Zenith ZBTSH Series User manual

Revised October, 1996

INSTRUCTION

MANUAL

ZBTSH SERIES BYPASS/ISOLATION TRANSFER SWITCH

100 -400 AMPS

IMODEL

NO.

SERIAL

NO.I

L-..-=====

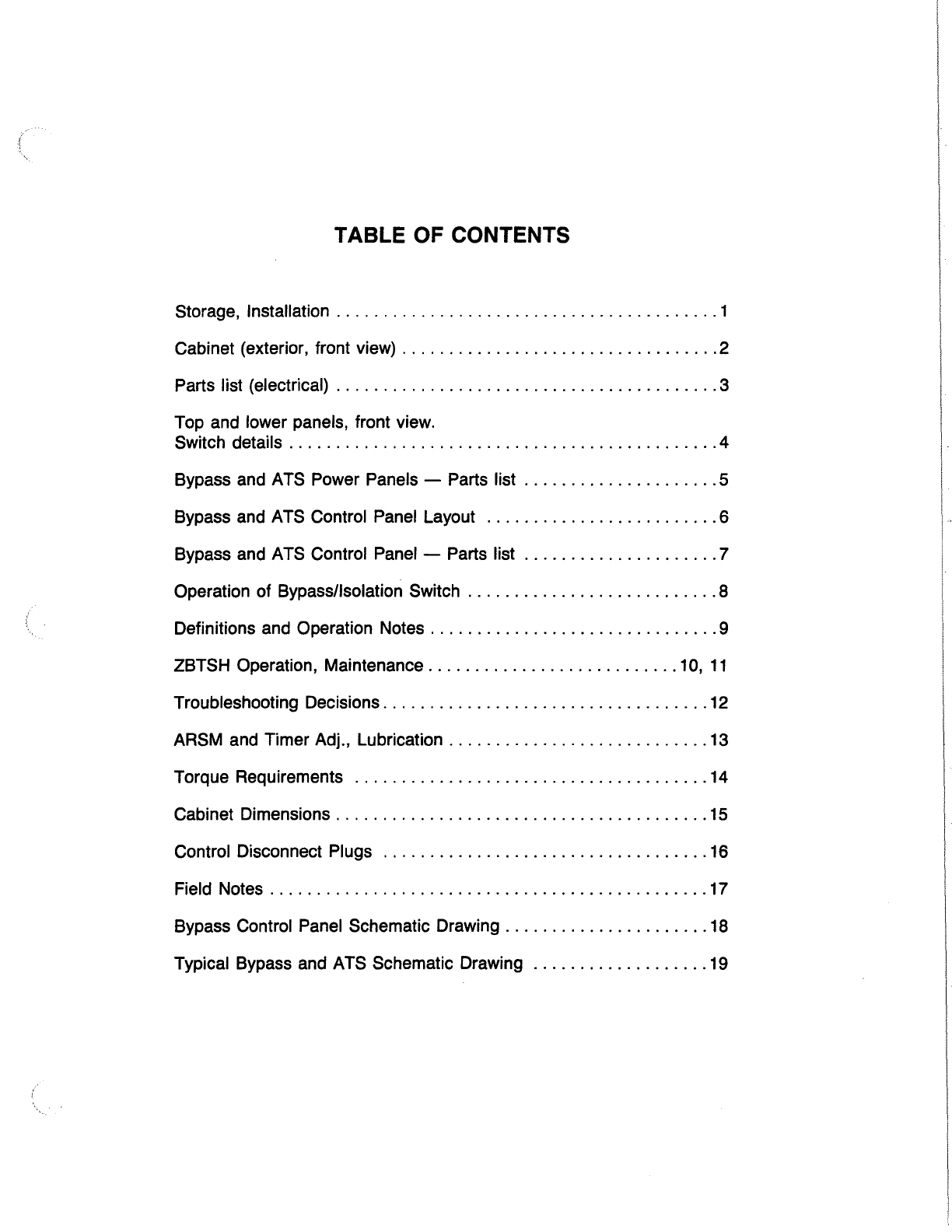

TABLE OF CONTENTS

Storage, Installation

.........................................

1

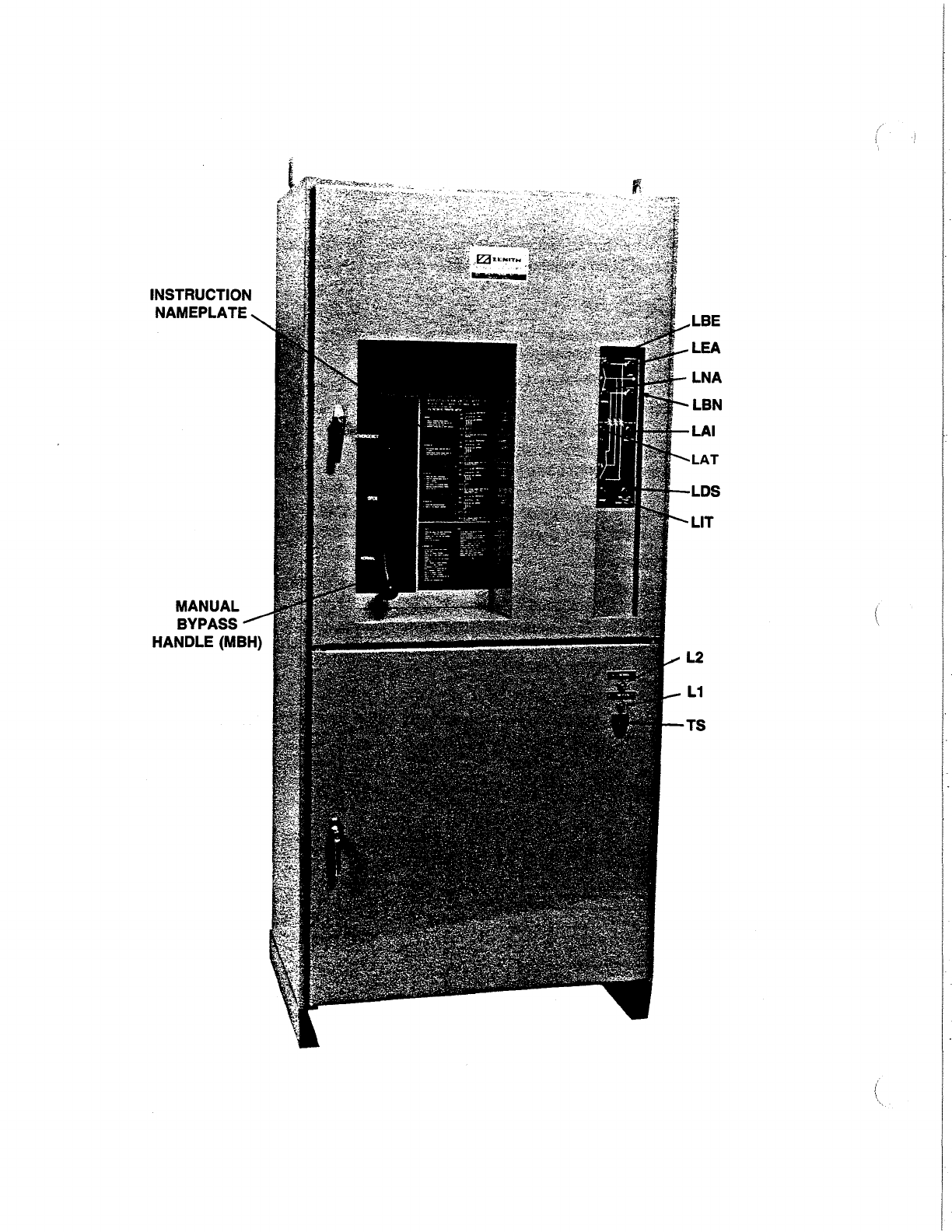

Cabinet (exterior, front view)

..................................

2

Parts list (electrical)

.........................................

3

Top and lower panels, front view.

Switch details

..............................................

4

Bypass and ATS Power Panels -Parts list

.....................

5

Bypass and ATS Control Panel Layout

.........................

6

Bypass and ATS Control Panel -Parts list

.....................

7

Operation of Bypass/Isolation Switch

...........................

8

Definitions and Operation Notes

...............................

9

ZBTSH Operation, Maintenance

...........................

10,

11

Troubleshooting Decisions

...................................

12

ARSM and Timer Adj., Lubrication

............................

13

Torque Requirements

......................................

14

Cabinet Dimensions

........................................

15

Control Disconnect Plugs

...................................

16

Field Notes

...............................................

17

Bypass Control Panel Schematic Drawing

......................

18

Typical Bypass and ATS Schematic Drawing

...................

19

STORAGE:

The ZBTSH should be stored in a clean dryarea. AVOID STORAGE BENEATH STEAM OR WATER PIPES.

Excessive moisture may damage the unit. The switch should only be stored on a level (horizontal) surface.

