Moog DR2020 Series User manual

4

6

INDICE

4

4

4

5

5

6

6

7

11

12

13

14

15

15

16

17

18

19

20

20

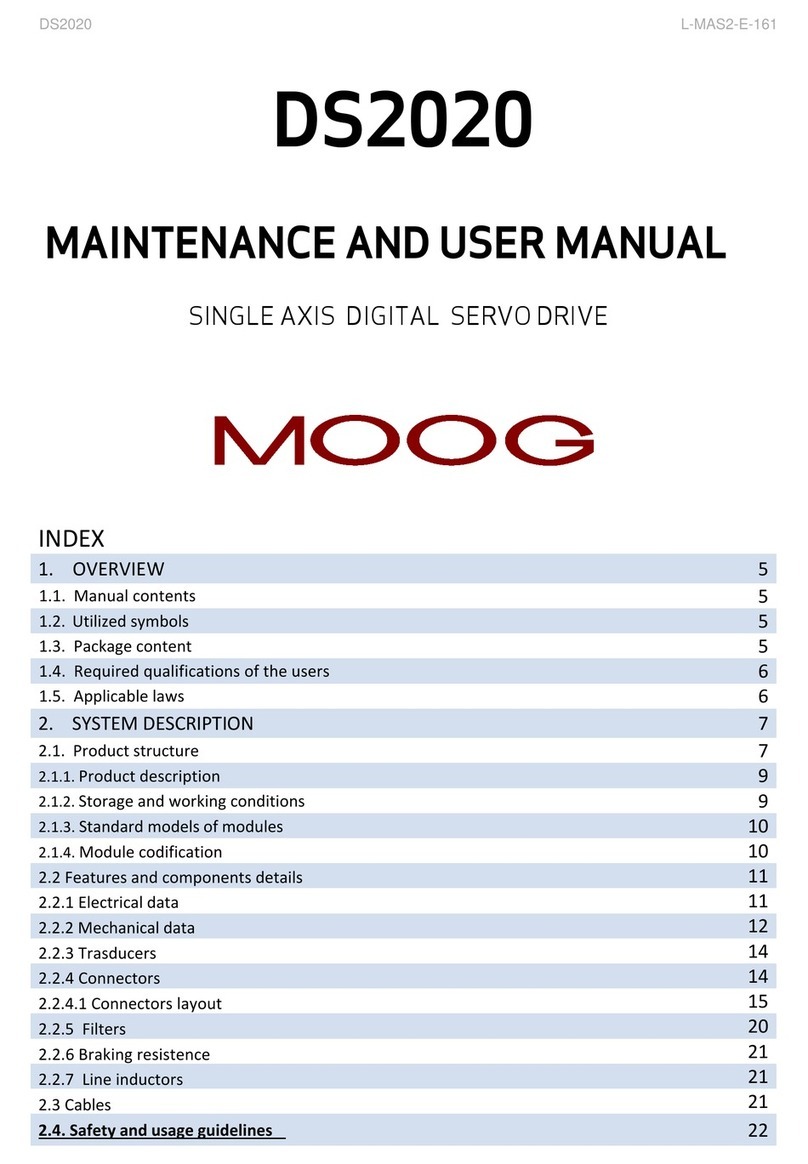

1. OVERVIEW

1.1. Contents

1.2. Utilized symbols

1.3. Packaging contents

1.4. Qualifications of recipients

1.5. Standards of reference

2. DESCRIPTION OF THE SYSTEM

2.1. Product structure

2.1.1. Product description

2.1.2. Operating and storage conditions

2.1.3. Standard power supply unit models

2.1.4. Power supply unit coding

2.1.5. Standard axis modules

2.1.6 Axis module coding

2.1.7. Capacitor modules models and coding (ABC Auxiliary Bus Capacitor)

2.2. Characteristics and components details

2.2.1. Power supply unit electrical data

2.2.2. Power supply unit mechanical data

2.2.3. Connectors

2.2.3.1. Connectors Layout

2.2.4. Filters

2.2.5. Brake resistors

2.2.6. Line inductors

2.2.7. Cables

2.2.8. Capacitor module (ABC)

2.3. Axis Module

2.3.1. General description of functions

2.3.2. Mechanical dimensions

2.3.3. Position transducers

2.3.4. Interfaces with “field” and other modules

21

23

24

25

25

26

26

10

MAR2-E-191

DR2020

USE AND MAINTENANCE MANUAL

DECENTRALIZED DIGITAL SERVO DRIVE

m

27

30

33

27

27

27

27

28

28

28

28

28

28

29

29

29

29

29

30

31

33

33

33

33

33

33

33

33

34

34

35

35

35

36

36

36

36

37

38

38

2.4. Safety and Usage Instructions

2.4.1.

General safety Description

2.4.2.

STO Safety Function

2.4.2.1.

Description

2.4.2.2.

Safety instructions

2.4.3. Instructions for drive usage

2.4.3.1. Directed use

2.4.3.2.

Distribution board and wiring

