036-21489-001-C-1004

8Unitary Products Group

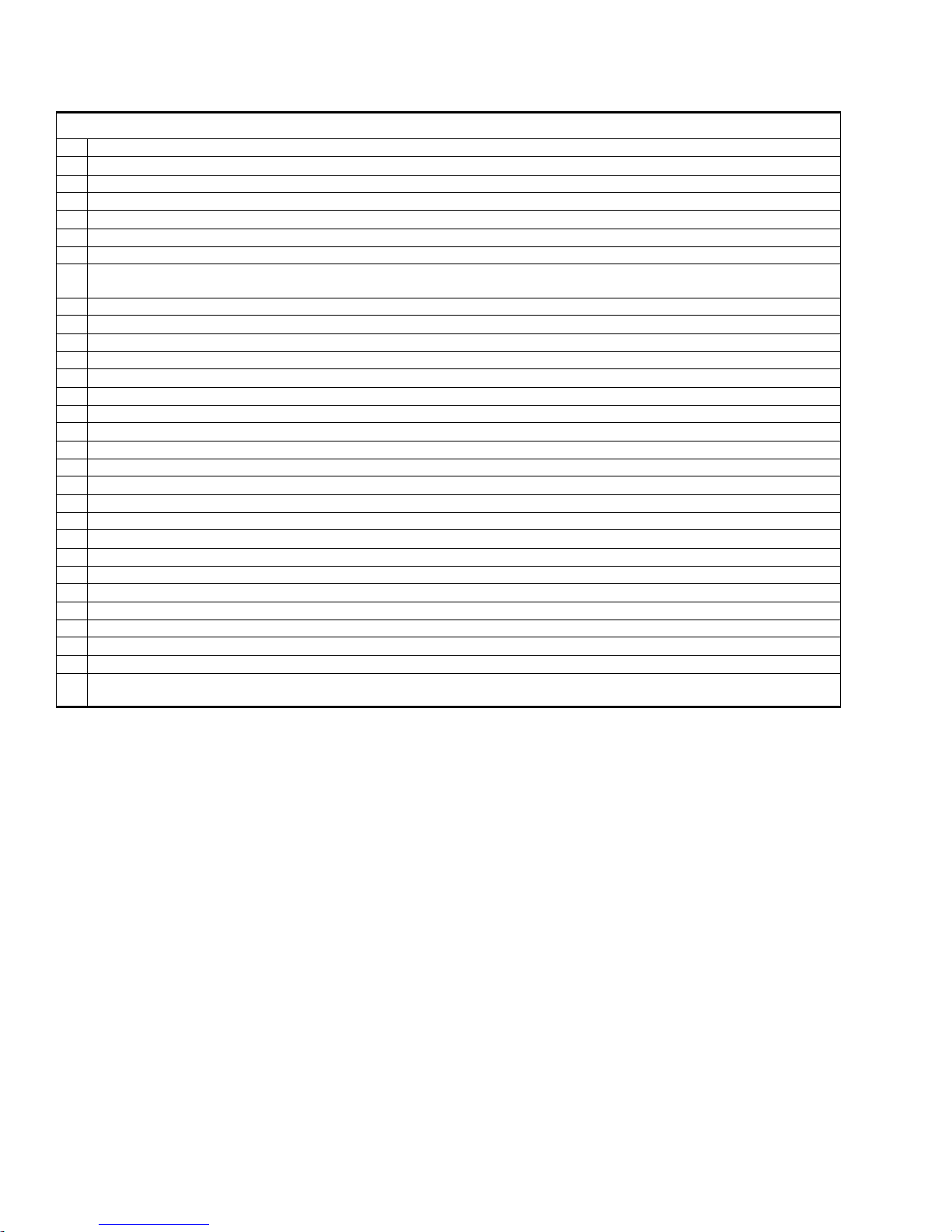

EF Johnson UNT Controller, DFS, APS, Technicoat Cond. Coil, & Phase Monitor, Hinged Filter Door & Toolless Access Panels

EG Johnson UNT Controller, DFS, APS, Technicoat Cond. Coil, & Coil Guard, Hinged Filter Door & Toolless Access Panels

EH Johnson UNT Controller, DFS, APS, Technicoat Cond. Coil, Phase Monitor, & Coil Guard, Hinged Filter Door & Toolless Access Panels

EJ Johnson UNT Controller, DFS, APS & Technicoat Evap. Coil, Hinged Filter Door & Toolless Access Panels

EK Johnson UNT Controller, DFS, APS, Technicoat Evap. Coil, & Phase Monitor, Hinged Filter Door & Toolless Access Panels

EL Johnson UNT Controller, DFS, APS, Technicoat Evap. Coil, & Coil Guard, Hinged Filter Door & Toolless Access Panels

EM Johnson UNT Controller, DFS, APS, Technicoat Evap. Coil, Phase Monitor, & Coil Guard, Hinged Filter Door & Toolless Access Panels

EN Johnson UNT Controller, DFS, APS & Technicoat Evap. & Cond Coils, Hinged Filter Door & Toolless Access Panels

EP Johnson UNT Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Phase Monitor, Hinged Filter Door & Toolless Access Panels

EQ Johnson UNT Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Coil Guard, Hinged Filter Door & Toolless Access Panels

ER Johnson UNT Controller, DFS, APS, Technicoat Evap. & Cond Coils, Phase Monitor, & Coil Guard, Hinged Filter Door & Toolless Access

