................6

1.7.3 Responsibility of the operator .......................7

1.7.4 User requirements .........................................7

1.7.5 Alarm signals..................................................8

1.8 Technical data ................................................8

1.8.1 Approved operating conditions......................8

1.8.2 General technical data...................................8

1.8.3 Specic technical data ...................................9

1.8.4 Views............................................................15

1.8.5 Control elements..........................................17

1.9 Construction and function............................18

1.9.1 General description......................................18

1.9.2 Block diagram ..............................................18

1.9.3 Scope of delivery .........................................19

1.9.4 Optional accessories ...................................19

1.9.5 The control panel (HMI)...............................20

1.9.6 USB port (optional) ......................................22

1.9.7 Ethernet port (optional) ................................22

1.9.8 Analog interface (optional)...........................23

1.9.9 “Sense” connector (remote sensing)...........23

2INSTALLATION &

COMMISSIONING

2.1 Storage.........................................................24

2.1.1 Packaging ....................................................24

2.1.2 Storage.........................................................24

2.2 Unpacking and visual check........................24

2.3 Installation ....................................................24

2.3.1 Safety procedures before installation and

use................................................................24

2.3.2 Preparation...................................................24

2.3.3 Installing the device .....................................24

2.3.4 Connection to DC loads...............................26

2.3.5 Grounding of the DC output ........................26

2.3.6 Connection of remote sensing ....................27

2.3.7 Connecting the analog interface .................27

2.3.8 Connecting the USB port.............................27

2.3.9 Connecting the LAN port .............................28

2.3.10 Initial commission.........................................28

2.3.11 Commission after a rmware update or a

long period of non use .................................28

3OPERATION AND APPLICATION

3.1 Personal safety ............................................29

3.2 Operating modes .........................................29

3.2.1 Voltage regulation / Constant voltage .........29

3.2.2 Current regulation / constant current / current

limitation .......................................................30

3.2.3 Power regulation / constant power / power

limitation .......................................................30

3.3 Alarm conditions ..........................................31

3.3.1 Power Fail ...................................................31

3.3.2 Overtemperature..........................................31

3.3.3 Overvoltage..................................................31

3.3.4 Overcurrent protection.................................31

3.3.5 Overpower protection ..................................31

3.4 Manual operation .........................................32

3.4.1 Powering the device ....................................32

3.4.2 Switching the device o...............................32

3.4.3 Conguration via MENU..............................32

3.4.4 Adjustment limits..........................................36

3.4.5 Manual adjustment of set values.................36

3.4.6 Switching the main screen view ..................37

3.4.7 Switching the DC output on or o ...............37

3.5 Remote control.............................................38

3.5.1 General.........................................................38

3.5.2 Controls locations ........................................38

3.5.3 Remote control via a digital interface ..........38

3.5.4 Remote control via the analog interface

(AI)................................................................39

3.6 Alarms and monitoring.................................43

3.6.1 Device alarm and event handling................43

3.7 Control panel (HMI) lock..............................44

3.8 Loading and saving a user prole ...............45

3.9 Other applications........................................46

3.9.1 Series connection ........................................46

3.9.2 Parallel operation .........................................46

3.9.3 Operation as battery charger.......................46

4SERVICE AND MAINTENANCE

4.1 Maintenance / cleaning................................47

4.2 Fault nding / diagnosis / repair...................47

4.2.1 Replacing a defect mains fuse ....................47

4.2.2 Firmware updates ........................................47

5CONTACT AND SUPPORT

5.1 Repairs .........................................................48

5.2 Contact options ............................................48

Page 4

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

1. General

1.1 About this document

1.1.1 Retention and use

This document is to be kept in the vicinity of the equipment for future reference and explanation of the operation of

the device. This document is to be delivered and kept with the equipment in case of change of location and/or user.

1.1.2 Copyright

Reprinting, copying, also partially, usage for other purposes as foreseen of this manual are forbidden and breach

may lead to legal process.

1.1.3 Validity

This manual is valid for the following equipment, including derived variants.

Model Article number Model Article number

PS 3040-10 C 35 320 208 PS 3200-04 C 35 320 213

PS 3080-05 C 35 320 209 PS 3040-40 C 35 320 214

PS 3200-02 C 35 320 210 PS 3080-20 C 35 320 215

PS 3040-20 C 35 320 211 PS 3200-10 C 35 320 216

PS 3080-10 C 35 320 212

1.1.4 Symbols and warnings

Warning and safety notices as well as general notices in this document are shown in a box with a symbol as follows:

Symbol for a life threatening danger

Symbol for general safety notices (instructions and damage protection bans)

Symbol for general notices

1.2 Warranty

EA Elektro-Automatik guarantees the functional competence of the device within the stated performance param-

eters. The warranty period begins with the delivery of free from defects equipment.