2.4.3.3. Power supply

2.4.3.4. Motors

2.4.3.5. Prohibited use

2.4.3.6. In house storage duration

2.4.3.7. Maintenance/cleaning

2.4.3.8. Decommissioning

2.4.3.9. Repair

2.4.3.10 Disposal

3. TYPE APPROVALS

3.1. EC

3.2. Safety and Safe Torque Off (Block on restart)

4.ELECTRICAL AND MECHANICAL INSTALLATION

4.1.

Tools and instruments

4.2. Mechanical installation

4.2.1. Assembling the components

4.2.1.1. Assembling the power supply unit

4.2.1.2. Assembling the axes

4.2.1.3. Assembling the filters

4.2.1.4. Assembling the inductors

4.2.1.5. Brake resistor positioning

4.3. Electrical installation and thermal sizing

4.3.1. Safety and general instructions

4.3.2. Thermal sizing of the board

4.3.2.1. Dissipation of the power supply unit

4.3.2.2. Dissipation of the axes

4.3.2.3. Thermal dissipation of the accessories

4.3.3. Auxiliary power supply characteristics

4.3.4. Connection to the mains

4.3.4.1. Types of mains network

4.3.4.2. Protection components

4.3.4.3. Earth connection

4.3.5. Power supply unit wiring

1

DR2020

MAR2-E-191

1

45

38

38

38

39

39

39

39

40

41

41

42

43

45

46

46

46

47

48

49

51

51

52

52

52

53

53

54

55

55

55

55

56

58

59

60

61

64

64

65

66

4.3.5.1.

Earthing

4.3.5.2.

Power cable connection

4.3.5.3.

Brake resistorconnector

4.3.5.4.

BUS BAR connection

4.3.5.5.

Auxiliary power connection

4.3.6.

Axis module wiring

4.3.6.1.

Earthing

4.3.6.2.

Motor cable connection

4.3.6.3.

Motor brake cable connection

4.3.6.4.

STO signal connectors

4.3.6.5.

Trasducers connection

4.3.6.6.

