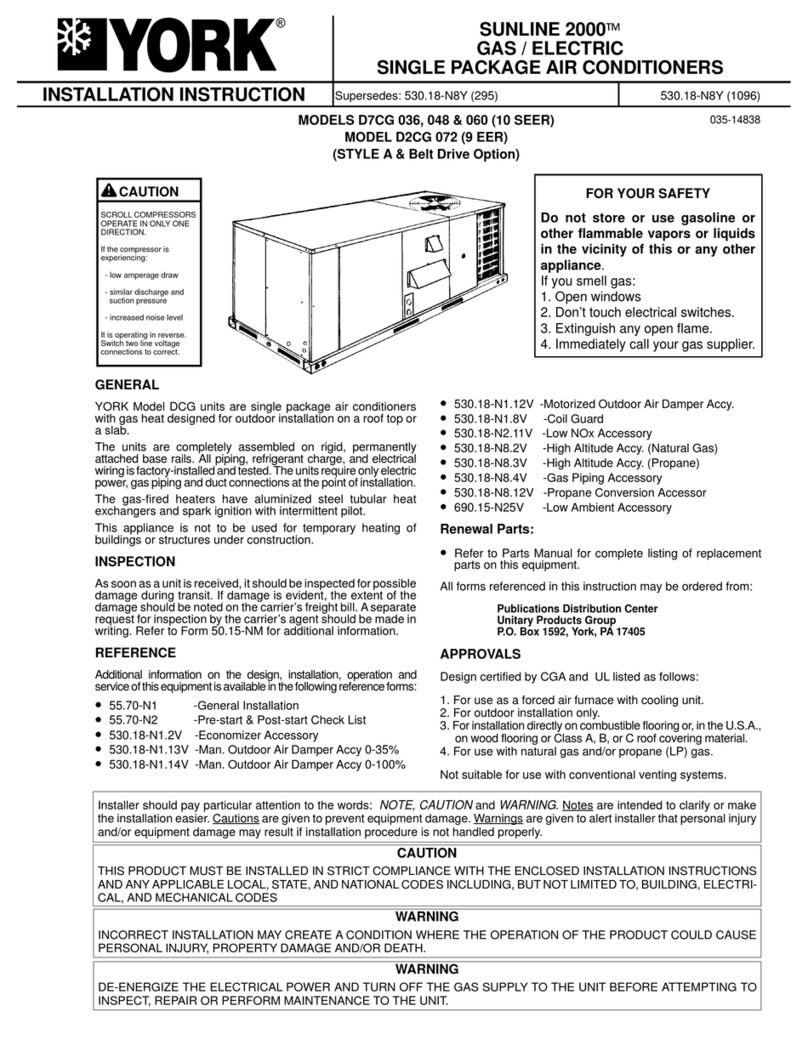

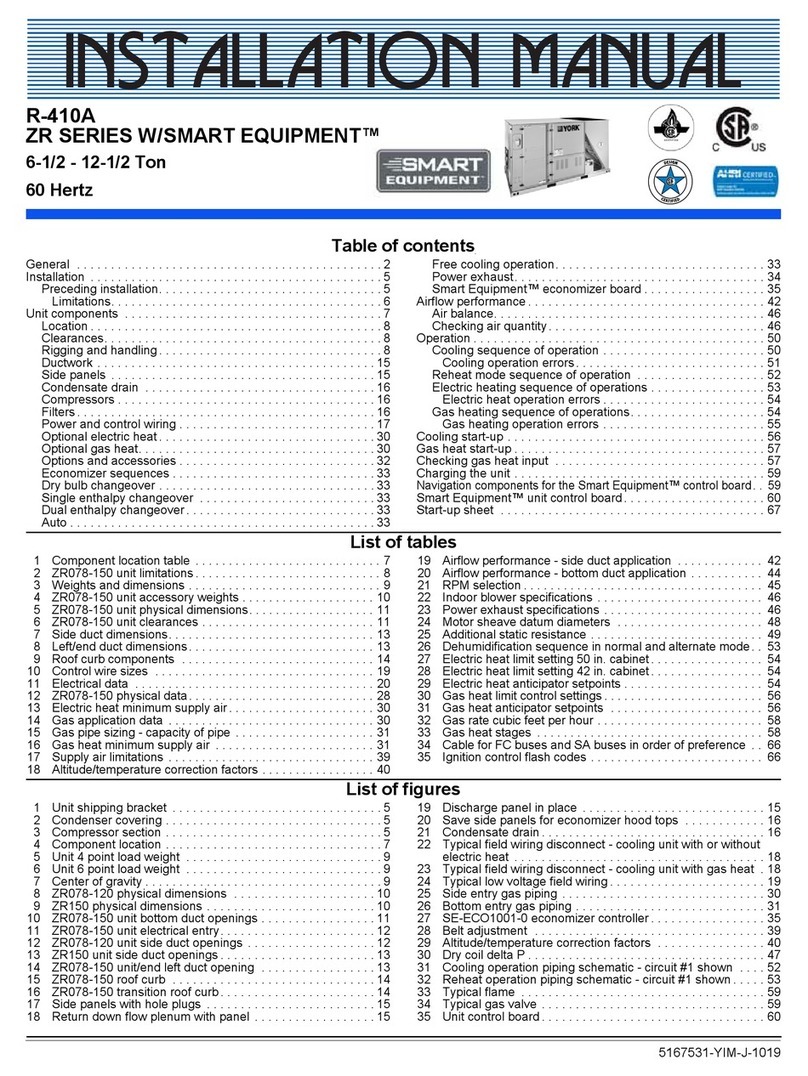

Installation Instructions

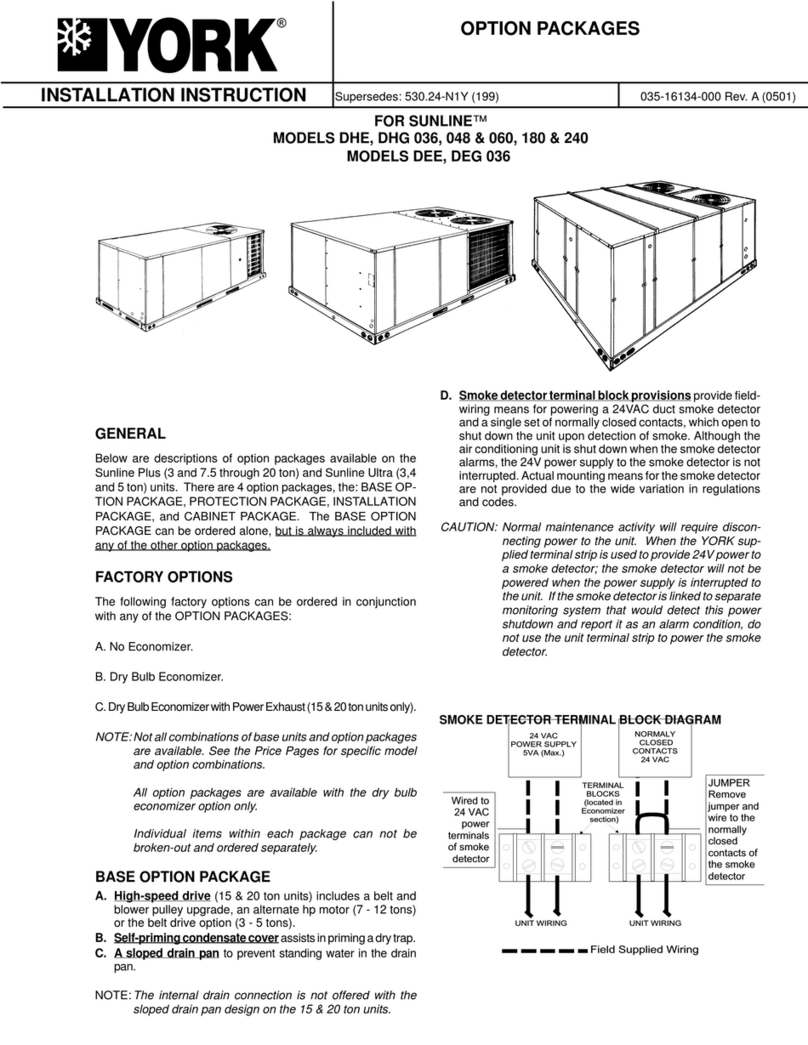

• Connect the duct connections to unit supply and return air ducts.

• Refer to GA drawing for unit supply and return duct connection sizes and locations.

• Use canvas connection between unit & supply air duct to avoid the transmission of vibration to the duct.

