GB-9

G

B

EX2600

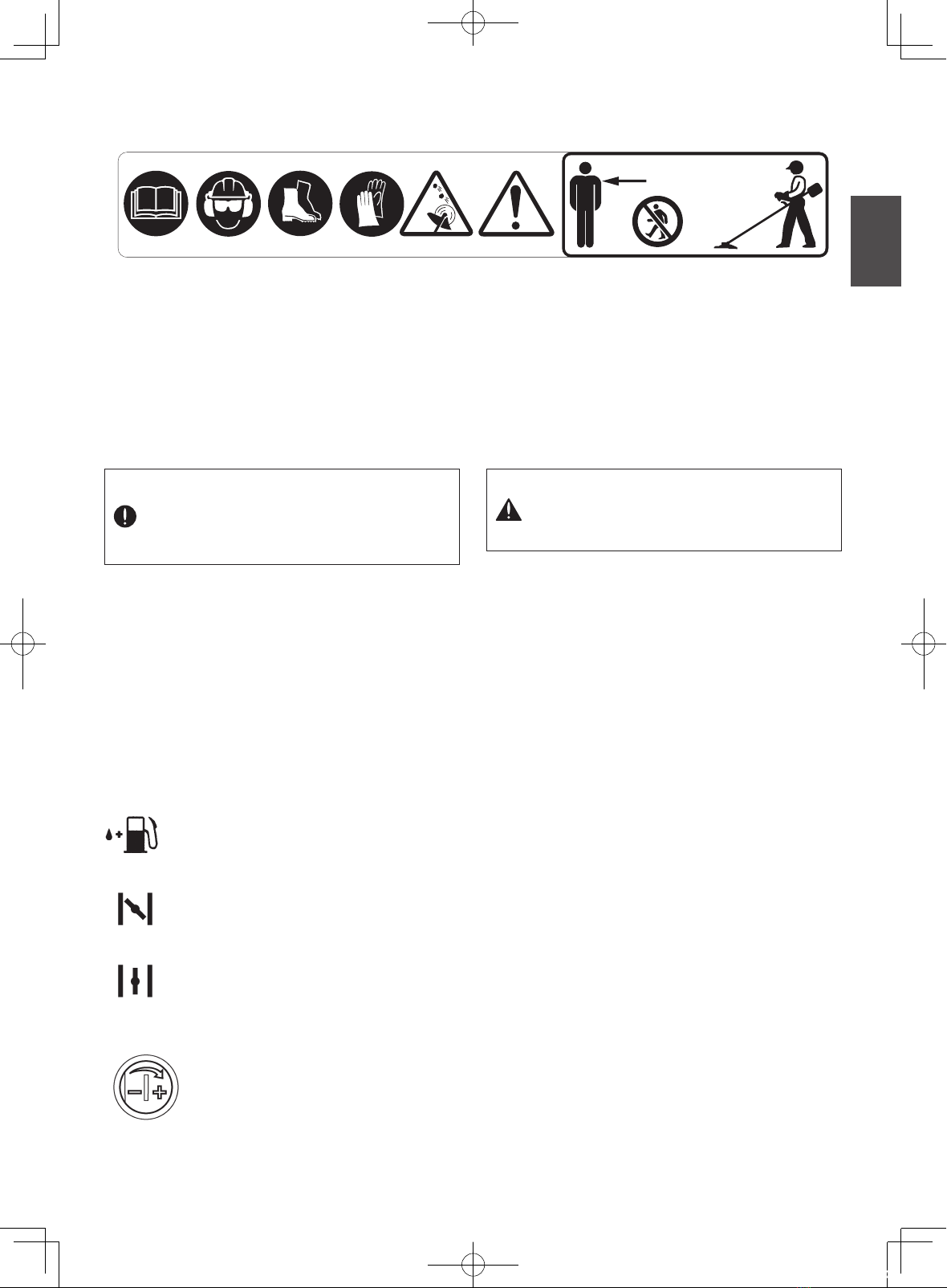

5. For safe operation

1. When you finish cutting in one lo-

cation and wish to continue work

in another spot, turn off the en-

gine, lift up the unit and carry it

paying attention to the blade.

2. Never forget to place the protec-

tive cover over the blades.

3. When hand-carrying the product,

cover over the cutting attachment

if necessary, lift up the product

and carry it paying attention to the

cutting attachment.

4. Never transport the product over

rough roads over long distances

by vehicle without removing all

fuel from the fuel tank. If doing so,

fuel might leak from the tank dur-

ing transport.

