controller

/

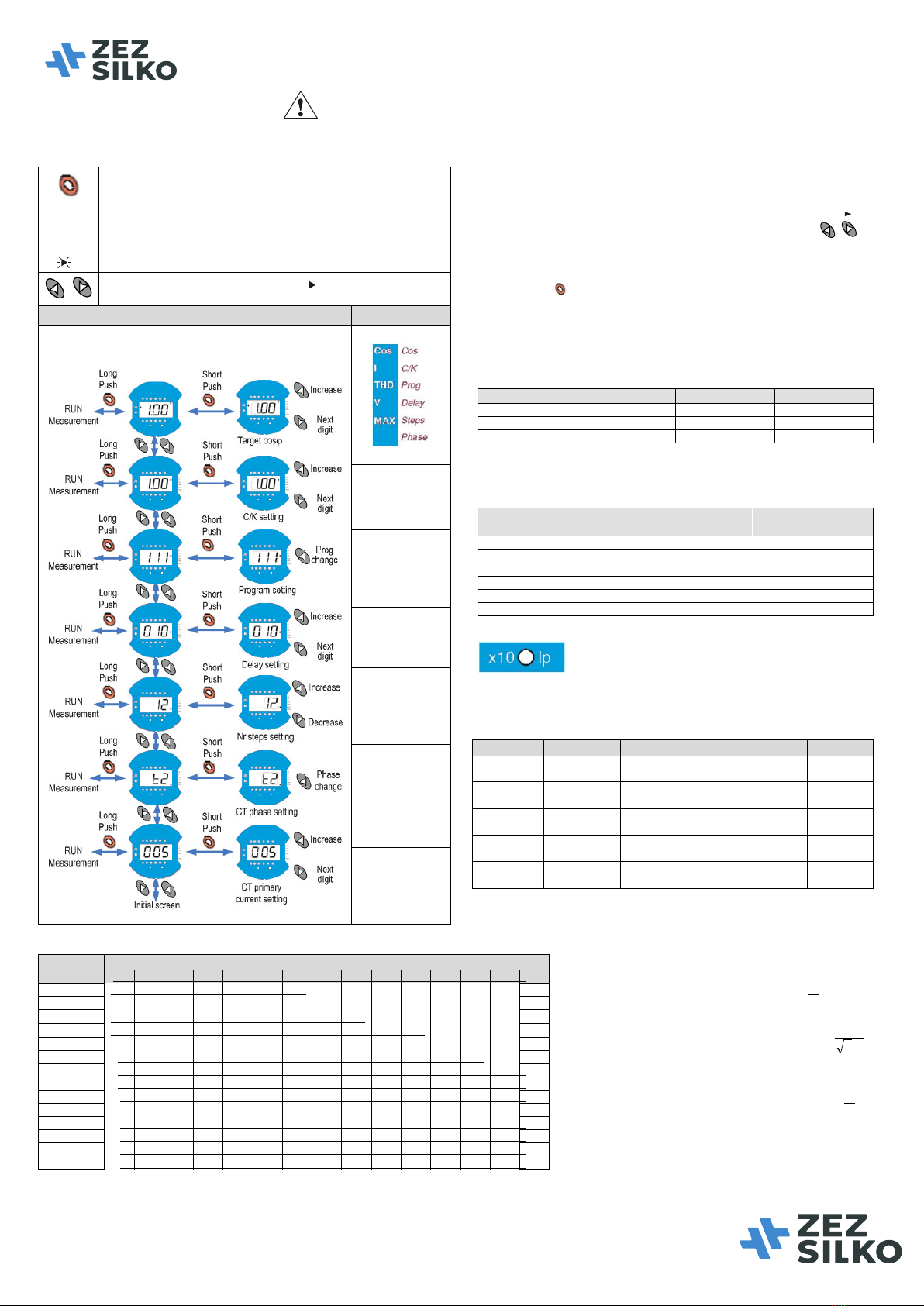

4.- SETUP AND MEASUREMENTS

To enter the SETUP mode, press the setup key (9), for more than 1s. If all the capacitors are disconnected, the access in immediate, otherwise a disconnection sequence

starts and then accesses to setup menu. In the SETUP mode, if no key is pressed for 3 minutes, the equipment exits such mode and returns to normal operation mode.

Key to access the SETUP mode:

- Long push to enter and exit SETUP mode. Also DELETE max values when

in the measuring mode

- Short push: to change from display mode to editmode and vice versa.

If no key ispushed during more than 3 minutes, the regulator exits the SETUP

mode without changing the setup.

Symbolshowing whichparameter isbeing displayedor edited.