Connecting Filedbus - connectors X8, X9, X10

5. COMMISIONING USING THE GUI

5.1. Safety

5.2. Dx2020 GUI

5.2.1. General description

5.2.2. Minimum PC requirements

5.2.3 Dx2020GUI Installation

5.2.4 Connection GUI-drive

5.2.5. Layout

5.2.6. Firmware Update (BootLoader)

5.2.7. How to access the Online Help

5.3. System Configuration

5.3.1. Axis module identification

5.3.2. Motor Parameters Configuration

5.3.3. Transducers Configuration

5.3.3.1. Sensorless

5.3.4. I/O Configuration

5.3.5. Control Loops Configuration

5.3.5.1 Control Mode Configuration

5.3.5.2. Torque Loops Parameters Configuration

5.3.5.3. Speed Loops Parameters Configuration

5.3.5.3.1 Filter configuration

5.3.5.4. Position Loops Parameters Configuration

5.3.6. Fault configuration

5.3.7. Application parameters

5.3.8. Configuration of modes and commands

5.4. Power supply

5.5. Enabling the STO

5.5.1 Autophasing

5.6 . Enabling the Axis

5.7. Oscilloscope function and log files (*.UCX) 67

DR2020

MAR2-E-191

2

72

67

67

68

69

70

71

72

72

72

73

73

73

74

74

74

74

75

76

76

76

77

77

78

81

82

82

82

83

83

83

84

84

85

87

89

89

89

90

90

5.7.1.

Configure recording

5.7.2.

Launch recording

5.7.3.

View the record

5.7.4.

UCX file management

5.8.

Use of the GUI in OFF LINE mode

5.9.

Parameter management menu

6. TROUBLESHOOTING

6.1. Introduction

6.2. Power supply unit anomalies

6.3. Axis module anomalies

6.3.1. Power section Alarms

6.3.2. Alarm due to VBUS voltage not within tolerance limits

6.3.3. Drive or motor overtemperature

6.3.4. STO signal removal

6.3.5. Memory device errors

6.3.6. Data Corrupted Fault

6.3.7. Brake Chopper Fault

6.3.8. Feedback device errors

6.3.9. Synchronization, Interrupt Time and Task Time Error

6.3.10. EtherCAT Faults

6.3.11. Internal Communication Fault

6.3.12. Control loop Alarms

6.3.13. CAN Bus Alarms

6.4. Alarms Identification

6.5. Anomalies during GUI-Drive connection

7. SAFE TORQUE OFF SAFETY FUNCTION

7.1.

Application

7.2.

Risk assessment of the installation

7.3.

Safe Torque Off function

7.3.1.

Characteristic values according to

UNI EN ISO 13849-1

7.3.2.

Characteristic values according to

CEI EN 62061

7.4.

Safety requirements

7.5.

Safe Torque Off Circuit

7.6.

Safe Torque Off Connections

7.7.

Application example

7.8.

Safe Torque Off installation and and maintenance procedure

7.9.

Assembly and production tests

7.10.

Identification of Safe Torque Off function on the drive plate

8 Annexes

8.1.

Glossary

8.2.

Metric/AWG cinversion table 93

DR2020

MAR2-E-191

3

1. OVERVIEW

Contents

This manual provides information on the correct installation and optimal operation of the DR2020 series of digital multi-axis

servo drives.

All information in this manual, including methods, technologies and concepts is the exclusive property of Moog-Casella, and may

not be copied or reused without specific authorisation.

Moog-Casella reserves the right to make changes to the product and relative documentation, at any time, without notice.

The following documents are available on the Website:

•QUICK GUIDE - INSTRUCTIONS AND GUIDELINES FOR INITIAL START-UP

•USER AND INSTALLATION MANUAL (this document)

•FIELDBUS MANUAL

•CONFIGURATION SOFTWARE Dx2020 GUI

WARNING

When the drive is operating, there is a risk of death, serious injury or serious material damage.

The installer shall therefore make sure that the safety instructions in this manual are read, understood

and observed by all personnel responsible for operating the drive.

AVERTISSEMENT

Lorsque l'entrainement est en marche, il existe un risque de mort, blessures graves ou dommages

matériels importants. L'installateur doit donc veiller à ce que les consignes de sécurité dans ce manuel

sont lues, comprises et respectées par tout les le personnel responsable de commander l'entraînement.

1.2.

S

ymbols used

WARNING: Hazard that may result in death or serious injury

Hazard that may result in minor injury and/or material damage

Important information

1.3. Contents

A DR2020 includes:

•

A DR2020 module

Note: a connectors' kit (see page 6) or a connection cable between DR2020 modules, must be ordered

separately, specifying the needed length.

