ADBZP0AB - CAN TILLER - User Manual Page - 5/18

2 TECHNICAL SPECIFICATION

2.1 Digital inputs

All the digital inputs have the positive input at Key voltage (+12 V or +24 V).

Proper microswitches must be connected between the digital input and the

positive supply output CMM (CNA#15); each input has a pull-down resistor.

The FW, REV, RAISE, LOS, HORN, ETC microswitches are typically open, so

the functions related to them become active when the microswitch is closed.

The safety microswitches, as SR, are typically closed, so the functions related to

them become active when the microswitch is open.

2.1.1 Digital inputs technical details

DI1 ÷ DI2

- Commutation threshold ON to OFF: 7 V [±0,5 V].

- Commutation threshold OFF to ON: 9 V [±0,5 V].

- Input impedance: 4,3 kohm [±0,5 kohm].

DI3 ÷ DI11 and DI14

- Commutation threshold: 6 V [±0,5 V].

- Input impedance: 4,25 kohm [±0,3 kohm].

- Input impedance: 7,4 kohm [±0,4 kohm] only for DI4 and DI5.

DI12/AI5

- Commutation threshold: 5 V [±0,5 V].

- Input impedance: 47,3 kohm [±2,4 kohm].

DI13/AI6

- Commutation threshold ON to OFF: 3,2 V [±0,3 V].

- Commutation threshold OFF to ON: 7,5 V [±0,5 V].

- Input impedance: 47,3 kohm [±2,4 kohm].

4NOTE: DI12 AND DI13 can be used as Analog Input, as well see 2.2.

2.1.2 Microswitches

- The recommended microswitches must have a contact resistance lower than

0.1 Ωand a leakage current lower than 100 µA.

- When full load connected, the voltage between the key switch contacts must

be lower than 0.1 V.

- If the used microswitches have different features, it is recommended to talk

about their utilization with Zapi’s technicians.