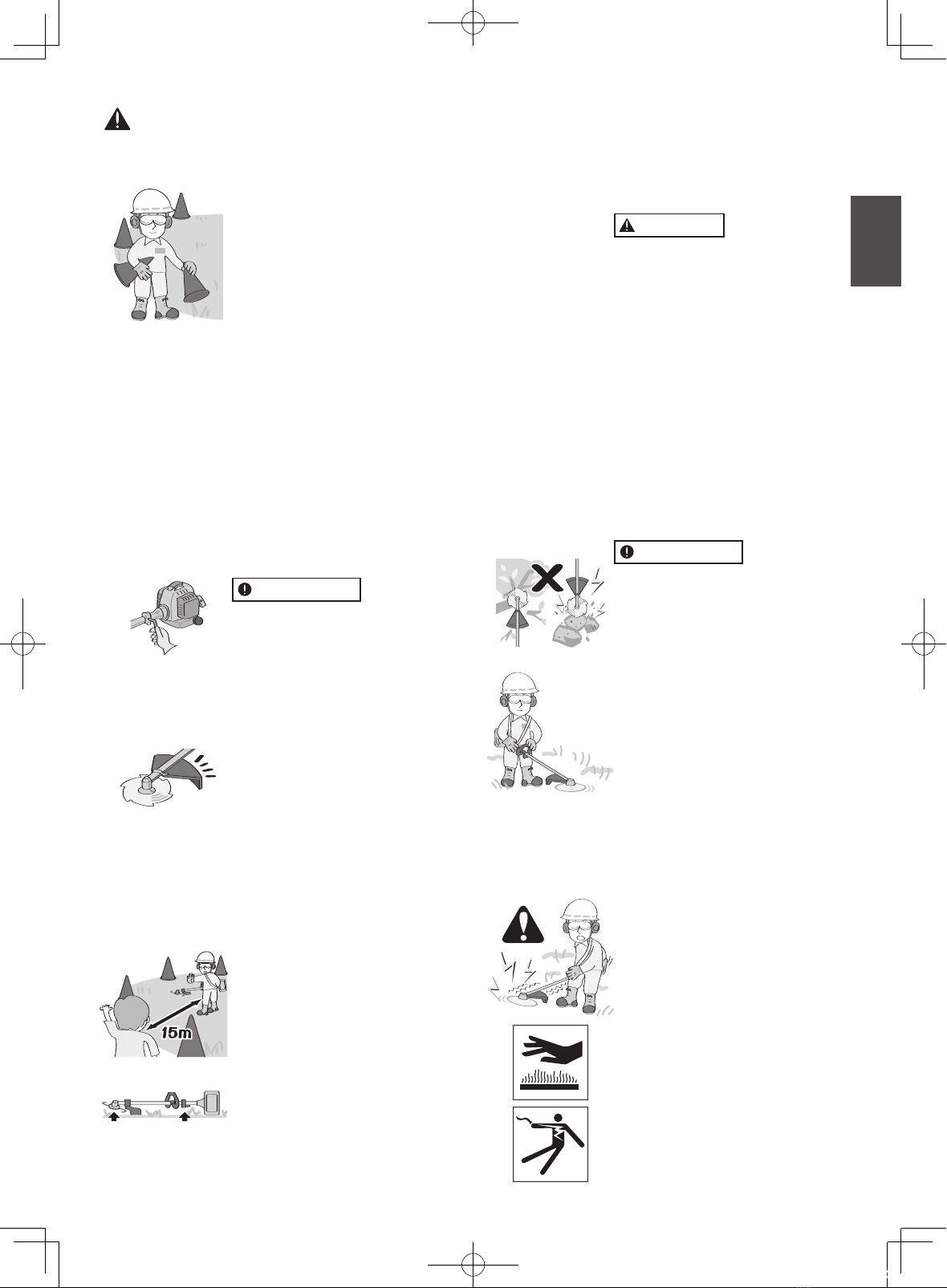

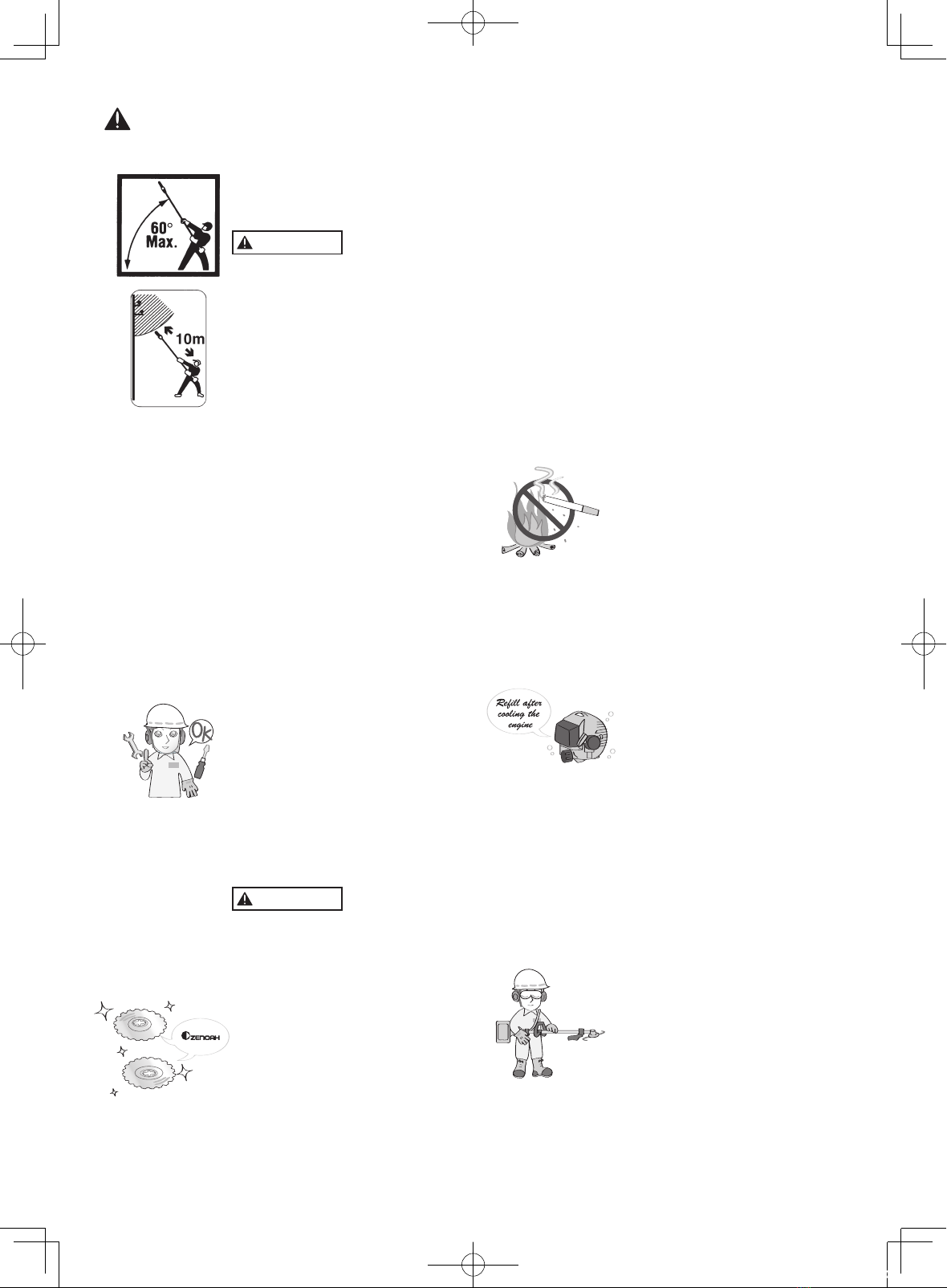

KICKBACK SAFETY PRECAU-

TIONS FOR CHAIN SAW USERS

WARNING

• Kickback may occur when the

nose or tip of the guide bar

touches an object, or when the

wood closes in and pinches the

saw chain in the cut. Tip contact

in some cases may cause a light-

ning fast reverse reaction,kicking

the guide bar up and back to-

wards the operator. Pinching the

saw chain along the top of the

guide bar may push the guide

bar rapidly back towards the

operator. Either of these reac-

tions may cause you to Iose con-

trol of the saw, which could re-

sult in serious personal injury.

• Do not rely exclusively on the

safety devices built into your saw.

As a chain saw user you should

take several steps to keep cut-

ting jobs free from accident or

injury.

(1) With a basic understanding of

kickback you can reduce or

eliminate the element of surprise.

Sudden surprise contributes to

accidents.

(2) Keep a good grip on the saw with

both hands, the right hand on the

rear handle, and the left hand on

the front handle, when the engine

is running. Use a firm grip with

thumbs and fingers encircling

the chain saw handles. A firm

grip will help you reduce kick-

back and maintain control of the

saw.

(3) Make certain that the area in

which you are cutting is free from

obstructions. Do not let the nose

of the guide bar contact a log,

branch, or any other obstruction

which could be hit while you are

