DESLIGANDO

• Solte o gatilho interruptor de liga e desliga.

APLAINANDO

• Sustente a ferramenta com a peça extrema da base metálica apoiada sobre a superfície da peça

de trabalho.

• Ligue a ferramenta.

• Mova a ferramenta para frente numa linha reta para realizar a passada do corte.

• Apague a ferramenta logo após completar a passada.

Efetuar Rebaixos

• Insira e ajuste o suporte guia paralelo.

• Siga as mesmas instruções do item “Aplainando”.

BISEL DE BORDAS

A ranhura com forma de “V” na peça extrema da base metálica, lhe permite biselar bordas em

ângulos de 45°.

• Sustente a ferramenta em um ângulo com a ranhura sobre a borda da peça de trabalho e realize a

passada de corte.

• É indicado fazer uma prova com um pedaço de madeira que não será utilizado antes de realizar

trabalhos denitivos.

ESVAZIANDO O SACO COLETOR DE PÓ / REBARBAS

O saco coletor de pó / rebarbas deverá ser esvaziado regularmente durante o uso.

• Abra o fecho da bolsa e esvazie o saco antes de prosseguir o serviço.

CONSELHOS PARA UM USO CORRETO

• Mova a ferramenta na direção dos veios da madeira.

• Se o veio for transversal ou frisado, ou se o material da peça de trabalho for uma madeira dura,

ajuste a profundidade do corte para que corte somente uma camada na por passada. Serão

necessárias várias passadas para se chegar ao resultado desejado.

• Para que a ferramenta se mantenha em linha reta, pressione para baixo a parte frontal da ferramenta

ao iniciar a passada e a parte traseira quando estiver nalizando a passada.

TROCANDO A CORREIA DE TRANSMISSÃO

• Solte os parafusos (g. 20) e retire a cobertura (g. 21).

• Retire a correia de transmissão velha.

• Coloque a correia nova (g. 22) sobre as roldanas. Coloque a correia primeiro sobre a roldana maior

(g. 23) e logo em seguida sobre a roldana menor (g. 24) enquanto gira manualmente a coreia até

que esta esteja bem encaixada.

• Coloque a cobertura em seu lugar novamente e aperte os parafusos.

MANUTENÇÃO

Sua ferramenta foi desenhada para funcionar durante um período longo de tempo, necessitando de uma

manutenção mínima. Seu funcionamento contínuo e satisfatório dependerá do cuidado devido da

ferramenta, que são eles:

• Limpe regularmente as entradas de ventilação de sua ferramenta com uma escova suave ou

um panoseco.

• Limpe regularmente a caixa protetora do motor com um pano úmido.

• Não utilize materiais abrasivos ou que tenham em sua fórmula solventes para limpar a ferramenta.

Nunca deixe entrar ou escorrer líquidos para dentro da ferramenta ou mergulhe quaisquer peças da

ferramenta em produtos líquidos.

ASSISTÊNCIA TÉCNICA

Para sua maior segurança, cone os reparos, manutenção e ajustes (incluindo inspeção e reposição) aos

Postos de Assistência Técnica Autorizada BLACK & DECKER, que utilizarão sempre peças de reposição e

acessórios genuínos, remontando sua ferramenta de maneira idêntica a original.

Antes de usar um cabo de extensão, verique se ele tem os soltos ou expostos, isolação danicada e

encaixes defeituosos. Faça os reparos ou troque a extensão se necessário.

GENERAL SAFETY RULES

W:GNINRA

Read and understand all instructions. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious personal injury.

AS VE THESE INSTRUCTIONS

WORK AREA

•Keep your work area clean and well lit. rettulC ed benches and dark areas invite accidents.

•Do not operate power tools in explosive atmospheres, such as in the presence of ammable liquids,

gases, or dust. Power tools create sparks which may ignite the dust or fumes.

•Keep bystanders, children, and visitors away while operating a power tool. Distractions can cause you to

lose contr .lo

ELECTRICAL SAFETY

•Double insulated tools are equipped with a polarized plug (one blade is wider than the other.) This plug

will t in a polarized outlet only one way. If the plug does not t fully in the outlet, reverse the plug. If it

still does not t, contact a qualied electrician to install a polarized outlet. Do not change the plug in any

yaw.Double insulation eliminates the need for the three wire grounded power cord and grounded power

supply system.

•Avoid body contact with grounded surfaces such as pipes, radiators, ranges and r .srotaregirfe rehTeisan

rcni eased risk of electric shock if your body is gr .dednuo

•’noD t expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of

electric shock.

•Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cor sd

rcni ease the risk of electric shock.

•When operating a power tool outside, use an outdoor extension cord marked "W-A" or "W." These cor sd

ra e rated for outdoor use and reduce the risk of electric shock.