DR2020

MAR2-E-191

4

1.4. Qualifications of recipients

This manual is intended for qualified personnel, i.e. with the following skills, depending on their functions:

Transport: personnel shall have knowledge of handling electrostatically sensitive components

Unpacking: personnel shall have knowledge of handling electrostatically sensitive components that are sensitive to impact

Installation: personnel shall have knowledge of installing electrical equipment

Start-up: personnel shall have extensive technical knowledge of electrical drive technology.

INFORMATION

Qualified personnel shall be familiar with and observe the following standards:

IEC 60364, IEC 60664 and national accident prevention regulations.

WARNING

When the drive is operating, there is a risk of death, serious injury or serious material damage.

The installer shall therefore make sure that the safety instructions in this manual are read, understood

and observed by all personnel responsible for operating the drive.

AVERTISSEMENT

Lorsque l'entrainement est en marche, il existe un risque de mort, blessures graves ou dommages

matériels importants.

L'installateur doit donc veiller à ce que les consignes de sécurité dans ce manuel sont lues, comprises et

respectées par tout le personnel responsable de commander l'entraînement.

1.5. Reference standards

The DR2020 drives conform to the Low Voltage Directive (2014/35/EC) and EMC Directive (2014/30/EC).

The “Safe Torque Off” (STO) safety function built into the drive conforms to the Machinery Directive (2006/42/EC).

To conform to European Directives, the product meets the requirements of the relevant harmonised installation standards

EN61800-5-1 (LVD), EN61800-3 (EMC) and EN 61800-5-2 (Safety of machinery), EN60034-1, EN60034-5 (Electric Rotary

Machines).

The DR2020 drives are CE certified.

DR2020

MAR2-E-191

5

2. DESCRIPTION OF THE SYSTEM

2.1. Product structure

2.1.1.

Product description

The DR2020 drive is the new generation of digital servo drives manufatured by Moog-Casella for controlling brushless

synchronous or asynchronous motors. It's a decentralized servo drive that can be positioned directly on the machinery with a DC power

supply module.

•The power supply of the DM2020 supplies the "power" in direct current (+ AT and -AT) to the different DR2020 through the

connection cable applied on the terminal board

•The first two upper connectors of the power supply terminal board carry the auxiliary power supply + 24Vdc

•The second two connectors at the bottom carry the power supply +/- AT (ATTENTION HIGH VOLTAGE 560VDC or higher)

•There are two standard power supply models (those of the DM2020 multi-axis drive)

•Each DR2020 axis module is only available in the single axis version

•The current flows of the various DR2020 axes range from 2 Arms to 8 Continuous Arms and 4 Arms to 16 Peak Arms

•Sizes are 4

•The control modes are 3

ModeNote

Analog input Opzional (*)

Can Bus Fieldbus Opzional (*)

EtherCat Fieldbus Standard version

(*) under development

•The DR2020 is equipped with the circuit for controlling a stationary brake integrated in the motor.

Size Rated Current

Arms Peak Current

Arms

2/4 2,0 4.0

4/8 4,0 8.0

6/15 6,0 12.0

8/16 8,0 16,0

•Compatable feedback devices (to be specified on the order)

−Serial RESOLVER

−USB RESOLVER

−Sincos Serial ENCODER

−Sincos USB ENCODER

DR2020

MAR2-E-191

6

2.1.2.

