Directory

1.Specifications..............................................................................................................1

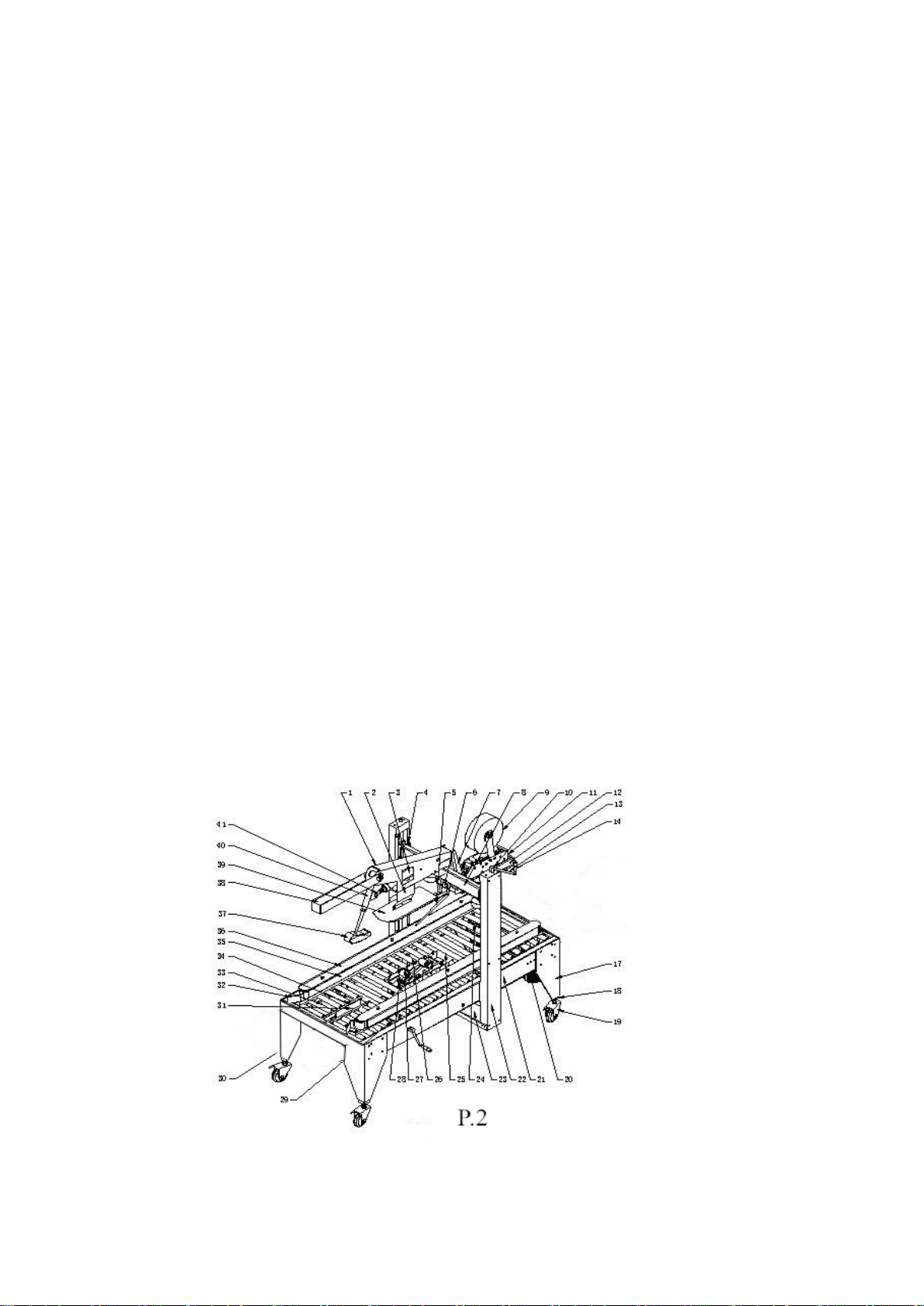

2. Brief introduction of main struture (P.2)....................................................................1

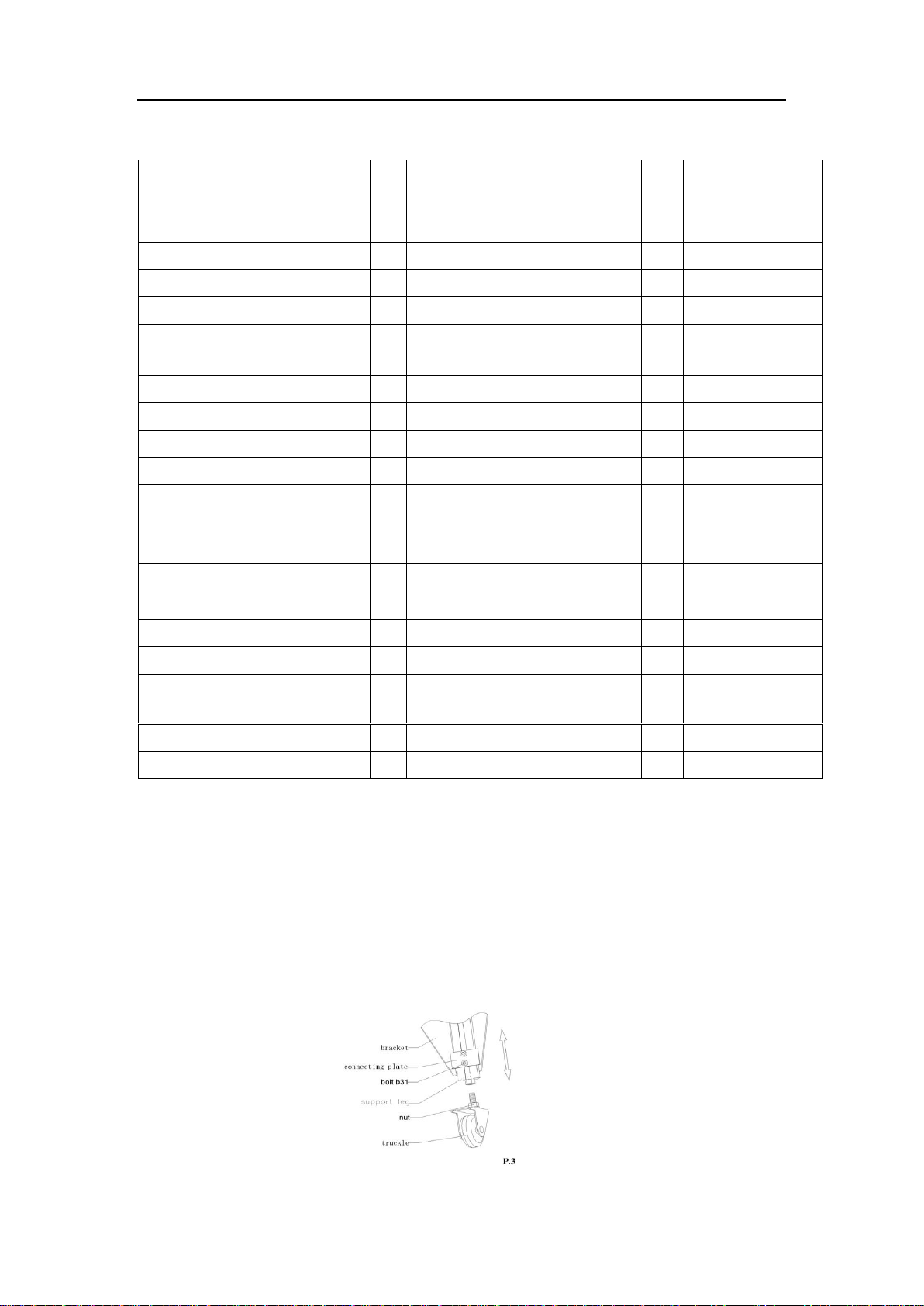