• Don't run the unit without filter on return air side.

• Avoid abnormal duct size increases and reductions. It can adversely affects air and cooling performance.

• When electrical heater is installed, use fireproof canvas (or similar heat resistance material) between duct & unit

discharge connection.

• Do the proper duct sizing for air quantity (L/s or cfm) recommended at various External Static Pressures.

• All ducting should be insulated properly to avoid heat transfer.

• All ducts should be secured properly to building structural opening should be sealed properly to avoid any air

leakage or condensation.

• All main branch ducts (without 90° elbow) should be acoustically lined up to min. 10 ft length with the help of all

perforated sheet & fiber glass insulation of recommended density & thickness.

• Ensure Room thermostat fixed at proper location, sensing return air or room temperatures and set the thermostat

not less than 70° F.

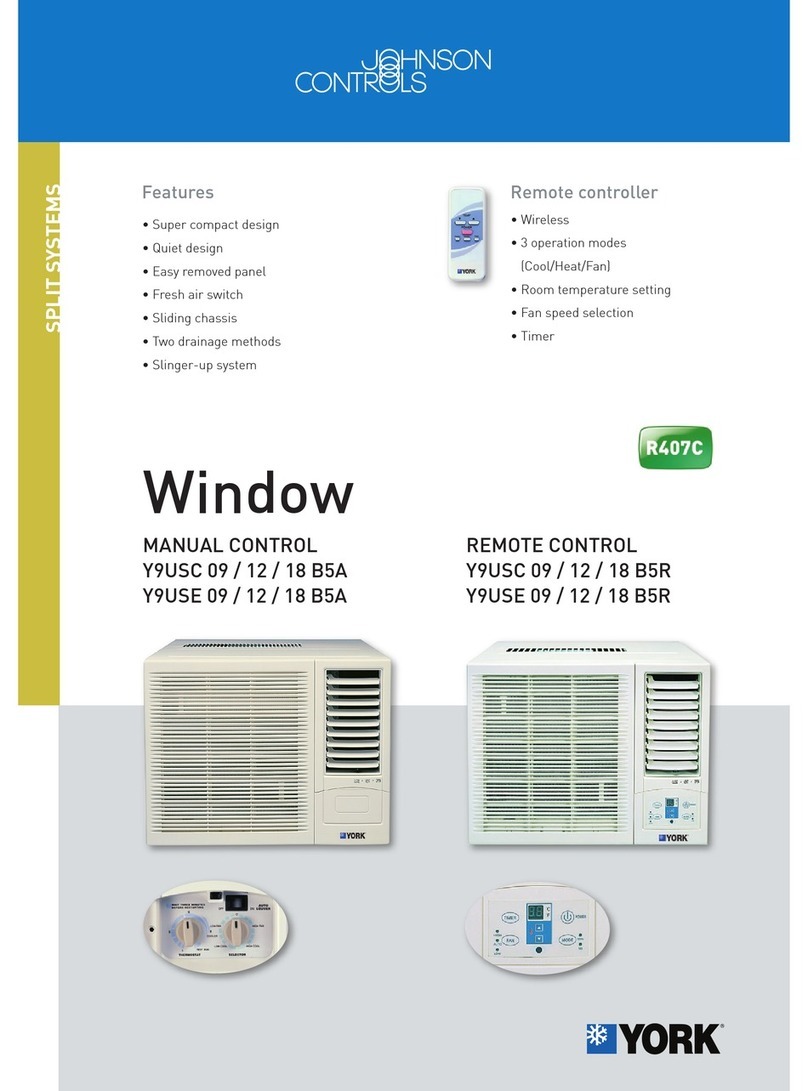

Indoor Units

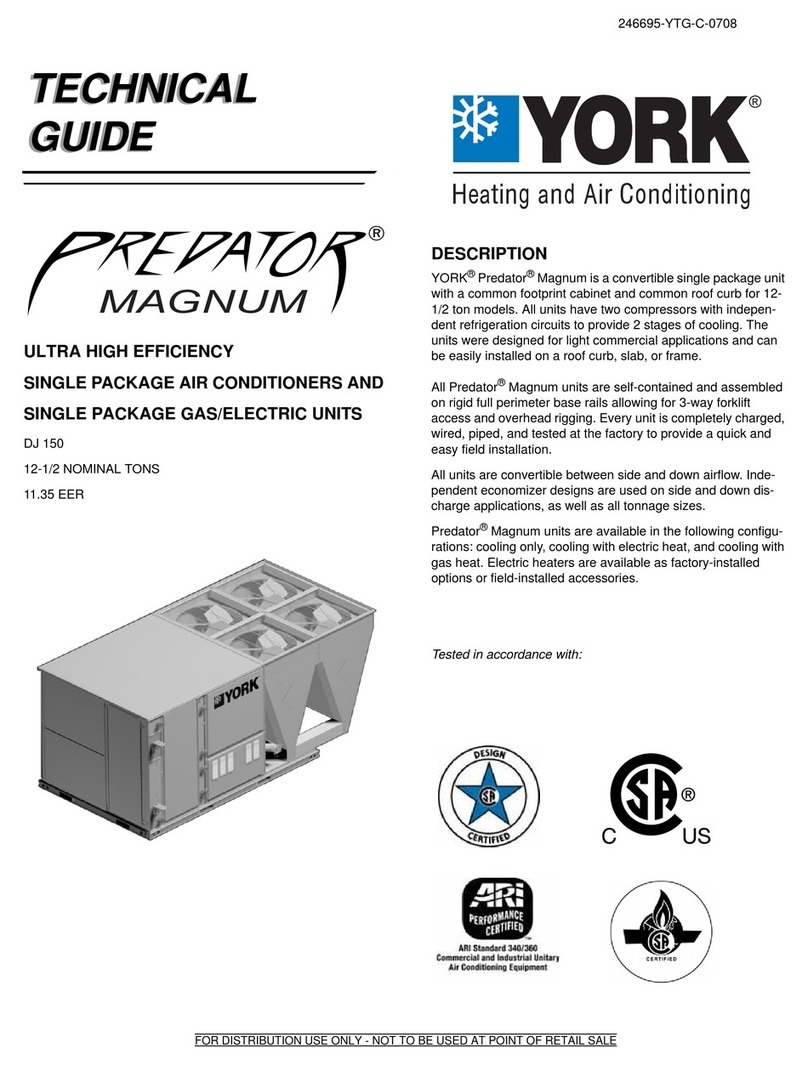

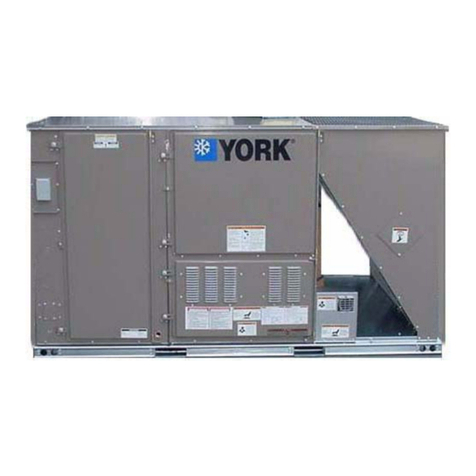

Outdoor Unit Location and Mounting

•

• Unit must be lifted by 2” pipe hook rigging sling in base rail, use spreader bar to prevent the sling from damaging

the unit.

• A minimum clearance of 1 m on serviceable side, 300 mm for air inlets on all sides and 1.5 m for air discharge (unit

top) is required.

• The unit must be located outdoor only and cannot be connected to duct work.

• The metal parts of the unit if subjected to salt spray, fog or mist in seacoast areas could lead to rapid

corrosion/oxidation and may lead to premature failure.

• Interconnecting tubing.

• Vapor and Liquid lines.

• Keep all lines sealed until connection is made.

• Make connections at the indoor coil first.

• In dual circuit units, ensure Liquid & Suction tubes at indoor & out door units are brazed to

corresponding systems.

• Connect the filter drier and sight glass at the liquid line in the flow direction marked on the components.

• Perform the Leak check at all the brazed and flare joints.

• Perform system Evacuation up to 200 microns.

• Factory charged unit is sufficient for 25 feet of interconnecting tubing.

• Maximum length of lines

• The maximum equivalent length of interconnecting line is 200 feet. Always use the shortest length

possible with minimum number of bends.

• If the application call for more length of piping, please contact our sales officer.

• Sizing

Please refer the Guideline for inter connecting piping.

Consult local building codes or ordinances for special installation requirements.

Locating Unit

COMMERCIAL DUCTED SPLITS 07