Safety Instruction

Please conserve this manual as operation guidance. If you sell this product to other user,

please make sure that they also receive this user manual.

Always make sure that you are connecting to the proper voltage and that the line

voltage you are connecting to is not higher than that stated on the decal or rear panel of

the fixture.

If the fixture is intended to indoor use only. To prevent risk of fire or shock, do not

expose fixture to rain or moisture. Make sure there are no flammable, explosive or

corrosive materials surrounded in 10meters while operating.

The unit must be installed in a location with adequate ventilation, at least 5m away from

adjacent surfaces. Be sure that no ventilation slots are blocked.

Some fixture may carry high heat, do not aim at objective more than 2minutes.

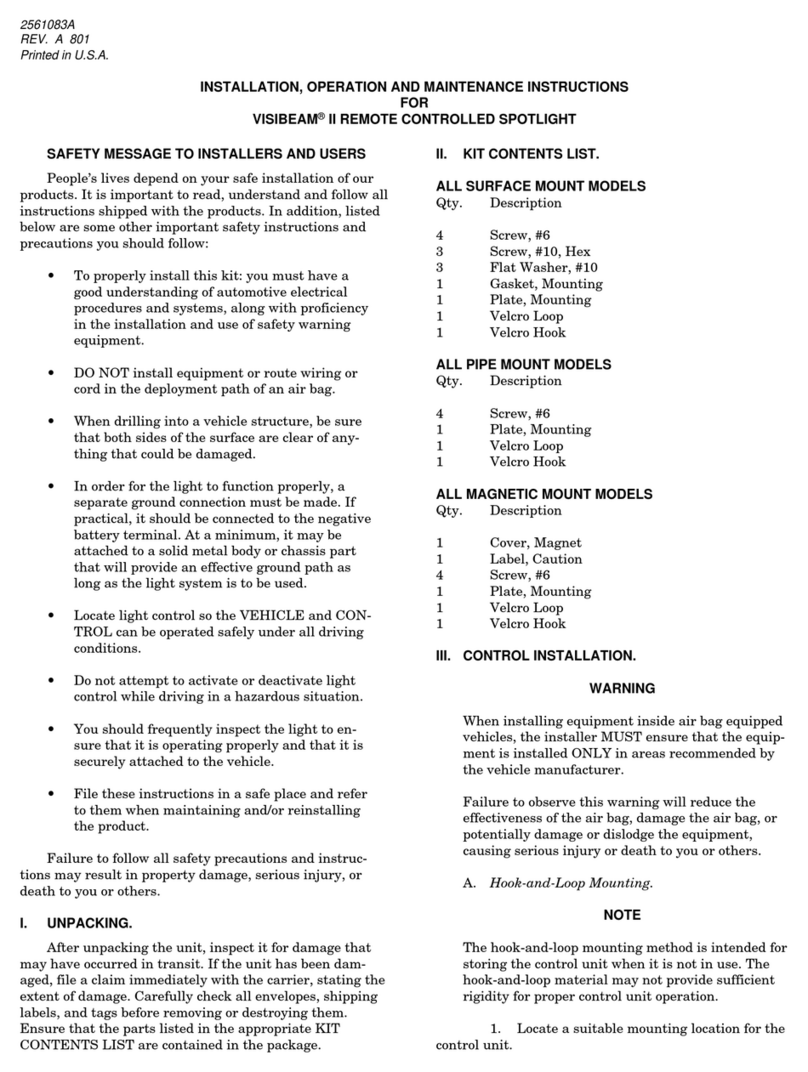

Safe rope should be used to install machine. Bearing of safe rope should be more than

