2IM 77J10P01-01EN 1st Edition

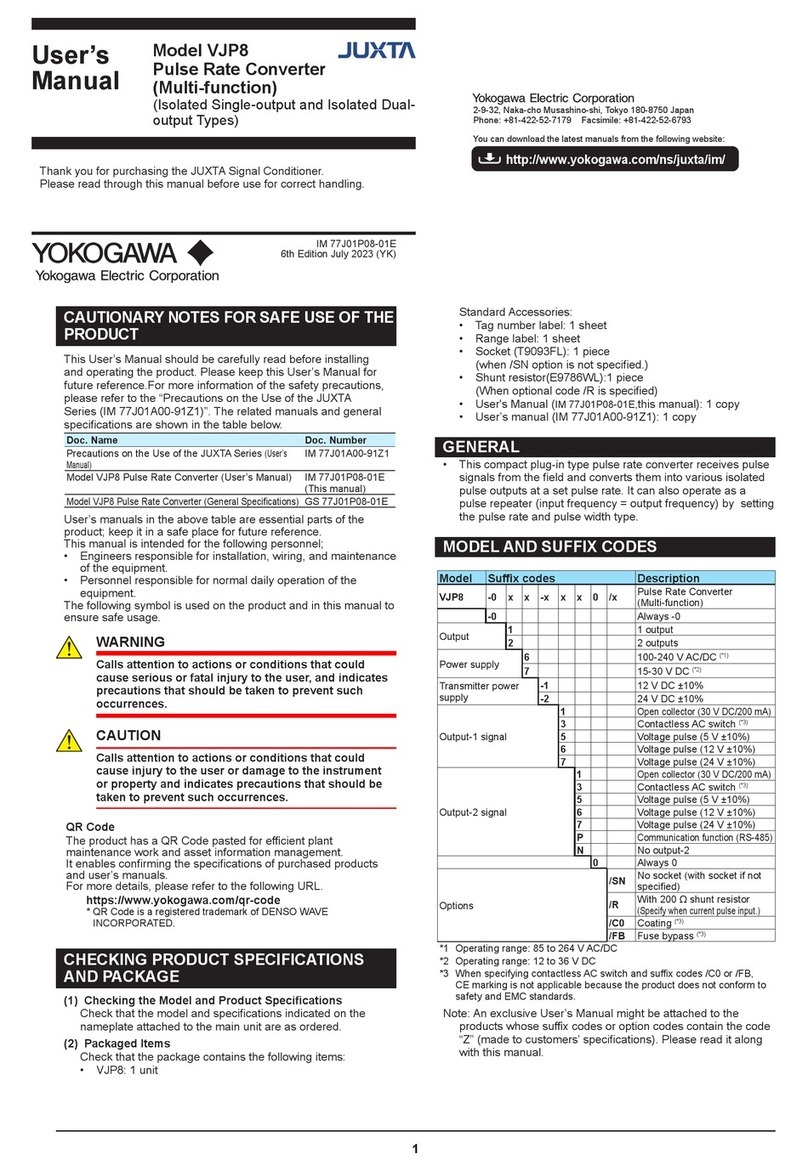

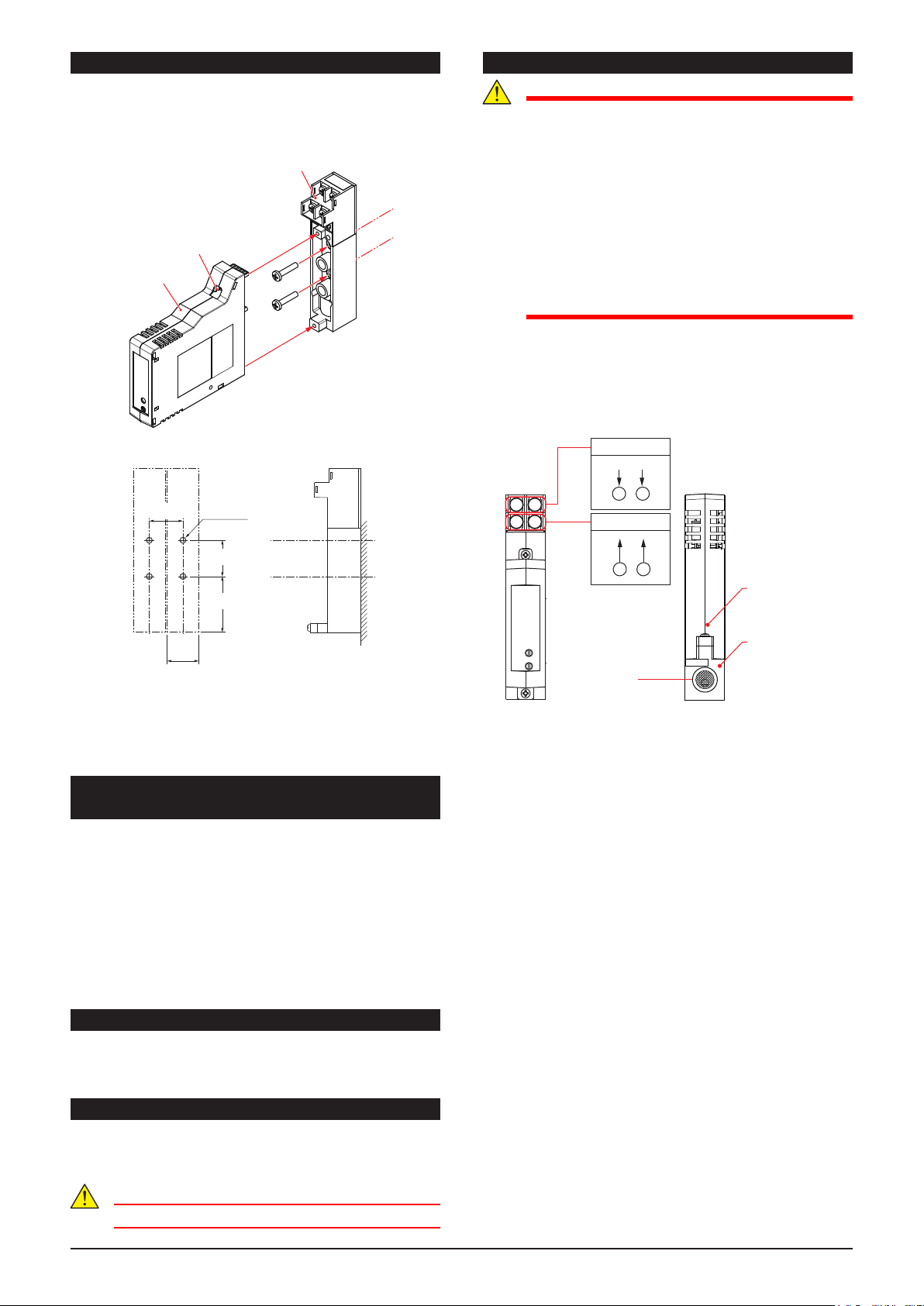

1. MOUNTING METHOD

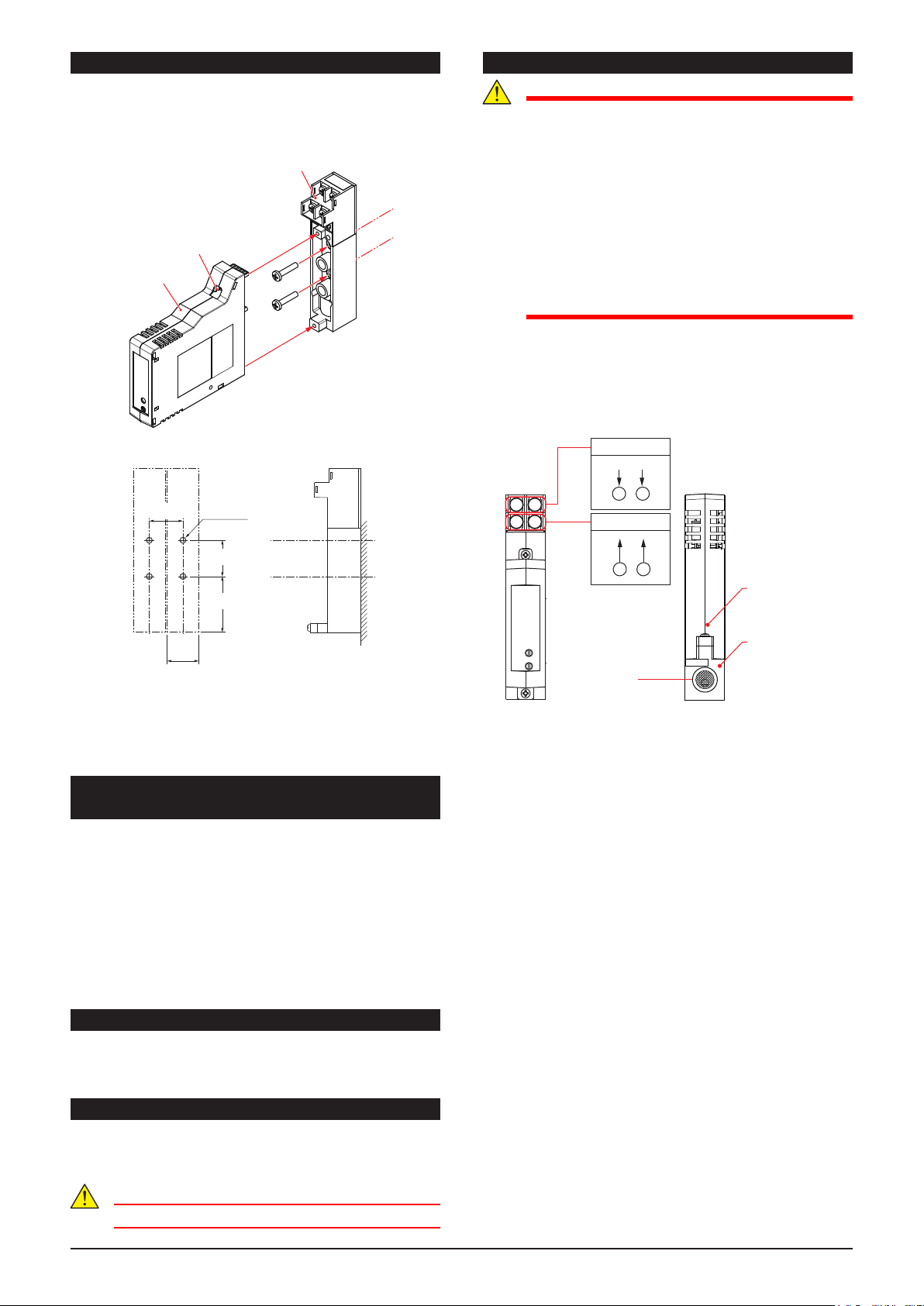

First, Fix the terminal board to the wall as shown in the gure

below (*). Then x the main body on terminal board with two

screws.

* Terminal board can be detached from the main body by

removing two screws.

Main body

Mounting screws

(upper and lower)

Terminal board

Mounting dimensions (Unit: mm)

24

M4 screw

43

27

25.5

The PF1 can be mounted on the Air Supply Unit (PPU) and

can be mixed mounting with the PH10 (Electrical to Pneumatic

Converter).

The mounting method is the same as PH10. Refer to the PH10

user’s manual.

• Document number: IM 77J10P10-01EN

2. INSTALLATION AND ENVIRONMENTAL

CONDITIONS

• Avoid the following environments for installation locations:

Areas with vibrations, corrosive gases, dust, water, oil,

solvents, direct sunlight, radiation, a strong electric eld,

and/or a strong magnetic eld, direct radiant heat, wind,

temperature uctuation.

• If there is any risk of a surge being induced into the power line

and/or signal lines due to lightning or other factors, a dedicated

lightning arrester should be used as protection for both the

product and a eld-installed device.

• Use indoors at an altitude of 2000 m or less.

• Operating temperature/humidity range: 0 to 50°C/5 to 90%RH

(no condensation)

3. AUTOMATIC SEALING

When main body of the PF1 is removed from the terminal board,

air will be sealed automatically by closing a valve of terminal

board.

4. PIPING

Connect pipe for input pneumatic signal to inlet (Rc 1/4 (PT 1/4

female thread)) of terminal board. The thread size for pipes is R

1/4 (PT 1/4 male thread).

