4

Intended Use

Important Warnings

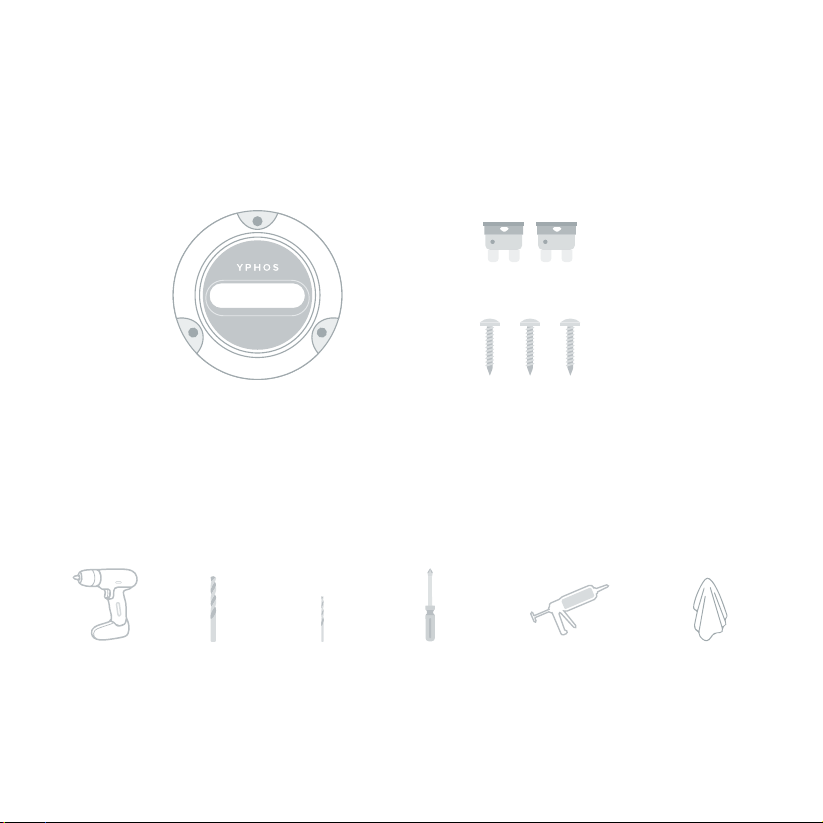

• Installation must be performed by a qualified installer.

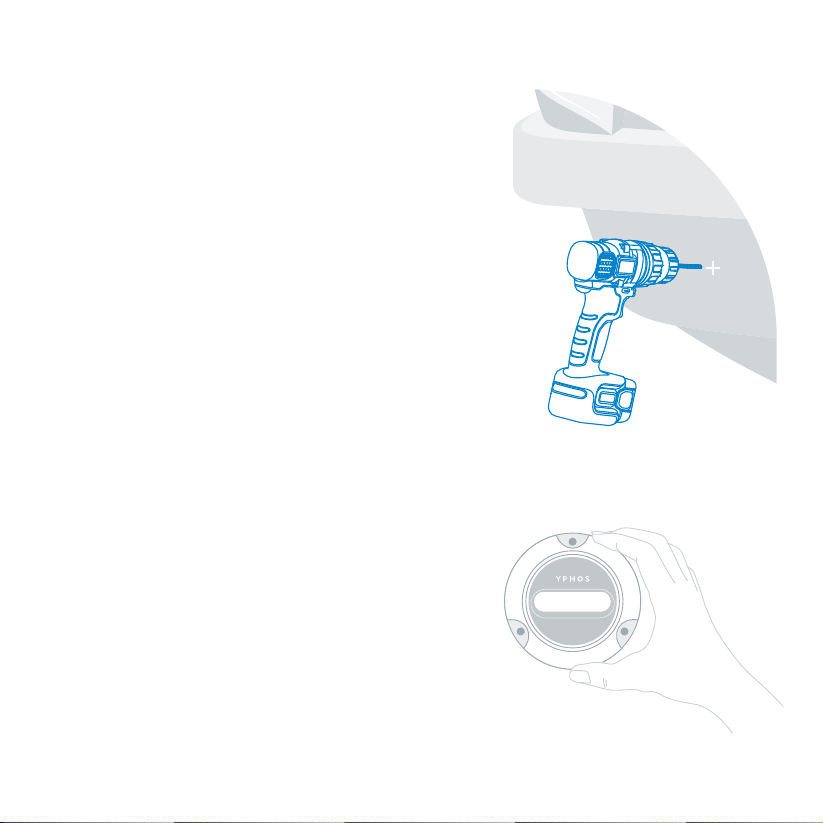

• Installation must be done outside of water.