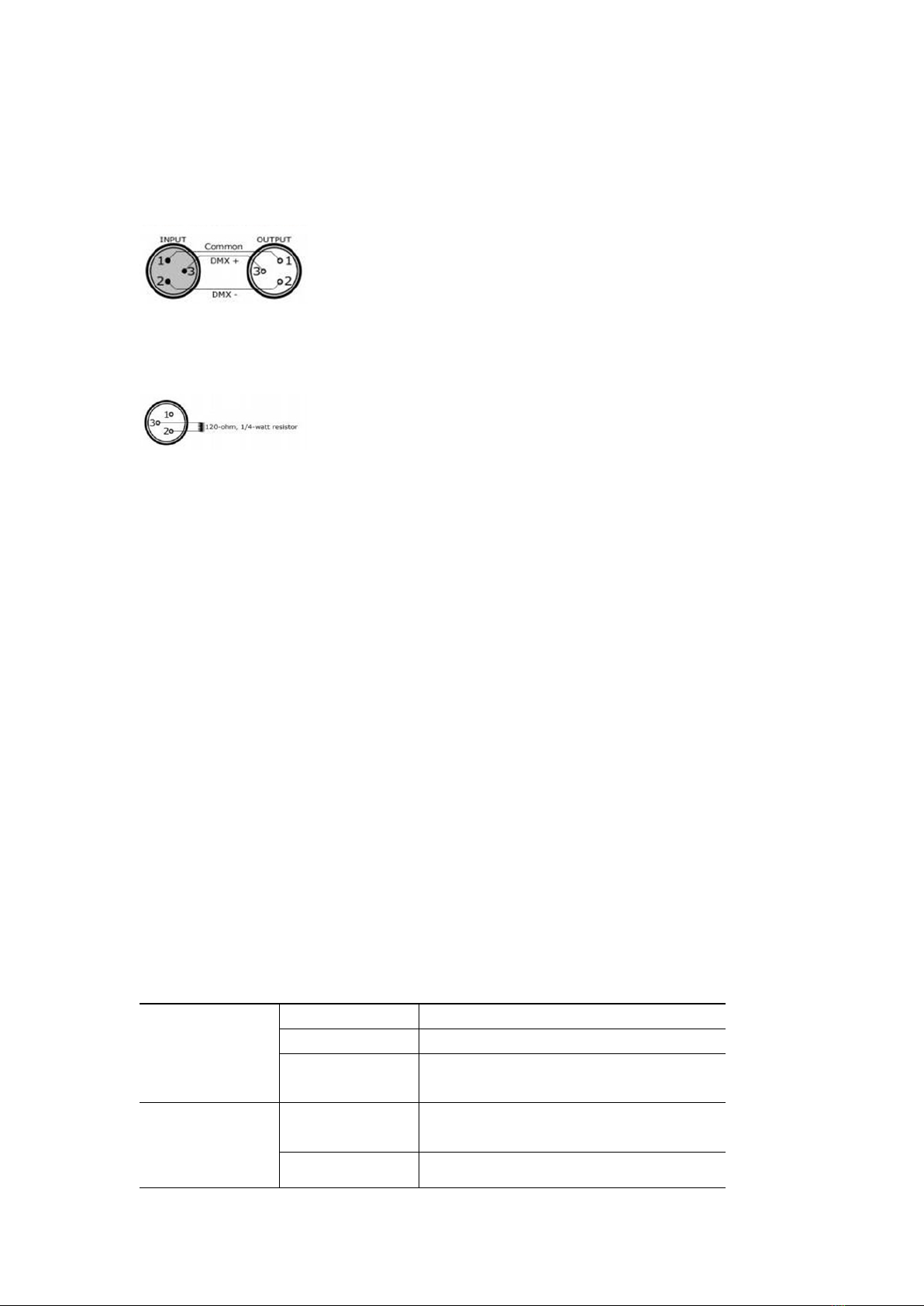

3times of the machine weight. Complimentary signal cable transmits signals to 20 unit

fixtures at most. Signal amplifier is a must to connect more fixtures. And a terminal

should be added at the end of last fixtures’ DMX sockets, 120 Ohm, 1/4W resistance

need welding between Pin 2 and Pin3.

Always disconnect from the power source before servicing or replacing fuse/lamp and

be sure to replace with same fuse/lamp size and type. Cut off power before moving,

repairing and cleaning the machine.

To avoid electric shock, all fixtures must be connected to circuits with a suitable earth

connection.

Always secure fixture using a safety chain and carrying handles.

Do not operate at ambient temperatures higher than 104℉(40℃).

The power cable for this fixture is 0.5 m㎡, please mind the safety requirements in

actual using, if any wrong operation, our company takes no responsibility for any loss.

Also, make sure the power cord is never crimped or damaged.

In case of failure or mis-function occurred, stop using immediately. Never try to repair

the fixture by yourself. Repairs carried out by unskilled people can lead to damage or

malfunction. Please contact the nearest authorized technical assistance center. Buy the

same spare parts/components from manufacturer directly.

Avoid direct eye exposure to the light source while it is on.

Do not power on and power off the fixture frequently

When use DMX controller, please make sure that there is no interference sources(e.g.

intercom, high frequency radio waves and radiation source)

Caution! There are no user serviceable parts inside the unit. Do not open the housing or attempt any

repairs yourself. In the unlikely event your unit may require service, please contact your local distribution

For your safe, please read this user manual carefully before turn on

the fixture. This machine should be operated by qualified engineer!