KEY INFORMATION YOU SHOULD KNOW:

•For aggressive material removal, use several controlled passes at a shallow

depth of cut.

•For optimum results use smooth uninterrupted passes.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Copyright © 2006 Black & Decker

Printed in China

PERSONAL SAFETY

•Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use

tool while tired or under the inuence of drugs, alcohol, or medication. A moment of inattention while

operating power tools may result in serious personal injury.

•rD ess pr ylrepo . Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing, and

gloves away from moving parts. Loose clothing, jewelry, or long hair can be caught in moving par .st

•Avoid accidental starting. Be sure switch is o before plugging in. raC rying tools with your finger on the

switch or plugging in tools that have the switch on invites accidents.

•Remove adjusting keys or wrenches before turning the tool on. A wrench or key that is left attached to a

rotating part of the tool may result in personal injury.

•Do not overreach. Keep proper footing and balance at all times. rP oper footing and balance enables better

rtnoc ol of the tool in unexpected situations.

•Use safety equipment. Always wear eye pr .noitceto Dust mask, non-skid safety shoes, hard hat, or hearing

rp otection must be used for appropriate conditions.

TOOL USE AND CARE

•Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the

work by hand or against your body is unstable and may lead to loss of control.

•Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer

at the rate for which it is designed.

•Do not use tool if switch does not turn it on or o. Any tool that cannot be controlled with the switch is

dangerous and must be repaired.

•Disconnect the plug from the power source before making any adjustments, changing accessories, or

storing the tool.Such preventative safety measures reduce the risk of starting the tool accidentally.

•Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of

untrained users.

•Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting

edges are less likely to bind and are easier to control.

•Check for misalignment or binding of moving parts, breakage of parts, and any other condition that

may aect the tools operation. If damaged, have the tool serviced before using. Many accidents are

caused by poorly maintained tools.

•Use only accessories that are recommended by the manufacturer for your model. Accessories that may

be suitable for one tool, may become hazardous when used on another tool.

rofmedby

amperes

watts

alternating current

no load speed

earthing terminal

evolutions or

reciprocations per minute

ECIVRES

•Tool service must be per rof med only by qualied repair personnel. reSviceormaintenanceper

unqualified personnel could result in a risk of injury.

•When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance

section of this manual. Use of unauthorized parts or failure to follow Maintenance Instructions may create a

risk of electric shock or injury.

CIFICEPSYTEFASSELUR

•Hold tool by insulated gripping surfaces w hen per rof ming an operation where the cutting tool may

contact hidden wiring or its own cor .dContact with a "live" wire will make exposed metal parts of the tool

"live" and shock the operator.

:NOITUAC Use of this tool can generate dust containing chemicals known to cause cancer, birth defects or

other r rpe oductive harm. Use appropriate r rotaripseypr.noitceto

:NOITUAC Some wood contains pr rese vatives such as copper chromium arsenate (CCA) which can be toxic.

When cutting these materials extra care should be taken to avoid inhalation and minimize skin contact.

The label on your tool may include the following symbols.

V ..........................volts A ........................

Hz ........................hertz W ......................

min ......................minutes ......................

....................direct current no ......................

........................Class II Construction

........................

........................safety alert symbol .../min ................r

ADDITIONAL SAFETY INSTRUCTIONS FOR PLANERS

•Read instruction manual thoroughly before using this tool.

•Be sure the switch is in OFF position before connecting tool to power supply.

•Switch FFO immediately if tool is jammed in work.

•Disconnected from power source when cleaning or making adjustments to the tool.

•Be sure tool is properly held or set for right use before turning switch to NO .

•Maintain tool with care. Follow instructions for lubricating and changing accessories.

rotS• e tool in a clean dry place after disconnecting from power sour .ec

•Keep air vents unobstructed for proper motor cooling.

•DONOT lay tool down on shoe when the blades are exposed. This can chip the blades.

•Keep side discharge chute unobstructed at all times.

•Never reach under the tool for any reason unless it is turned off and UNPLUGGED. BLADES ARE EXPOSED

AND EXTREMELY SHARP.

•Use this tool for working with wood and wood products only.

•Never operate without securely holding the front handle.

•Always operate planer with two hands.

•Planer blades are extremely sharp - Handle with great car .e

SAVE THESE INSTRUCTIONS

ROTOM

Be sure your power supply agrees with nameplate marking. Do not operate AC tools on DC. This infor noitam

is printed on the nameplate. All Black & Decker tools are factory-tested; if this tool does not operate, check

the power supply.

USE OF EX TENSION CORDS

Make sure the extension cord is in good condition before using. Always use the proper size extension cor sd

with the tool – that is, proper wire size for various lengths of cord and heavy enough to carry the current the

tool will draw. Use of an undersized cord will cause a drop in line voltage resulting in loss of power dna

gnitaehrevo . For proper size cords see chart below.

