5

Assembly Instructions

1. Before unpacking or assembling, please note that the

motherboard ange is somewhat susceptible to

bending, we do not recommend resting the weight of

the case directly on this flange, or holding the chassis

by this flange. For ease of assembly, you may lay the

chassis in the provided foam packaging insert when

you are installing the motherboard and graphics card.

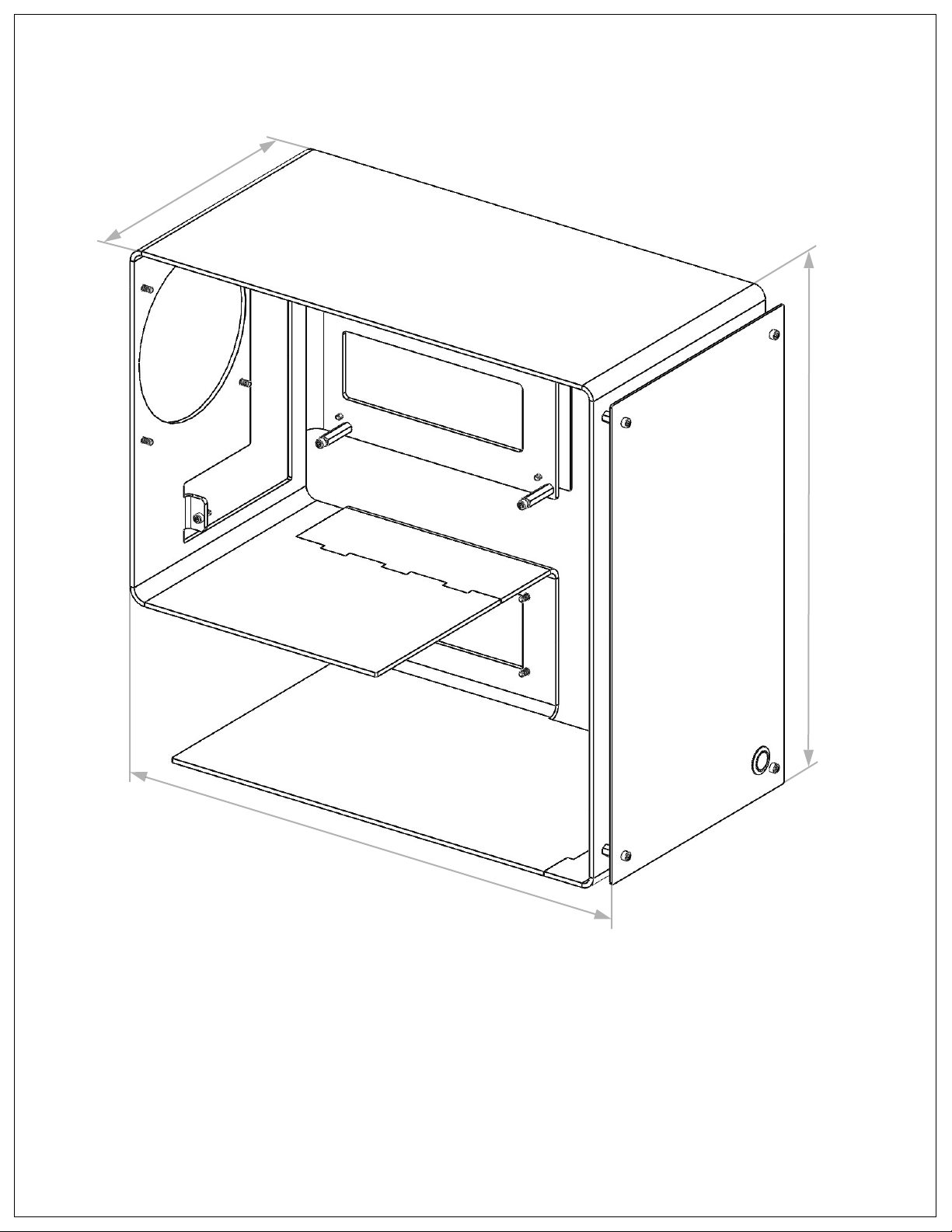

2. Screw the four 1” standoffs into the motherboard

flange by hand (fig. 1). Pre-install the CPU cooler as

well as the RAM, then mount the motherboard to the

stand-offs using the provided 6-32 screws.

3. Install the GPU and use the thumb screw to secure the

card into the GPU flange. If there is mis-registration

between the GPU and the mounting flange, double

check that the correct 1” motherboard standoffs were

used.