Terms of guarantee are included in the general terms and conditions of EA Elektro-Automatik.

1.3 Limit of liability

All statements and instructions in this manual are based on current norms and regulations, up-to-date technology

and our long term knowledge and experience. EA Elektro-Automatik accepts no liability for losses due to:

• Usage for purposes other than dened

• Use by untrained personnel

• Rebuilding by the customer

• Technical changes

• Use of non authorized spare parts

The actual delivered device(s) may dier from the explanations and diagrams given here due to latest technical

changes or due to customized models with the inclusion of additionally ordered options.

Page 5

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

1.4 Disposal of equipment

A piece of equipment which is intended for disposal must, according to European laws and regulations (ElektroG,

WEEE) be returned to EA Elektro-Automatik for scrapping, unless the person operating the piece of equipment or

another, delegated person is conducting the disposal. Our equipment falls under these regulations and is accord-

ingly marked with the following symbol:

1.5 Product key

Decoding of the product description on the label, using an example:

PS 3 080 - 10 C

Construction/Version:

C= Third generation

Maximum current of the device in Ampere

Maximum voltage of the device in Volt

Series: 3= Series 3000

Type identication:

PS = Power Supply, usually programmable

1.6 Intended usage

The equipment is intended to be used, if a power supply or battery charger, only as a variable voltage and current

source, or, if an electronic load, only as a variable current sink.

Typical application for a power supply is DC supply to any relevant user, for a battery charger the charging of vari-

ous battery types and for electronic loads the replacement of Ohm resistance by an adjustable DC current sink in

order to load relevant voltage and current sources of any type.

• Claims of any sort due to damage caused by non-intended usage will not be accepted.

• All damage caused by non-intended usage is solely the responsibility of the operator.

Page 6

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

1.7 Safety

1.7.1 Safety notices

Mortal danger - Hazardous voltage

• Electrical equipment operation means that some parts will be under dangerous voltage.

Therefore all parts under voltage must be covered!

• All work on connections must be carried out under zero voltage (output not connected

to a load which is also a voltage source) and may only be performed by qualied and

informed persons. Improper actions can cause fatal injury as well as serious material

damage.

• Never touch cables or connectors directly after unplugging from mains supply as the

danger of electric shock remains.

• Never touch a blank contact on the DC output right after usage of the device, because

between DC- and DC+ there is potential against ground (PE) which discharges more or

less slowly or not at all!

• The equipment must only be used as intended

• The equipment is only approved for use within the connection limits stated on the product label.

• Do not insert any object, particularly metallic, through the ventilator slots

• Avoid any use of liquids near the equipment. Protect the device from wet, damp and conden-

sation.

• For power supplies and battery chargers: do not connect loads, particularly such with low

resistance, while the DC output is switched on; sparking may occur which can cause burns

as well as damage to the equipment and to the user.

• For electronic loads: do not connect power sources to equipment under power, sparking may

occur which can cause burns as well as damage to the equipment and to the source.

• ESD regulations must be applied when plugging interface cards or modules into the relative slot

• Interface cards or modules may only be attached or removed after the device is switched o.

It’sn’t necessary to open the device.

• Do not connect external power sources with reversed polarity to DC inputs or outputs! The

equipment will be damaged.

• For power supply devices: avoid where possible connecting external power sources to the

DC output, and never those that can generate a higher voltage than the nominal voltage of

the device.

• For electronic loads: do not connect a power source to the DC input which can generate a

voltage more than 120% of the nominal input voltage of the load. The equipment isn’t protected

against over voltage and may be irreparably damaged.

• Always congure the various protecting features against overcurrent, overpower etc. for sensi-

tive sources to what the currently used application requires

1.7.2 Responsibility of the user

The equipment is in industrial operation. Therefore the operators are governed by the legal safety regulations.

Alongside the warning and safety notices in this manual the relevant safety, accident prevention and environmental

regulations must also be applied. In particular the users of the equipment:

• must be informed of the relevant job safety requirements

• must work to the dened responsibilities for operation, maintenance and cleaning of the equipment

• before starting work must have read and understood the operating manual

• must use the designated and recommended safety equipment.

Furthermore, anyone working with the equipment is responsible for ensuring that the device is at all times techni-

cally t for use.

Page 7

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

1.7.3 Responsibility of the operator

Operator is any natural or legal person who uses the equipment or delegates the usage to a third party, and is

responsible during its usage for the safety of the user, other personnel or third parties.

The equipment is in industrial operation. Therefore the operators are governed by the legal safety regulations.

Alongside the warning and safety notices in this manual the relevant safety, accident prevention and environmental

regulations must also be applied. In particular the operator has to

• be acquainted with the relevant job safety requirements

• identify other possible dangers arising from the specic usage conditions at the work station via a risk assessment

• introduce the necessary steps in the operating procedures for the local conditions

• regularly check that the operating procedures are current

• update the operating procedures where necessary to reect changes in regulation, standards or operating con-

ditions.