OPERATION

HCTIWS

LA WAYS PICK UP YOUR PLANER BEFORE DEPRESSING THE SWITCH. The planer is started by depr gnisse

the trigger in the handle. To turn the planer OFF, release the trigger.

ADJUSTINGPLANINGDEPTH

Tru n off and unplug Planer. Planing depth is10 positive steps and is adjustable by rotating the knob on the top

of the planer near the front, as shown in Figure 2. The position on the knob marked “P” is the “Park” position;

use this setting when storing the tool or whenever it is unattended. As the knob is rotated clockwise from the

“P” position the cutting depth will increase from 1/32” (.080mm) to as much as 5/64” (1.9mm). It is

recommended that test cuts be made in scrap wood after each readjustment to make sure that the desir de

amount of wood is being removed by the planer. Several shallow passes will produce a smoother finish than

one deep one.

GNINALP

Hold the planer as shown in with one hand on the switch handle and the other hand on the front handle.

Place the front shoe on the surface to be planed, making certain that the cutting blades are not touching the

rus face. Push down firmly on the front handle of the planer so that the front shoe is ABSOLUTELY FLAT on the

work surface. Pull the trigger switch and allow the motor to reach full speed before beginning to plane.

Move the tool slowly into the work and maintain downward pr russe e to keep the planer flat. Be par ylralucit

rac eful to keep the tool flat at the beginning and the end of the work sur .ecaf

PLANING TIP: For a smoother appearance, fasten a piece of scrap wood to the end of the piece you are

planing. Don’t stop planing until the cutting blades of the planer are past your work piece and into the

scrap material.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

220V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

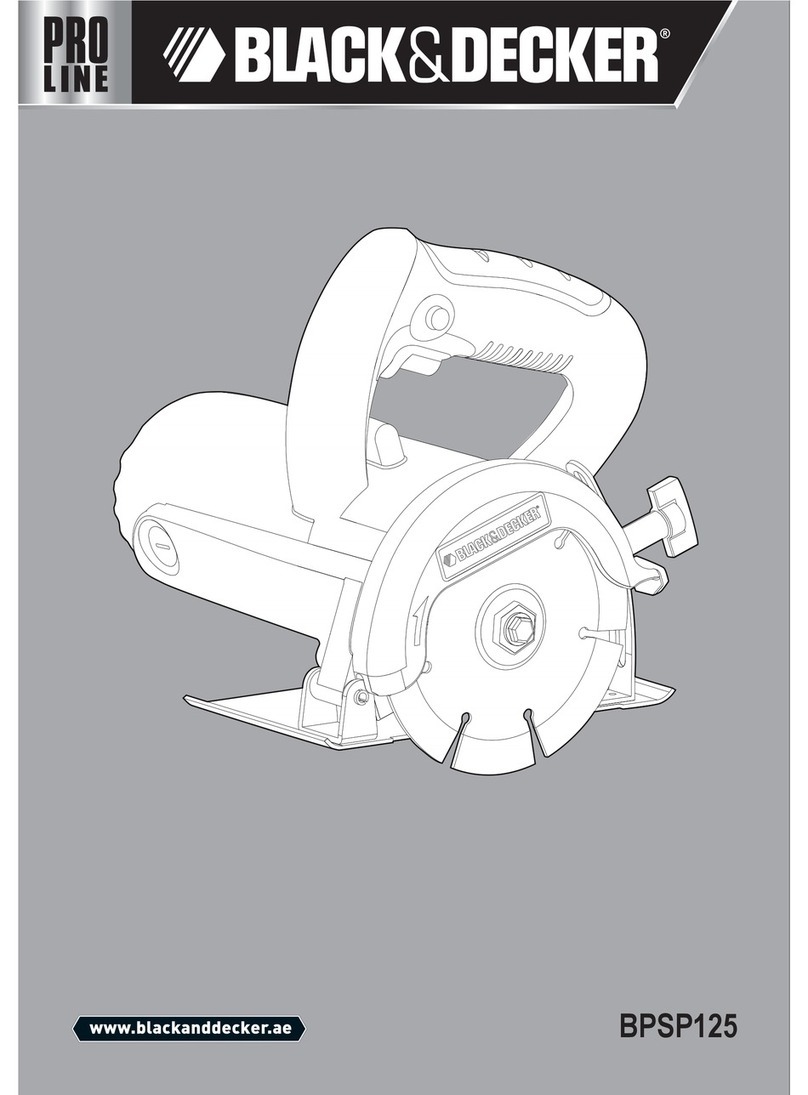

FEATURES

1. On/off switch

2. Lock-on button

3. Shavings discharge outlet

4. Planing depth adjustment knob

5. Planing depth graduation

3-1/4” Planer3-1/4” Planer

INSTRUCTION MANUAL

Catalog number 7698