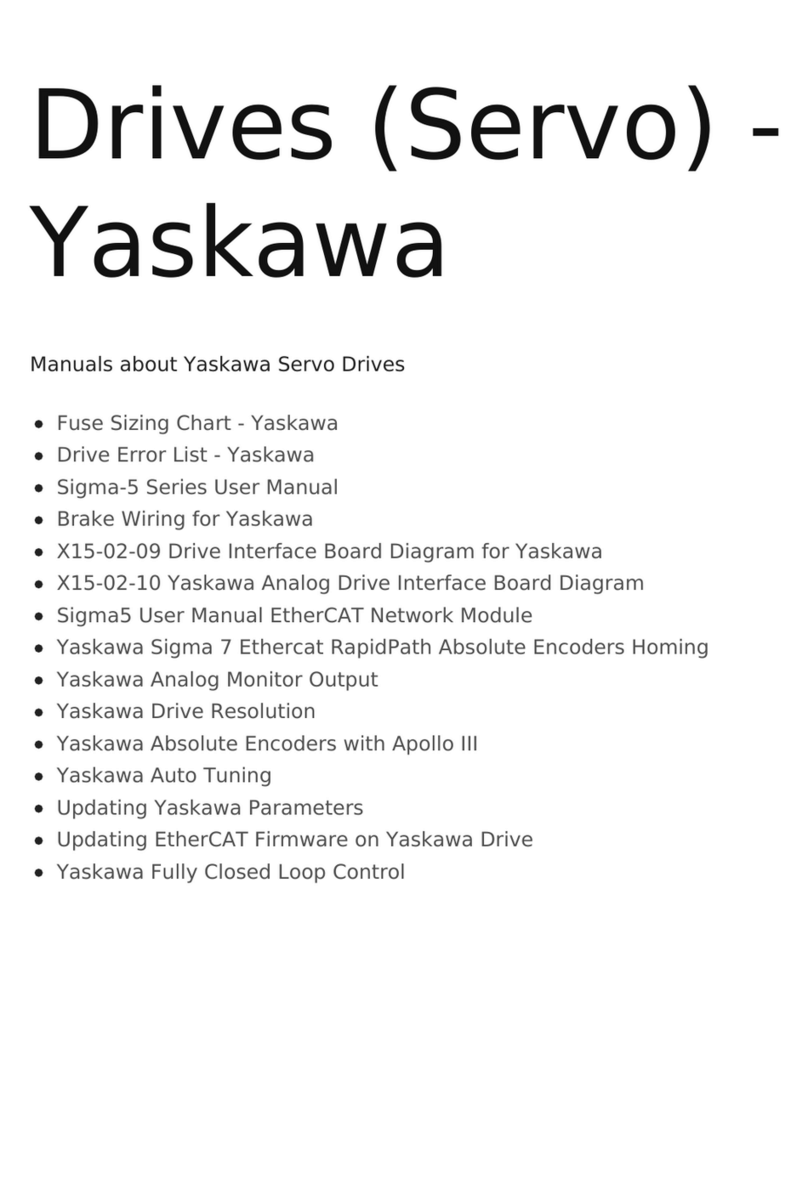

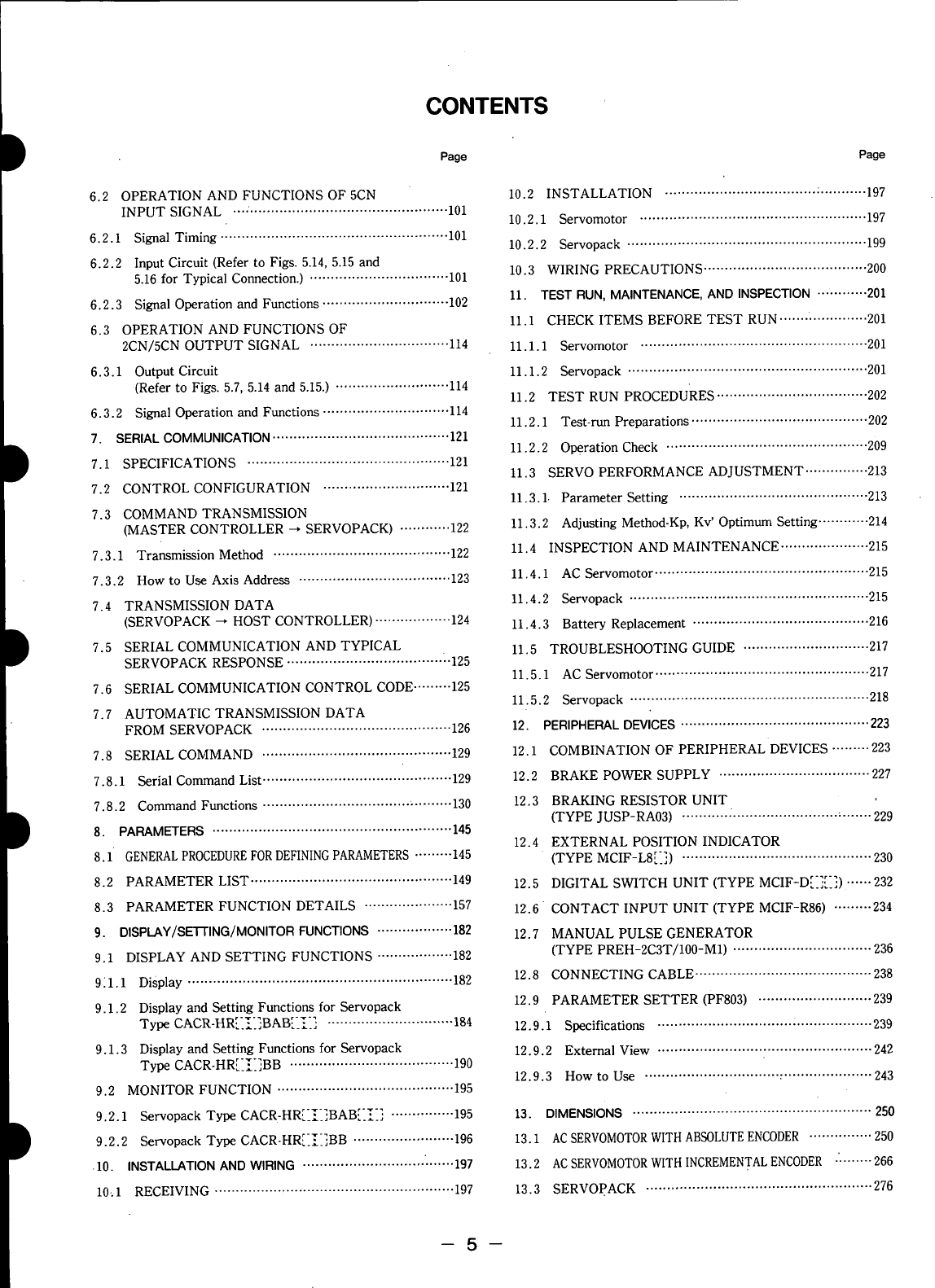

CONTENTS

DPage Page

6.2 OPERATION AND FUNCTIONS OF 5CN 10.2INSTALLATION .................................... "........... 197

INPUT SIGNAL .... ............................................... 101

10.2.1 Servomotor ...................................................... 197

6.2.1 Signal Timing ...................................................... 101 10.2.2 Servopack ......................................................... 199

6.2.2 Input Circuit (Refer to Figs. 5.14, 5.15 and

10.3 WIRING PRECAUTIONS ....................................... 200

5.16 for Typical Connection.) ................................. 101

11. TEST RUN,MAINTENANCE,ANDINSPECTION............ 201

6.2.3 Signal Operation and Functions .............................. 102 11.1CHECK ITEMS BEFORE TEST RUN ....... .............. 201

6.3 OPERATION AND FUNCTIONS OF

2CN/5CN OUTPUT SIGNAL ................................. 114 11.1.1 Servomotor ...................................................... 201

6.3.1 OutputCircuit 11.1.2 Servopack ......................................................... 201

(Referto Figs. 5.7, 5.14and 5.15.)........................... 114 11.2 TEST RUN PROCEDUREs .................................... 202

