YouKits TJ2B Instructions for use

Other YouKits Transceiver manuals

YouKits

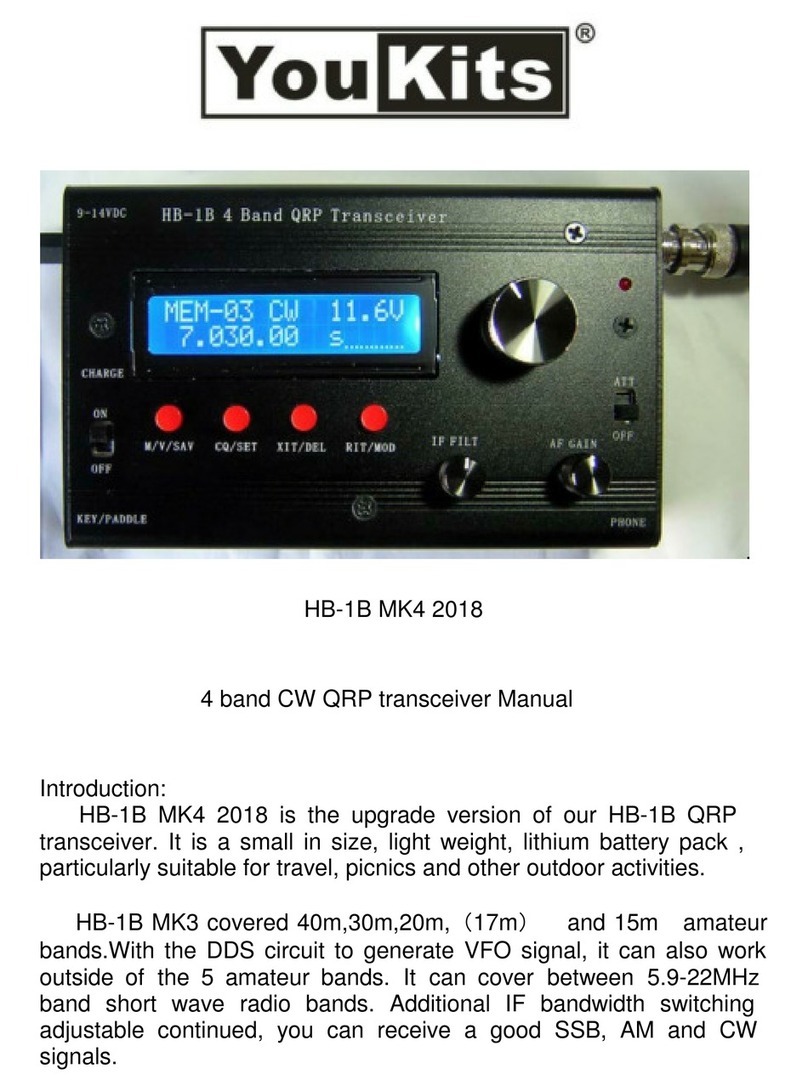

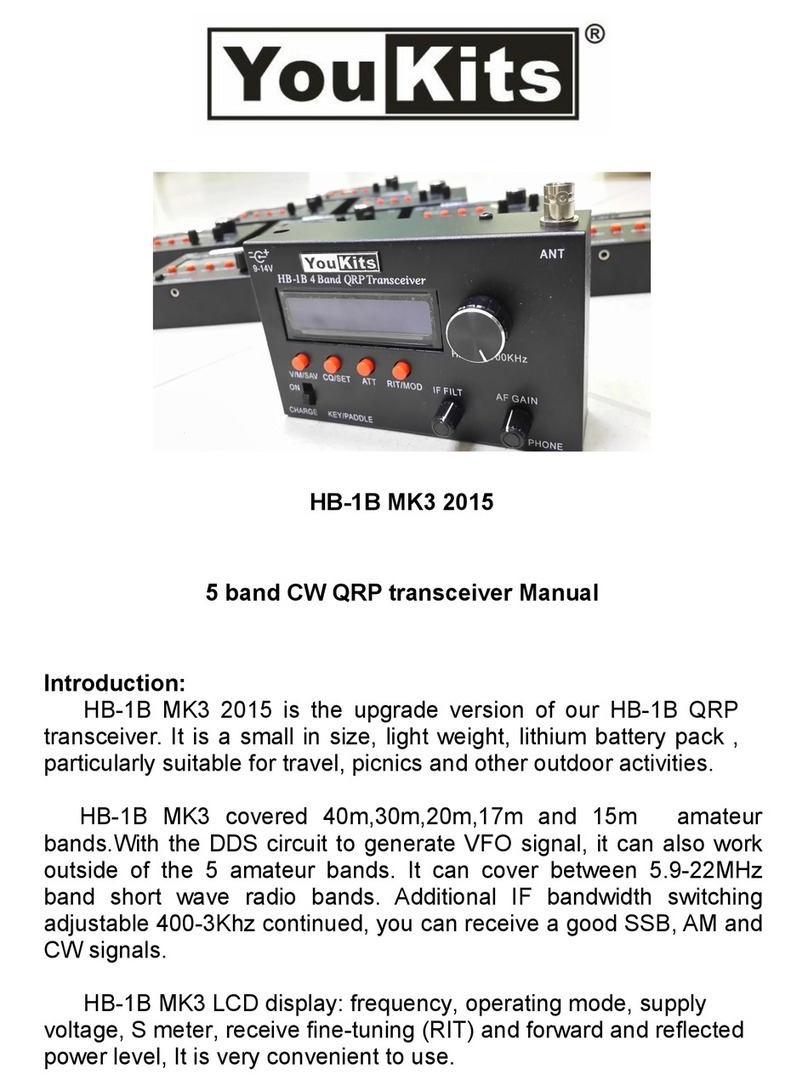