Operating and storage conditions

Ambient operating

temperature

from 0 °C to 40 °C

Storage temperature from -25 °C to 55 °C

Transport temperature from -25 °C to 70 °C

Humidity permitted

during operation

5…95 %

condensation not allowed

Humidity permitted

for storage 5…95 %

Humidity permitted for transport

transportnsport 95 % a 40 °C

Operating height Up to 1000 m above AMSL, over 1000 m above AMSL with reduced

current (-2%/100 m) max. 2000 m above AMSL

Certification CE, UL (pending)

IP Protection rating IP65

Tab 2.1 Environmental conditions

•The modules can be cooled by natural convention or by a radiating back surface

•Ethernet interface on which the EtherCAT Real Time protocol is implemented with the DS402 profile (standard)

•Standard CANOpen interface (under development) on which the CANOpen protocol is implemented with the DS402

profile

•“Safe Torque Off” (STO) (protection against accidental start-up) incorporated into each DR2020 module

•Configuration/commissioning via GUI: Dx2020GUI, with USB interface (X6 connector), located at the side of the

Fieldbus connectors allows users to configure, calibrate and control the drive

•Alarm diagnostics: Via GUI or Field Bus

•Accessories:

oEMC filters (supplied with the power supply)

oPower and signal cables

oBrake resistor (supplied with the power supply)

Note: High voltage power can be obtained from the DM2020 Power Supply.

Mechanical resistance in

compliance with EN 60721-3-3

CLASS 3M7

Vibration: stat/sinusoidal:

•10mm for frequences between 2…9

•30 m/s2 for non-stationary vibration

Non-stationary vibration and Type II impacts:

•250 m/s2 (25 g) for 6

ms

Machine Safety STO (Safe Torque Off) SILCL 3 PL “e” (pending)

DR2020

MAR2-E-191

7

Drive Dimensions

DR2020

MAR2-E-191

8

BR8904-R

BR8905-R

BR8907-R

BR8903-R

CVAMM

CVDMM

CVMMM

BR8901-R

BR8902-R

BR8900-R

Connectors and Cable coding

Connerctors' coding

X1 input connector with terminals (to the power

supply) X2 output connector (to the next DR2020

module) X3 motor connector

X4 e X5 EtherCat connectors

Connertors Kit:

it includes 4 connectors: X1, X2, X4 e X5 Cables

Coding *)

To the Power Supply

To the DR2020

To the Motor

Nota: “MM”

refers to the cables length in meters

Wire Terminal Code

X2 Connector ended for STO Feedback

Cap X5 ended for EtherCat

Cap for X2 not ended

(*) under development

BR8906-R

DR2020

MAR2-E-191

9

The power supply model code is shown on two plates: One located on the front above the protector for the module's terminal

block and the other on the right-hand side of each axis module.

To request any kind of information about a specific power supply, the details on the side plate identifying each individual

power supply must be communicated to Moog-Casella.

Nota: a 32Arms power supply module is under development

Model code

Nominal data

(A)

(B)

Serial Number

Model/Code CC201xxxxx CC202xxxxx

Mechanical dimensions 50 mm/1.97 inches 150 mm/5.9 inches

Type L50 L150

Electrical line power supply 3-phase, from 200 to 528 V AC, 50/60 Hz

Auxiliary busbar power supply 24 V DC +/- 10% (supplied externally)

Arms rated current 54 128

Arms peak current 130 256

Protection

Communication CANopen for sharing data with the drives

Cooling Incorporated ventilation

Weight (kg) 5.1 13.5

Connector code BC0004R BC0006R

Fig 2.2 Example of power supply side plate (A) and front plate (B)

DR2020

MAR2-E-191

10

NTC and bi-metallic thermal protection to 85°C

Detection of loss during input phase

Detection of insufficient input voltage or overvoltage

2.1.4. Power supply coding

Example: The code CC201A0000 identifies the standard 54 A standard power supply in the production version, with no

special variant.