6.3.2 Signal Operation and Functions .............................. 114 11.2.1 Test-run Preparations .......................................... 202

7.SERIALCOMMUNICATION.......................................... 121 11.2.2 OPeration Check ................................................ 209

7.1 SPECIFICATIONS ................................................ 121 11.3 SERVO PERFORMANCEADJUSTMENT ............... 213

7.2 CONTROL CONFIGURATION .............................. 121

11.3.1. Parameter Setting ............................................. 213

7.3 COMMAND TRANSMISSION

(MASTER CONTROLLER --,SERVOPACK) ............ 122 11.3.2 Adjusting Method-Kp, Kv' Optimum Setting ............ 214

7.3.1 Transmission Method .......................................... 122 11.4INSPECTION AND MAINTENANCE ..................... 215

7.3.2 How to Use Axis Address .................................... 123 11.4.1 AC Servomotor ................................................... 215

7.4 TRANSMISSION DATA 11.4.2 Servopack ......................................................... 215

(SERVOPACK --* HOST CONTROLLER) .................. 124 11.4.3 Battery Replacement .......................................... 216

7.5 SERIAL COMMUNICATION AND TYPICAL 11.5 TROUBLESHOOTING GUIDE .............................. 217

SERVOPACK RESPONSE ..................................... -'125

11.5.1 AC Servomotor ................................................... 217

7.6 SERIAL COMMUNICATION CONTROL CODE ......... 125

11.5.2 Servopack ......................................................... 218

7.7 AUTOMATIC TRANSMISSION DATA

FROM SERVOPACK ............................................. 126 12. PERIPHERALDEVICES............................................. 223

7.8 SERIAL COMMAND ............................................. 129 12.1 COMBINATION OF PERIPHERAL DEVICES ......... 223

7.8.1 Serial Command List ............................................. 129 12.2 BRAKE POWER SUPPLY .................................... 227

7.8.2 Command Functions ................................... ;......... 130 12.3 BRAKING RESISTOR UNIT

(TYPE JUSP-RA03) ............ ................................. 229

8. PARAMETERS......................................................... 145

12.4 EXTERNAL POSITION INDICATOR

8.1 GENERAL PROCEDURE F0R DEFINING PARAMETERS ......... 145 (TYPE MCIF-L8[_]) ............................................. 230

8.2 PARAMETER LIST ................................................ 149 12.5 DIGITAL SWITCH UNIT (TYPE MCIF-D[_][_]) ...... 232

8.3 PARAMETER FUNCTION DETAILS ..................... 157 12.6 CONTACT INPUT UNIT (TYPE MCIF-R86) ......... 234

9. DISPLAY/SE'I-FING/MONITORFUNCTIONS.................. 182 12.7 MANUAL PULSE GENERATOR

9.1 DISPLAY AND SETTING FUNCTIONS .................. 182 (TYPE PREH-2C3T/100-M1) ................................. 236

9_1.1 Display ............................................................... 182 12.8 CONNECTING CABLE .......................................... 238

12.9 PARAMETER SETTER (PF803) ........................... 239

9.1.2 Display and Setting Functions for Servopack

Type CACR-HR[-_]BAB[-__] .............................. 184 12.9.1 Specifications ................................ :.................. 239

9.1.3 Display and Setting Functions for Servopack 12.9.2 External View ................................................... 242

Type CACR-HR[_I_]BB ....................................... 190

12.9.3 How to Use ................................ _..................... 243

9.2 MONITOR FUNCTION .......................................... 195

9.2.1 Servopack Type CACR-HR[_I_]BAB[_] ............... 195 13.DIMENSIONS ......................................................... 250

9.2.2 Servopack Type CACR-HR[_:_]BB ........................ 196 13.1 ACSERVOMOTORWITHABSOLUTEENCODER............... 250

10. INSTALLATIONAND WIRING ............................. "....... 197 13.2 ACSERVOMOTORWITHINCREMENTALENCODER-"........ 266

10_1 RECEIVING ......................................................... 197 13.3 SERVOP.ACK ...................................................... 276

- 5-