INSTALLATION:

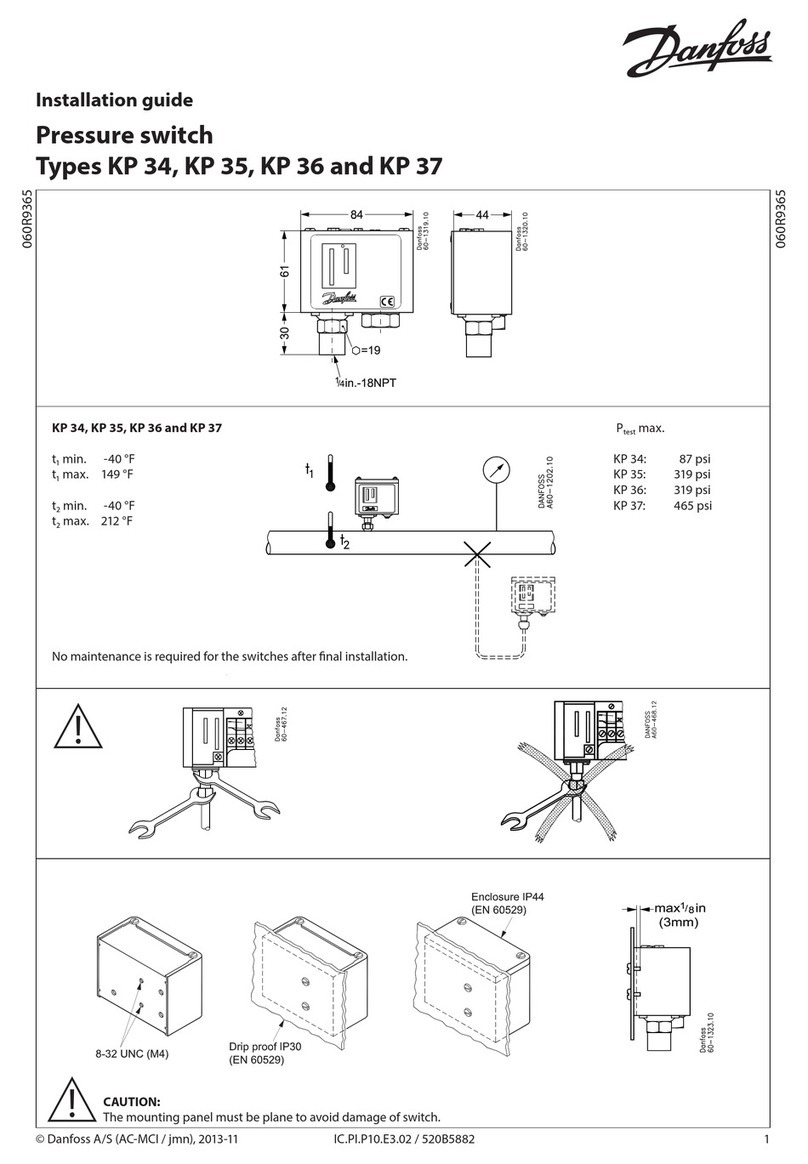

1.

Lifting:

To lift and manuever the Bypass Switch use lifting angles. See Fig. 1 (below). CAUTION: Depen-

ding upon the model, aZBTSH weighs between

650-

700 lbs. Use adequate machineryand cables

to handle the load.

2.

Equipment

Preparation:

a)

. Check nameplate

to

assure switch system voltage and amperage is correct. Any discrepancy

should be immediately reported to a Zenith representative.

b)

. Lock open breakers to normal and emergency lines.

3.

Cabinet

Preparation:

a)

. A small amount of cabinet work is required before the cables are connected.

Cover

the

switch

and

the

controls

to

avoid

metal

fragments

from

entering

mechanical

and

electrical

com-

ponents.

Visually verify that metal filings are removed from top bus support. (Use vacuum if

necessary).

b).

Standard cable entry is through the top or bottom

of

the cabinet. Fig. 2 below shows one sug-

gested knockout order. For a guide to assist in the hole layout, refer to page 15.

4. Cable

and

Wire

Connections:

a).

To remove possible oxide, clean cable conductor with a wire brush and apply a contact oxide

inhibitor. Insert cables into appropriate lugs.

b)

. Connect all auxiliary wires for external electrical operation. Example: E-start, remote alarm lights

or buzzers, motor control contacts, etc. Allow enough slack in wires to allow movement of the

ATS to isolate position (approx. 1 ft.).

5.

Prior

to

the

Unit's

Energization:

a)

. Remove any debris incurred due to installation (cut cable strands, m'etal filings, etc.).

b)

. Inspect the unit and verify torque

of

cable and wire connections.

H

CABINET REMOVABLE

LIFTING ANGLES

TOP

VIEW

OF

CABINET

EMERGENCY

TYPICAL LAYOUT FIG. 2

Note: When lifting the switch, a

spreader must be used. The height

H must be equal

to

0/2.

FIG. I

1

INSTRUCTION

NAMEPLATE

MANUAL

BYPASS

HANDLE (MBH)

A. CABINET ELECTRICAL PARTS

TAG DESCRIPTION PART NO.

LNA Normal Available Indicator

(G)

LEA Emergency Available Indicator (R)

LBN Bypass Normal Location Indicator

(G)

LBE Bypass Emergency Location Indicator (R)

LAT ATS Test Position Indicator

(A)

LAI ATS Isolate Position Indicator

(A)

LIT ATS Inhibit Indicator (R)

LOS ATS Disconnect Switch

"Off"

Indicator (R)

Flashing Bulb, PS-1272

COMMON PARTS BYPASS INDICATORS

Bulb Y500005

Socket PS-5046

Red Lens (R) PS-5047

Green Lens

(G)

PS-5048

Amber Lens

(A)

PS-5049

L1

L2 ATS Emergency Position Indicator

ATS Normal Position Indicator

Bulbs (Incandescent) P8-5105

Bulb Socket (Incandescent) PS-5046

Emergency Lens (Red) P8-5047

TS

Normal Lens (Green)

Test Switch

PS-5048

Operator, Momentary L-1025

Contact Block N.C. L-1029

Contact Mounting Base PS-3473

3

Rev.

11/94

~A

0B

0C

NEUT.

r--

-

~EMERG.~

BYPASS

EMERGENCY

CONTACTS

T2 LOAD T3

~

~

EN

N2

NORM.

N3

~

l.

u-

~

Ill ENGINE

START

CONNECTIONS

\

r:

AB3+4

./

AB4

t--

DETAIL 2

DETAIL

2A

DETAIL

28

DETAIL

2C

DETAIL

2D

DETAIL 2E

NYLON

ROLLER

SWITCH DETAILS

I r

AI

I

AT-I,

AT-2

\.

ZBTSH 4 POLE

4

B. BP-BYPASS AND ATS AUTOMATIC TRANSFER SWITCH POWER PANEL

TAG DESCRIPTION PART NUMBER BY AMPERAGE

Bypass 100 150 225 260 400

N1,

2,

3, N Normal }

E1,

2,

3, N Emergency LUGS P8-4418 P8-4418 P8-4418 S-1422 S-1422

T1, 2, 3, N Load

BYPASS Contact Assembly (Movable & Stationary for 3 Pole Units)

N1,2,3

Normal 46P-1104A 46P-1104B 46P-1104C 46P-1104D 46P-1104E

N (Sw. Neut. Norm.) 46P-1105A 46P-1105B 46P-1105C 46P-1105D 46P-1105E

E1,2,3

Emergency 46P-1106A 46P-1106B 46P-1106C 46P-1106D 46P-1106E

N (Sw. Neut. Emerg.) 46P-1107A 46P-1107B 46P-1107C 46P-1107D 46P-1107E

ATS Contact Assembly (Movable & Stationary for 3 Pole Units)

NL1, 2, 3 Normal 46P-1100A 46P-1100B 46P-1100C 46P-1100D 46P-1100E

N (Sw. Neut. Norm) 46P-1101A 46P-1101B 46P-1101C 46P-1101D 46P-1101E

EL1, 2, 3 Emergency 46P-1102A 46P-1102B 46P-1102C 46P-1102D 46P-1102E

N (Sw. Neut. Emerg.) 46P-1103A 46P-1103B 46P-1103C 46P-1103D 46P-1103E

Arc Grid Assy. 46P-1099

XBN,XBE

Bypass Step-Down VOLTAGE PART NO.

Transformer 25VA 120/240

K-3061

Secondary 24V 208/416 K-3063

220/440 K-3064

240/480 K-3062

380 K-3067

575 K-3065

600 K-3066

CNE Main ATS Ooerating Coils

Voltage Systems

No. Volts

Ph

Wire Coil Volts Poles PART NO.

-1

120 1 2 120 2

K-2178

-2 120/240 1 3 240 2,3 K-2189

-3 240 3 3 240 3 K-2189

-38 120/240 3 4 240 3,4 K-2189

-4 120/208 3 4 208 3,4 K-2177

-5 480 3 3 480 3 K-2176

-6 575/600 3 3 575/600 3 K-2196

-7 277/480 3 4 480 3,4 K-2176

-9 240/416 3 4 416 3,4 K-2188

-91

220/380 3 4 380 3,4 K-2188

SN

CN1

Limit Switch

SE

CE1

Limit Switch

A3 ATS Emergency Position Switch L-3002 (Detail 2)

A4 ATS Normal Position Switch

SCN/SCE CNE Limit Switches L-3079 (Detail 2a)

AA

ATS Auto Location Switch

AE1, 2 ATS Isolate/Remove Location Switch

L-3071

(Detail 2b)

PLS1,2

Position Lever Switch

AI ATS Isolate Location Switch L-3070 (Detail 2c)

AT1, 2 ATS Test Location Switch

AB3/ABE Bypass Emergency Position Switch

AB4/ABN Bypass Normal Position Switch L-5021 (Detail 2d)

NA4 Normal TRS Limit Switch

EA3 Emergency TRS Limit Switch

BTE Bypass Emergency Position Switch

BTN Bypass Normal Positiion Switch

TSE ATS Engaged Switch L-3054 (Detail 2e)

BLL

Bypass Lock Location Switch

ALL ATS Lock Location Switch

OS ATS Solenoid Disconnect Switch

Operator 2-Position Maintain L-4018

Contact Block N.C.