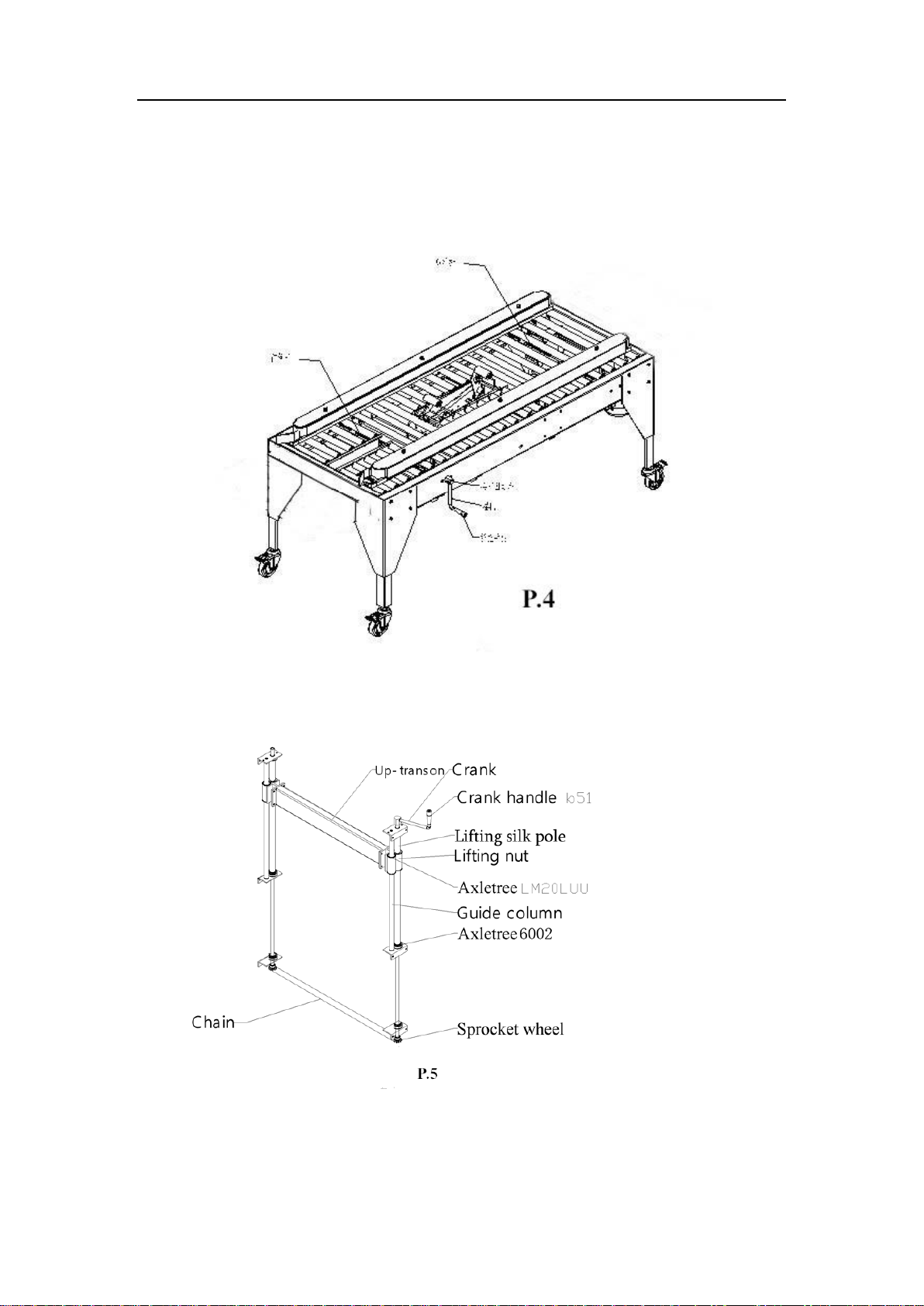

3. Instructions to adjusting parts....................................................................................2

3.1 Table height adjustment (P.3)............................................................................2

3.2 Width adjustment..............................................................................................3