YouKits HB-1B MK3 User manual

YouKits

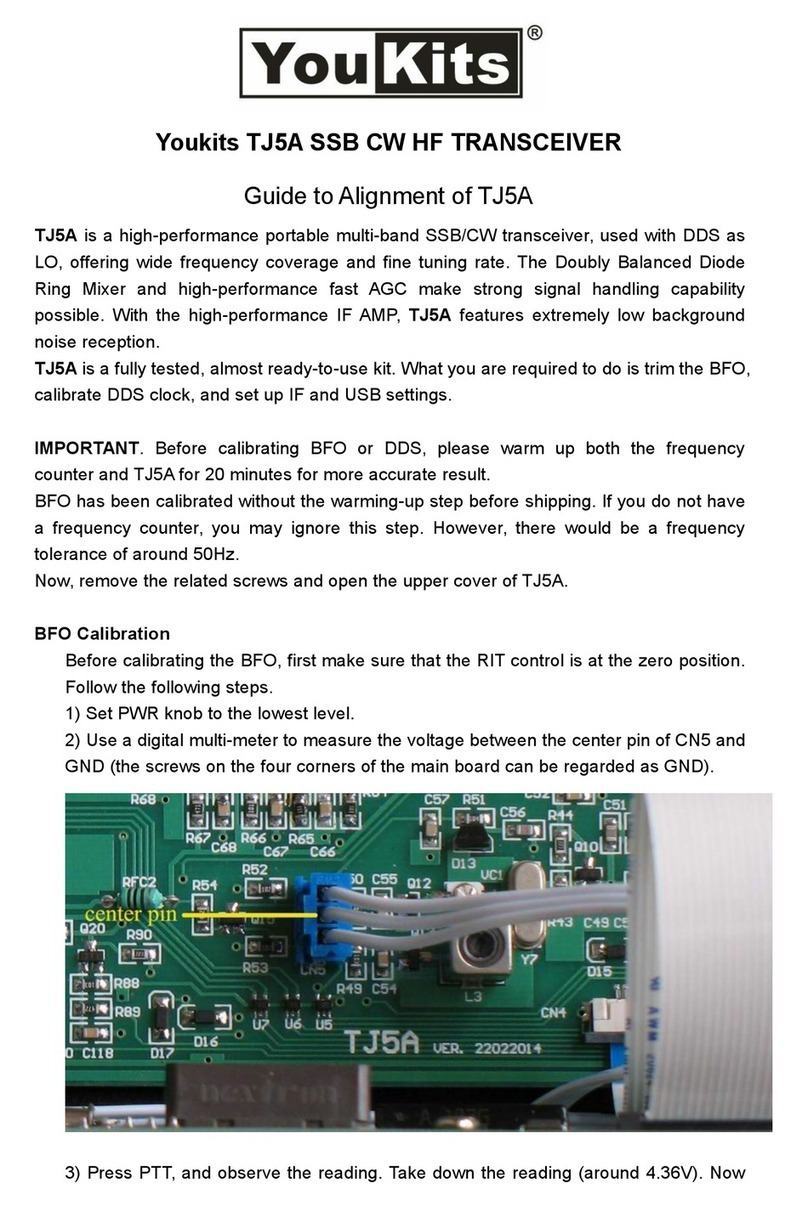

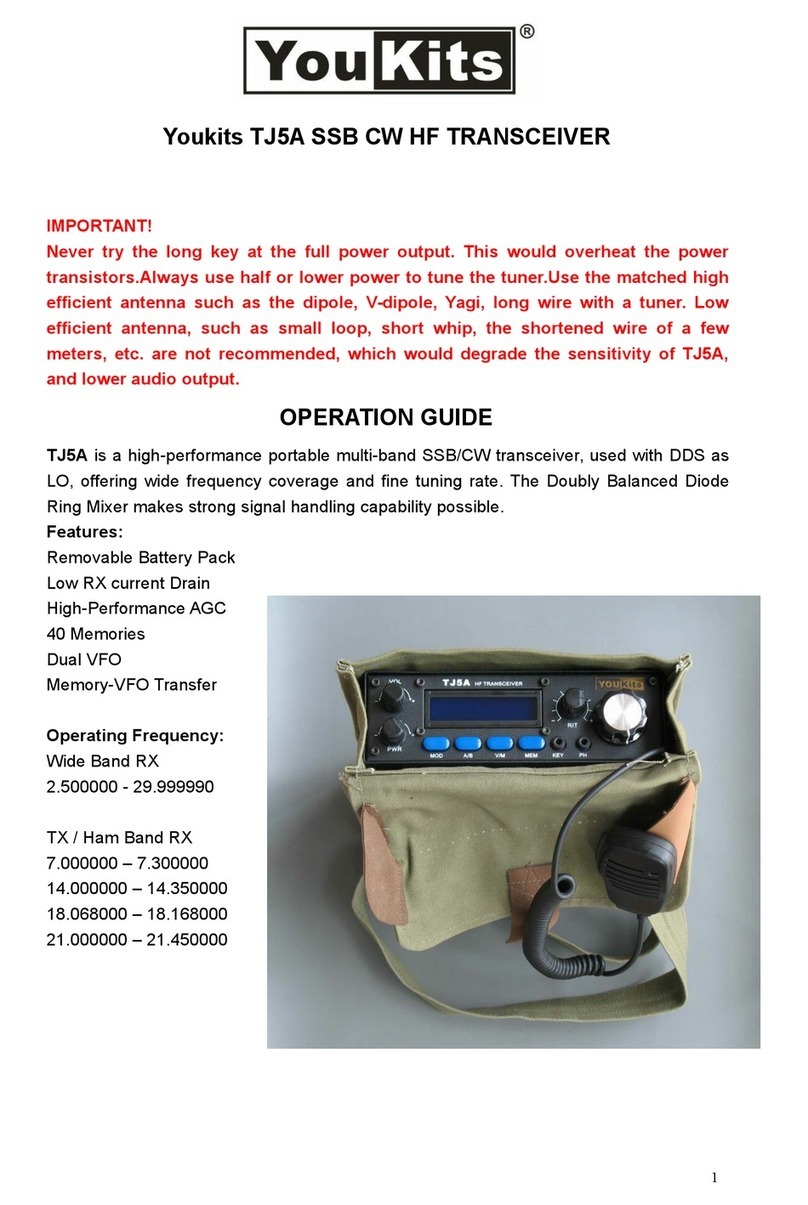

YouKits TJ5A User manual

YouKits