(1)

L-1029

Contact Block N.O. (2) L-1028

Contact Block Mounting Plate P8-3473

BPS Bypass Interlock Solenoid K-2180

TRS Transfer Release Solenoid K-2180

5 Rev. 11/94

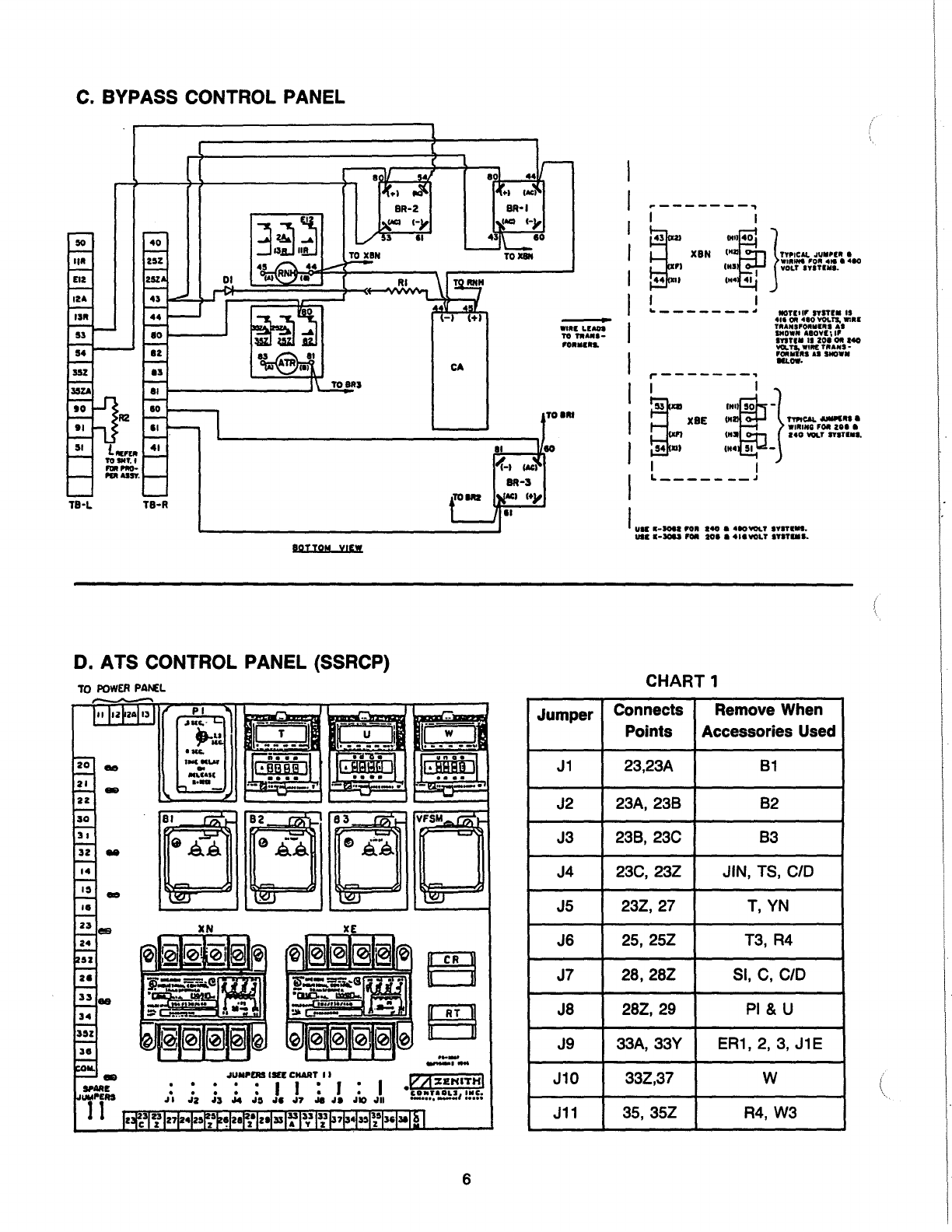

C.

BYPASS CONTROL PANEL

CA

Will

LIAOI

TO

fiiAJII•

POIIIII.L

TOIIII

BOTTOM

VIEW

TB·L

TB-R

,--------,

I XBN

,:to

I }TYPICAl.

JUII•I~

1

WUUHI

'OR

4te

a

410

I

:::

I

VOLT

IYifllll.

41

I I

~-------~

tiOTIIfP'

Sl'ITIM

IS

411

Oft

410

YOLTS.

Will

TRANSPOftlllltl

AI

SHOWN

AIOYI\

IP

lftflll

II

ZOI

ft

140

VOI..TS.WIR!TIIANS•

FOfii!MIRS

AI

SHOWN

IlL

OW·

,..-------,

I I }

XII

XBE

=~~O

-TYI'ICAL

-~•

1

~

WINING

F~

ZOI

•

:

:::

Ol

-

140

_,

IYifllll.

I I

L-----

--~

I

uu:

•·-•

•o•

140

•

•ao-.r

IYifiiiS.

1111··~

fOil

101

I 411VOLT

IYITIIII.

D. ATS CONTROL PANEL (SSRCP) CHART 1

TO

POWER

PAI\£L

JUMPERS

IIU

CHART

II

..••.

11:1.1

Jl

JZ

J:S

J4

JO , • .17

Jl

Jl

JIO

Jll

Jumper Connects

Points Remove When

Accessories Used

J1

23,23A

81

J2 23A,238 82

J3 238,

23C

83

J4

23C,

23Z

JIN,

TS,

C/0

J5 23Z,27

T,

YN

J6

25,

25Z

T3,

R4

J7 28,28Z

Sl,

C,

C/0

J8

28Z,

29

PI

& U

J9

33A,

33Y

ER1,

2,

3,

J1E

J10

33Z,37

w

J11

35,

35Z

R4,

W3

6

C.

BYPASS CONTROL PANEL (46P-1079) INCLUDES PARTS BELOW

( TAG DESCRIPTION PART NUMBER

BR1,

2.

3 Bridge Rectifier PS-5076

RNH Normal Voltage Relay Y260000

R1

Resistor RNH, 30 ohm PS-4056

R2

Resistor

LOS,

120 ohm PS-4057

01 Diode PS-4812

CA Capacitor

RNH

PS-4058

ATR Auxilary Test Relay Y260000

D. ATS CONTROL PANEL (SSRCP) STANDARD ITEMS

TAG DESCRIPTION VOLTAGE 50/60 HZ PART NO.

XN,XE

Control Transformers

(See Note

1)

120V K-3076

208V K-3070

240 or 480V

K-3071

416V K-3089

B-1,

2,

3 Phase Relays

Solid State

(See Note

1)

120V K-1185

208 or 240V K-1186

480V K-1188

VFSM Voltage Frequency Sensor 120V K-1192R

CR Control Relay 120V K-1204

AT Bypass T Relay 120V K-1204

CN1/CE1 CNE Transfer Relays (not shown) 120V K-1120

J1-J11 Jumpers PS-5067

(OPTIONAL ITEMS)

TAG DESCRIPTION VOLTAGE PART NUMBER

T Time Delay to Normal, Timer Solid State 120V

.1

Sec. to 9990 Hrs. (Adj.) K-1230

u Engine Cool Down, Timer Solid State 120V

.1

Sec. to 9990 Hrs. (Adj.) K-1230

w Time Delay Emergency, Timer Solid State 120V

.1

Sec. to 9990 Hrs. (Adj.) K-1230

PI

Time Delay Engine Start, Timer 120V (.5 to 6 sec. Adjustable)

K-1201

P2 Optional (Mounted below SSRCP) 120V (300 Sec. Adjustable)

K-1061

Notes:

1.

If -6 voltage system (575/600V) is supplied, then XN,

XE

is K-3087 and B1,2, 3 is K-1185 (120V) supplied with XB

(575;600V/120V) 3 phase transformer assembly. B1,

2,

3 mounted below SSRCP.

7

Rev. 11/94

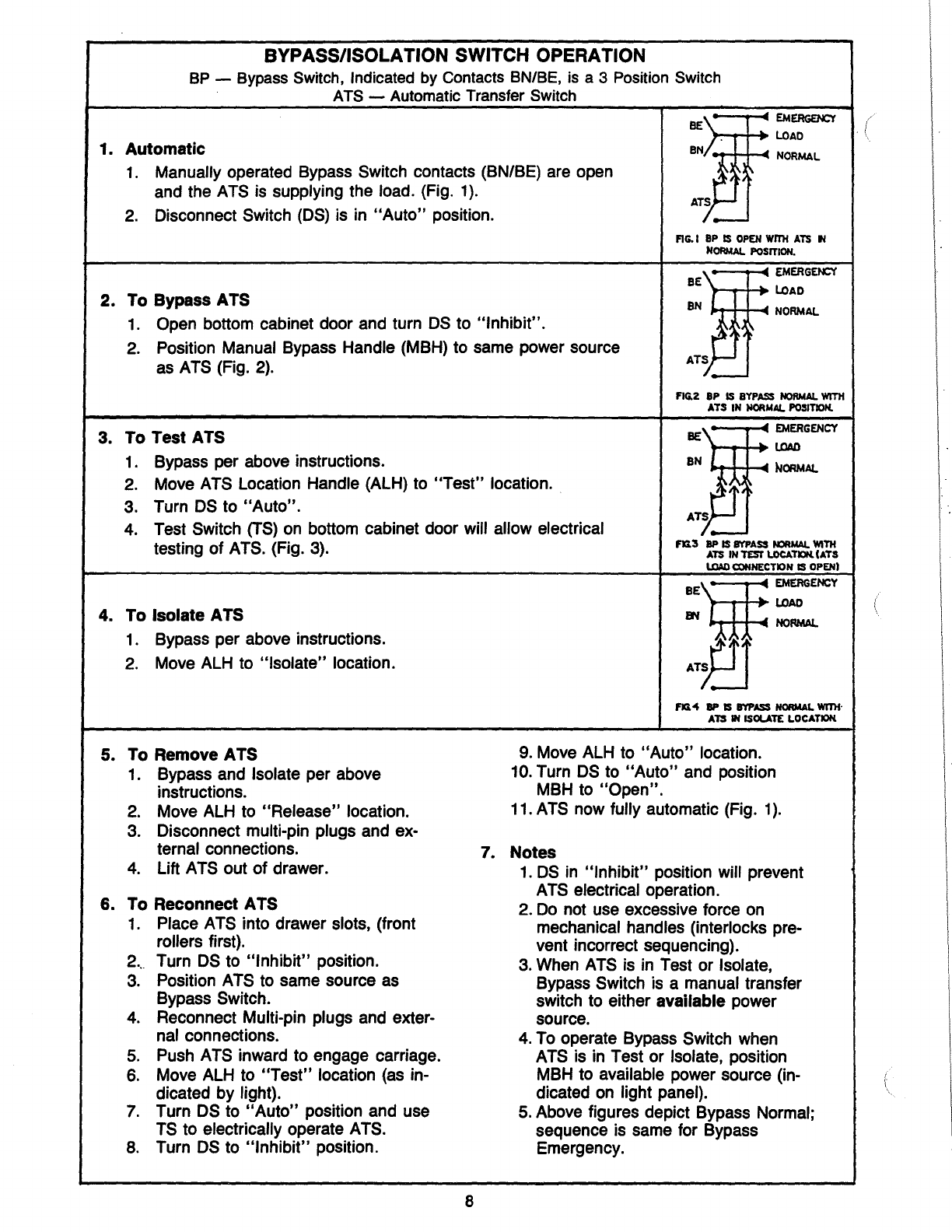

BYPASS/ISOLATION SWITCH OPERATION

BP-

Bypass

Switch,

Indicated

by

Contacts

BN/BE,

is

a 3

Position

Switch

ATS-

Automatic

Transfer

Switch

-:.

