ZENAIR CH2000 SERVICE MANUAL

________________________________________________________________________

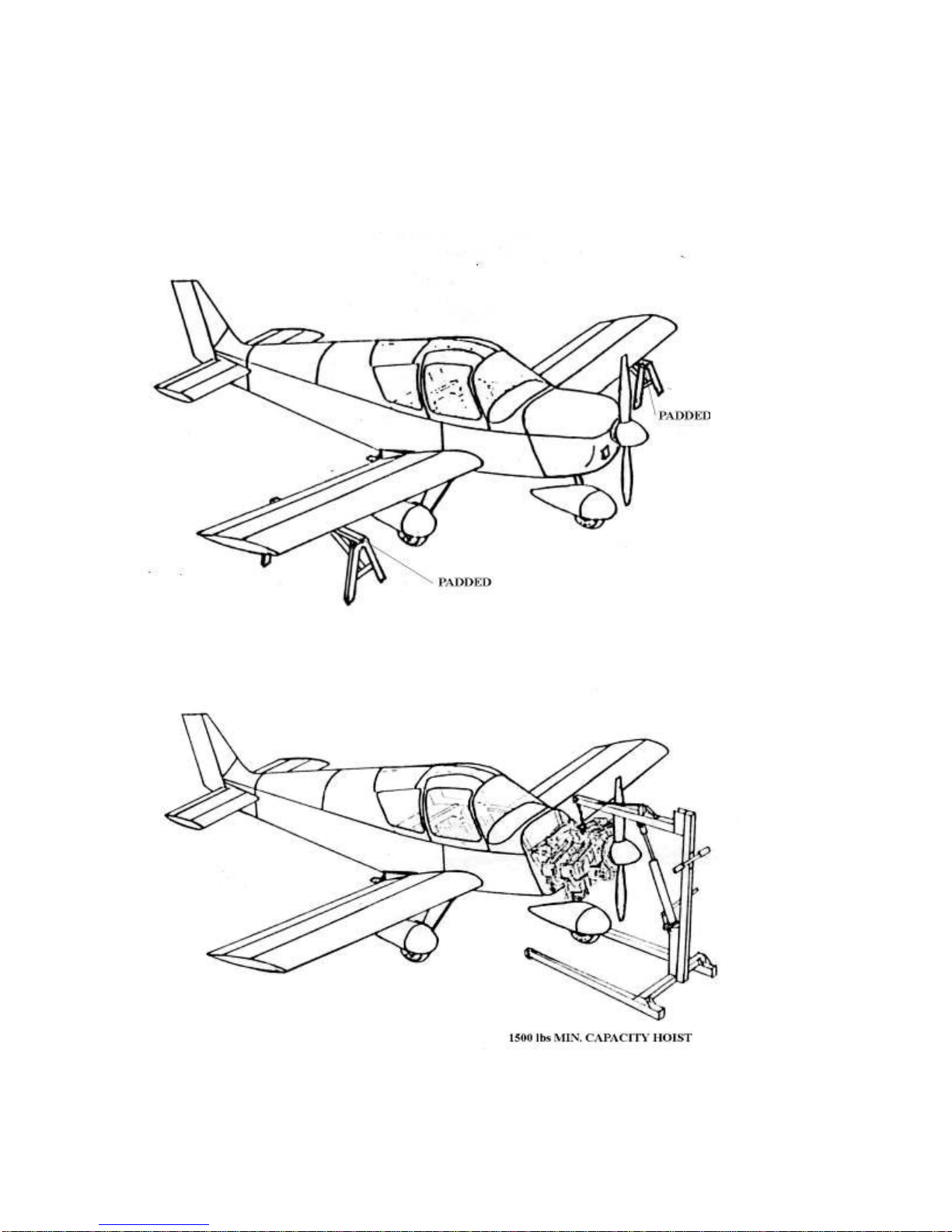

DESCRIPTION - Fig. 1

The Zenair CH2000 is a single engine, two-seat, low-wing monoplane of all-metal

construction.

WING: The wing is of all-metal stressed-skin, full cantilever, low-wing design, consisting

of two wing panels bolted to a spar box assembly in the fuselage. The ailerons are cable

and push rod controlled. The wing trailing edge split flaps are electrically operated.

EMPENNAGE: The empennage consists of the rudder, stabilator, and stabilator trim tabs.

The stabilator is dynamically balanced.

FUSELAGE: The fuselage consists of three basic sections: the engine section, the cabin

section, and the sheet-metal tail cone.

LANDING GEAR: The tricycle landing gear is of the fixed type, consisting of a nose

wheel and two main wheels.

HYDRAULIC SYSTEMS: The dual brake system is operated by master cylinders.

ENGINE: The aircraft is powered by one horizontally opposed Lycoming Model 0-235-

N2C four-cylinder air-cooled engine. The engine employs a wet sump oil system with oil

temperature and pressure indicators.

PROPELLER: The propeller used is a Sensenich fixed pitch, all metal, aluminum alloy,

Model 72-CK series.

FUEL SYSTEM: The fuel system on the Zenair CH2000 consists of one rear aluminum

tank or tanks in the wings, one engine-driven pump, and one electrical auxiliary pump.

FLIGHT CONTROLS: The flight controls are conventional equipment, consisting of a

control wheel which operates the ailerons and stabilator, and pedals which operate the

rudder. Duplicate controls are provided for the co-pilot.

RADIO: Provisions for radio installations consist of microphone and headset jacks and

mounting brackets, necessary wiring, and panel space for extra radios.

CABIN HEATER, DEFROSTER, AND FRESH AIR SYSTEM: Heated air for the cabin

and defroster is obtained directly from the exhaust system muffler shroud. Fresh air is

supplied to the cabin through two individual and orientable air inlet vents in the right and

left door window.

INSTRUMENTS: Provisions for optional instruments are provided, including full IFR

equipment.

1.2 3 Apr 96