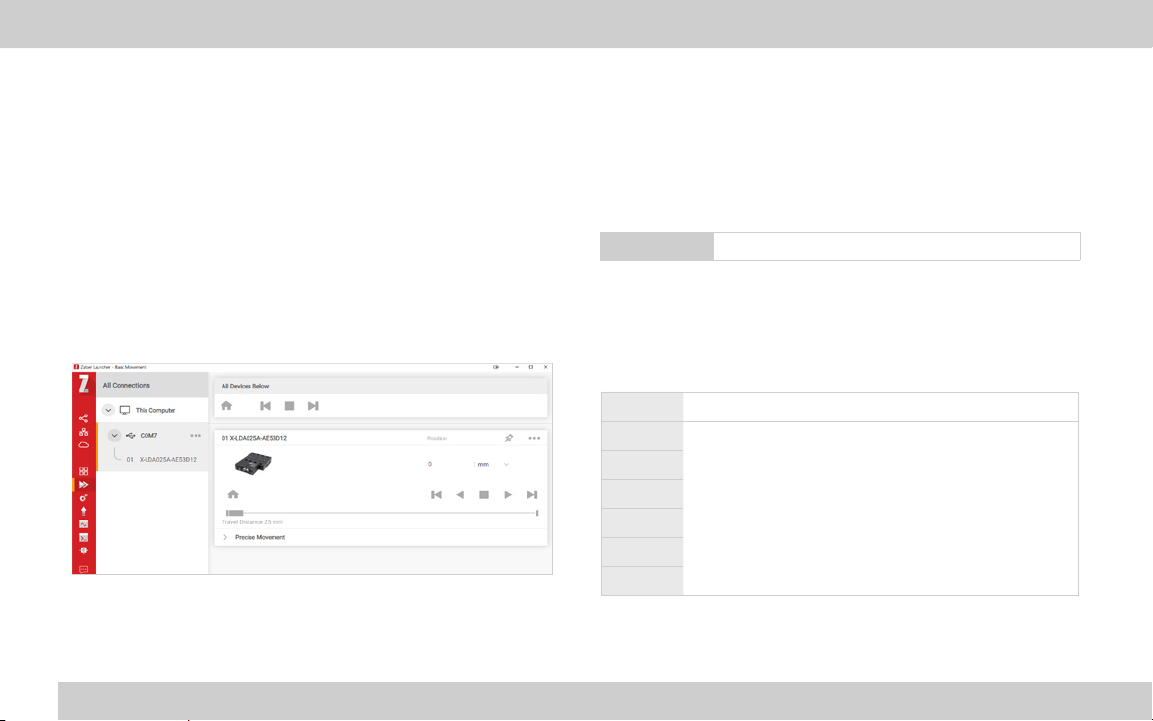

3 ZABER TECHNOLOGIES INC.

Getting Started Guide

Common Terminology

Positioner

A motorized product with moving mechanics, such as a linear

stage, a rotational stage, or a stepper motor.

Peripheral

A positioner that includes a motor and mechanics but does not

include an integrated controller. Peripherals are designed for use

with Zaber’s motor controllers, but they can also be used with

compatible third-party motor drivers and controllers.

Device

A stand-alone controller or a positioner with an integrated

controller. Stand-alone controllers are designed for use with

Zaber’s peripherals, but they can also be used with compatible

third-party peripherals.

Joystick

A product that allows multi-axis manual input and push-button

input for positioners. Joysticks do not function as controllers;

instead, they are designed to communicate with Zaber’s motor

controllers when connected in series.

X-Series, A-Series, and T-Series

Devices that share common features, such as connectors,

protocols, and power. The series is indicated by the rst letter of

the device’s name. For example, the X-LSM025A model belongs

to the X-Series family. This guide specically relates to X-Series

devices. See an older version of the manual for setup instructions

for T-Series or A-Series devices at:

www.zaber.com/documents/Getting-started-guide.pdf.

Closed-Loop and Servo Devices

For Zaber devices, closed-loop refers to any device where encoder

feedback is used to inform the trajectory of the controller. Servo

devices refer to a sub-set of these where encoder feedback is also

required for the driver. Direct-drive stages are servo devices.

Stepper motor devices with encoders use closed-loop control

but are not servo devices, as the driver controls stepping directly

without encoder feedback. Encoder feedback is still used to inform

the trajectory of the controller on these.

Servo devices require tuning of their control loop to get the best

performance (more on page 9). They also use encoder counts as

their unit of resolution, as opposed to stepper motors, which use

microsteps (more on page 8).