-In the display mode: Cursors toselect anoption.

pointsto theoption

- In edit mode: Change a parametervalue

Display SETUP Parameters Edit SETUP parameters Description

Targetcosϕ(def=1)

st

C/Kadjustment

Range: 0.02–1.00

Seeparagraph6

Dependsonthekvar

relationshipbetween

successivesteps.

Seeparagraph 4.2

steps (4-999s).

Re-connectiondelay

is =5timesTON

SelectionofNrof

relays,PFR6or12

dependingon type

paragraph 4.3. The

displayshows T1,T2,

T3,T4,T5orT6.

Accepttheoption

givingcosϕbetween

0.7Ind and0.98Cap

CTprimarycurrent

setting.See

paragraph4.4

4.1.- RUN & Measuring mode

In normal operation mode (RUN mode) the regulator display may show different

parameters (V, I, cosϕ, etc.) The displayed parameter is pointed by the sign .

By default the regulator displays the cosϕ, but pushing the keys the

following parameters can be explored: Current (I), Current harmonics (THD), Mains

Voltage (V), Maximum current (I MAX) y Maximum voltage (V MAX). If both keys

are pushed simultaneously the regulator displays the Nr of connected steps.

A long push of key when maximum values are displayed causes de deletion of

recorded max values.

4.2.- Program selection

This setting depends on the kvar ratio between the different capacitor steps. For

instance if the bank is 10+20+20+20 kvar the program is 1:2:2:2, so the option 122

must be selected.

Display Program Display Program

4.3.- Selecting the CT connection phase

Choose among the options in the table depending on CT connection and the

phases where V is measured. In normal installations (no exported energy) choose

the option for which the displayed cosϕis between 0.7 Ind and 0.98 Cap.

Display

V-I phase shift at

cosϕ=1

Measuring phases

for V Phase where TC is

connected

4.4.- Selecting the rated primary current of CT

If the LED is blinking indicates that we are in SETUP mode and

adjusting primary CT current. When in RUN mode or when Iprimary is displayed,

the LED indicates whether the displayed current has a scale factor x1 (LED OFF)

or x10 (LED ON)

