How to Safely Use Your Zero Pro Hand Truck

Recommended Load Capacity: 300kg

Check Before Using

1. Make sure there is no damage to the frame or toe plate before each use.

Bends, fractures and cracks could cause a fault in the truck.

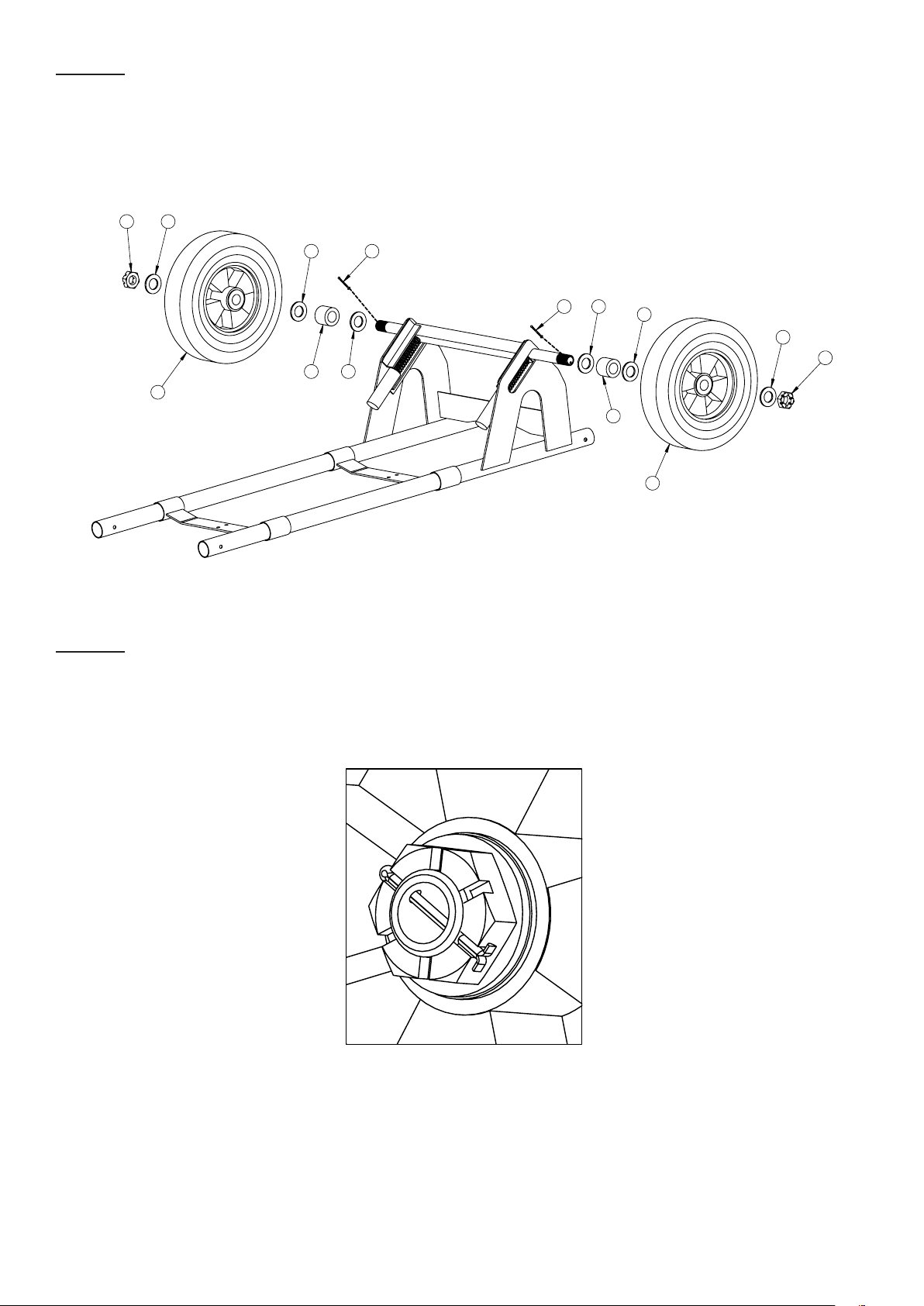

2. Check the wheels for damage and make sure they both spin freely on the

axle.