Version

.Stnr Model

Eec Model

Mechanical hardware configuration

Value Length Nominal

Current (CC)

..

nc

r

nc

r

ue eron

tnr

OPT2 - Special configurations

ue eron

tnr

Hardware revision

Internal lue 2

Special Variations

ue Internal coding 2

CC

2 Values assigned by Moog

Fig 2.3 The first two characters are "CC" and refer to the family (DM2020)

-

DR2020

MAR2-E-191

11

OPT1 - Special configurations

DR2020

Model/Code CH6 52 X X X XX XX CH6 54 X X X XX XX CH6 56 X X X XX XX CH6 58 X X X XX XX

Machanical dimensions 135 L * 83 P * 222 H mm (H = 270 mm with connectors)

Configuration Single

Type L1 L2 L3 L4

Module current

@ 8 kHz 2 4 4 8

Arms rated currrent 2 4

6

8-

Arms peak current 4 8

12

16

Cooling Natural Dissipation on the plate

Weight 4.4 4.4 4.4 4.4

Connector code See p. 8

The module code is shown on the plate near the Fieldbus connectors.

To request any kind of information about a specific module, the details on the side plate identifying each individual

module must be communicated to Moog-Casella.

Nominal data

Serial Number

Model code

Fig 2.4 Example of a DR2020 axis module plate

DR2020

MAR2-E-191

12

Version

6Standard model

ESpecial model

(1) Standard Version

(2) Values assigned by Moog

Transducer type

Value Type

RRESOLVER

TUSB RESOLVER

ESerial Sincos ENCODER

USincos USB ENCODER

Value Type

0Analogue references (option)

1

2EtherCAT configuration

Hardware Revision

00Standard

Special variations

CH-

System data

Value Peak

Current

52 2 Arms

54 4 Arms

56 6 Arms

58 8 Arms

Nominal

Current Dimension

in mm

4 Arms

8 Arms

12 Arms

16 Arms

135x220x83

(1)

01OBE Special

30 SBC low level

31 SBC low level OBE Special

60 SBC high level

61 SBC high level OBE Special

135x220x83

135x220x83

135x220x83

CanBus configuration (option)

Note: Serial interface for drive setup is under development.

Value - Internal Coding

DR2020

MAR2-E-191

13

Special configurations

Fieldbus configuration

Model Code Capacity (µF) Dimension

DM2020 ABC5

CC55000

5400

50 mm (1.97 in)

DM2020 ABC4 CC55012 4500

DM2020 ABC3 CC55013 3600

DM2020 ABC2 CC55014 2700

DM2020 ABC1 CC55015 1800

Fig 2.5 Example of capacitor module side plate (A) and front plate (B))

The capacitive module can be placed alongside the power supply and the DR2020 in order to recover

kinetic energy in the braking phases; in this way, in the presence of repeated cycles of acceleration and

load braking, it is avoided to dissipate energy on the braking resistor.

Model Code

Serial Number

(A)

Nominal Data

(B)

DR2020

MAR2-E-191

14

The main function of the power supply module is to directly convert (without a transformer) mains voltage to direct voltage,

which powers the various modules that operate the servo-system motors via busbars.

Fig 2.6 Power supply block diagram (power components)

Model Type L50 (M) Type L150 (L)

ELECTRICAL DATA

Mains voltage Three-phase from 200 to 528 V AC 50/60 Hz

Auxiliary voltage 24 V DC +/-10%, 1 A (supplied externally)

Rated output current, DC BUS side 54 A 128 Arms

Peak output current, DC BUS side 130 A 256 Arms

DC-link voltage (Vout) From 282 to 744 V DC -

Protection

Communication CANopen for sharing data with the drives

Cooling Incorporated ventilation

MECHANICAL DATA

Weight 5.1 kg 13.5 kg

Height 455 mm (17.91 inches) 455 mm (17.91 inches)

Width 50 mm/1.97 inches 150 mm/5.91 inches

Depth 249 mm (9.80 inches) 249 mm (9.80 inches)

Tab 2.4 Power supply characteristics

FUNCTIONS

Soft-start circuit

Braking circuit

BUS cc voltage monitoring

Mains voltage presence and value monitoring

Power supply internal temperature monitoring

TO THE THREE-

PHASE NETWORK

R

S

T

SOFT START

RR

IGBT

CAPACITORS

PS MANAGEMENT

BUS READING

SOFT START

RR CONTROL

+AT Vbus

-AT Vbus

DR2020

MAR2-E-191

15

NTC and bi-metallic thermal protection on heat sink to 85°C

Identification of absense of input phase

Identification of insufficient voltage (undervoltage) or excessive voltage (overvoltage)