EMERGENCY

BE

,._,...p-_._+

lOAD

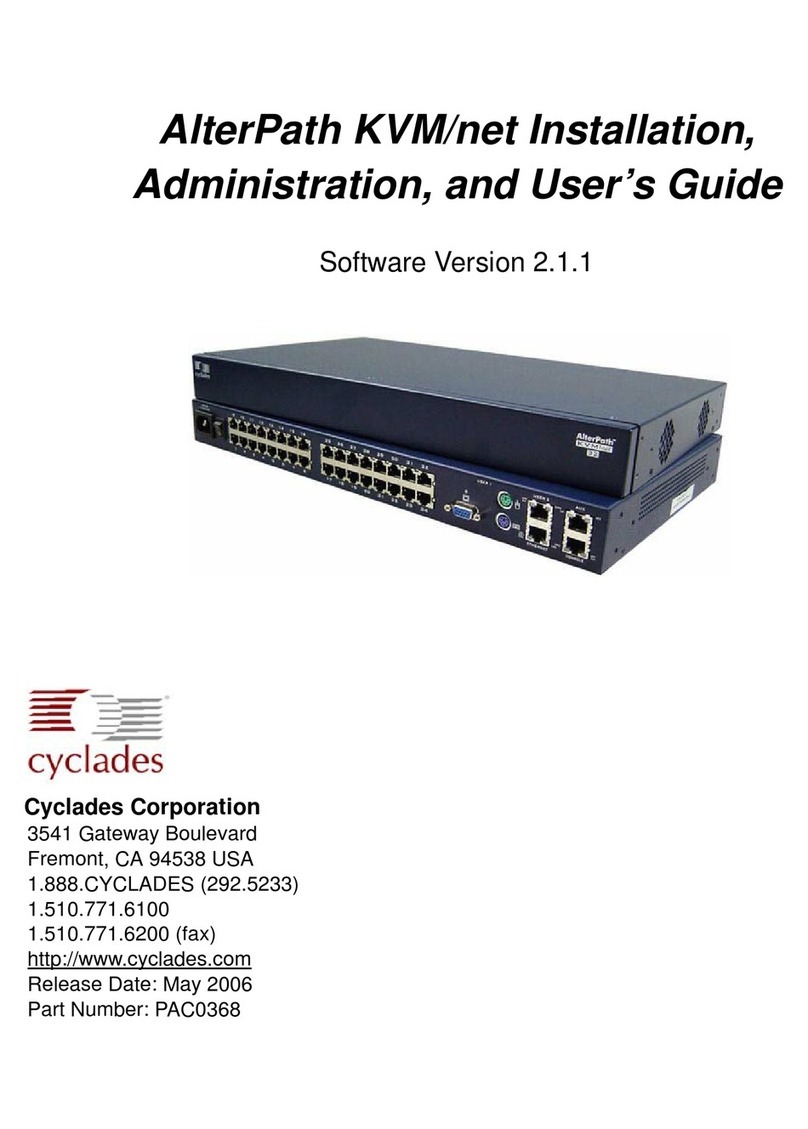

1. Automatic

BNJ_~~:"-

~

NORMAL

1.

Manually operated Bypass Switch contacts (BN/BE) are open

and the

ATS

is

supplying the load. (Fig.

1).

AT

2.

Disconnect Switch

(OS)

is

in

"Auto"

position. -

FIG. I

BP

IS

OPEN

WrrH

ATS

N

NORMAL

POSITION.

-:.EMERGENCY

BE

lOAD

2. To Bypass ATS

BN,/;_(

~J ~

~

NORMAL

1.

Open bottom cabinet door and turn

OS

to "Inhibit".

2.

Position Manual Bypass Handle (MBH) to same power source AT

as

ATS

(Fig.

2).

·-

FIG.2 BP

IS

BYPASS

NORMAL

WITH

ATS

IN

NORMAL.

POSITION.

3. To Test ATS

1.

Bypass per above instructions.

---.-

.....

~

EMERGENCY

BE

..,_,...p-_._+

LOAD

BN

L

-.c

~ORMAL

2.

Move

ATS

Location Handle (ALH) to

"Test"

location.

3. Turn

OS

to "Auto".

.l_

4.

Test Switch

(TS)

on

bottom cabinet door will allow electrical

Fn3

8P IS

BYPASS

NJRioiAL.

WITH

testing of

ATS.

(Fig.

3).

ATS

IN

TESI'

lOCATXlN.

CATS

l.OAO

CCNNECTION

IS

OPEN)

4. To Isolate ATS

1.

Bypass per above instructions.

2.

Move

ALH

to "Isolate" location.

5. To Remove ATS

1. Bypass and Isolate per above

instructions.

2.

Move

ALH

to "Release" location.

3.

Disconnect multi-pin plugs and ex-

ternal connections.

4.

Lift

ATS

out of drawer.

6. To Reconnect ATS

1.

Place A

TS

into drawer slots, (front

rollers first).

2..

Turn

OS

to "Inhibit" position.

3.

Position

ATS

to same source

as

Bypass Switch.

4.

Reconnect Multi-pin plugs and exter-

nal connections.

5.

Push

ATS

inward to engage carriage.

6.

Move

ALH

to

"Test"

location

(as

in-

dicated by light).

7.

Turn

OS

to

"Auto"

position and use

TS

to electrically operate

ATS.

8.

Turn

OS

to "Inhibit" position.

BE'ij:

EMERGENCY

LOAD

BN

NOIWAL.

·~

Fn4

8P

IS

IM'ASS

NORMAL

WITH·

ATS

IN

ISOLATE

LOCATIOK

9.

Move

ALH

to

"Auto"

location.

10.

Turn

OS

to

"Auto"

and position

MBH

to "Open".

11.

ATS

now fully automatic (Fig.

1).

7. Notes

1.

OS

in

"Inhibit" position will prevent

A

TS

electrical operation.

2.

Do

not use excessive force

on

mechanical handles (interlocks pre-

vent incorrect sequencing).

3.

When

ATS

is

in

Test or Isolate,

Bypass Switch

is

a manual transfer

switch to either available power

source.

4.

To

operate Bypass Switch when

ATS

is

in

Test or Isolate, position

MBH

to available power source (in-

dicated

on

light panel).

5.

Above figures depict Bypass Normal;

sequence

is

same for Bypass

Emergency.

8

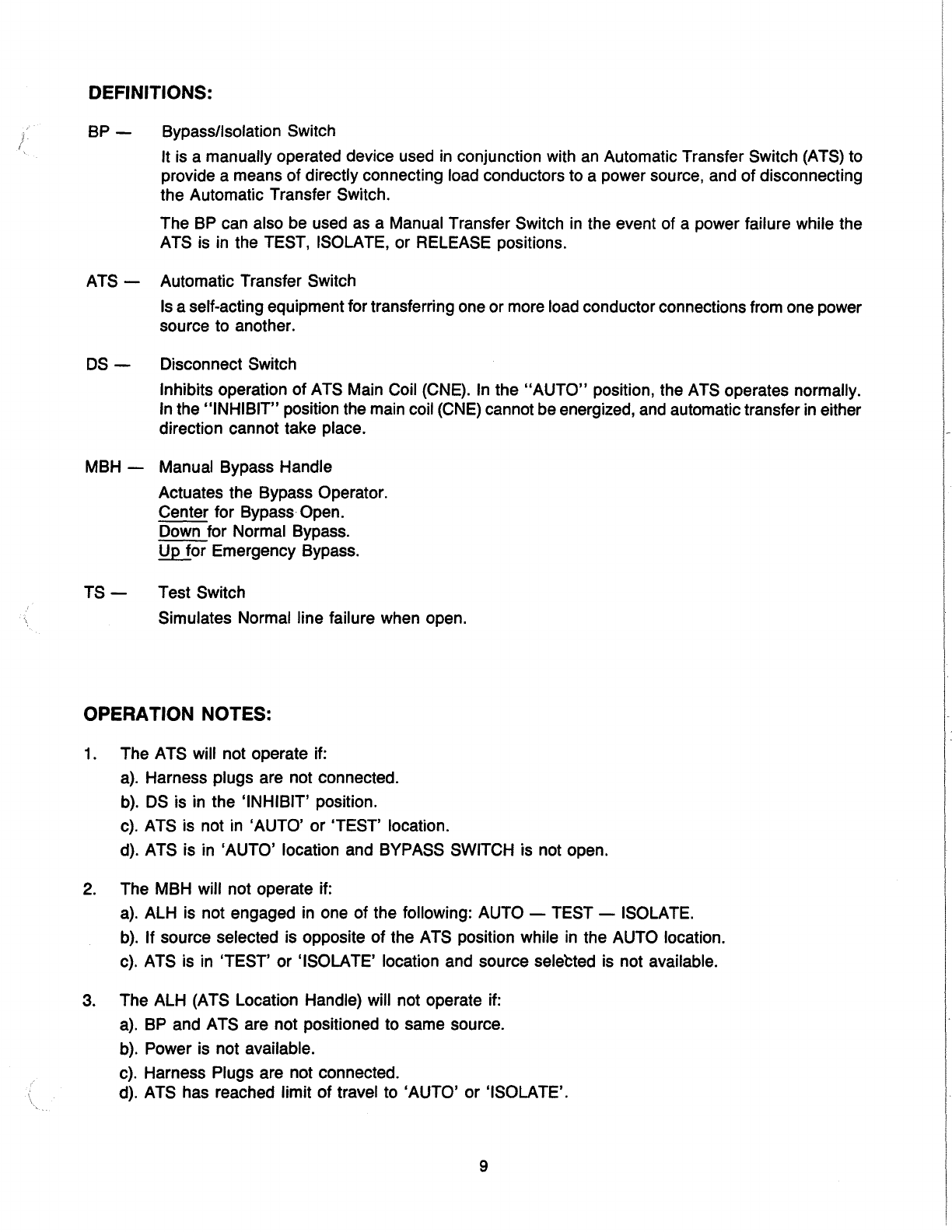

DEFINITIONS:

BP

-Bypass/Isolation Switch

) It

is

a manually operated device used

in

conjunction with

an

Automatic Transfer Switch (ATS) to

provide a means of directly connecting load conductors to a power source, and of disconnecting

the Automatic Transfer Switch.