3.3 Lateral pressure wheel adjustment (P.7) ...........................................................4

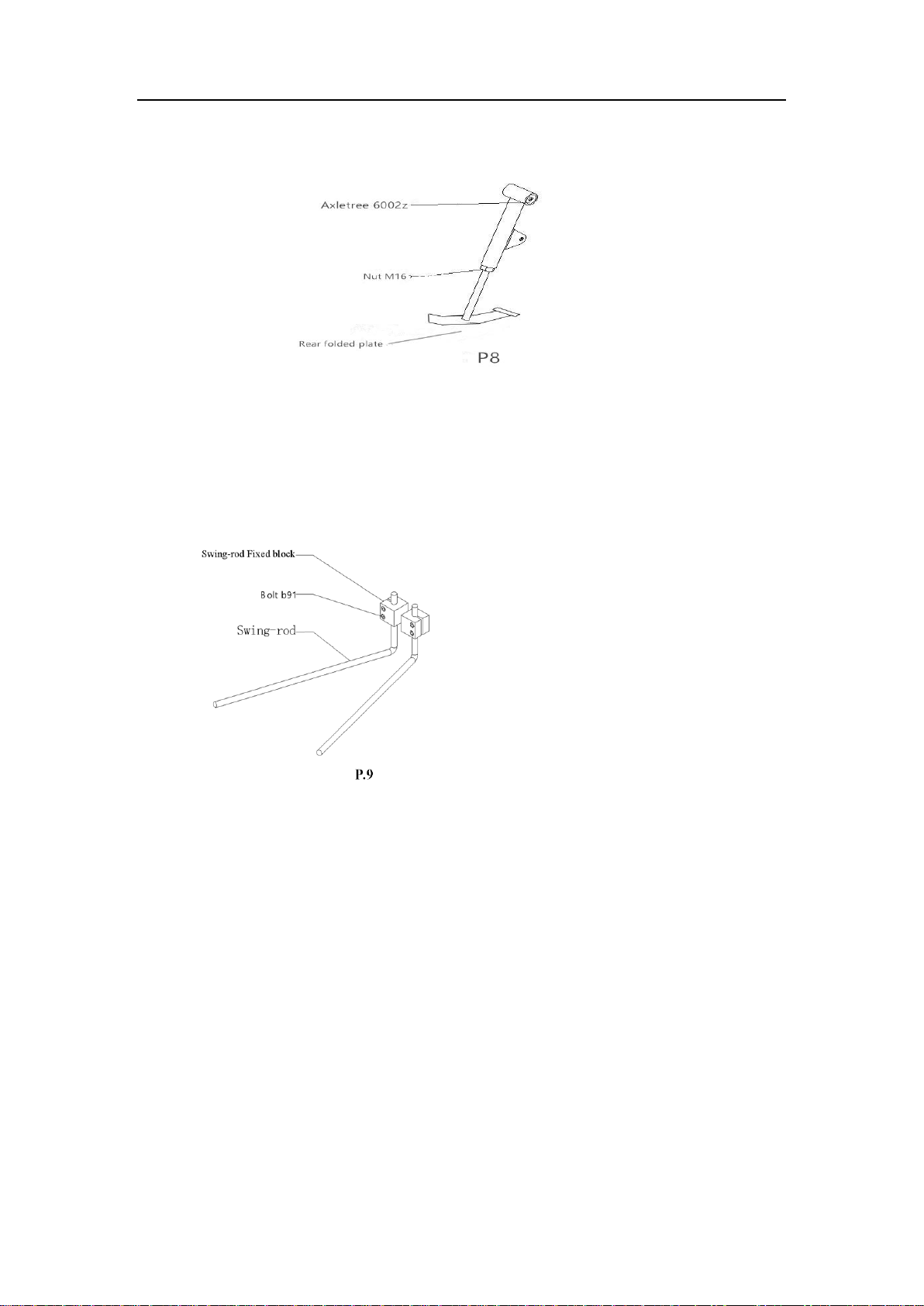

3.4 Back folding plate adjustment (P.8)..................................................................5

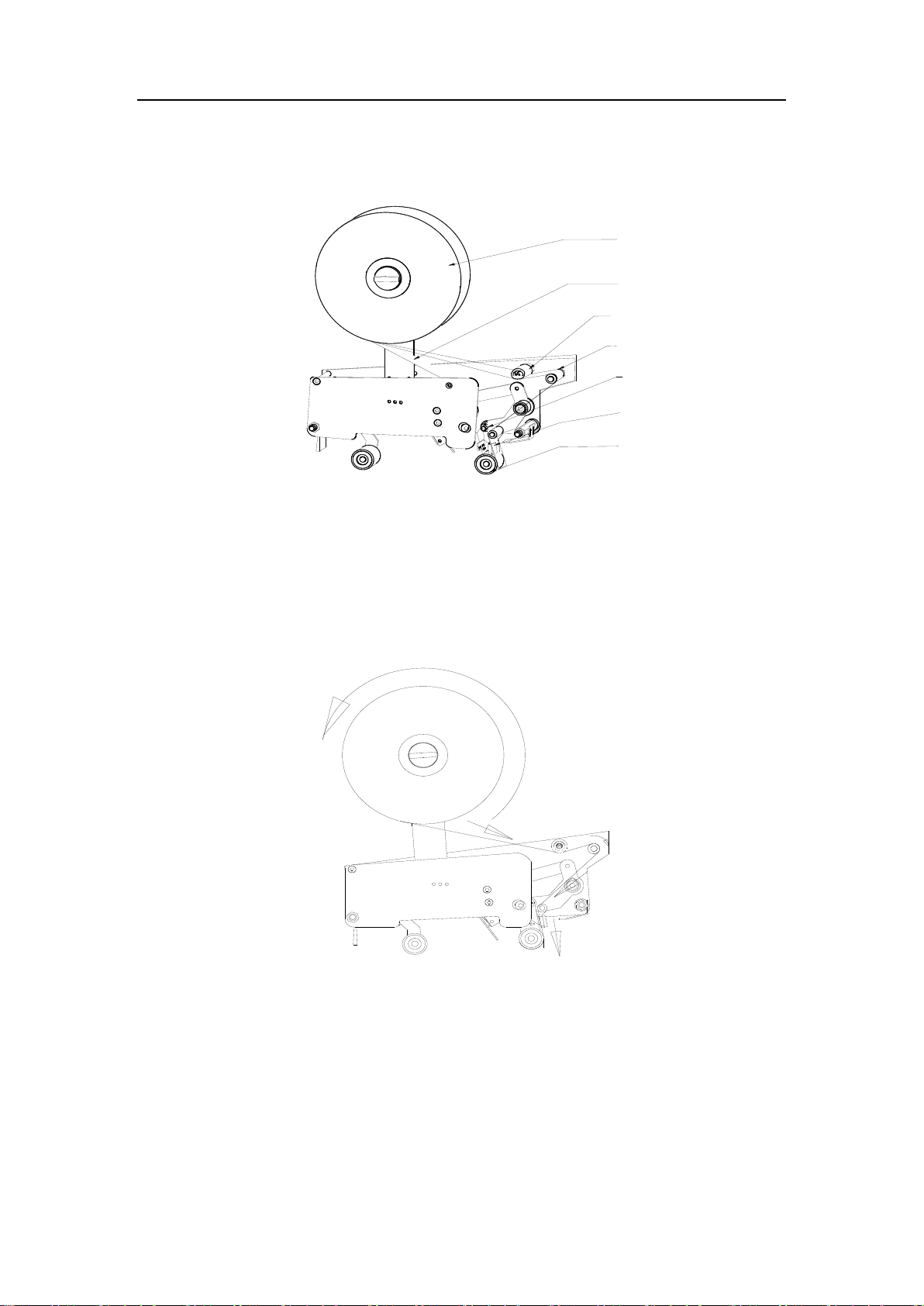

3.5 Swing-rod adjustemnet (P.9).............................................................................5

3.6 Adhesive tape installation and adjustment (P.10) .............................................5

4. Operating instruction .................................................................................................8

5. Maintenance...............................................................................................................9

6. Restrictions on cartons...............................................................................................9

7. Exploded figure........................................................................................................10