Fig 2.7 Drawing of the power supply L50

Fig 2.8 Drawing of the power supply L150

2.2.2. Power supply unit mechanical data

DR2020

MAR2-E-191

16

0 Volt

+ DC bus

- DC bus

GND

X1 Brake resistor

X2 Power connector

+24 Volt

Bus Bar

}

Status Led

CAN connectors

(Earth)

Fig 2.9 Connection layout

DR2020

MAR2-E-191

17

The tables below give details of connectors

X1: brake resistor

1+RR1

2-RR2

X2: mains

1U1

2V1

3W1

4Earth

YELLOW LED GREEN LED RED LED Status

Off Off Off Power supply off or failed

Off Off 24 Volt applied

Flashing Flashing Off Three-phase power supply present, BUS charging

Flashing Off BUS stable, axes ready to be enabled

Off Off Power supply fault

X10 LN A CAN connector (according to CIA 402 CAN on RJ45 connector)

Pin Designation Function

1Can_H CAN line positive terminal

2Can L CAN line negative terminal

30V_Ca n CAN line 0 logic

4Aux_Ps_Fault_neg Signal (denied) of power supply status

5Addr_sx_dx Address for internal communications

6Ps_out Power supply command output

7nc

8+5V_Can CAN line power supply (supplied by power supply)

2.2.3.1. Connectors layout

The tables below give details of connectors and the meaning of signalling LEDs

DR2020

MAR2-E-191

18

On, fixed light

On, fixed light

On, fixed light

X10 LN B CAN connector (according to CIA 402 CAN on RJ45 connector)

Pin Designation Function

1Can_H CAN line positive terminal

2Can L CAN line negative terminal

30V_Ca n CAN line 0 logic

4Aux_Ps_Fault_neg Signal (denied) of power supply status

5Addr_sx_dx Address for internal communications

6Ps_out Power supply command output

7nc

8+5V_Can CAN line power supply (supplied by power supply)

Filter code AT6013 (power supply M) / AT6014 (power supply L)

Rated voltage 3 x (400/480 V), 50/60 Hz, at 50 °C

Overload 1.5x per 60 s, repeatable every 60 min.

Ambient temperature From -25 °C to +100 °C, with current reduction starting from 60 °C (1.3%/°C)

Assembly height 1000 m, with current reduction of up to 4000 m (6%/1000 m)

Relative air humidity 15 - 85% (condensate not permitted)

Storage temperature From -25 °C to +70 °C

IP protection rating IP20

Acceptance test Complies with EC

Non-industrial environment -

EN61800-3

complies with radio shielding

Cable length permitted between the drive and motor up to 50 m

Industrial environment -

EN61800-3

complies with radio shielding

Cable length permitted between the drive and motor up to 100 m

Code Suitable for

power supply Type

Rated

current

[A]

Total

current

loss [W]

Current

on contact

[mA]

Weight

[kg] Connection [mm2 ]

AT6013 L50 A 1 55 26 33.4 1.8 13 mm2�ex.

PE M6 bolt

AT6014 L150 B 1 130 50 39 2.6 Up to 50 mm2

PE M10 bolt

DR2020

MAR2-E-191

19

2.2.4 Filters

If the motor power cables are shorter than 50 m, an EMC filter (code AT6013/AT6014 or equivalent can be positioned between

the network and the drive.

If cables are no longer than 50 m, we recommend contacting Moog-Casella's Application Dept.

If the application requires a direct current less than the maximun than can be managed by the power supply, filters with lower rated

curent values may be used.

Contact the Application Service for ratings and a selection of alternative models to those described above.

