MUGL Page 4 of 38

rev. 18 November 2009

Summary

1. Preface ............................................................................................. 5

1.1 How to use and understand the instructions provided in this manual ............................... 5

1.2 Safety instructions ................................................................................................ 5

1.3 Compliance declaration ......................................................................................... 7

1.4 Identification la el ............................................................................................... 8

2. Preliminary operations ........................................................................... 9

2.1 Working environment ............................................................................................ 9

2.2 Precautions ......................................................................................................... 9

2.3 Equipment operation ............................................................................................ 10

3. Auxiliary Inputs / Outputs .................................................................... 11

3.1.1 Inputs ...................................................................................................... 11

3.1.2 Outputs ................................................................................................... 11

3.2 Communication port ............................................................................................. 11

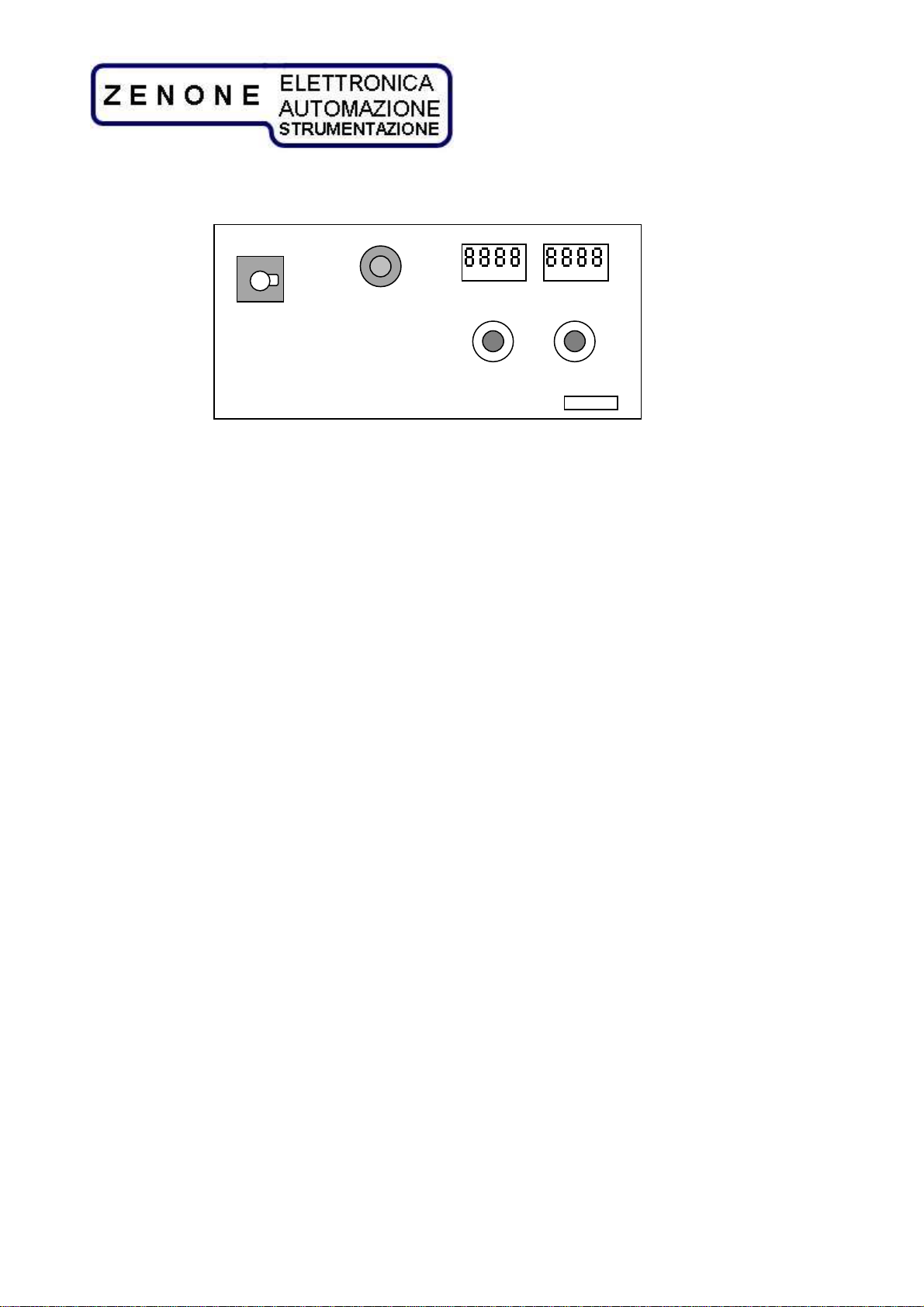

4. Converter operation ........................................................................... 12

4.1 Starting the output of power .................................................................................. 12

4.2 Setting voltage and frequency ................................................................................ 12

4.3 Scale selection .................................................................................................... 12

4.3 Display of set values ............................................................................................ 12

4.4 Command type selection ....................................................................................... 13

4.5 Measurements display .......................................................................................... 13

4.5 change of scale ................................................................................................... 13

5 Maintenance instructions..................................................................... 13

6. External connections .......................................................................... 14

6.1 DB15 I/O connections ............................................................................................ 14

6.2 DB15 RS485 connection ........................................................................................ 15

6.3 DB15 analog connections ....................................................................................... 16

7. Error and faults signaling: ................................................................... 17

8 Converter diagram ............................................................................. 18

9 Control scheme ................................................................................. 19

10 Control and regulation unit ............................................................... 19

10.1 Control system lock diagram ............................................................................. 19

10.2 Control system description ................................................................................. 20

10.3 Parameters definition and function ...................................................................... 21

10.4 Procedure for adjusting the control system ............................................................ 22

10.5 Technique for adjusting the loops ........................................................................ 23

11 GesPWM soft are ........................................................................... 26

11.1 Connecting the equipment to the PC ..................................................................... 26

12 FVC Manager soft are ...................................................................... 28

12.1 Software installation ........................................................................................ 28

12.2 Presentation .................................................................................................... 28

12.3 Preliminary operations ...................................................................................... 29

12.4 identification of FVC connected ........................................................................... 29

12.5 Address change ................................................................................................ 29

12.6 Test applications ............................................................................................. 29

12.7 Command mask ................................................................................................ 29

13 Communication protocol V1.1 ............................................................ 32