Panels

ES Johnson UNT Controller, DFS, APS, SS Drain Pan Hinged Filter Door & Toolless Access Panels

ET Johnson UNT Controller, DFS, APS, SS Drain Pan, Phase Monitor, & Coil Guard Hinged Filter Door & Toolless Access Panels

EU Johnson UNT Controller, DFS, APS, SS Drain Pan, & Technicoat Cond Coils Hinged Filter Door & Toolless Access Panels

EV Johnson UNT Controller, DFS, APS, SS Drain Pan, & Technicoat Evap Coil Hinged Filter Door & Toolless Access Panels

EW Johnson UNT Controller, DFS, APS, SS Drain Pan, & Technicoat Evap and Cond Coils Hinged Filter Door & Toolless Access Panels

EX Johnson UNT Controller, DFS, APS, SS Drain Pan, Phase Monitor, Coil Guard, & Technicoat Evap and Cond Coils Hinged Filter Door &

Toolless Access Panels

GA Honeywell Excel 10 Controller with Dirty Filter Switch & Air Proving Switch, Hinged Filter Door & Toolless Access Panels

GB Honeywell Excel 10 Controller, DFS, APS & Phase Monitor, Hinged Filter Door & Toolless Access Panels

GC Honeywell Excel 10 Controller, DFS, APS & Coil Guard, Hinged Filter Door & Toolless Access Panels

GD Honeywell Excel 10 Controller, DFS, APS, Phase Monitor, & Coil Guard, Hinged Filter Door & Toolless Access Panels

GE Honeywell Excel 10 Controller, DFS, APS & Technicoat Cond. Coil, Hinged Filter Door & Toolless Access Panels

GF Honeywell Excel 10 Controller, DFS, APS, Technicoat Cond. Coil, & Phase Monitor, Hinged Filter Door & Toolless Access Panels

GG Honeywell Excel 10 Controller, DFS, APS, Technicoat Cond. Coil, & Coil Guard, Hinged Filter Door & Toolless Access Panels

GH Honeywell Excel 10 Controller, DFS, APS, Technicoat Cond. Coil, Phase Monitor, & Coil Guard, Hinged Filter Door & Toolless Access

Panels

GJ Honeywell Excel 10 Controller, DFS, APS & Technicoat Evap. Coil, Hinged Filter Door & Toolless Access Panels

GK Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. Coil, & Phase Monitor, Hinged Filter Door & Toolless Access Panels

GL Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. Coil, & Coil Guard, Hinged Filter Door & Toolless Access Panels

GM Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. Coil, Phase Monitor, & Coil Guard, Hinged Filter Door & Toolless Access

Panels

GN Honeywell Excel 10 Controller, DFS, APS & Technicoat Evap. & Cond Coils, Hinged Filter Door & Toolless Access Panels

GP Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Phase Monitor, Hinged Filter Door & Toolless Access

Panels

GQ Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Coil Guard, Hinged Filter Door & Toolless Access Panels

GR Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. & Cond Coils, Phase Monitor, & Coil Guard, Hinged Filter Door & Toolless

Access Panels

GS Honeywell Excel 10 Controller, DFS, APS, SS Drain Pan

GT Honeywell Excel 10 Controller, DFS, APS, SS Drain Pan, Phase Monitor, & Coil Guard

GU Honeywell Excel 10 Controller, DFS, APS, SS Drain Pan, & Technicoat Cond Coils

GV Honeywell Excel 10 Controller, DFS, APS, SS Drain Pan, & Technicoat Evap Coil

GW Honeywell Excel 10 Controller,DFS, APS, SS Drain Pan, & Technicoat Evap and Cond Coils

GX Honeywell Excel 10 Controller,DFS, APS, SS Drain Pan, Phase Monitor, Coil Guard, & Technicoat Evap and Cond Coils

PA Novar ETC-3 Controller with Dirty Filter Switch & Air Proving Switch, Hinged Filter Door & Toolless Access Panels

PB Novar ETC-3 Controller, DFS, APS & Phase Monitor, Hinged Filter Door & Toolless Access Panels

PC Novar ETC-3 Controller, DFS, APS & Coil Guard, Hinged Filter Door & Toolless Access Panels

PD Novar ETC-3 Controller, DFS, APS, Phase Monitor, & Coil Guard, Hinged Filter Door & Toolless Access Panels

PE Novar ETC-3 Controller, DFS, APS & Technicoat Cond. Coil, Hinged Filter Door & Toolless Access Panels

PF Novar ETC-3 Controller, DFS, APS, Technicoat Cond. Coil, & Phase Monitor, Hinged Filter Door & Toolless Access Panels

PG Novar ETC-3 Controller, DFS, APS, Technicoat Cond. Coil, & Coil Guard, Hinged Filter Door & Toolless Access Panels

PH Novar ETC-3 Controller, DFS, APS, Technicoat Cond. Coil, Phase Monitor, & Coil Guard, Hinged Filter Door & Toolless Access Panels

PJ Novar ETC-3 Controller, DFS, APS & Technicoat Evap. Coil, Hinged Filter Door & Toolless Access Panels

PK Novar ETC-3 Controller, DFS, APS, Technicoat Evap. Coil, & Phase Monitor, Hinged Filter Door & Toolless Access Panels

Hinged Filter Door & Toolless Access Cabinet