Table of Contents

Chapter 1, Basic Operation ..................................1-1

Introduction................................................................................................ 1-1

Description................................................................................................. 1-1

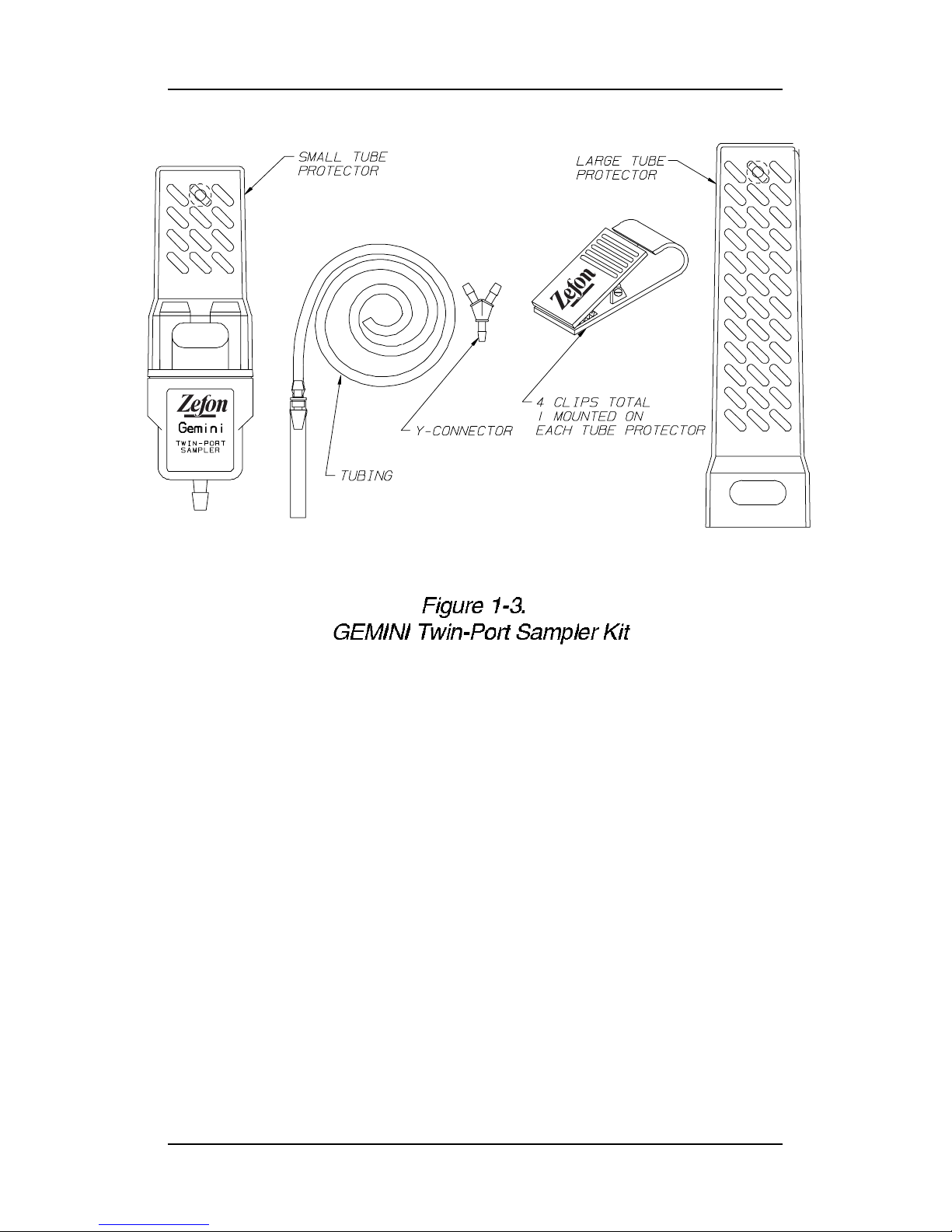

Contents of Kit............................................................................................ 1-1