The

BP

can also be used as a Manual Transfer Switch

in

the event of a power failure while the

ATS

is

in

the TEST, ISOLATE, or RELEASE positions.

ATS -Automatic Transfer Switch

Is

a self-acting equipment for transferring one or more load conductorconnections from one power

source to another.

DS-

Disconnect Switch

Inhibits operation of ATS Main Coil (CNE).

In

the

"AUTO"

position, the ATS operates normally.

In

the "INHIBIT" position the main coil

(CNE)

cannot be energized, and automatic transfer

in

either

direction cannot take place.

MBH -Manual Bypass Handle

Actuates the Bypass Operator.

Center for Bypass Open.

Down for Normal Bypass.

~or

Emergency Bypass.

TS-

Test Switch

Simulates Normal line failure when open.

OPERATION NOTES:

1.

The ATS will not operate if:

a).

Harness plugs are not connected.

b).

DS

is in the 'INHIBIT' position.

c).

ATS is not in 'AUTO' or 'TEST' location.

d). ATS is in 'AUTO' location and BYPASS SWITCH is not open.

2.

The MBH will not operate if:

a).

ALH

is

not engaged

in

one of the following:

AUTO-

TEST-

ISOLATE.

b).

If source selected is opposite of the ATS position while

in

the AUTO location.

c).

ATS is in 'TEST' or 'ISOLATE' location and source selected

is

not available.

3.

The ALH (ATS Location Handle) will not operate if:

a).

BP

and ATS are not positioned to same source.

b).

Power is not available.

c). Harness Plugs are not connected.

d). ATS has reached limit of travel to 'AUTO' or 'ISOLATE'.

9

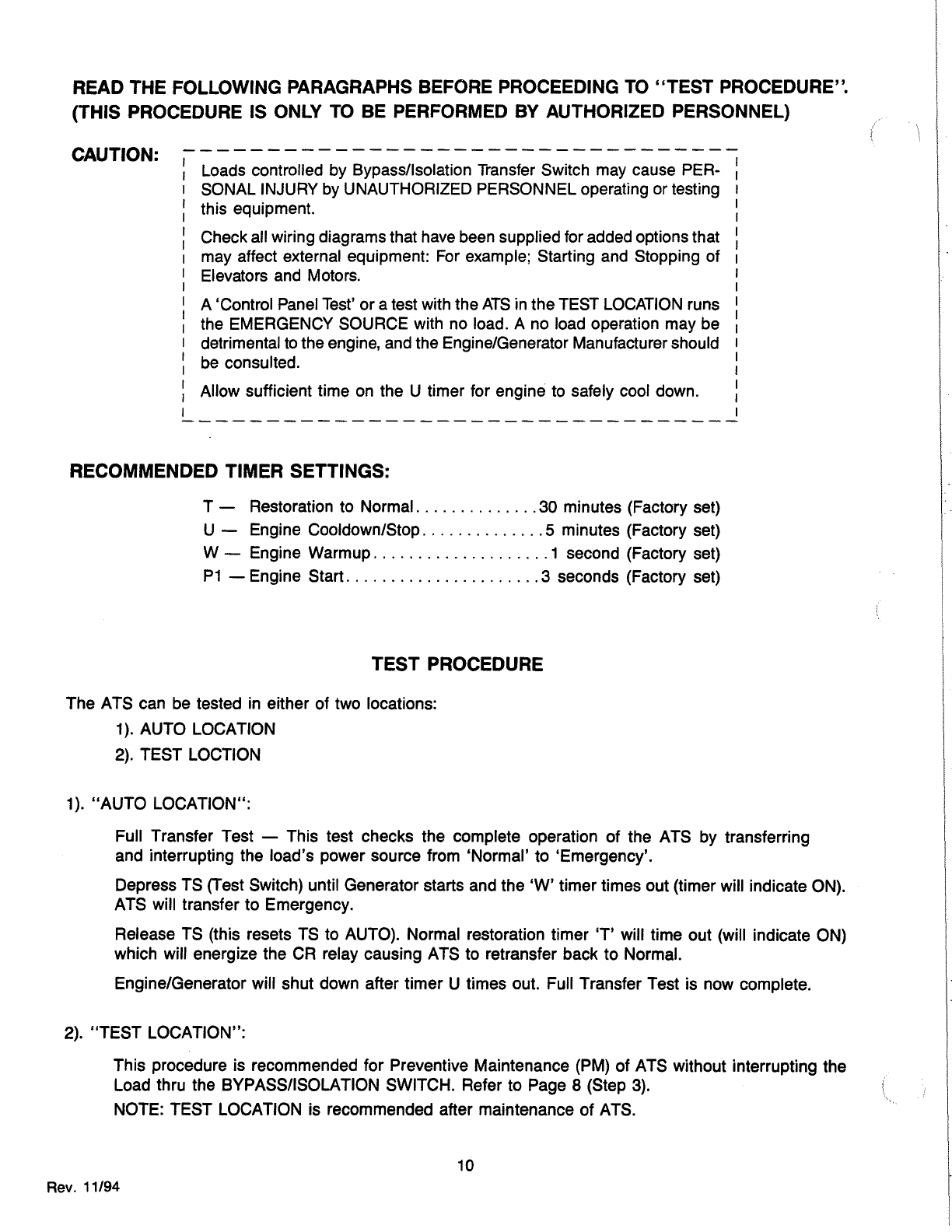

READ THE FOLLOWING PARAGRAPHS BEFORE PROCEEDING

TO

''TEST PROCEDURE''.

{THIS PROCEDURE IS ONLY

TO

BE PERFORMED

BY

AUTHORIZED PERSONNEL)

CAUTION: Loads controlled by Bypass/Isolation Transfer Switch may cause PER-

SONAL INJURY by UNAUTHORIZED PERSONNEL operating or testing

this equipment.

Checkall wiring diagrams that have been supplied for added options that

may affect external equipment: For example; Starting and Stopping of

Elevators and Motors.

A 'Control Panel Test'

or

a test with the

ATS

in the TEST LOCATION runs

the EMERGENCY SOURCE with no load. A no load operation may be

detrimental to the engine, and the Engine/Generator Manufacturer should

be consulted.

Allow sufficient time on the U timer for engine to safely cool down.

RECOMMENDED TIMER SETTINGS:

T - Restoration to Normal

..............

30 minutes (Factory set)

U - Engine Cooldown/Stop

..............

5 minutes (Factory set)

W - Engine Warmup

....................

1 second (Factory set)

P1

-Engine Start.

.....................

3 seconds (Factory set)

TEST

PROCEDURE

The ATS can be tested in either

of

two locations:

1

).

AUTO LOCATION

2). TEST LOCTION

1).

"AUTO

LOCATION":

Full Transfer Test -This test checks the complete operation

of

the ATS by transferring

and interrupting the load's power source from 'Normal' to 'Emergency'.

Depress TS (Test Switch) until Generator starts and the

'W'

timer times out (timer will indicate ON).

ATS will transfer

to

Emergency.

Release TS (this resets TS to AUTO). Normal restoration timer 'T' will time out (will indicate ON)

which will energize the CR relay causing ATS to retransfer back

to

Normal.

Engine/Generator will shut down after timer U times out. Full Transfer Test is now complete.

2).

"TEST

LOCATION":

This procedure is recommended for Preventive Maintenance (PM) of ATS without interrupting the

Load thru the BYPASS/ISOLATION SWITCH. Refer to Page 8 (Step 3).

NOTE: TEST LOCATION is recommended after maintenance

of

ATS.

10

Rev.