operating the saw.

(4) Cut at high engine speeds.

(5) Follow the manufacturer’s sharp-

ening and maintenance instruc-

tions for the saw chain.

(6) Only use replacement bars and

chains specified by the manufac-

turer or the equivalent.

WARNING

• Makesurethechainandsprocket

are correctly adjusted before op-

erating the pruner (see page

13~14 for adjustment proce-

dures). Never attempt chain ad-

justment with the engine running!

•

Always make sure the cutting at-

tachment is properly installed and

firmly tightened before operation.

• Neveruseacrackedorwarped

guide bar: replace it with a ser-

viceable one and make sure it fits

properly.

• Ifasawchainshouldbindfastin

a cut, shut off the engine imme-

diately. Push the branch or tree to

ease the bind and free the saw

chain.

• Donotoperatetheprunerwiththe

muffler removed.

• Whencuttingalimbthatisunder

tension, be alert for springback so

that you will not be struck by the

moving limb.

• Alwaysstoptheengineimmedi-

ately and check for damage if you

strike a foreign object or if the ma-

chine becomes tangled. Do not

operate with broken or damaged

equipment.

IMPORTANT

• Donotmakeunauthorizedmodi-

fications or substitutions to the

guide bar or chain.

• Neverallowtheenginetorunat

high RPM without a load. Doing

so could damage the engine.

• Keeptheprunerascleanaspos-

sible. Keep it free of loose vegeta-

tion, mud, etc

(PS-EX2 only)

01-EX2600_GB_cs5_二.indd 9 17/04/14 18:09