5.- Error Codes

ERRCODE DISPLAY DESCRIPCIÓN ACTUACIÓN

E.01 Alll zeros

Load current below measuring threshold or

CT notconnected

relaysOFF

E.02 cosϕand E.02

Overcompensation.Theregulador isaskingto

disconnectCsandtheyareall disconnected

E.03 cosϕand E.03

Sub-compensation.Theregulatorisaskingformore

Csandthey areallconnected

E.04

ϕ

and E.04

alternate blinking

Overcurrent.Thecurrentis+20%.Aboveprimary

ratedcurrent

E.05

ϕ

and E.05

alternate blinking

Overvoltage.Voltageis +15%.Aboveratedvoltage

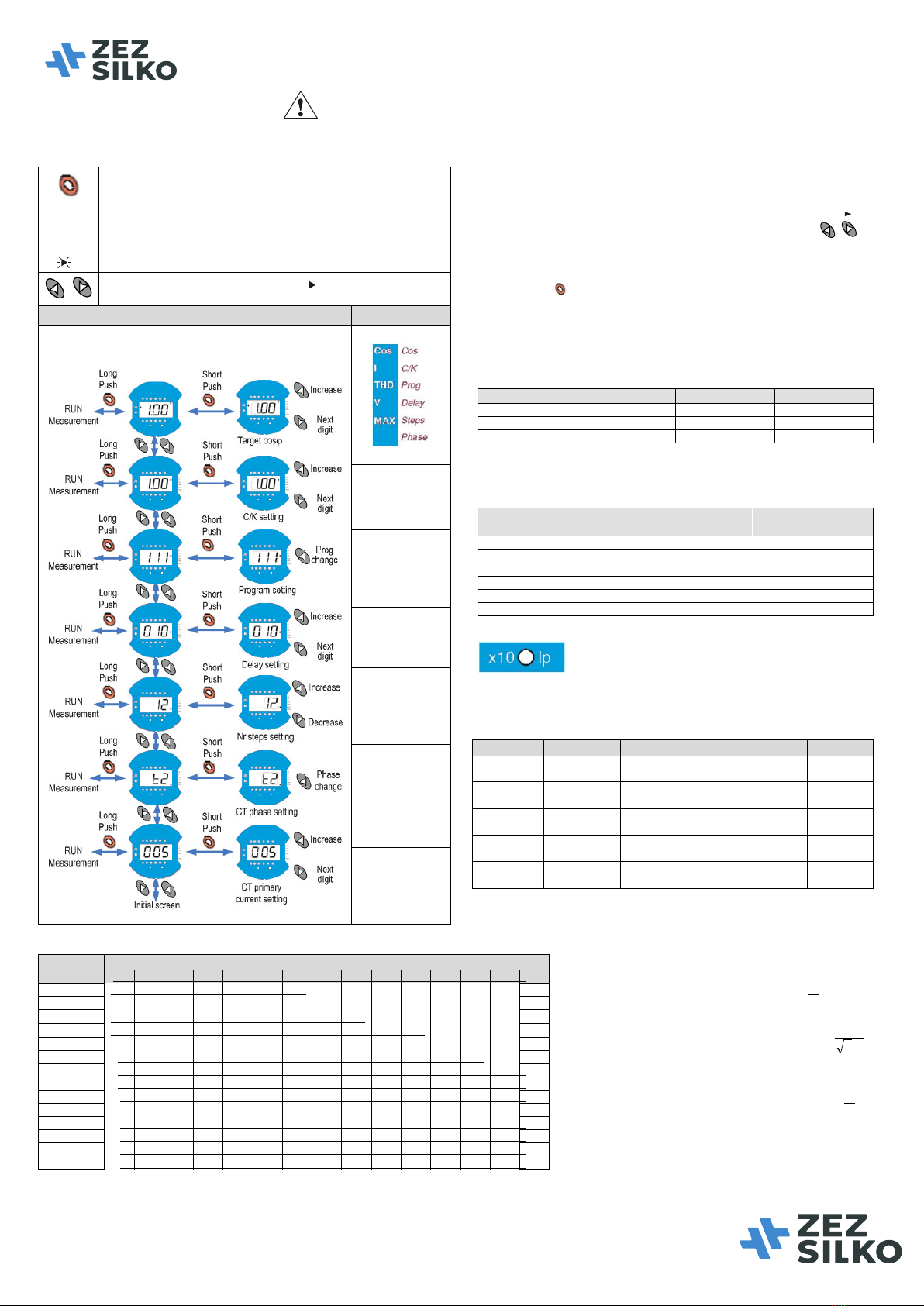

6.- C/K table depending on initial cosϕ, desired cosϕand CT ratio

Lower step reactive power (kvar) at 400V

C/K calculation:

If It is the primary rated current of the CT and

Ic the rated current of the lower capacitor step,

the C/K must be set according to the

calculations shown below:

Example : CT current ratio = 500/5

Lower step power: 60 kvar at 400V

A7,86

40073,1 000.60

I;100

5

500

KC=

×

===

=

CT 2.5 5,00 7.5 10,0 12,5 15,0 20,0 25,0 30,0 37,5 40,0 50,0 60,0 75,0 80,0

150/5 0,12 0,24 0,36 0,48 0,60 0,72 0,96

200/5 0,09 0,18 0,27 0,36 0,45 0,54 0,72 0,90

250/5 0,07 0,14 0,22 0,29 0,36 0,43 0,58 0,72 0,87

300/5 0,06 0,12 0,18 0,24 0,30 0,36 0,48 0,60 0,72 0,90 0,96

400/5 0,05 0,09 0,14 0,18 0,23 0,24 0,36 0,48 0,58 0,67 0,72 0,87

500/5 0,07 0,11 0,14 0,18 0,22 0,29 0,36 0,45 0,54 0,54 0,72 0,87

600/5 0,06 0,09 0,12 0,15 0,18 0,24 0,30 0,36 0,45 0,48 0,60 0,72 0,90 0,96

800/5 0,07 0,09 0,11 0,14 0,18 0,23 0,27 0,33 0,36 0,45 0,54 0,68 0,72

1000/5 0,05 0,07 0,09 0,11 0,14 0,18 0,22 0,27 0,29 0,36 0,43 0,54 0,57

1500/5 0,05 0,06 0,07 0,10 0,12 0,14 0,18 0,19 0,24 0,29 0,36 0,38

2000/5 0,05 0,07 0,09 0,11 0,13 0,14 0,18 0,22 0,27 0,28

2500/5 0,06 0,07 0,09 0,10 0,12 0,14 0,17 0,22 0,23

3000/5 0,05 0,06 0,07 0,09 0,10 0,12 0,14 0,18 0,19

4000/5 0,05 0,06 0,07 0,09 0,11 0,14 0,14

For different voltages (V) of 400V, table result must be multiply for 400/V, or calculate C/K parameter using the expressions.

7.- Technical Service

For any inquiry about the regulator operation or in case of malfunction please

contact with technical service.

ZEZ SILKO, s.r.o.

Pod Černým lesem 683

56401 Žamberk

Česká republika

tel.: +420 465673111

e-mail: zez@zez-silko.cz

www.zez-silko.cz Nabijte se energií s námi