11/94

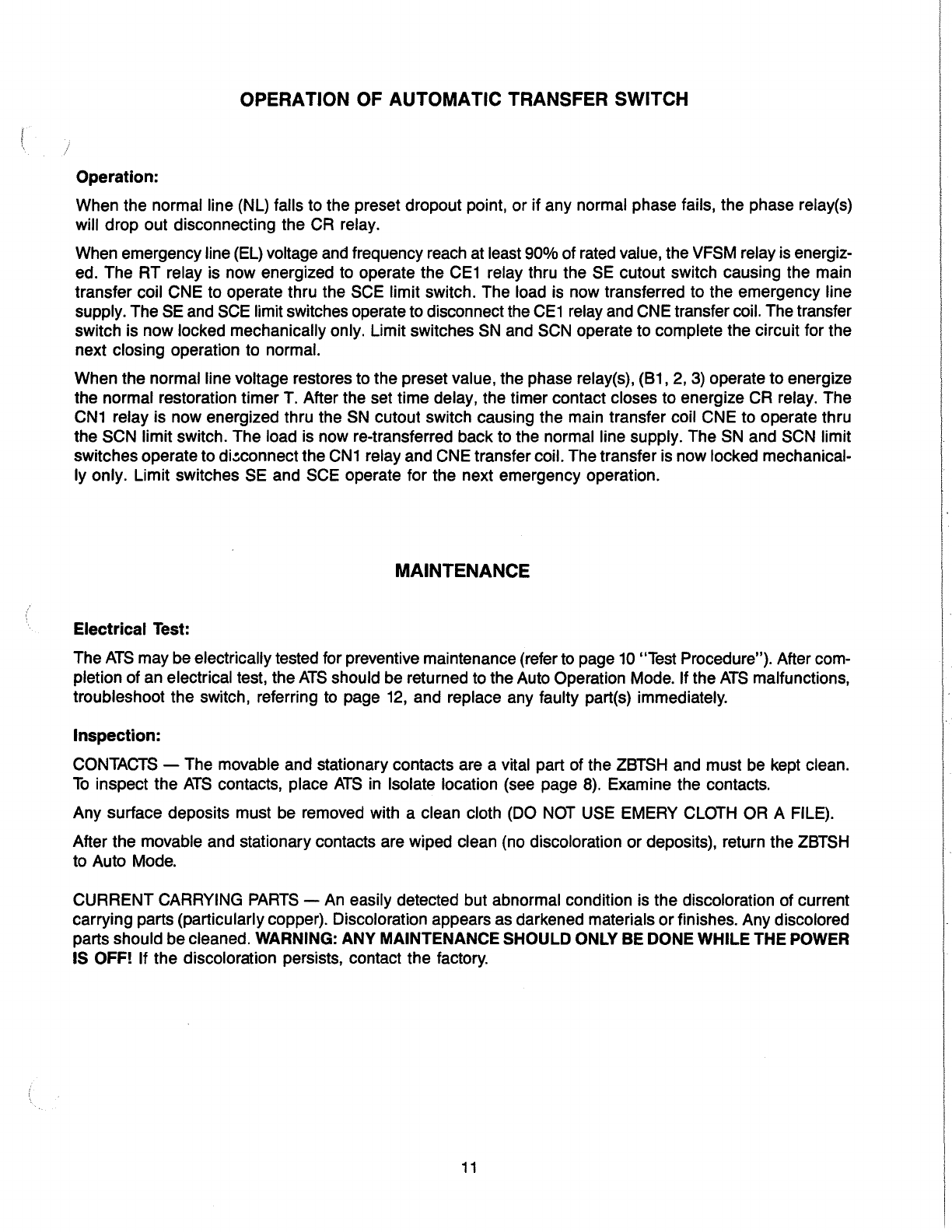

OPERATION OF AUTOMATIC TRANSFER SWITCH

Operation:

When

the

normal line (NL) falls to

the

preset

dropout

point,

or

if

any

normal phase fails,

the

phase

relay(s)

will

drop

out

disconnecting

the

CR

relay.

When emergency line (EL) voltage and frequency reach at least

90%

of

rated value, the VFSM relay is energiz-

ed.

The

RT

relay

is

now

energized to operate

the

CE1 relay thru

theSE

cutout

switch

causing

the

main

transfer

coil

CNE

to

operate

thru

the

SCE

limit

switch.

The

load is

now

transferred

to

the

emergency

line

supply.

The

SE and SCE limit switches operate to disconnectthe

CE1

relay and CNE transfer coil. Thetransfer

switch is

now

locked

mechanically

only. Limit switches SN

and

SCN operate to

complete

the

circuit

for

the

next

closing operation

to

normal.

When

the

normal

line voltage restores to

the

preset value,

the

phase

relay(s),

(81,

2, 3) operate

to

energize

the

normal

restoration

timer

T.

After

the

set

time

delay,

the

timer

contact

closes

to

energize

CR

relay.

The

CN1 relay is

now

energized thru

the

SN

cutout

switch causing

the

main

transfer

coil

CNE

to

operate

thru

the

SCN

limit

switch.

The

load is

now

re-transferred

back

to

the

normal line supply.

The

SN

and

SCN limit

switches

operate

to

di~connect

the

CN1 relay

and

CNE

transfercoil.

The

transfer

is

now

locked mechanical-

ly

only.

Limit

switches

SE

and

SCE

operate

for

the

next

emergency

operation.

MAINTENANCE

Electrical Test:

The

ATS

may

be

electrically tested for preventive maintenance (referto page 10 "Test Procedure"). After com-

pletion

of

an electrical test,

the

ATS

should

be

returned to

the

Auto Operation Mode. If

the

ATS

malfunctions,

troubleshoot

the

switch, referring to page 12,

and

replace any faulty part(s) immediately.

Inspection:

CONTACTS -The movable

and

stationary contacts are a vital

part

of

the

ZBTSH and

must

be kept clean.

To

inspect

the

ATS

contacts, place

ATS

in Isolate location (see page 8). Examine

the

contacts.

Any

surface

deposits must be removed with a clean cloth (DO NOT USE EMERY CLOTH

OR

A FILE).

After

the

movable and stationary contacts are wiped clean (no discoloration

or

deposits), return

the

ZBTSH

to Auto Mode.

CURRENT

CARRYING

PARTS-

An easily detected

but

abnormal condition is

the

discoloration

of

current

carrying

parts (particularlycopper). Discoloration appears as darkened materials

or

finishes.

Any

discolored

parts

should

be

cleaned. WARNING: ANY MAINTENANCE SHOULD ONLY BE DONE WHILE THE POWER

IS OFF! If

the

discoloration persists, contact

the

factory.

11

PROCESS

INORMAL OPERATitjG CONDITIONS I

l

URN

..

T$""

SWITCH

0

TEST

IUNTIL

TRANSFER

TO

EMERGENCY!

W

BEGINS

TIMING

RT

I N RGI

I.

ATS

TRANSFERS

TO

EMERGENCY

AND

MECHANICALLY

LOCKS.

2.

LIMIT SWITCHES SE, A3

ARE

DE-ACTIVATED

3.

Ll

IS

ENERGIZED

T BEGINS TIMING

CR

ENERGIZED

I.

ATS

TRANSFERS

TO

NORMAL

AND

MECHANICALLY

LOCKS.

2.

LIMIT SWITCHES SN,

A4

ARE

ACTUATED.

3.

L2

IS

ENERGIZED.

4,

U

BEGINS

TIMING.

TABLE

3

"TROUBLE

SHOOTING"

DECISIONS CORRECTIONS

CHECK

IF

ENGINE

START CIRCUIT IS

RECEIVING E·CONTACT

CLOSURE.

I.

CHECK

SE

LIMIT

SWITCH.

2.

CHECK

FOR

DEFECTI'VE

CCE.

1.

RELEASE

TS

SWITCH.

-,..:~--------412.

WAIT

FORT

TO

COMP'LETE

TIMING.

3.

TURN

1)$

TO.

ON.

I.

CHECK

SN

LIMIT

L-.:..=::.....----------·

2.

~mroEFECTIVE

CNI.

1.

CHECK

OS

SWITCH.

2.

CO<ECK

SOLENOID.

3.

REPEAT TEST

I.

CHECK

DEFECTIVE U.

I.

CHECK

DEFECTIVE

ENGINE

START

DEVICE.

12

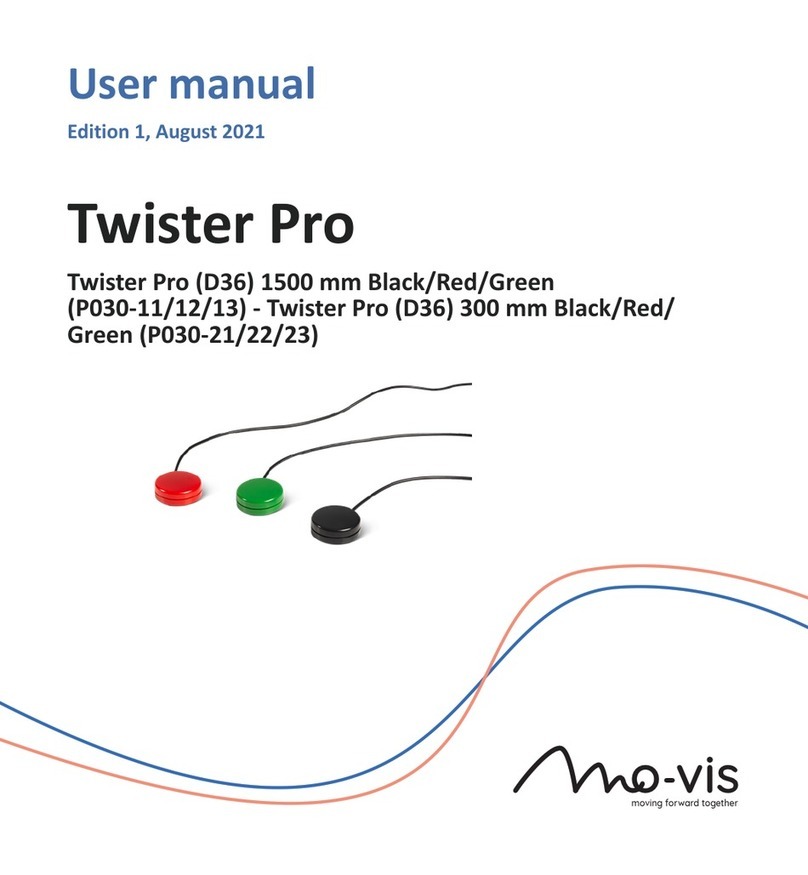

New Solid State Time Delay

r--

-::-

-.

-:-."

I

',

\

---

_

..

'~-

Accessories T, U, W

Solid

State Timers

Adjustable

in

Seconds, Minutes and Hours (Plug-In Style).

To select a time unit, operate the pushbuttons of the rightmost

thumbwheel switch until the desired time unit

is

shown

in

win-

dow. The time unit can be selected by pushing the plus

(+)bot-

tom

button or the minus(-) top button. The desired time

is

specified

by operating the three thumbwheel switches

in

the middle of the

front panel.