4. Remove the chassis from the foam insert and stand

it up normally. If you are using an AIO CPU or GPU

cooler, secure the radiators to the inside fan mounting

hole patterns.

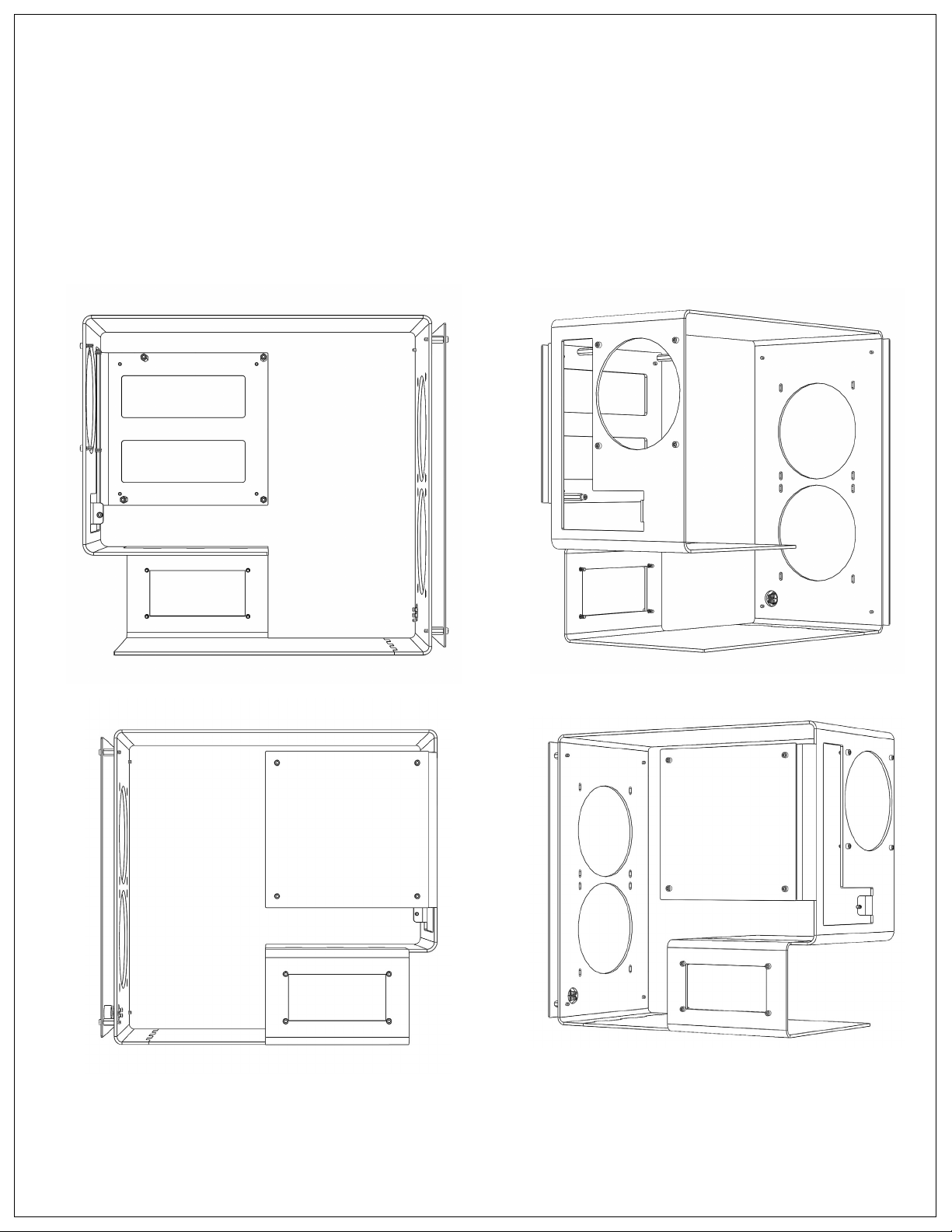

5. Screw four of the 1/2” standoffs into the front of

the chassis, and the other four into the back of the

motherboard flange (fig. 2). Screw the thread caps

onto the exposed threads of the front panel and

motherboard standoffs.

6. Secure the PSU into the hole pattern on the lower area

of the chassis, we recommend adhering cable clips to

the horizontal band in the middle of the motherboard

flange.

7. Fasten the backplate into place behind the

motherboard. Mount the provided 16mm button onto

the hole in the front plate. Screw the ferrules of the

power wire into the button contacts and mount the

front plate so the button fits into the through hole on

the chassis (fig. 3).

fig. 1

fig. 2

fig. 3