• dene clearly and unambiguously the responsibilities for operation, maintenance and cleaning of the equipment.

• ensure that all employees who use the equipment have read and understood the manual. Furthermore the users

are to be regularly schooled in working with the equipment and the possible dangers.

• provide all personnel who work with the equipment with the designated and recommended safety equipment

Furthermore, the operator is responsible for ensuring that the device is at all times technically t for use.

1.7.4 User requirements

Any activity with equipment of this type may only be performed by persons who are able to work correctly and

reliably and satisfy the requirements of the job.

• Persons whose reaction capability is negatively inuenced by e.g. drugs, alcohol or medication may not operate

the equipment.

• Age or job related regulations valid at the operating site must always be applied.

Danger for unqualied users

Improper operation can cause person or object damage. Only persons who have the necessary training,

knowledge and experience may use the equipment.

Delegated persons are those who have been properly and demonstrably instructed in their tasks and the atten-

dant dangers.

Qualied persons are those who are able through training, knowledge and experience as well as knowledge of

the specic details to carry out all the required tasks, identify dangers and avoid personal and other risks.

Page 8

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

1.7.5 Alarm signals

The equipment oers various possibilities for signalling alarm conditions, however, not for danger situations. The

signals may be optical (on the display as text) acoustic (piezo buzzer) or electronic (pin/status output of an analog

interface). All alarms will cause the device to switch o the DC output.

The meaning of the signals is as follows:

Signal OT

(OverTemperature)

• Overheating of the device

• DC output will be switched o

• Non-critical

Signal OVP

(OverVoltage)

• Overvoltage shutdown of the DC output occurs due to high voltage being generated by

the device or is entering the device from outside

• Critical! The device and/or the load could be damaged

Signal OCP

(OverCurrent)

• Shutdown of the DC output due to excess of the preset limit

• Non-critical, protects the load from excessive current drain

Signal OPP

(OverPower)

• Shutdown of the DC output due to excess of the preset limit

• Non-critical, protects the load from excessive power drain

Signal PF

(Power Fail)

• DC output shutdown due to AC undervoltage or internal auxiliary supply defect

• Critical on AC overvoltage! AC mains input circuit could be damaged

1.8 Technical data

1.8.1 Approved operating conditions

• Use only inside dry buildings

• Ambient temperature 0-50 °C

• Operational altitude: max. 2000 m above sea level

• Maximum 80% humidity, not condensing

1.8.2 General technical data

Display: Colour TFT display, 480pt x 128pt

Controls: 2 rotary knobs with pushbutton functions, 7 pushbuttons

The nominal values for the device determine the maximum adjustable ranges.