CAUTION

Fastening torque of pipe is 2±0.5 N•m

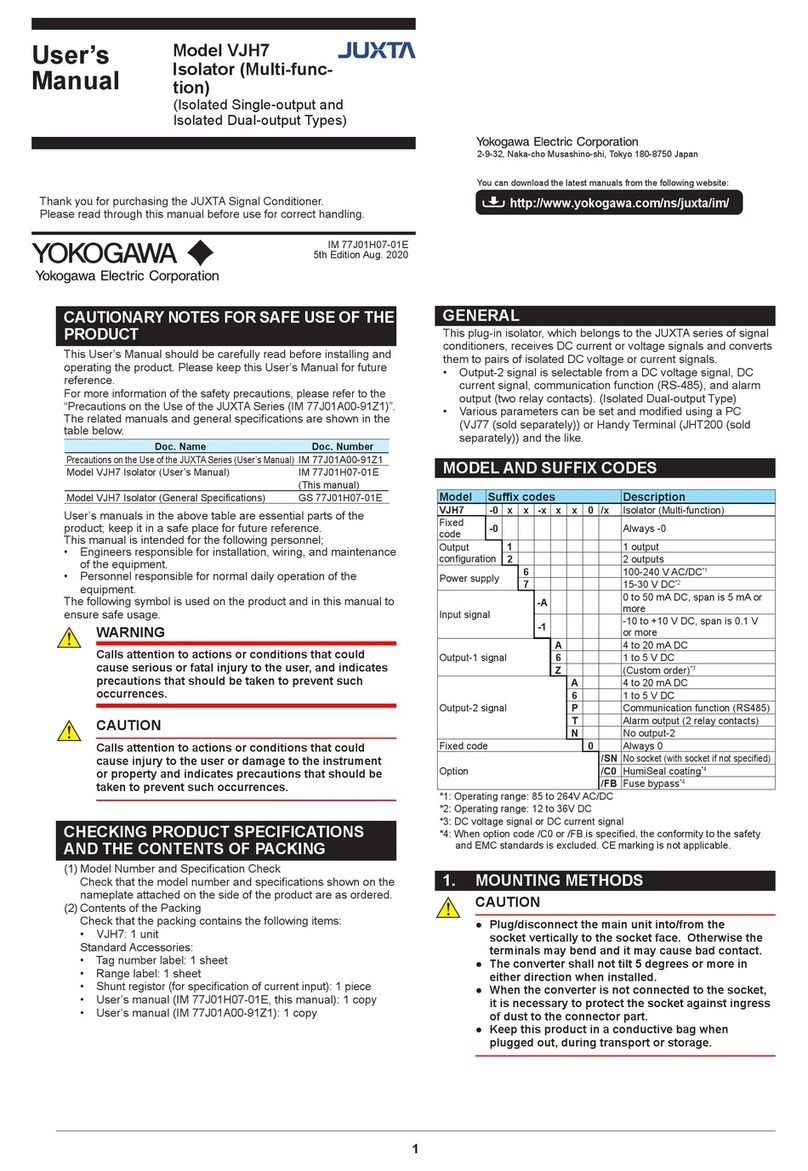

5. EXTERNAL WIRING

WARNING

●To avoid the risk of an electric shock, turn o the

power supply and use a tester or similar device to

ensure that no power is supplied to a cable to be

connected, before carrying out wiring work.

●Do not operate the product in the presence of

ammable or explosive gases or vapors. To do so is

highly dangerous.

●Use of the product ignoring the specications may

cause overheating or damage. Before turning on

the power, ensure the following:

•Power supply voltage and input signal value

applied to the product should meet the required

specications.

•The external wiring to the terminals and wiring to

ground are as specications.

Wiring should be connected to the terminals on the socket of the

product. The terminals for external connections are of M3 screws.

Use crimp-on terminal lugs for connections to the terminals.

• Recommended cables: A nominal cross-sectional area of

0.5 mm2or thicker for signal cables, and that of 1.25 mm2or

thicker for power cables.

Wiring Diagram

PF1

bottom view

1 2

3 4

+ –

34

Power supply

+

24 V DC

–

1 2

Output signal

Input signal

(Air pressure piping

inlet)

PF1

Main body

Terminal

board