• Choose a flat area, easily accessible from the inside to mount the fixture.

• Install this fixture only on transom or sides of the hull.

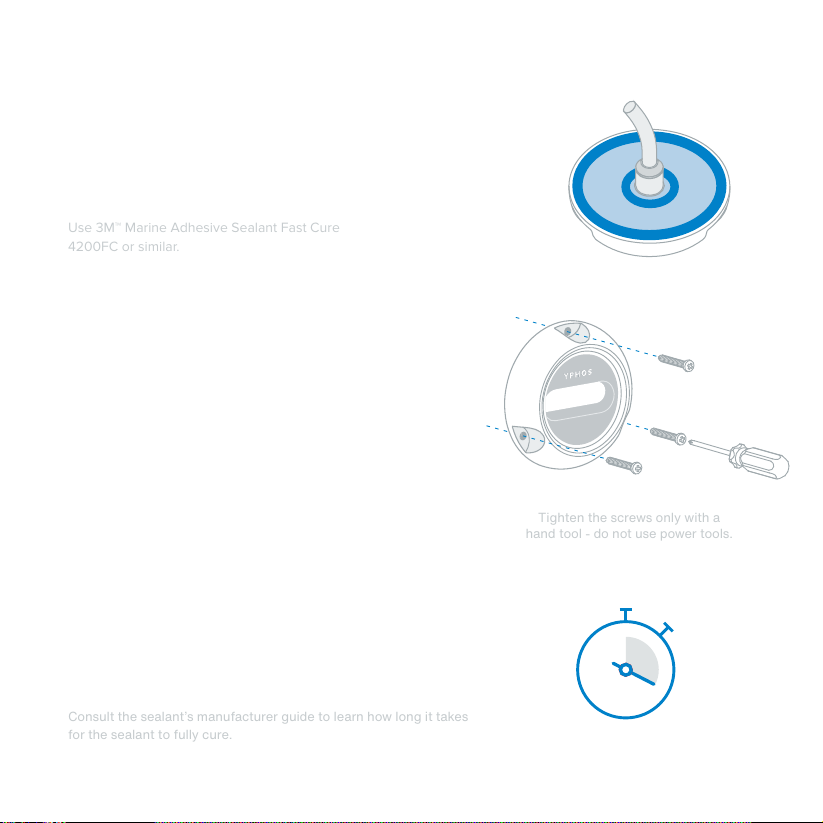

• Do not use power tools to secure the fixture.

• Do not use solvents to clean the fixture.

• Do not modify whole or any part of this product.

• Wear personal protection gear during installation.

• Complete an electrical mock-up before you modify the boat.