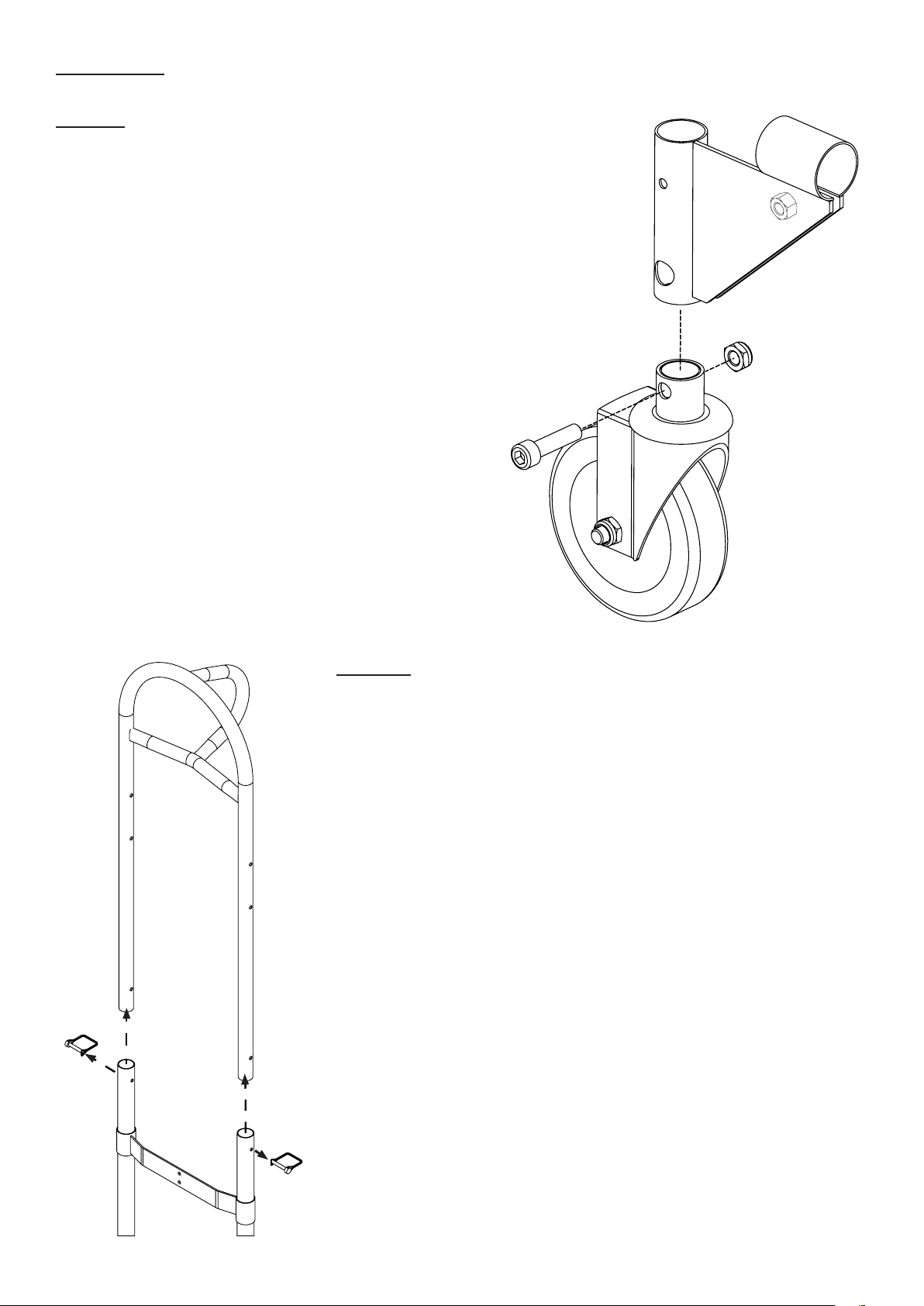

3. Check all bolts and nuts to make sure they are intact and tightly secure. Do

not use if a bolt or nut has come loose or is missing.