Page 9

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

1.8.3 Specic technical data

160 W

Model

PS 3040-10 C PS 3080-05 C PS 3200-02 C

AC supply

Voltage range 90...264 V AC 90...264 V AC 90...264 V AC

Connection Wall outlet Wall outlet Wall outlet

Frequency 45-65 Hz 45-65 Hz 45-65 Hz

Fusing MT 4 A MT 4 A MT 4 A

Inrush current @ 230 V ≈ 23 A ≈ 23 A ≈ 23 A

Leak current < 3.5 mA < 3.5 mA < 3.5 mA

Power factor ≈ 0.99 ≈ 0.99 ≈ 0.99

DC output

Max. output voltage UMax 40 V 80 V 200 V

Max. output current IMax 10 A 5 A 2 A

Max. output power PMax 160 W 160 W 160 W

Overvoltage protection range 0...44 V 0...88 V 0...220 V

Overcurrent protection range 0...11 A 0...5.5 A 0...2.2 A

Overpower protection range 0…176 W 0…176 W 0…176 W

Output capacitance 3225 μF 1210 μF 294 μF

Temperature coecient for set values Δ/K Voltage / current: 100 ppm

Voltage regulation

Adjustment range 0...40.8 V 0...81.6 V 0...204 V

Accuracy (1 (at 23 ± 5°C) < 0.1% UMax < 0.1% UMax < 0.1% UMax

Line regulation at ±10% ΔUAC < 0.02% UMax < 0.02% UMax < 0.02% UMax

Load regulation at 0...100% load < 0.05% UMax < 0.05% UMax < 0.05% UMax

Settling time after load step < 1.5 ms < 1.5 ms < 1.5 ms

Display: Resolution See section „1.9.5.4. Resolution of the displayed values“

Display: Accuracy (3 ≤ 0.2% UMax ≤ 0.2% UMax ≤ 0.2% UMax

Ripple (2 < 30 mVPP

< 3 mVRMS

< 35 mVPP

< 4 mVRMS

< 70 mVPP

< 13 mVRMS

Remote sensing compensation Max. 5% UMax Max. 5% UMax Max. 5% UMax

Output voltage fall time (at no load) after

switching DC output o - Down from 100% to <60 V: less than 10 s

Current regulation

Adjustment range 0...10.2 A 0...5.1 A 0...2.04 A

Accuracy (1 (at 23 ± 5°C) < 0.2% IMax < 0.2% IMax < 0.2% IMax

Line regulation at ±10% ΔUAC < 0.05% IMax < 0.05% IMax < 0.05% IMax

Load regulation at 0...100% ΔUOUT < 0.15% IMax < 0.15% IMax < 0.15% IMax

Ripple (2 < 15 mARMS < 7.5 mARMS < 3 mARMS

Display: Resolution See section „1.9.5.4. Resolution of the displayed values“

Display: Accuracy (3 ≤ 0.2% IMax ≤ 0.2% IMax ≤ 0.2% IMax

Power regulation

Adjustment range 0…163.2 W 0…163.2 W 0…163.2 W

Accuracy (1 (at 23 ± 5°C) < 1% PMax < 1% PMax < 1% PMax

Line regulation at ±10% ΔUAC < 0.05% PMax < 0.05% PMax < 0.05% PMax

Load regulation at 10-90% ΔUOUT * ΔIOUT < 1% PMax < 1% PMax < 1% PMax

(1 Related to the nominal values, the accuracy denes the maximum deviation between an adjusted values and the true (actual) value.

(2 RMS value: LF 0...300 kHz, PP value: HF 0...20MHz

(3 The display error adds to the error of the related actual value on the DC output

Page 10

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

160 W

Model

PS 3040-10 C PS 3080-05 C PS 3200-02 C

Power regulation

Display: Resolution See section „1.9.5.4. Resolution of the displayed values“

Display: Accuracy (1 ≤ 0,5% PNenn ≤ 0,5% PNenn ≤ 0,5% PNenn

Analog interface (optional) (2

Set value inputs U, I, P

Actual value output U, I

Control signals DC on/o, remote control on/o

Status signals CV, OVP, OT

Insulation

Output (DC) to enclosure (PE) DC minus: permanent max. ±400 V

DC plus: permanent max. ±400V + output voltage

Input (AC) to output (DC) Max. 2500 V, short-term

Miscellaneous

Cooling Temperature controlled fan, side inlet, rear exhaust

Ambient temperature 0..50°C

Storage temperature -20...70°C

Humidity < 80%, not condensing

Standards EN 61010-1:2011-07, EN 61000-6-4:2011-09, EN 61000-6-2:2011-06 Class B

Overvoltage category 2

Protection class 1

Pollution degree 2

Operational altitude < 2000 m

Digital interfaces (optional)

Available plug-in cards

IF-KE5 USB: 1x USB

IF-KE5 USBLAN: 1x USB + 1x LAN

IF-KE5 USBANALOG: 1x USB + 1x Analog

Terminals

Rear side AC input, analog interface (optional), USB (optional), Ethernet (optional)

Front side DC output, USB-A, remote sensing

Dimensions

Enclosure (WxHxD) 260 x 88 x 323 mm

Total (WxHxD) 308 x min. 103 x min. 359 mm

Weight ≈ 4 kg ≈ 4 kg ≈ 4 kg

Article number 35320208 35320209 35320210

(1 The display error adds to the error of the related actual value on the DC output

(3 For technical specications of the analog interface see „3.5.4.4 Analog interface specication“ on page 40