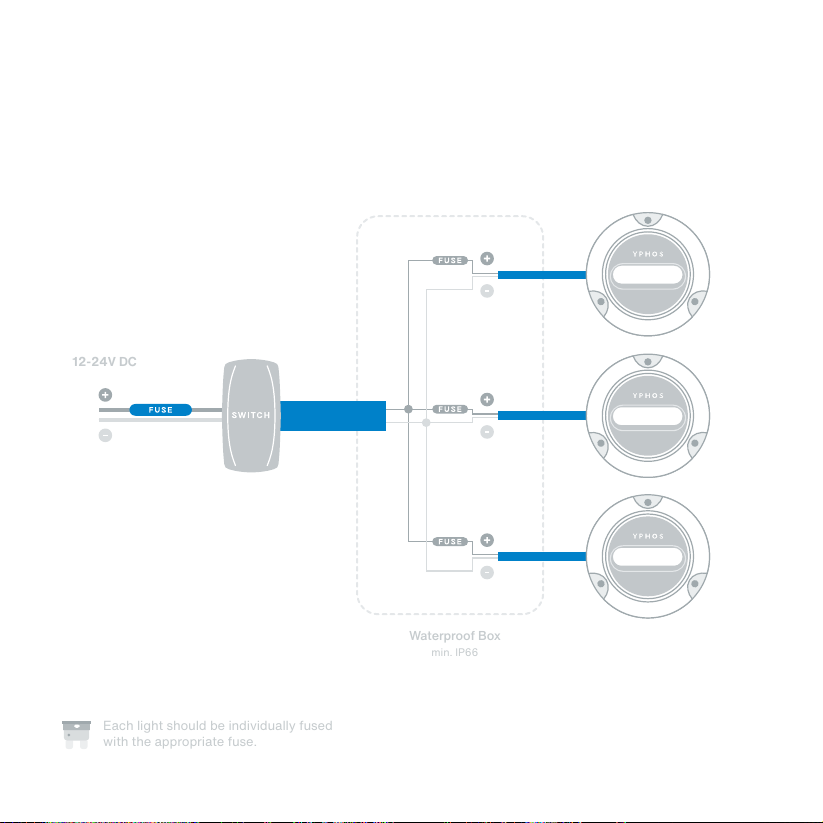

• This is a 12-24V DC light fixture. Do not connect to mains or other voltage than 12-24V DC.

• Do not look directly at the LEDs when in operation.

• Isolate power source prior to electrical installation.

• Each light should be individually fused.

• Do not allow exposed cable ends to come in contact with water. Capillary action will allow the ingress of water

through the cable, damaging the fixture or corroding the cable. This is not covered under warranty.

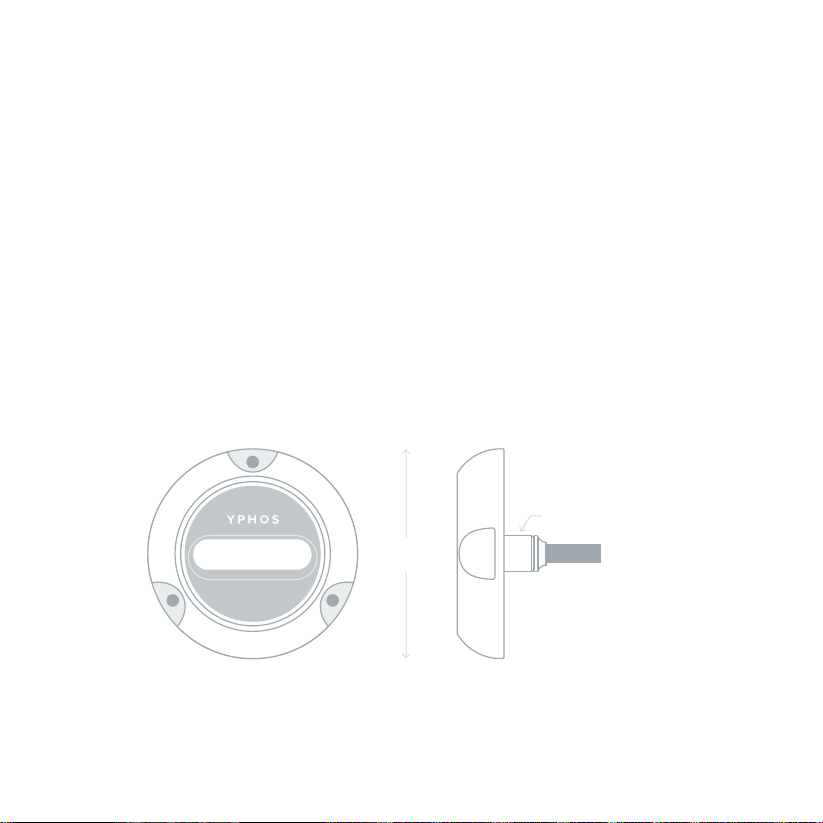

Model 03 is designed to operate as an LED Illumination unit for mounting on GRP or

wooden boat hulls. It can be installed partially or completely submerged in both fresh

and sea water and can be used anytime – while the boat is still or underway. This

installation manual does not supersede any National or Local Electrical Code.