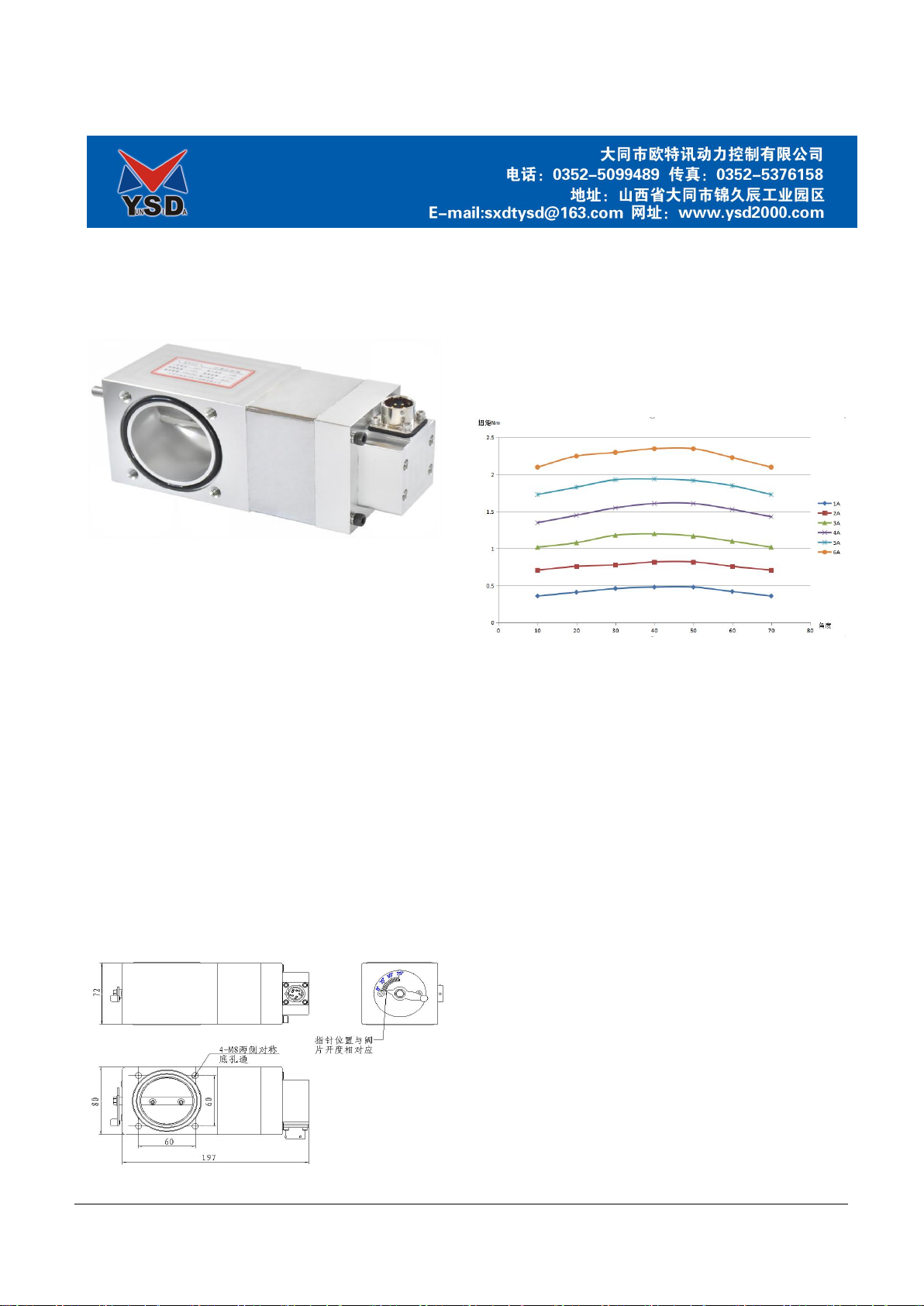

2.3 Corner position sensor

The angular position sensor is mounted coaxially with the

rotor of the angular motor. The sensor is a linear, non-contact

angular position sensor. Its power supply voltage is 5VDC. The

feedback voltage is approximately: 1.6VDC at 0 ° corner,

3.3VDC at 75 ° corner (refer to 0V voltage measurement).

三 installation

Use caution when unpacking the position control valve. If

you find that the casing is deformed, scratched, or damaged,

please contact the supplier immediately.

3.1 power supply

The power output should be low-resistance (for example,

directly from the battery). The power connection wire uses

two-core insulated sheathed wires, and the ground wire uses a

single-core insulated sheathed wire. Neither the power or

ground wires need to be shielded.

If the power source is a battery, make sure the system has

an alternator or other battery charging device.

When the engine is stopped, the ESC will control the

corner motor to maintain the minimum position. At this time, if

the battery charging system is turned off, it may cause the

battery to run out of energy. To prevent this, the control system

should be closed with a switch or relay. The switch or relay

should be interlocked with the engine start switch to prevent

the engine from starting when the power to the ESC system is

cut off.

3.2 Warning-speeding

Do not use the power off method to stop the engine. Do

not turn off the power on the controller during shutdown

operation. Because closing the control valve plate will be in a

free state, all control valve position commands come from the

controller, through the drive circuit, and finally to the corner

motor. Turning off the power to the controller while the engine

is running may cause the engine to overspeed.

3.3 Position speed control valve installation

The KZ55 position speed regulating valve is suitable for

installation on the gas line of an engine or the intake pipe of an

engine below 150KW for gas or mixer air intake control. When

the position regulating valve is working normally, the current is

≤0.5A, and the heat generation is very small. Only under the

conditions of blocked rotor or other conditions that require the

maximum torque output, large heat will be generated. The main

heat of the speed control valve comes from the heat transferred

by the engine.

The installer should consider the thermal conductivity of

the mounting bracket and the engine body temperature at the

installation location. If the engine body temperature at the

installation location is too high, appropriate insulation

measures should be taken. Under normal circumstances,

aluminum and low carbon steel materials with higher thermal

conductivity should be selected as the mounting bracket, and

the installation location should be selected in a place with good

air circulation.

If there is a problem with the operating temperature,

please contact the manufacturer's engineer.

The installation method is shown in Figure 3-1. The

connection flanges are installed on both sides of the valve body,

and the contact surfaces are sealed with rubber rings. The

connection pipe can be connected to the flange.

Manual detection: The scale corresponding to the pointer

of the position control valve is the opening angle of the valve

disc. Before starting, pull the handle to confirm that the valve

disc rotates without jamming.

3-1KZ55 Connection diagram

3.4 Electrical connections

KZ55 position control valve external electrical wiring

diagram shown in Figure 3-2。

skills requirement:

1. The position control valve harness motor wire uses

more than 1.5 strands of plastic copper wire, and the sensor

wire uses 0.5 shielded wire. The length of the used wire is ≤

20m.

2. To connect the position control valve, just connect the

aviation plug of the corresponding wiring harness with the

aviation socket on the position control valve, and connect the

other end of the wiring harness to the corresponding terminal of

3120A as shown in Figure 3-4.

3-2 Electrical wiring diagram