Setting of the timer at 000 will result in

an

infinite delay. The

min. setting for OSA-A timers is 1

/,

0 of 1 second

as

shown. See

instructions.

0.1

I

0 0 1

Sec.

Close Differential (ARSM) Relay

Adjustment

The voltage points at which the relay operates are adjustable.

When the relay pulls in,

an

audible click

is

heard, and the LED

will come on.

Setting

the Relay:

If the relay should

be

set with a variable voltage supply (Variac):

1.

Turn pick-up control fully clockwise.

2.

Turn drop-out control fully counterclockwise.

3.

Set Variac pick-up voltage to desired level.

4. Very

slowly

rotate pick-up adjustment counterclockwise until

relay picks up. (LED will energize).

5.

Set Variac drop-out voltage to desired level.

6. Very

slowly

rotate drop-out adjustment clockwise until relay

drops out (LED de-energizes).

Verify settings by raising voltage until relay picks up, then lower

voltage until relay drops out, making sure that relay operates at

desired voltage levels.

LUBRICATION

The cams of the ZBTSH are lubricated with Super Lube PTFE grease, and gears with Dow Chemicals

"Molykote"

(321

R or GN paste). These lubricants provide adequate lubrication for a clean and properly main-

tained switch's lifetime. Should debris contaminate the mechanism, clean and apply additional lubricants.

Mobiltemp SHC-32

is

used

on

isolating contacts.

LUBRICATION MAINTENANCE CHART

Date Inspected Date Lubricated Lubricant Used (Cams) (Gears)

13

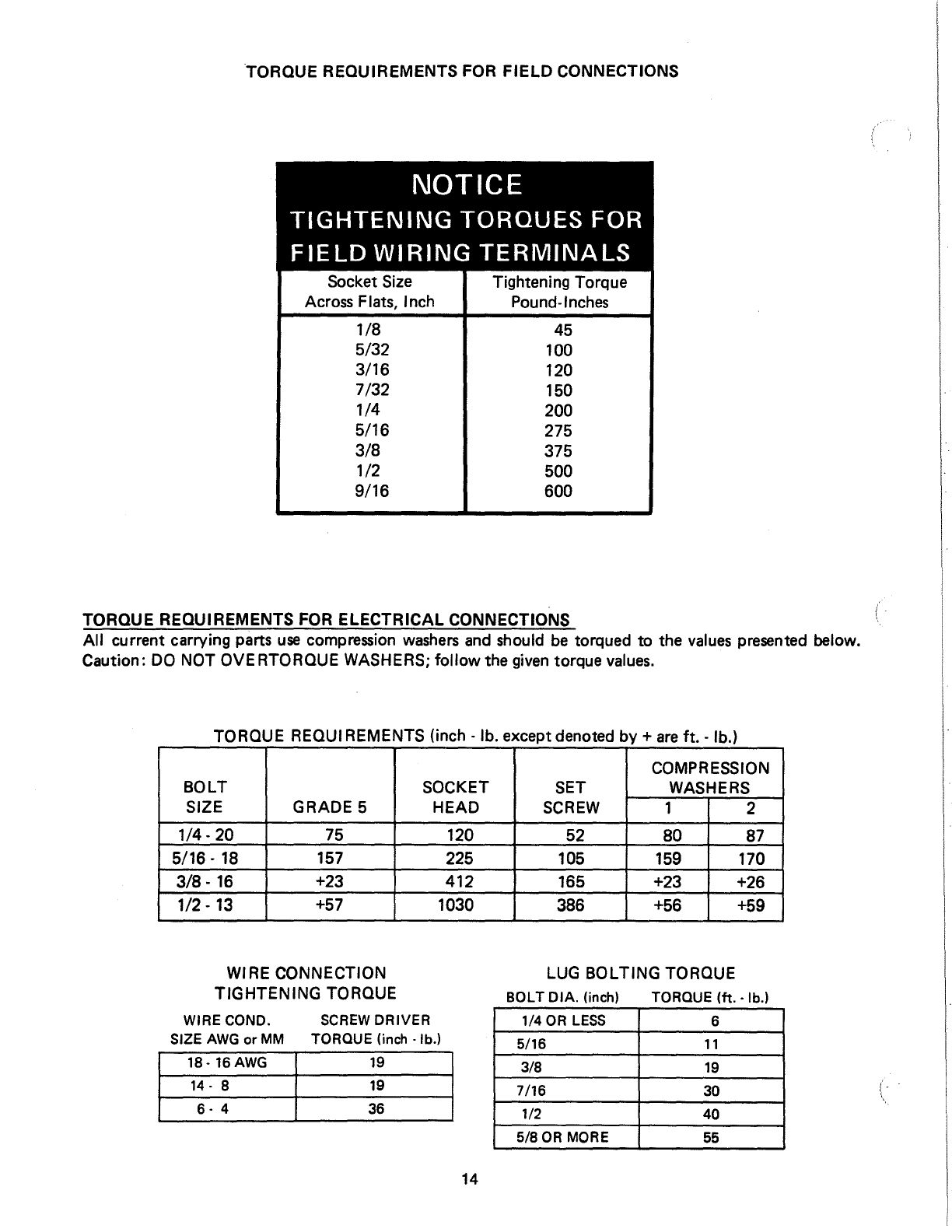

Notes

TORQUE REQUIREMENTS FOR

FIELD

CONNECTIONS

NOTICE

TIGHTENING

TORQUES

FOR

FIELD

WIRING

TERMINALS

Socket

Size

Across Flats, Inch

1/8

5/32

3/16

7/32

1/4

5/16

3/8

1/2

9/16

Tightening Torque

Pound-Inches

45

100

120

150

200

275

375

500

600

TORQUE REQUIREMENTS FOR ELECTRICAL CONNECTIONS

All

current carrying parts

use

compression

washers

and

should

be

torqued to the

values

presented below.

Caution:

DO

NOT OVE RTORQUE WASHERS;

follow

the

given

torque

values.

TORQUE REQUIREMENTS

(inch-

lb. except denoted

by+

are

ft.-

lb.)

BOLT

SIZE GRADE 5 SOCKET

HEAD SET

SCREW

COMPRESSION

WASHERS

1 2

1/4-

20 75 120 52 80 87

5/16-

18

157 225 105 159 170

3/8.

16

+23 412 165 +23 +26

1/2.

13

+57 1030 386 +56 +59

WIRE CONNECTION LUG BOLTING TORQUE

TIGHTENING TORQUE BOLT DIA. (inch) TORQUE (ft.

-lb.)

WIRE COND.

SCREW

DRIVER

SIZE

AWG

or

MM

TORQUE (inch

-lb.)

{-

.

\

1/4

OR

LESS

6

5/16

11

3/8

19

7/16 30

1/2 40

5/8

OR

MORE

55

18-16AWG

19

14-

8

19

6-

4 36

14

.\

INSIDE

IU:NOVA!l.E

f..FT

AHCLI;S

IYPASS tNEfiCENCY

HOfiNAL

AVAILAILE

IYPASS

NOlltNAL

ATI

ISOLATE

ATS

TIJT

DISCONNECT

SWITCH

INKIIIT

POSITION

..L~~~!==;;;;;;;;;;~~;;;;~~·u

"'"'"t

~roT

Ill.

CONT

..

OL

fiANEL

OF

CAIINET 00011•

LUG

CONFIGURATION

t)•POLEI

3 POLE

ZBIIH

~liD

• I c D E

"f

G

~ZZI5PI

F-1510

79

oiZll.

liO

llll

12

1114

llll

-ISPI

F-1510

79

oiZll.

liO

llll

12

1114

llll

DISCONNECT

SWITCH

NfHIIIT

POSITION

ATI I<IOIIT

,}1~~~~~~~1

...

CCIIIUOI.

PANE~

CAll

NET

DOOft.

INitD£ 01'

Lz•

A·A

---====-

CONFIOURATlON

4 POLE

ZBIIH

~

•

~ZZioU'I

79

f'oWI

_..,.,

79

f'oWI

LUG

I

oiZll.

oiZll.

Sf:£

•••

.IWU.

IITYPE

I

ENCLOSUit£

ztALL

DtN

:t

Ye

31"

Willi•

WIA£

IEHCMNG

RADIUS.

!EE

1•1

'J

11

01Ai

4

1~~:!:~D

HOLES

lWU.

IJTTPE

I

ENCLOSUA£

ZIALL

DIM

:!,

Ye

31.Willt'"

WIAE

IEHDtNO

RADIUS.

c F

D G

N

12

1114

llll

U'"

