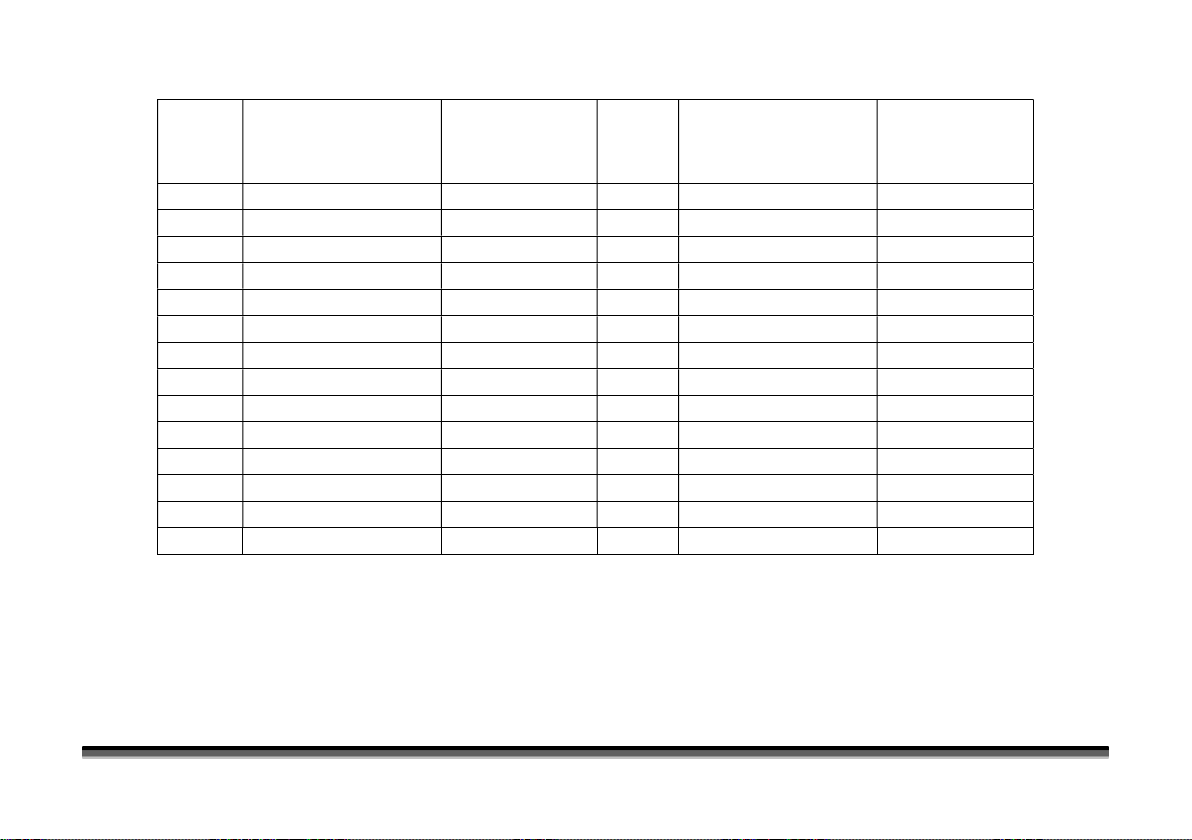

8

* KM

211

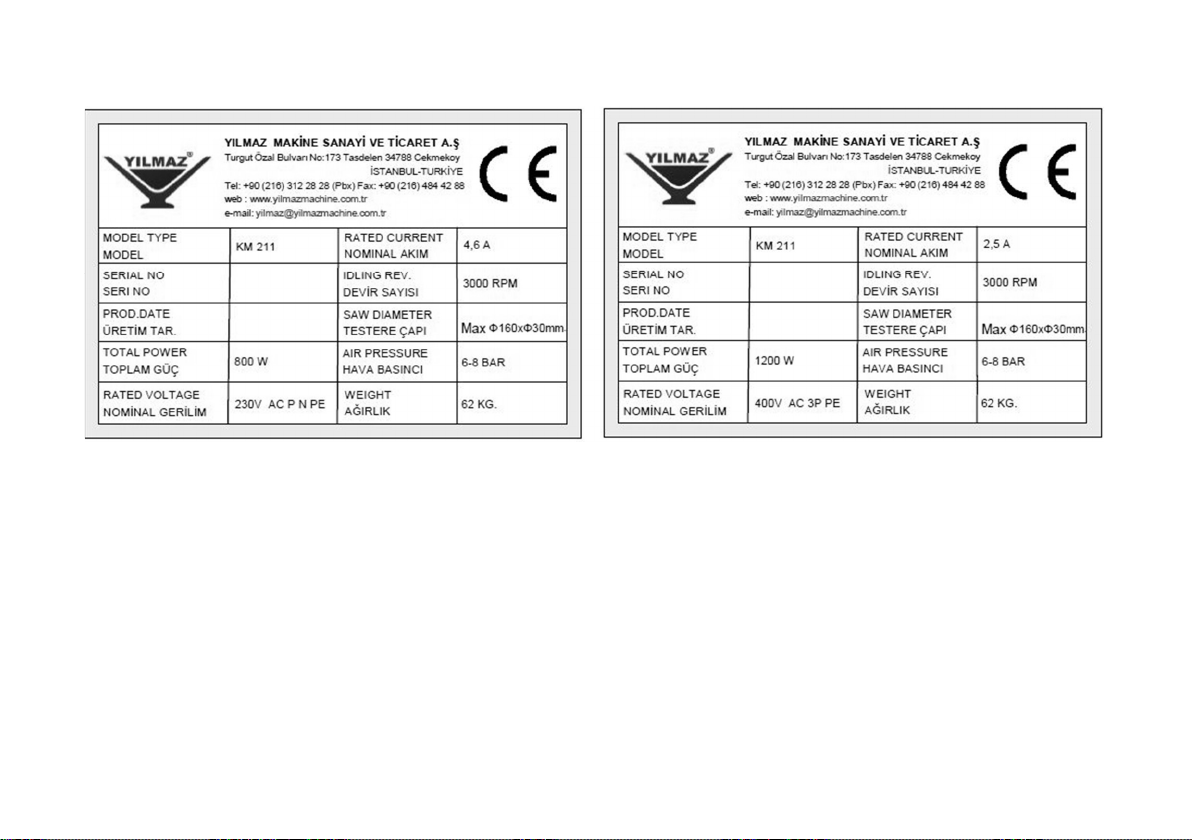

Modellerinde kullanılmaktadır. It is used for the KM 211 Models. Водораспылительная система охлаждения.

(На моделях KM 211)

** KM 211 Modellerinde, opsiyonel soğutma sisteminde kullanılmaktadır. It is used on the optional front

cooling system (On KM 211 Models). Он используется на дополнительные системы охлаждения фронта.

(На моделях KM 211)

NO

номер

STOK KODU

STOCK CODE

ПОРЯДОК КОД

ADET

QTY

КОЛИЧЕСТВО

NO

номер

STOK KODU

STOCK CODE

ПОРЯДОК КОД

ADET

QTY

КОЛИЧЕСТВО

1 1SA010000-0007 1 15 3UA060030-0005 1

2 1SC170000-0001 2 16 3UA040030-0005 1

3 3UA110030-0020 * 1 17 2TU012610-0054 * 1

4 1PN080000-0009 * 1 18 3UA060030-0004 * 1

1PN010000-0087* 1 19 3UA040030-0002 1

6 2TU012510-0096 1 20 2TU011110-0091 1

7 1SA030000-0003 1 21 1PL010000-0016 1

8 2TU012510-0191 1 22 1PL010000-0020 ** 1

9 2TU012510-0100 1 23 3UA370030-0003 1

10 2TU012610-0031 1 24 2TU012610-0009 1

11 2TU012610-0033 1 25 2TU011110-0150 1

12 2TU012610-0034 1 26 2TU012610-0050 1

13 2TU012610-0032 1 27 3UA370030-0001 1

14 2TU012610-0051 1