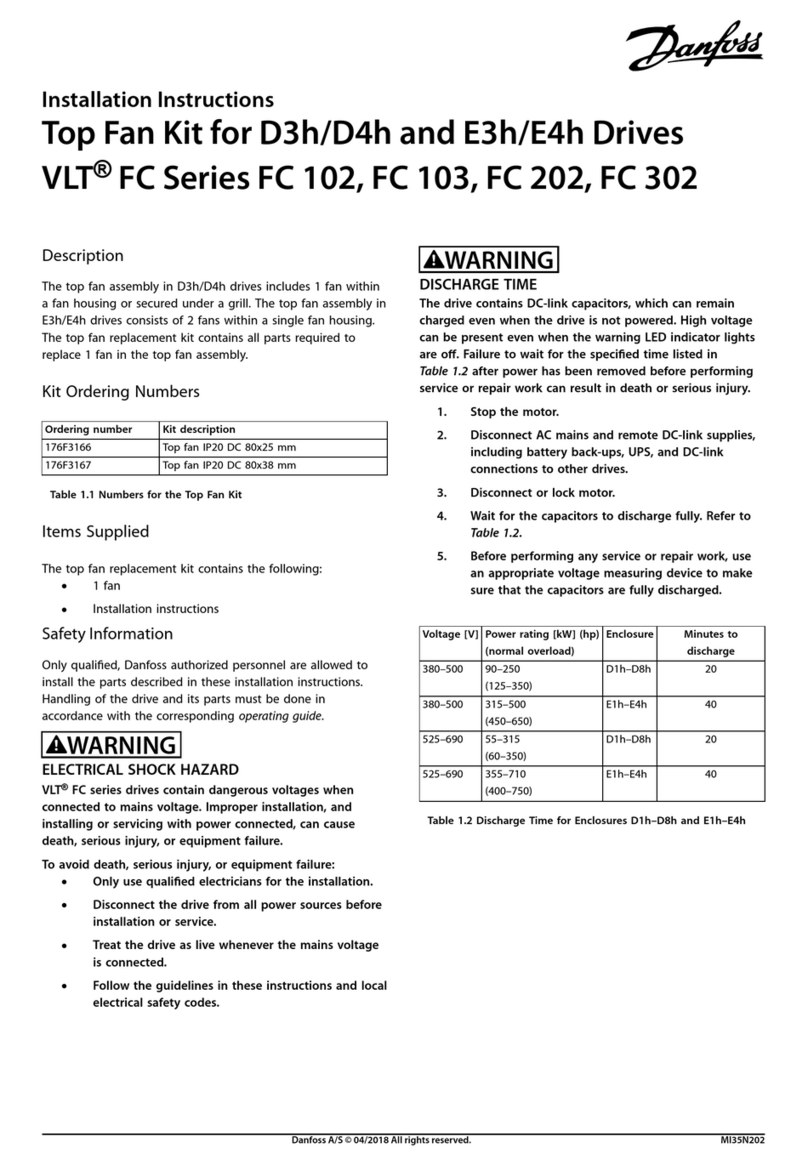

Table of contents

Other Moog Servo Drive manuals

Popular Servo Drive manuals by other brands

Danfoss

Danfoss 176F3166 installation instructions

Kollmorgen

Kollmorgen S20260 installation guide

Sanyo Denki

Sanyo Denki SANMOTION R3E manual

Smitec

Smitec COSMOS 301 Series Installation, use and maintenance manual

Shihlin electric

Shihlin electric SDA Series user manual

BLUM

BLUM Tandem installation instructions

Engel

Engel HBI22 Series operating manual

Fagor

Fagor ACSD series Original instructions

Ormec

Ormec XD-Indexer Kit Quick installation guide

Sanyo Denki

Sanyo Denki Sanmotion R instruction manual

Lenze

Lenze L-force Drives 9400 Series Mounting instructions

SSD Parvex

SSD Parvex DIGIVEX Little Drive Servoamplifier User and commissioning manual