Page 11

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

320 W

Model

PS 3040-20 C PS 3080-10 C PS 3200-04 C

AC supply

Voltage range 90...264 V AC 90...264 V AC 90...264 V AC

Connection Wall outlet Wall outlet Wall outlet

Frequency 45-65 Hz 45-65 Hz 45-65 Hz

Fusing MT 4 A MT 4 A MT 4 A

Inrush current @ 230 V ≈ 23 A ≈ 23 A ≈ 23 A

Leak current < 3.5 mA < 3.5 mA < 3.5 mA

Power factor ≈ 0.99 ≈ 0.99 ≈ 0.99

DC output

Max. output voltage UMax 40 V 80 V 200 V

Max. output current IMax 20 A 10 A 4 A

Max. output power PMax 320 W 320 W 320 W

Overvoltage protection range 0...44 V 0...88 V 0...220 V

Overcurrent protection range 0...22 A 0...11 A 0...4.4 A

Overpower protection range 0…352 W 0…352 W 0…352 W

Output capacitance 3225 μF 1210 μF 294 μF

Temperature coecient for set values Δ/K Voltage / current: 100 ppm

Voltage regulation

Adjustment range 0...40.8 V 0...81.6 V 0...204 V

Accuracy (1 (at 23 ± 5°C) < 0.1% UMax < 0.1% UMax < 0.1% UMax

Line regulation at ±10% ΔUAC < 0.02% UMax < 0.02% UMax < 0.02% UMax

Load regulation at 0...100% load < 0.05% UMax < 0.05% UMax < 0.05% UMax

Settling time after load step < 1.5 ms < 1.5 ms < 1.5 ms

Display: Resolution See section „1.9.5.4. Resolution of the displayed values“

Display: Accuracy (3 ≤ 0.2% UMax ≤ 0.2% UMax ≤ 0.2% UMax

Ripple (2 < 30 mVPP

< 3 mVRMS

< 35 mVPP

< 4 mVRMS

< 70 mVPP

< 13 mVRMS

Remote sensing compensation Max. 5% UMax Max. 5% UMax Max. 5% UMax

Output voltage fall time (at no load) after

switching DC output o - Down from 100% to <60 V: less than 10 s

Current regulation

Adjustment range 0...20.4 A 0...10.2 A 0...4.08 A

Accuracy (1 (at 23 ± 5°C) < 0.2% IMax < 0.2% IMax < 0.2% IMax

Line regulation at ±10% ΔUAC < 0.05% IMax < 0.05% IMax < 0.05% IMax

Load regulation at 0...100% ΔUOUT < 0.15% IMax < 0.15% IMax < 0.15% IMax

Ripple (2 < 20 mARMS < 15 mARMS < 6 mARMS

Display: Resolution See section „1.9.5.4. Resolution of the displayed values“

Display: Accuracy (3 ≤ 0.2% IMax ≤ 0.2% IMax ≤ 0.2% IMax

Power regulation

Adjustment range 0…326.4 W 0…326.4 W 0…326.4 W

Accuracy (1 (at 23 ± 5°C) < 1% PMax < 1% PMax < 1% PMax

Line regulation at ±10% ΔUAC < 0.05% PMax < 0.05% PMax < 0.05% PMax

Load regulation at 10-90% ΔUOUT * ΔIOUT < 1% PMax < 1% PMax < 1% PMax

(1 Related to the nominal values, the accuracy denes the maximum deviation between an adjusted values and the true (actual) value.

(2 RMS value: LF 0...300 kHz, PP value: HF 0...20MHz

(3 The display error adds to the error of the related actual value on the DC output

Page 12

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

320 W

Model

PS 3040-20 C PS 3080-10 C PS 3200-04 C

Power regulation

Display: Resolution See section „1.9.5.4. Resolution of the displayed values“

Display: Accuracy (1 ≤ 0,5% PNenn ≤ 0,5% PNenn ≤ 0,5% PNenn

Analog interface (optional) (2

Set value inputs U, I, P

Actual value output U, I

Control signals DC on/o, remote control on/o

Status signals CV, OVP, OT

Insulation

Output (DC) to enclosure (PE) DC minus: permanent max. ±400 V

DC plus: permanent max. ±400V + output voltage

Input (AC) to output (DC) Max. 2500 V, short-term

Miscellaneous

Cooling Temperature controlled fan, side inlet, rear exhaust

Ambient temperature 0..50°C

Storage temperature -20...70°C

Humidity < 80%, not condensing

Standards EN 61010-1:2011-07, EN 61000-6-4:2011-09, EN 61000-6-2:2011-06 Class B

Overvoltage category 2

Protection class 1

Pollution degree 2

Operational altitude < 2000 m

Digital interfaces (optional)

Available plug-in cards

IF-KE5 USB: 1x USB

IF-KE5 USBLAN: 1x USB + 1x LAN

IF-KE5 USBANALOG: 1x USB + 1x Analog

Terminals

Rear side AC input, analog interface (optional), USB (optional), Ethernet (optional)

Front side DC output, USB-A, remote sensing

Dimensions

Enclosure (WxHxD) 260 x 88 x 323 mm

Total (WxHxD) 308 x min. 103 x min. 359 mm

Weight ≈ 4 kg ≈ 4 kg ≈ 4 kg

Article number 35320211 35320212 35320213

(1 The display error adds to the error of the related actual value on the DC output

(2 For technical specications of the analog interface see „3.5.4.4 Analog interface specication“ on page 40