N

12

Ullo

llll

•

15 REV. 8/93

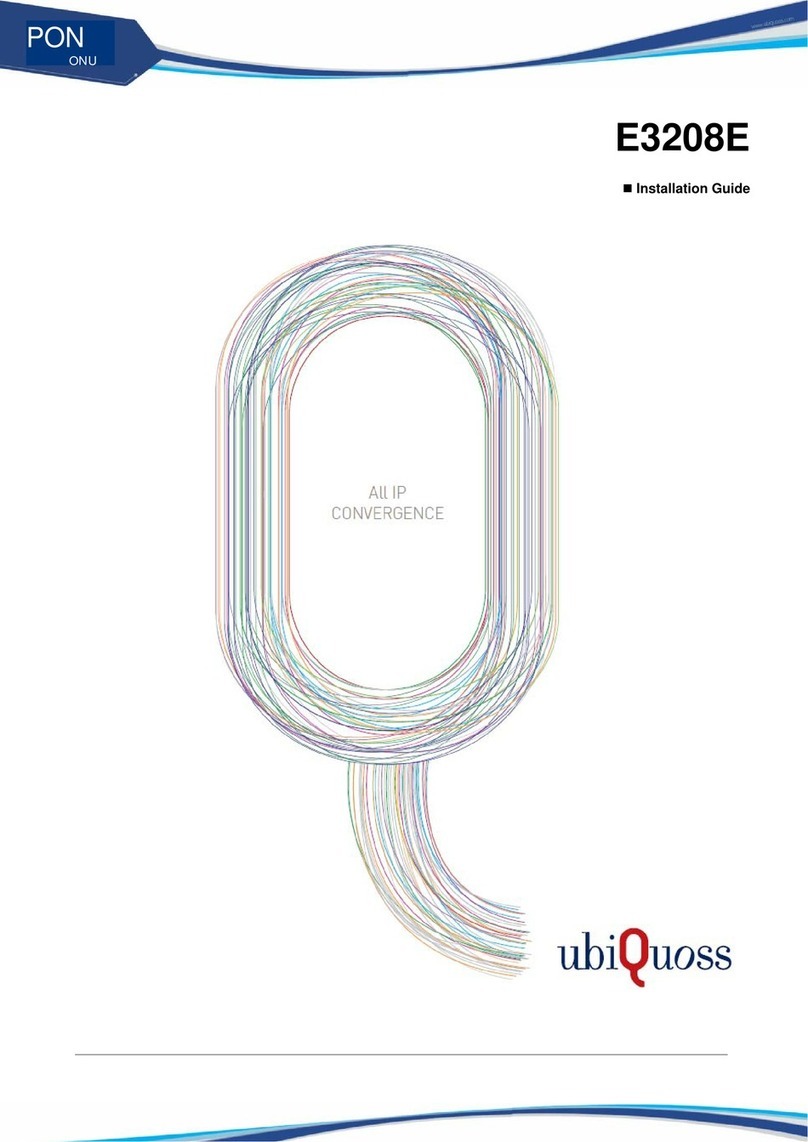

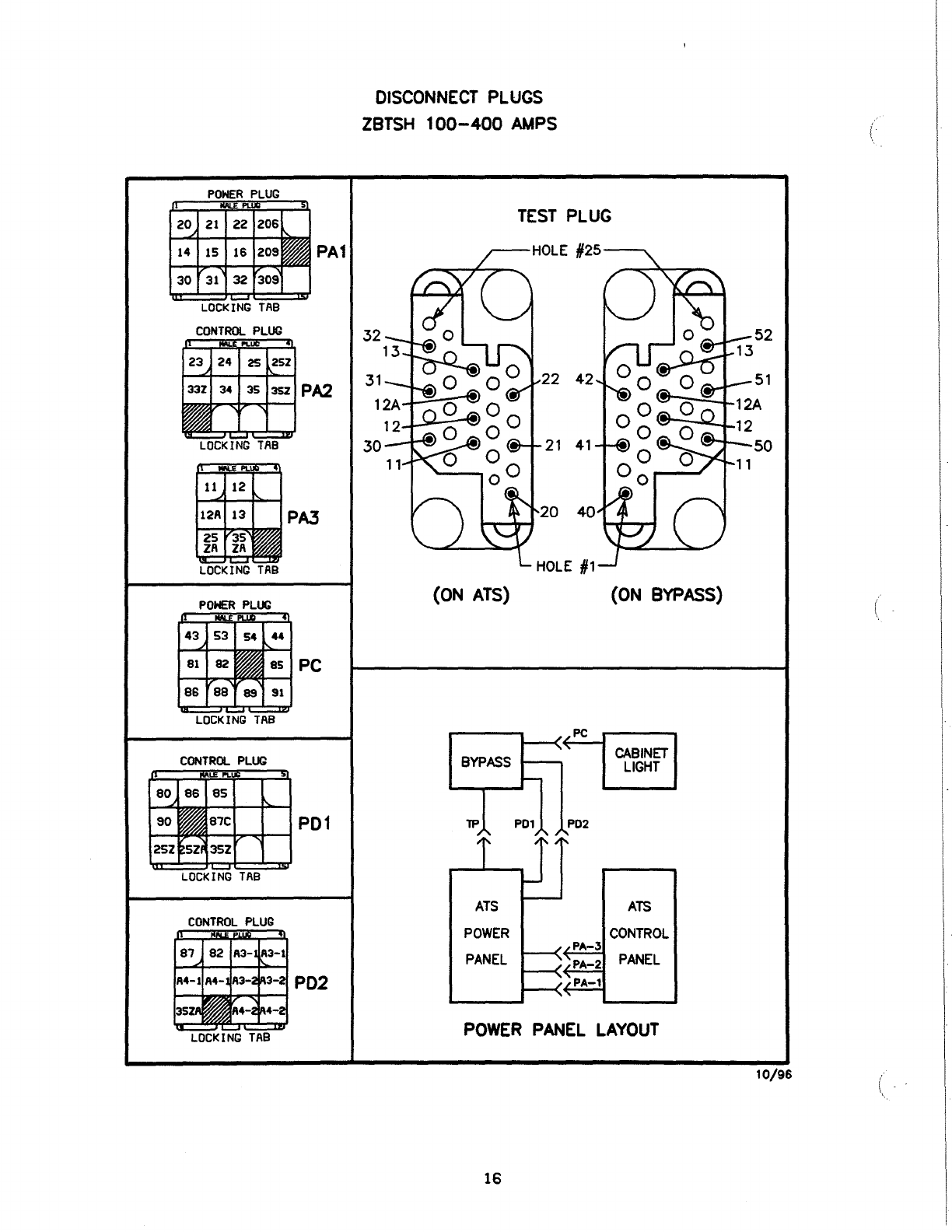

DISCONNECT

PLUGS

ZBTSH

100-400

AMPS (

PA1

LOCKING

TAB

TEST

PLUG

22

42

21

41

{ON ATS) {ON BYPASS)

PC

LOCKING

TAB

CABINET

LIGHT

ATS

ATS

CONTROL

PANEL

POWER

PANEL

LAYOUT

CONTROL

PLUG

10/96

(

16

FIELD NOTES

(

MODELNO:

--------------------------------------------------------

SERIALNO:

______________________________________________________

_

DATESHIPPED:

-----------------------------------------------------

START·UPDATE:

__________________________________________________

____

DRAWING

SUPPLIED:

-----------------------------------------------

TEST

AND

MAINTENANCE

NOTES:

DATE

TESTED

PROBLEMS

NOTES

17

2

3

4

7

•

•

10

ll

1Z

13

14

15

ENGINE

START

CIRCUIT

BYPASS CONTROL SCHEMATIC

PERMIT

CIRCUITS

25Z

ATR

25ZA

~r--=o

NORMAL

TRANSFER

PERMIT

CIRCUIT

IN

AUTO

AND

TEST

POSITIONS

35Z

ATR

35ZA

~~

EMERGENCY

TRANSFER

PERM

IT

CIRCUIT

IN

AUTO

AND

TEST

POSITIONS

LNA

-

NORMAL

AVAILABLE

LIGHT

LEA

-

EMERGENCY

AVAILABLE

LIGHT

RNH

-

NORMALLY

HELD

RELAY

01

-

DIODE

R1

-

RESISTOR.

RNH

C -

CAPACITOR.

RNH

BR-1.2.3 -

BRIDGE

RECTIFIER

AA-1

-

BTN

-

BTE

-

BPS

-

AA-2

-

ALL

-

AT-2

-

LIMIT

SWITCH.

ATS

AUTO

LOCATION

LIMIT

SWITCH.

BYPASS

TRANSFER

NORMAL

IMBH

MOVEMENT

TO

NORMALl

LIMIT

SWITCH.

BYPASS

TRANSFER

EMERG.

IMBH

MOVEMENT

TO

EMERGENCYJ

BYPASS

SOLENOID

LIMIT

SWITCH.

ATS

AUTO

LOCATION

LIMIT

SWITCH.

ATS

LOCK

LOCATION

LIMIT

SWITCH.

ATS

TEST

LOCATION

LAT

-LIGHT.

ATS

TEST

LOCATION

AI

-

LIMIT

SWITCH.

ATS

ISOLATE

LOCATION

LAI

-LIGHT.

ATS

ISOLATE

LOCATION

BLL

-

LIMIT

SWITCH.

BYPASS

LOCK

LOCATION

PLS-1-

PERMISSIVE

LIMIT

SHITCH

TSE

-

LIMIT

SWITCH.

TRANSFER

SWITCH

ENGAGED

TRS

-

SOLENOID.

TRANSFER

RELEASE

NA-4

-

LIMIT

SHITCH.

ATS

IN

NORMAL

EA-3

-

LIMIT

SWITCH•

ATS

IN

EMERGENCY

LBE

-LIGHT.

BYPASS

EMERGENCY

LBN

-LIGHT.

BYPASS

NORMAL

AB4

-

LIMIT

SWITCH.

BYPASS

NORMAL

AB3-1-

LIMIT

SHITCH.

BYPASS

EMERGENCY

PLS-2-

PERMISSIVE

LIMIT

SHITCH

ATR

-

AUTO/TEST

RELAY

AT-1

-

LIMIT

SWITCH.

ATS

TEST

LOCATION

LIT

-LIGHT.

ATS

INHIBIT

OS

-

ATS

DISCONNECT

SHITCH

R2

-

RESISTOR.

LOS

LOS

-LIGHT.

DISCONNECT

SHITCH

INHIBIT

POSITION

ALH

-

ATS

LOCATION

HANDLE

LIMIT

SWITCH

X =

ATS

ATfe

~:'fPASS

OCATION

J.too

MODE

ACTUATED

~

li

~~

01-

~~

~

l-UI

i!l!:!

AA-1.2 X

AT-1.2 X

AI

XX

ALL

X X X X

TSE

X X X

AE-1.2 X X

!NA-4

X

EA-3

X

AB4

X

AB3-1.2.3 X

BLL

X X X

PLS-1.2

ACTIVATED

HHEN

lUI

IS

OPERATED

CHART

LIM

IT

SWITCHES

oNO

~NO

~

NOT

NC

ACTUATED

r---,

ILOCATEI!

I

ON

I

~

I

IITS

I

I I

~

18

---~

..

(

10/96

Table of contents

Other Zenith Switch manuals