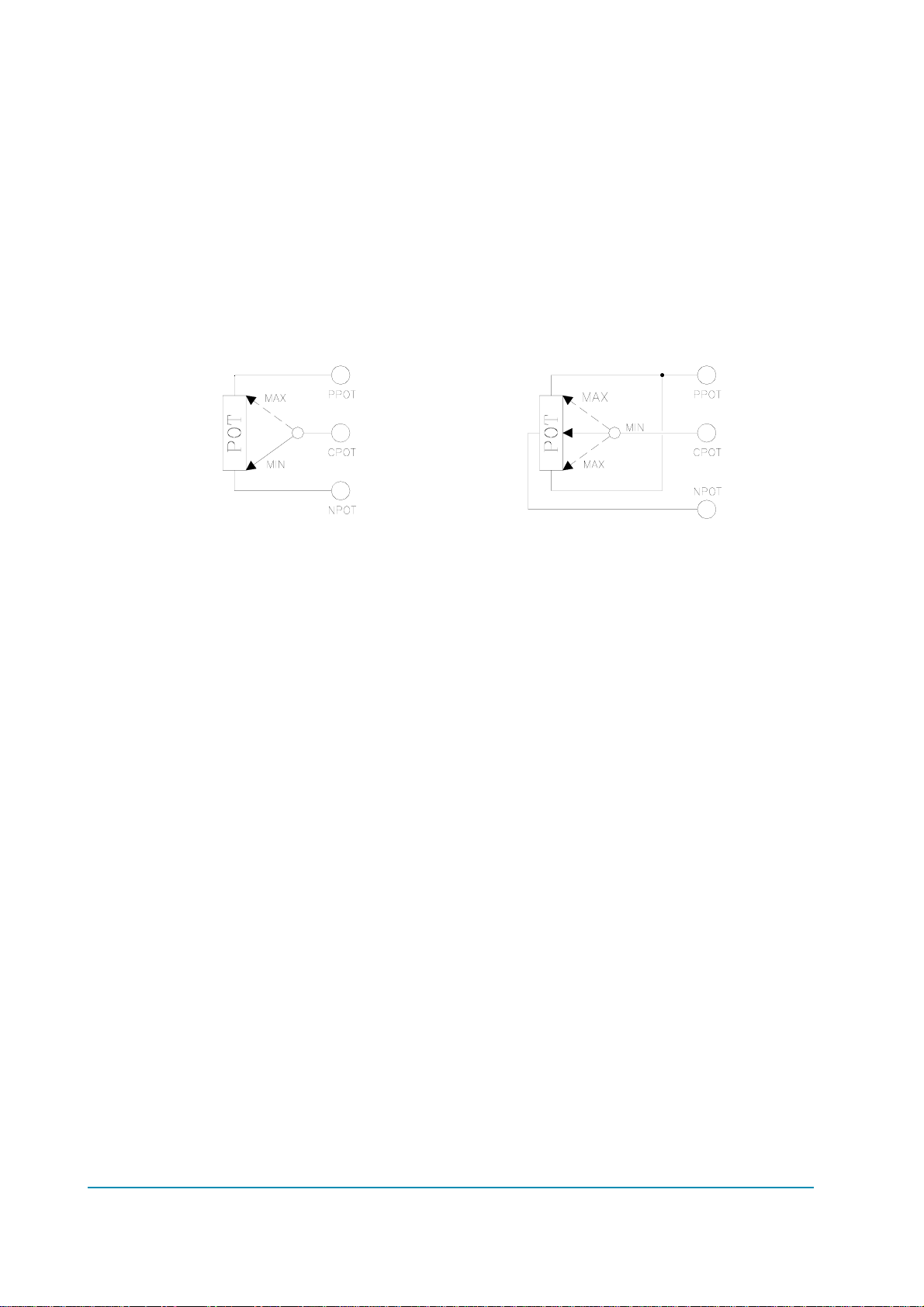

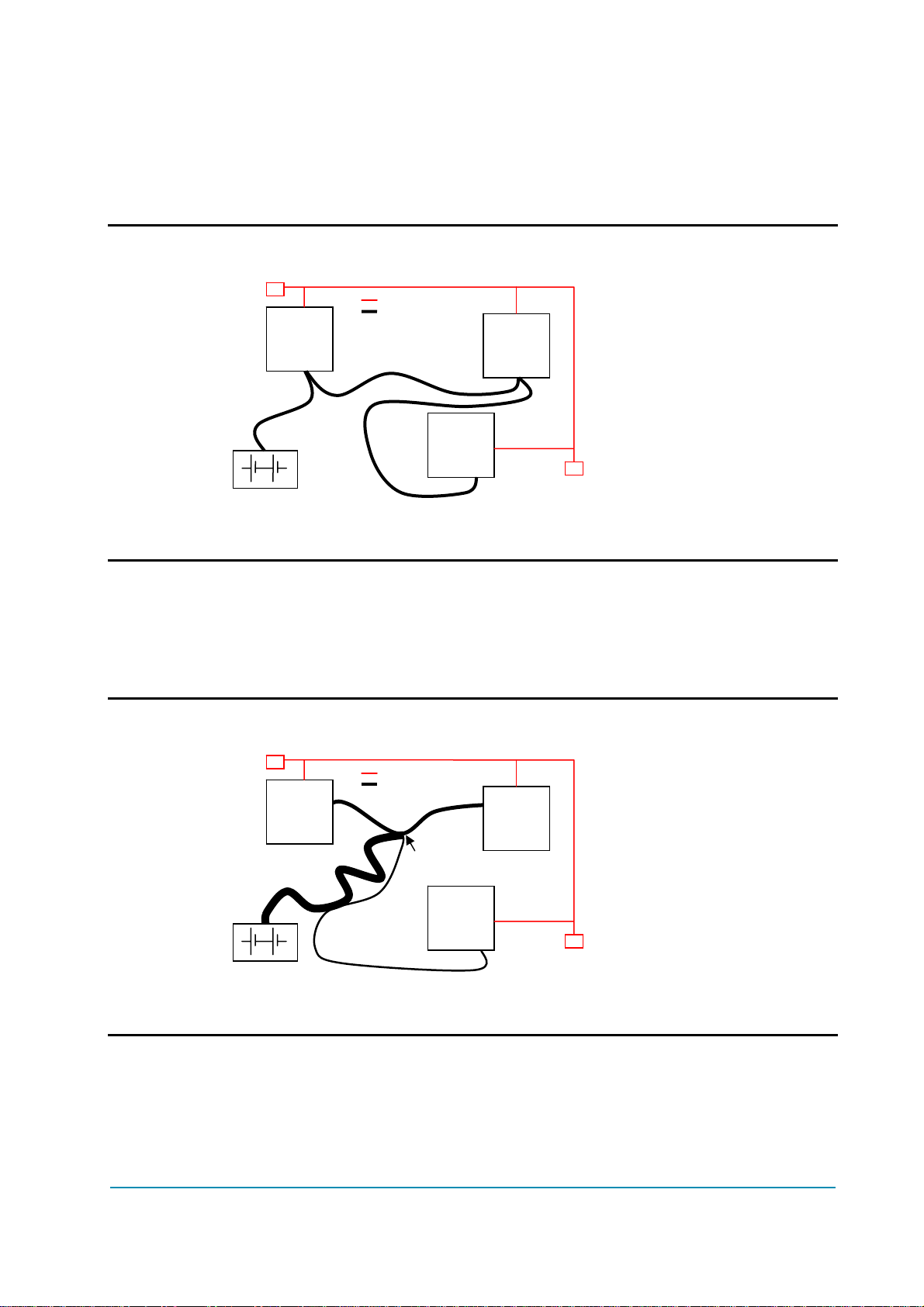

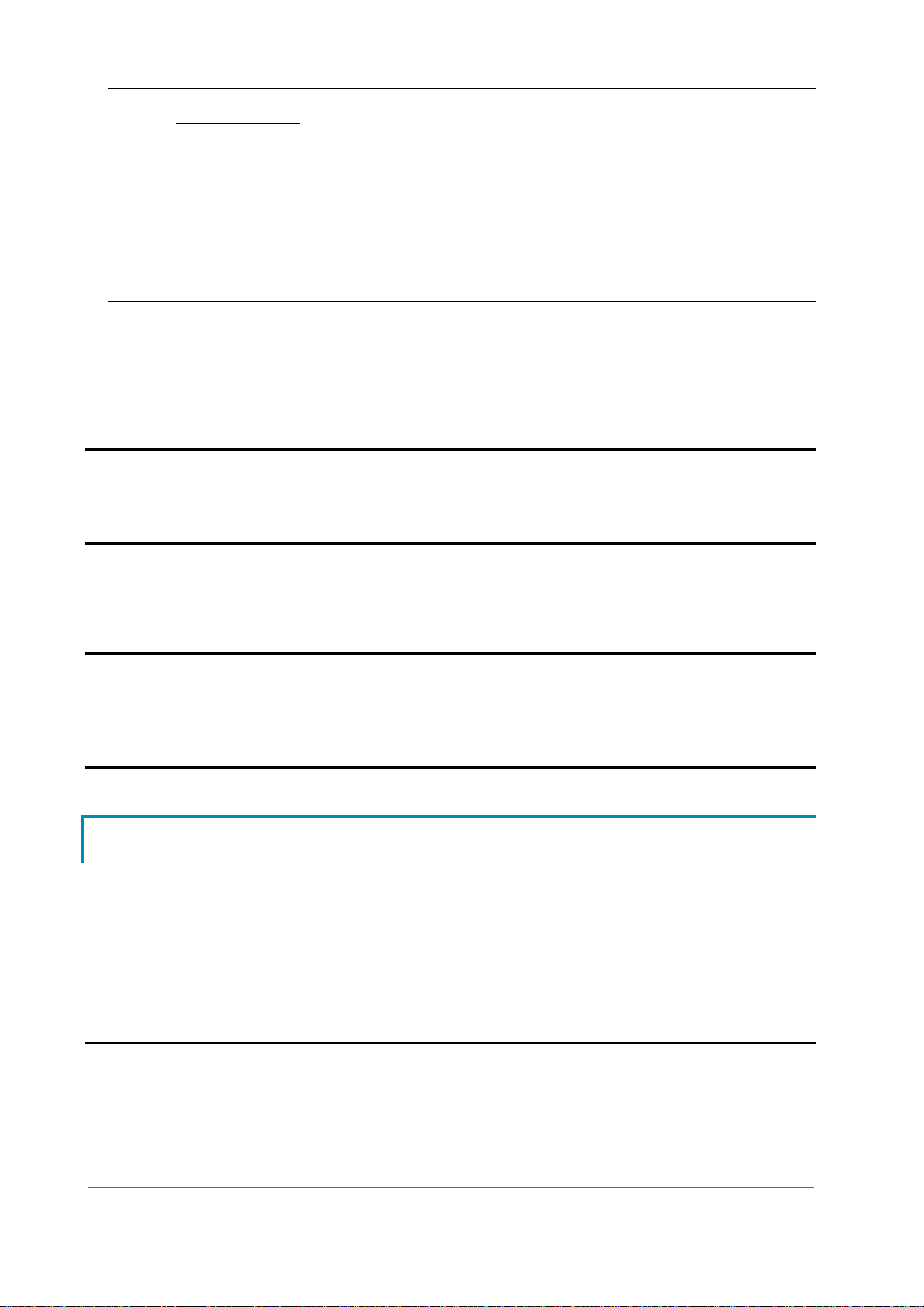

2.2 Analog inputs

The analog inputs are used to read the output of a potentiometer or an Hall effect

device, both with output continuously variable in the 0-5 V range or in the 0-12 V

range.

The potentiometer can be in a 3-wire configuration. The potentiometers related to