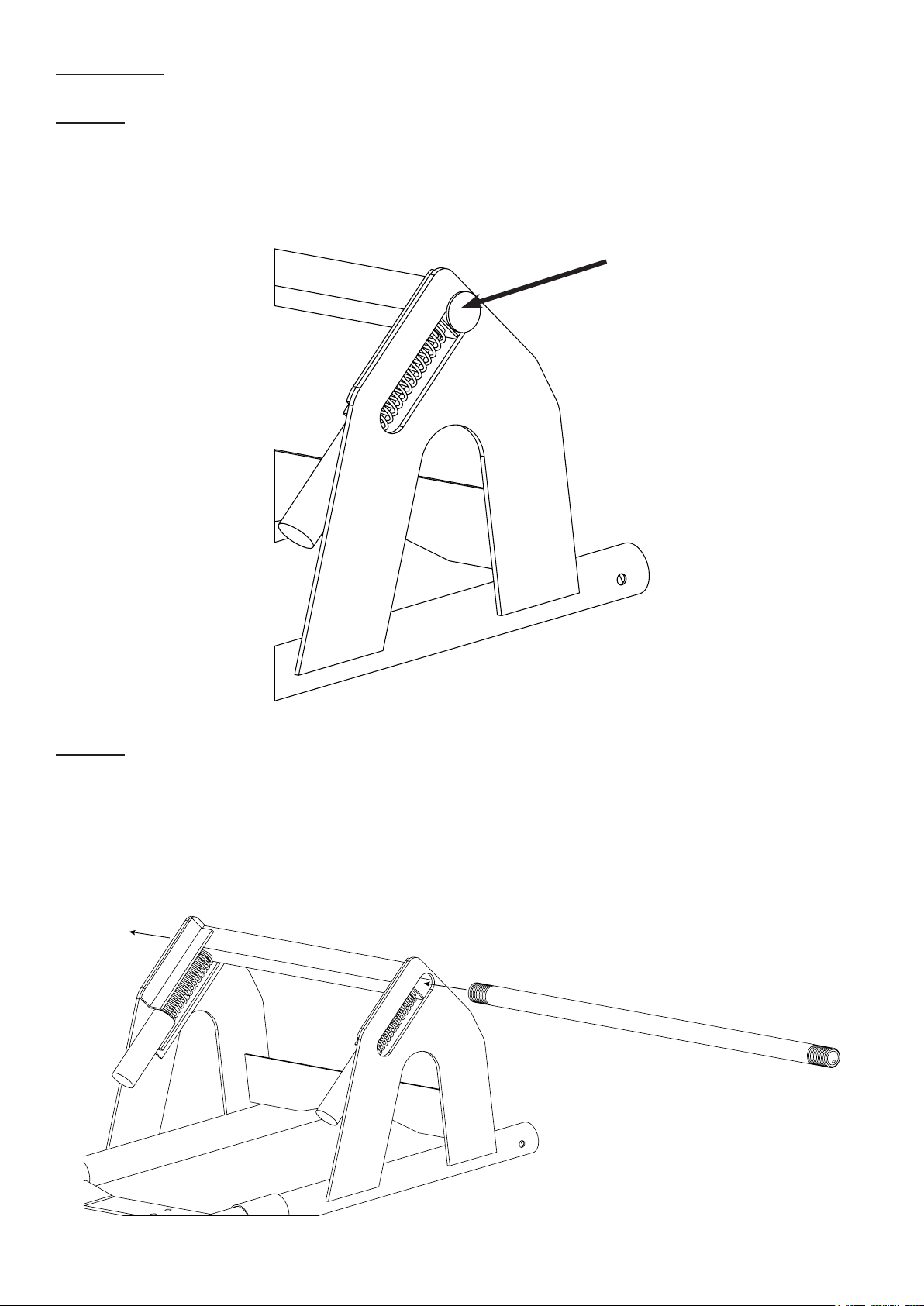

4. Make sure the pivot springs are intact and in the correct position. Any

bends or deformities could cause the truck to fail.

5. Check the nuts on the end of the wheels are still secure and held in place

by the split pins. Check that the split pin is not broken and cannot come

out. Do not use if the nut is loose or split pin missing.

6. Make sure the springs and roller bearings are always lubricated. Any unusual

noises from the wheels or springs can be solved by adding grease to the

components.

Use of the Truck

1. Be sensible about the load you place on the truck. Never exceed the

recommended load capacity of 300kg.

2. Make sure you can always see over the load on the truck. Do not place a

load higher than the frame of the hand truck.

3. When stacking a load onto the truck make sure larger and heavier items are

placed at the bottom of the truck and smaller and lighter items are placed

at the top.

4. For loads that are much larger than the toe plate and frame of the hand

truck (i.e. white goods) use restraints such as cam buckle or ratchet strap

and wrap around the load and the upright of the truck.

5. When transporting over uneven surfaces, make sure you use restraints to

secure the load to the truck.

6. When lifting the loads make sure you have both feet on the ground and

stand slightly back from the truck, Zero Hand Trucks do not require you to

place a foot on the axle.

7. Keep your back straight or with a slight bend when lifting and manoeuvring

the hand truck. Never operate in an awkward or bent over position.

8. Always make sure the load is balanced over the wheels. The operator is

only there to stabilise and push the load. Never take the brunt of the load

yourself, let the truck do the work.

9. When transporting the load, only ever push forward. Never pull the load

backwards – if you trip, the load will fall on top of you and could cause

serious injury.