Page 13

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

640 W

Model

PS 3040-40 C PS 3080-20 C PS 3200-10 C

AC supply

Voltage range 90...264 V AC 90...264 V AC 90...264 V AC

Connection Wall outlet Wall outlet Wall outlet

Frequency 45-65 Hz 45-65 Hz 45-65 Hz

Fusing MT 8 A MT 8 A MT 8 A

Inrush current @ 230 V ≈ 23 A ≈ 23 A ≈ 23 A

Leak current < 3.5 mA < 3.5 mA < 3.5 mA

Power factor ≈ 0.99 ≈ 0.99 ≈ 0.99

DC output

Max. output voltage UMax 40 V 80 V 200 V

Max. output current IMax 40 A 20 A 10 A

Max. output power PMax 640 W 640 W 640 W

Overvoltage protection range 0...44 V 0...88 V 0...220 V

Overcurrent protection range 0...44 A 0...22 A 0...11 A

Overpower protection range 0…704 W 0…704 W 0…704 W

Output capacitance 4400 μF 2940 μF 600 μF

Temperature coecient for set values Δ/K Voltage / current: 100 ppm

Voltage regulation

Adjustment range 0...40.8 V 0...81.6 V 0...204 V

Accuracy (1 (at 23 ± 5°C) < 0.1% UMax < 0.1% UMax < 0.1% UMax

Line regulation at ±10% ΔUAC < 0.02% UMax < 0.02% UMax < 0.02% UMax

Load regulation at 0...100% load < 0.05% UMax < 0.05% UMax < 0.05% UMax

Settling time after load step < 1.5 ms < 1.5 ms < 1.5 ms

Display: Resolution See section „1.9.5.4. Resolution of the displayed values“

Display: Accuracy (3 ≤ 0.2% UMax ≤ 0.2% UMax ≤ 0.2% UMax

Ripple (2 < 25 mVPP

< 4 mVRMS

< 40 mVPP

< 6 mVRMS

< 100 mVPP

< 25 mVRMS

Remote sensing compensation Max. 5% UMax Max. 5% UMax Max. 5% UMax

Output voltage fall time (at no load) after

switching DC output o - Down from 100% to <60 V: less than 10 s

Current regulation

Adjustment range 0...40.8 A 0...20.4 A 0...10.2 A

Accuracy (1 (at 23 ± 5°C) < 0.2% IMax < 0.2% IMax < 0.2% IMax

Line regulation at ±10% ΔUAC < 0.05% IMax < 0.05% IMax < 0.05% IMax

Load regulation at 0...100% ΔUOUT < 0.15% IMax < 0.15% IMax < 0.15% IMax

Ripple (2 < 60 mARMS < 30 mARMS < 12 mARMS

Display: Resolution See section „1.9.5.4. Resolution of the displayed values“

Display: Accuracy (3 ≤ 0.2% IMax ≤ 0.2% IMax ≤ 0.2% IMax

Power regulation

Adjustment range 0…652.8 W 0…652.8 W 0…652.8 W

Accuracy (1 (at 23 ± 5°C) < 1% PMax < 1% PMax < 1% PMax

Line regulation at ±10% ΔUAC < 0.05% PMax < 0.05% PMax < 0.05% PMax

Load regulation at 10-90% ΔUOUT * ΔIOUT < 1% PMax < 1% PMax < 1% PMax

(1 Related to the nominal values, the accuracy denes the maximum deviation between an adjusted values and the true (actual) value.

(2 RMS value: LF 0...300 kHz, PP value: HF 0...20MHz

(3 The display error adds to the error of the related actual value on the DC output

Page 14

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

640 W

Model

PS 3040-40 C PS 3080-20 C PS 3200-10 C

Power regulation

Display: Resolution See section „1.9.5.4. Resolution of the displayed values“

Display: Accuracy (1 ≤ 0,5% PNenn ≤ 0,5% PNenn ≤ 0,5% PNenn

Analog interface (optional) (2

Set value inputs U, I, P

Actual value output U, I

Control signals DC on/o, remote control on/o

Status signals CV, OVP, OT

Insulation

Output (DC) to enclosure (PE) DC minus: permanent max. ±400 V

DC plus: permanent max. ±400V + output voltage

Input (AC) to output (DC) Max. 2500 V, short-term

Miscellaneous

Cooling Temperature controlled fan, side inlet, rear exhaust

Ambient temperature 0..50°C

Storage temperature -20...70°C

Humidity < 80%, not condensing

Standards EN 61010-1:2011-07, EN 61000-6-4:2011-09, EN 61000-6-2:2011-06 Class B

Overvoltage category 2

Protection class 1

Pollution degree 2

Operational altitude < 2000 m

Digital interfaces (optional)

Available plug-in cards

IF-KE5 USB: 1x USB

IF-KE5 USBLAN: 1x USB + 1x LAN

IF-KE5 USBANALOG: 1x USB + 1x Analog

Terminals

Rear side AC input, analog interface (optional), USB (optional), Ethernet (optional)

Front side DC output, USB-A, remote sensing

Dimensions

Enclosure (WxHxD) 260 x 88 x 350 mm

Total (WxHxD) 308 x min. 103 x min. 359 mm

Weight ≈ 5 kg ≈ 5 kg ≈ 5 kg

Article number 35320214 35320215 35320216

(1 The display error adds to the error of the related actual value on the DC output

(2 For technical specications of the analog interface see „3.5.4.4 Analog interface specication“ on page 40

Page 15

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

1.8.4 Views

A - Power switch E - Remote control interfaces (optional, USB/Ethernet shown)

B - Control panel F - Air exhaust (models from 320 W with fan)

C - DC output G - AC socket with fuse holder

D - Remote sensing input

Figure 1 - Front side

Figure 2 - Rear side (320 W model sjhown)

Do not loosen the grounding point (brass screw next to AC socket G) in order to connect PE

cables! The device is supposed to be grounded via the AC cord, while the grounding point is

used to connect the enclosure to PE.