Figure 1-1. Worker Wearing GEMINI Twin-Port Sampler................... 1-2

Figure 1-2. Worker Wearing 2 Samplers with “Y” Connection.......... 1-3

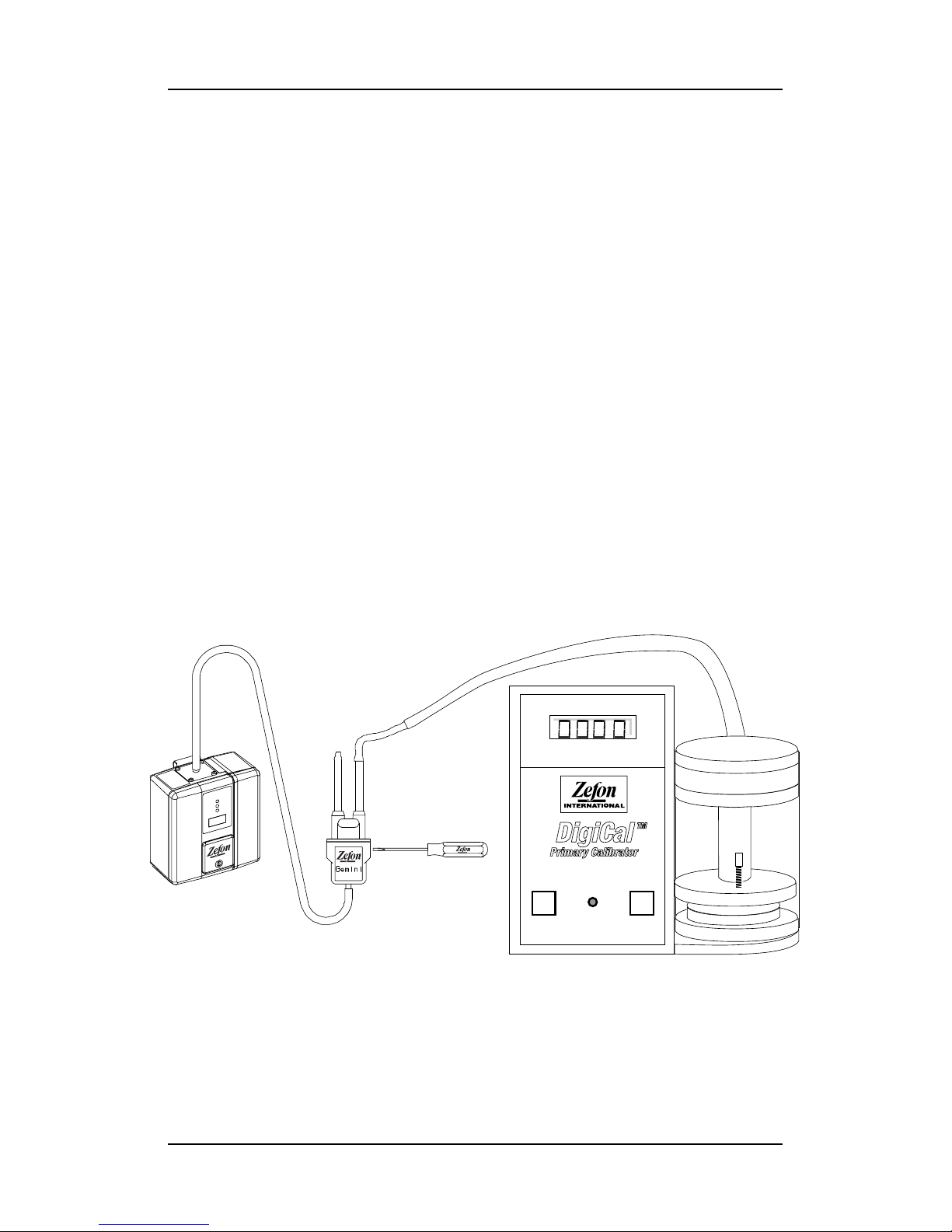

Operation Instructions ................................................................................ 1-4

Figure 1-3. GEMINI Twin-Port Sampler Kit........................................ 1-4

Figure 1-4. Inserting Sorbent Tubes into the GEMINI Sampler........... 1-5

Figure 1-5. Setting the Flow Rate with the DigiCal Calibrator............ 1-6

Helpful Hints............................................................................................... 1-7

Remote Sampling....................................................................................... 1-8

Chapter 2, Maintenance.......................................2-1

Tube Holder................................................................................................ 2-1

Foam Filter ................................................................................................. 2-1

Filter Disc ................................................................................................... 2-1

Valves......................................................................................................... 2-2

Performance Test ....................................................................................... 2-2

Chapter 3, Parts List.............................................3-1

Repair Kit Parts List.................................................................................... 3-1

Accessories Parts List ................................................................................ 3-2

Table of Contents

GEMINI Twin Port Sampler TOC-1