5

*Keep proper footing and balance at all times when operating the tool. Do not use

the tool when you are in an awkward position.

*Stay alert during operation. Watch what you are doing. Use common sense. Do not

operate the tool when you are tired

*Avoid long time idle running of motor which may cause damages on the control

system and mechanical parts.

*Dress properly. Do not wear loose clothing or jewelry. They can be caught in

moving parts. Rubber gloves and non-skid footwear are recommended when

working outdoors. Wear protecting hair covering to contain long hair.

Strap

* Use only recommended strap specifications in this manual. Poor quality strap or

improper strap specifications may reduce sealing performance.

Sealing Joint Examination

* Check the sealing joint after sealing. Please re-seal the article when sealing joint is

poor in order to secure goods in transit. Please adjust the sealing time according

to this manual to reach the best sealing efficiency.

Environmental, Recycle and Safety Precautions for Battery

*Do not dispose battery in household refusal, water or fire.

*Do not store battery together with metal objects to prevent any hazard of

short circuit.

*Do not open up battery cases. Keep it in dry place.

*Never attempt to short-circuit the battery by connecting the positive (+) and

negative (-) terminals.

*Remove battery from the tool when tool is not in use to prevent quick power

exhaustion. This good habit will extend the life of the battery.

*Remove battery from charger as soon as the charging process is completed.

*A fully charged battery will gradually lose its power naturally in storage.

Please activate the battery by a full charge every 3-6 months.

*When operation indicator of tool is flashing in red with continuous “beep”

sound alarm, please recharge the battery.

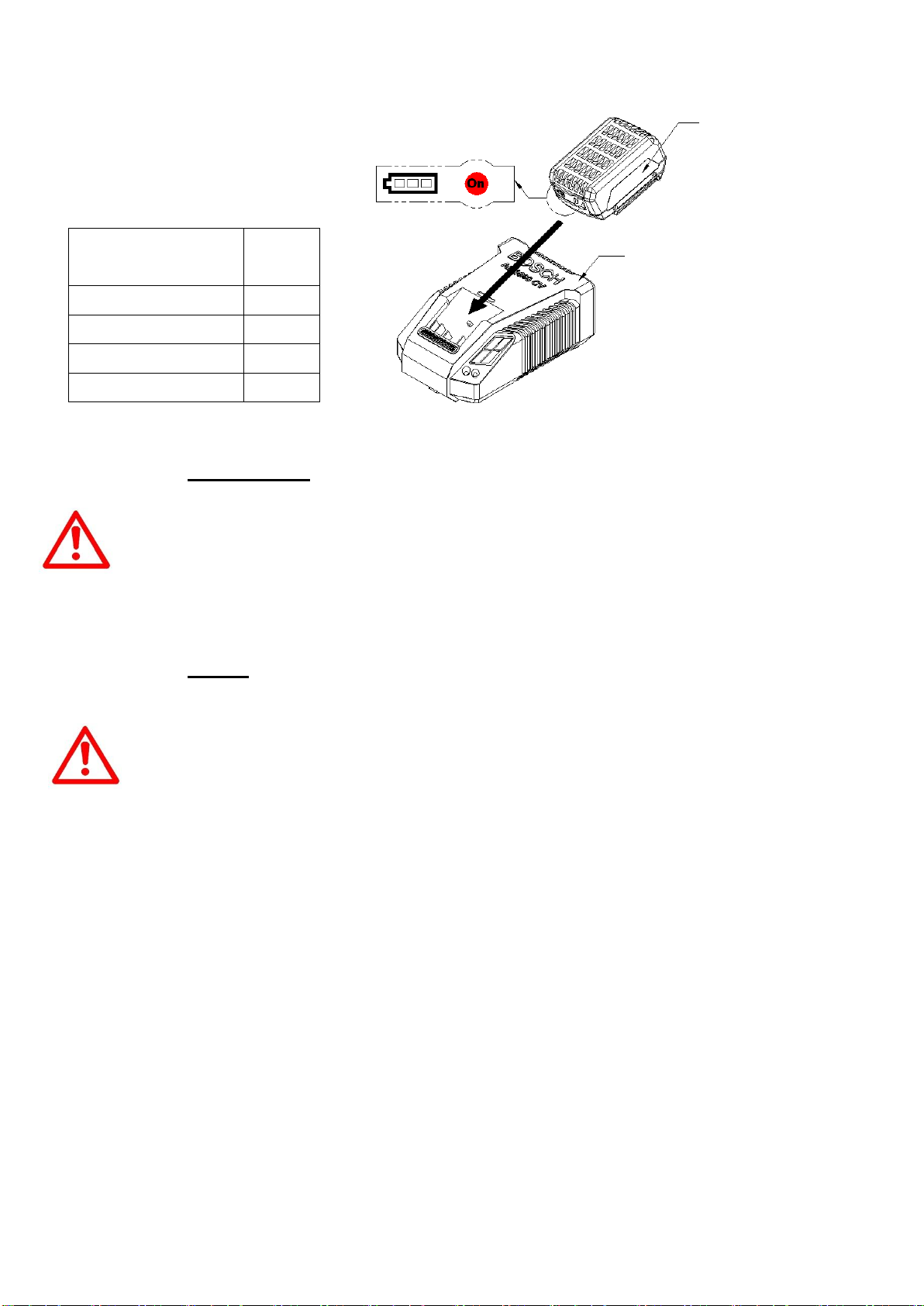

*Use BOSCH Li-Ion battery (part no. 9380) only for ZP-SW25. ZAPAK 9380

battery is only suitable for BOSCH Charger ( AL1860CV /GAL1880CV,

ZAPAK part no. 2382-XX), No adaptor is needed for charging battery part no.

9380. Using improper charger or improper battery may result in risks of

electric shock, overheat, explosion, burning or leakage of corrosive liquid

from the battery and invalidate your warranty.

*If corrosive liquid contacts your body, please clean and wash it with water

immediately.

Safety Precautions for Charger

*Please read and follow the safety instruction of the charger user manual before

using charger.

*Ensure the battery is clean and dry before plugging into the charger.