Page 16

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

Figure 3 - Side view from left, horizontal position (320 W model shown)

Figure 4 - Top view (320 W model shown)

Page 17

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

1.8.5 Control elements

Figure 5 - Control Panel

Overview of the elements on the control panel

For a detailed description see section „1.9.5. The control panel (HMI)“ and „1.9.5.2. Rotary knobs“.

(1) Colour display

Used for display of set values, menus, actual values, status and rotary knob assignment.

(2)

LED “Power”

Indicates dierent colours during the start of the device and once ready for operation, it turns green and

remains for the period of operation.

(3)

Rotary knob with push button function

Left knob (turn): adjustment of the voltage set value or setting parameter values in the menu

Left knob (push): selection of the decimal position (cursor) of the currently assigned value

Right knob (turn): adjustment of current or power set value or setting parameter values in the menu

Right knob (push): selection of the decimal position (cursor) of the currently assigned value

(4)

Pushbuttons

Is used to access the device menu (while the DC output is o) or to quick access the HMI

lock feature (while the DC output is on)

Are used to navigate in the sub menus of the device menu and to switch between param-

eters and values, as well as to switch the knob assignment in the main screen

Is used to access sub menus in the device menu, to submit changes of settings and

values, as well as to unlock the HMI

Is uses to exit menu pages and to cancel changes on values and settings

Is used to switch the DC output on or o during manual control. The two LEDs indicate

the DC output condition all the time, no matter if during manual or remote control (green

= on, red = o)

Page 18

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

1.9 Construction and function

1.9.1 General description

The laboratory power supply devices of PS 3000 C series are the third generation of small desktop units in the

power class up to 640 W. Due to their compact size they’re especially suitable for research laboratories, test ap-

plications or educational purposes.

For remote control using a PC the devices can be equipped with an optional, separately available and user-retrot-

table interface card. There is a choice of three dierent types: USB, USB+Ethernet or USB+Analog. All interfaces

are galvanically isolated from the device.

The standard carrying handle can serve as tilt stand, allowing for setup of dierent positions in order to make it

easier to read from the display or access the control elements.

All models are controlled by microprocessors.

1.9.2 Block diagram

The block diagram illustrates the main components inside the device and their relationships.

There are digital, microprocessor controlled components (KE, DR, HMI), which can be target of rmware updates.

See below (dotted elements are optional components):

Controller

(DR)

Commu‐

nication

(KE)

HMI

DC

USB

Ana

log

PS3000C

Blockdiagram

ETH

AC

=

≈

Sense

Power block

Controller

(DR)

Page 19

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

1.9.3 Scope of delivery

1 x Power supply device

1 x USB stick with documentation and software

1 x Mains cord

1 x UK wall socket adapter

1.9.4 Optional accessories

For these devices the following accessories are available:

IF-KE5 USB

Ordering nr. 33 100 232

Digital interface card with USB port. Can be ordered separately. Simple installa-

tion by the user on location. USB cable of 1.8 m length included.

IF-KE5 USB LAN

Ordering nr. 33 100 233

Digital interface card with USB port and Ethernet/LAN port. Can be ordered

separately. Simple installation by the user on location. USB cable of 1.8 m length

included.

IF-KE5 USB Analog

Ordering nr. 33 100 234

Digital/analog interface card with USB port and 15 pole analog D-Sub port. Can

be ordered separately. Simple installation by the user on location. USB cable of

1.8 m length included.

Page 20

EA Elektro-Automatik GmbH

Helmholtzstr. 31-37 • 41747 Viersen

Germany

Fon: +49 2162 / 3785-0

Fax: +49 2162 / 16230

www.elektroautomatik.com

PS 3000 C Series

1.9.5 The control panel (HMI)

The HMI (Human Machine Interface) consists of a display, two rotary knobs and six pushbuttons.

1.9.5.1 Display

The graphic display is divided into a number of areas. In normal operation the upper part (⅔) is used to show actual

and set values and thelower part (⅓) to display status information:

Actual voltage + set value

Regulation mode CV

Actual current + set value

Regulation mode CC

Actual power +

set value

Regulation

mode CP

Various status displays (symbols, strings)

• Actual / set values area (blue / green / red)

In normal operation the DC output values (large numbers) and set values (small numbers) for voltage (blue), cur-

rent (red) and power (green).

While the DC output is switched on, the actual regulation mode of the source being either constant voltage (CV),

constant current (CC) or constant power (CP) is displayed in the corresponding area, as exemplary shown in the

gure above with CV.