YouKits HB-1B User manual

YouKits

YouKits TJ2B User manual

YouKits

YouKits TJ5A User manual

YouKits

YouKits HB-1A MK2 User manual

YouKits

YouKits HB-1A MK2 User manual

YouKits

YouKits EK-1B User manual

YouKits

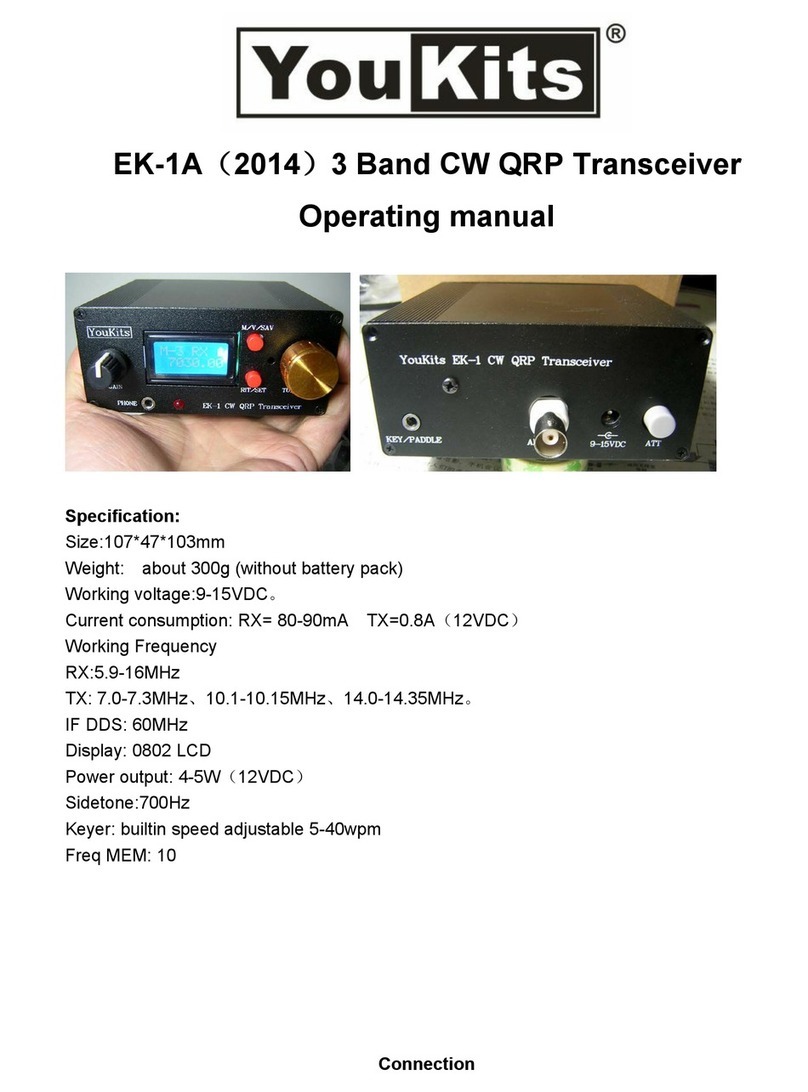

YouKits EK-1A Operation instructions

YouKits

YouKits TJ5A User manual