7.1 General exploded figure..................................................................................10

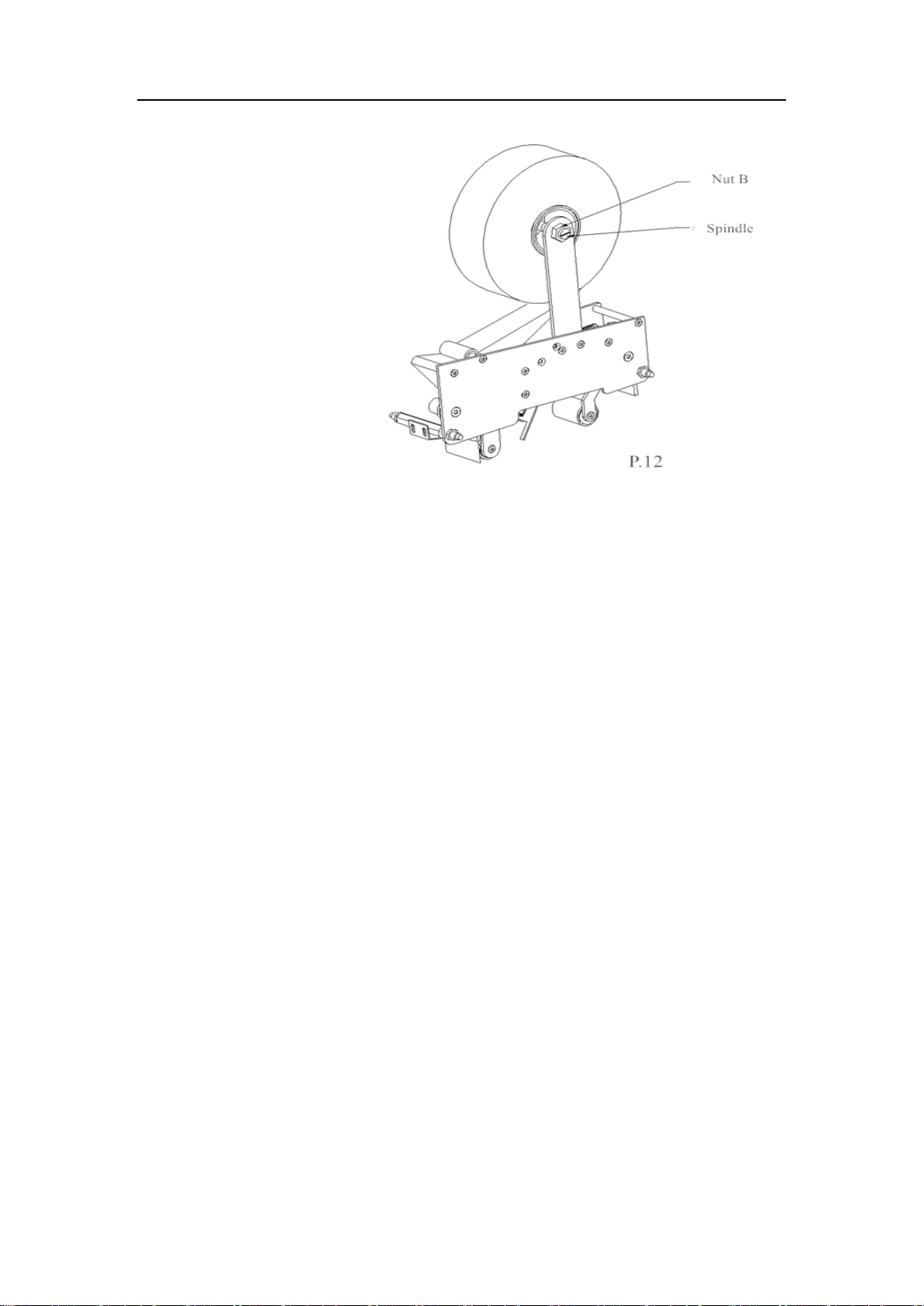

7.2 Exploded figure of adhesive tape adhibiting set.............................................12

8. Malfunctions and solutions......................................................................................14

9. Electric control.........................................................................................................15

9.1 Electric control sketch.....................................................................................15

9.2 Electric control operation................................................................................15

9.3 Inspection and Maintanance of pneumatic control.........................................17

9.4 Inspection and repair of electric control .........................................................17

9.5 Common malfunctions and solutions..............................................................18