The set values can be adjusted by rotating the knobs below the display, whereas pushing the knobs is used to

switch the digit to be changed. Logically, the values are increased by clockwise turning and decreased by anti-

clockwise turning. The currently active assignment of set a value to a knob is indicated by the corresponding set

value being displayed in inverted form and also by the knob depiction in the status area showing the physical sign

(U, I or P). In case these are not shown, the values can’t be adjusted manually, like when the HMI is lock or the

device is in remote control.

General display and setting ranges:

Display Unit Range Description

Actual voltage V 0.2-125% UNom Actual value of DC output voltage

Set value of voltage V 0-102% UNom Set value for limiting the DC output voltage

Actual current A 0.2-125% INom Actual value of DC output current

Set value of current A 0-102% INom Set value for limiting the DC output current

Actual power W 0.2-125% PNom Calculated actual value of output power, P = UIN * IIN

Set value of power W 0-102% PNom Set value for limiting the DC output power

Adjustment limits A, W, V 0-102% nom. U-max, I-min etc., related to the physical values

Protection settings A, W, V 0-110% nom. OCP, OVP and OPP, related to the physical values

This manual suits for next models

10

Table of contents

Other Electro-Automatik Power Supply manuals

Popular Power Supply manuals by other brands

Et system

Et system ELP/DCH Series user manual

multicomp pro

multicomp pro MP710079 user manual

Analytic Systems

Analytic Systems PWS610 Series Installation & operation manual

Wiesenfield

Wiesenfield WIE-SFE-1200 user manual

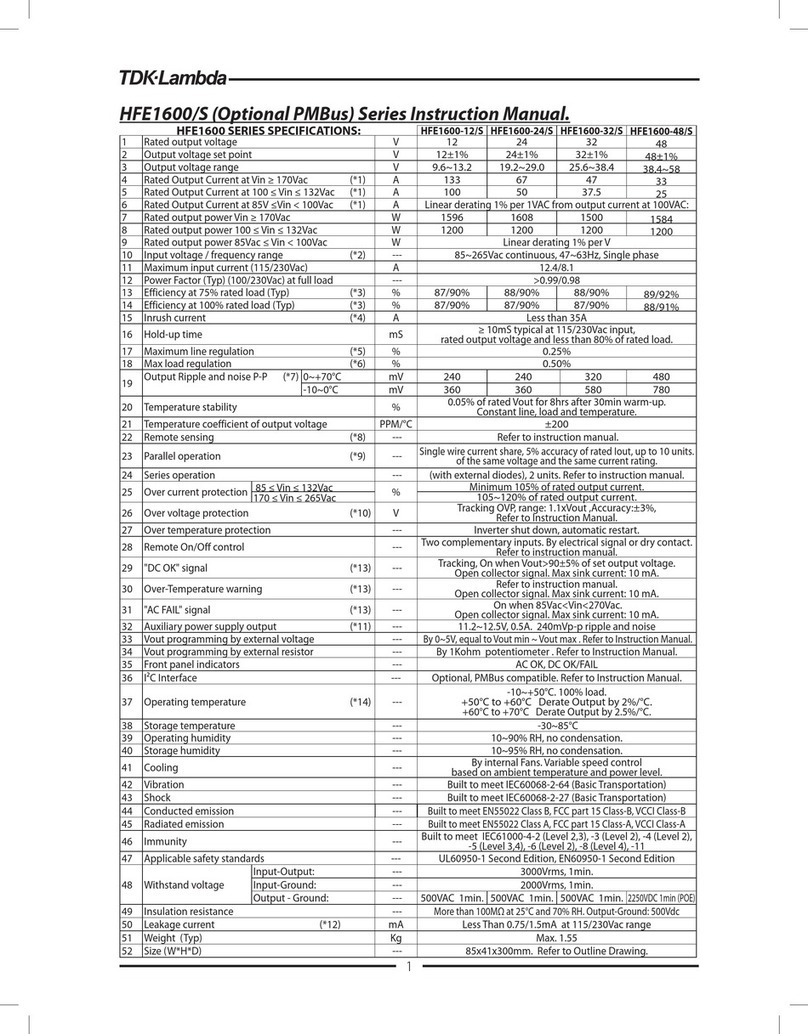

TDK-Lambda

TDK-Lambda HFE1600-12/S instruction manual

Smitec

Smitec ICOS-PS 3160 Series Installation, use and maintenance manual

Safety Vision

Safety Vision Observer 4000 HV Hardware user's guide

Trotec

Trotec PV30 operating manual

Schumacher Electric

Schumacher Electric SJ1 owner's manual

Kramer

Kramer VA-102P5 user manual

Horizont

Horizont trapper N15 instruction manual

Keysight Technologies

Keysight Technologies U8030A Series Service guide