12.3. Power Jet 1 Advanced Mode

Power Jet Advanced mode can be used only when TPS enabled!

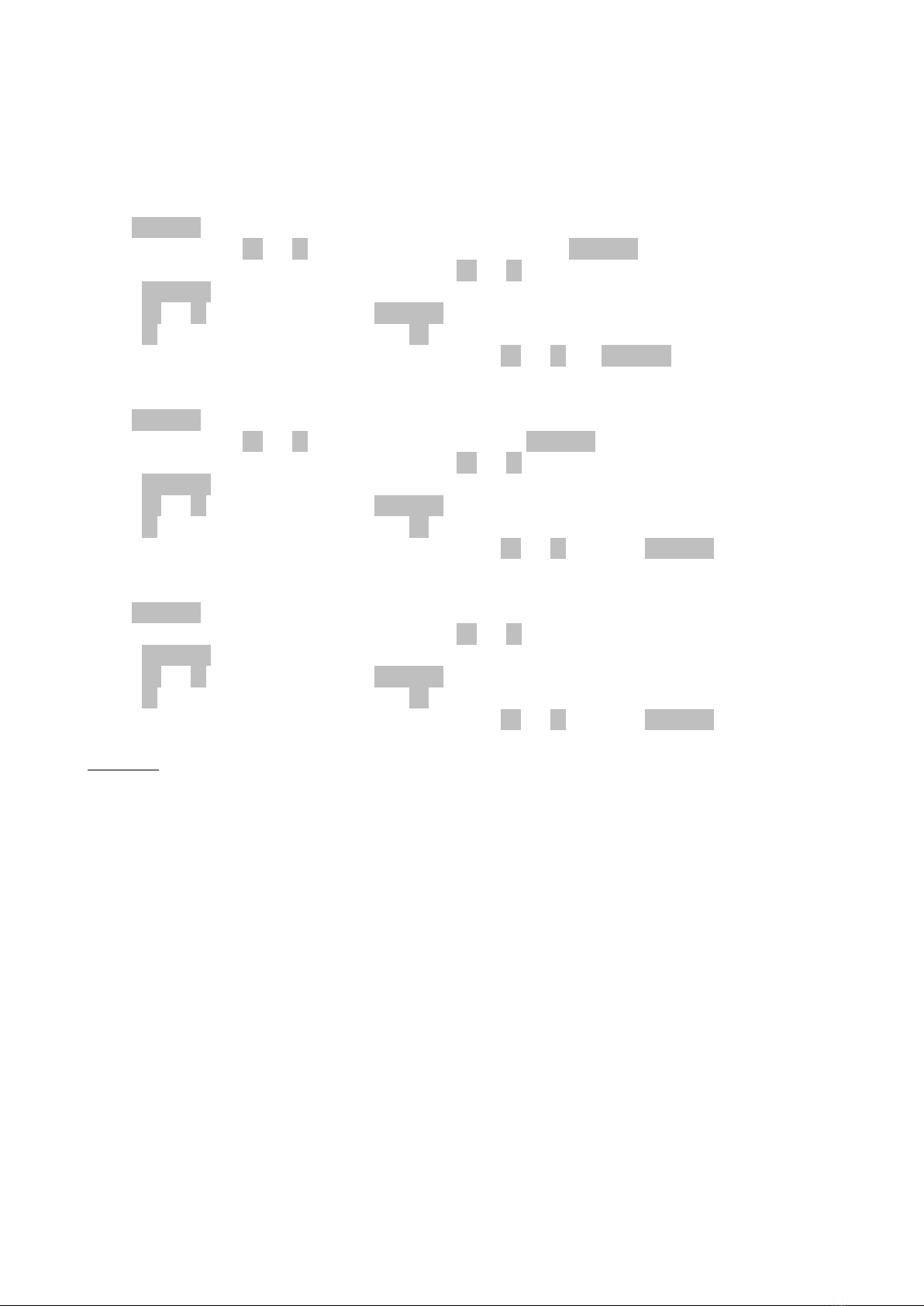

Power Jet Range 1:

Press ENTER to program range 1 parameters.

- TPS range ... press + , or - to select upper TPS value ... press ENTER to confirm

- move to switch point from 1, to 6 with pressing + , or -

- press ENTER to program switch point

- press + , or - to select revs ... press ENTER to confirm

- press - to switch 'off' power jet, or press + to switch 'on' power jet

- to exit Power Jet Range, move to Exit with pressing + , or - and ENTER enter to confirm

Power Jet Range 2:

Press ENTER to program range 2 parameters.

- TPS range ... press + , or - to select upper TPS value ... ENTER enter to confirm

- move to switch point from 1, to 6 with pressing + , or -

- press ENTER to program switch point

- press + , or - to select revs ... press ENTER to confirm

- press - to switch 'off' power jet, or press + to switch 'on' power jet

- to exit Power Jet Range, move to Exit with pressing + , or - and press ENTER to confirm

Power Jet Range 3

Press ENTER to program range 3 parameters.

- move to switch point from 1, to 6 with pressing + , or -

- press ENTER to program switch point

- press + , or - to select revs ... press ENTER to confirm

- press - to switch 'off' power jet, or press + to switch 'on' power jet

- to exit Power Jet Range, move to Exit with pressing + , or - and press ENTER to confirm

Example:

Power jet Range 1 ... 0-40%TPS (takes control when TPS position is between 0%, 40%)

1) 0RPM ... on (PJ 'on' when engine not running)

2) 3000RPM ... off (PJ switch 'off' when revs rise and pass 3000rpm)

(PJ switch 'on' when revs drop and pass 3000rpm)

3) 5000RPM ... off (PJ remain 'off' position)

4) 8000RPM ... off (PJ remain 'off' position)

5) 10000RPM ... off (PJ remain 'off' position)

6) 12000RPM ... on (PJ switch 'on' when revs rise and pass 12000rpm)

(PJ switch 'off' when revs drop and pass 12000rpm)

Power jet Range 2 ... 41-80%TPS (takes control when TPS position is between 41%, 80%)

1) 0RPM ... on (PJ 'on' when engine not running)

2) 3000RPM ... off (PJ switch 'off' when revs rise and pass 3000rpm)

(PJ switch 'on' when revs drop and pass 3000rpm)

3) 5000RPM ... off (PJ remain 'off' position)

4) 8000RPM ... on (PJ switch 'on' when revs rise and pass 8000rpm)

(PJ switch 'off' when revs drop and pass 8000rpm)

5) 10000RPM ... off (PJ switch 'off' when revs rise and pass 10000rpm)

(PJ switch 'on' when revs drop and pass 10000rpm)